Your Trusted Overhead Crane Manufacturer & Supplier

Maintenance Crane & Repair Crane for All Heavy Maintenance Work

All Types of Overhead Cranes for Quick & Accurate Load Lifting for Repairing & Maintenance

Maintenance cranes make heavy maintenance work easy. All types of overhead cranes, bridge cranes, jib cranes, portable gantry cranes customized for you with efficiency & accuracy.

Maintenance cranes are specialized cranes that are used for maintenance and repair work in industrial settings. These cranes are designed to be compact and maneuverable, making them ideal for use in tight spaces such as maintenance workshops or production lines. Maintenance cranes are used for a wide range of maintenance and repair tasks in industrial settings. These cranes are typically used in tight spaces where larger cranes cannot fit, and are designed to be highly maneuverable and versatile.

Generally speaking, the material handling and preparing cranes are has the following functions:

General material handling crane can be used as the repairing cranes,which can be used in the workshops and factory through of the complete processing lines, including raw material handling, transportation, and finished production storing, truck loading and unloading, etc. And also they can be used for manufacturing machinery installation and machinery maintenance works such as parts exchanging, and machinery repairing, etc.

Some typical applications of maintenance cranes include:

- Maintenance and repair work on machinery and equipment

- Loading and unloading of materials in production lines

- Handling of tools and parts in maintenance workshops

- Lifting and positioning of heavy components in assembly lines

- Inspection and repair work on building structures

To meet the multiple purpose, the lifting crane is required to be with double speed or variable speed to ensure precise loads or parts handling and positioning.

Features of overhead cranes for maintenance

It is important to ensure that maintenance cranes have features such as anti-swinging, high precision, variable speed/double speed including quick and slow speed, because these features can greatly improve the safety and efficiency of crane operation. Here are some reasons why:

- Anti-swinging: When lifting and positioning loads, cranes can be subject to swinging or swaying. This can be dangerous, as it can cause the load to collide with other objects or people. Anti-swinging features such as sway control systems or variable frequency drives can help to minimize swinging and improve overall control of the load.

- High precision: In maintenance and repair work, it is often necessary to position loads with a high degree of accuracy. High precision features such as fine speed control or proportional control can allow for precise positioning of loads, reducing the risk of damage to equipment or injury to personnel.

- Variable speed/double speed including quick and slow speed: Variable speed or double speed features can allow for greater flexibility in crane operation. Quick speed can be used for fast positioning of loads, while slow speed can be used for more precise movements. This can help to improve efficiency and reduce the risk of accidents.

Overall, these features can help to improve the safety and efficiency of crane operation, making them essential for maintenance cranes used in industrial settings.

In terms of maintenance and repair requirements for cranes, regular inspections and preventative maintenance are key to ensuring safe and efficient operation. Some common maintenance tasks for cranes include lubrication of moving parts, inspection of wire ropes and chains, and testing of safety features. Repairs may be necessary in the event of damage or wear and tear, and should be carried out promptly to prevent further damage or accidents. It is important to follow manufacturer guidelines and industry standards when performing maintenance or repairs on cranes.

Types of maintenance cranes

Light duty maintenance crane and repairing cranes

While maintenance and repair applications vary from operation to operation, one major factor in deciding which type of crane best suites your operation is environment and lifting requirements

- Features: Suspended from a beam or track, can move heavy loads horizontally and vertically

- Pros: Ideal for moving loads over a fixed path, can be operated remotely or manually

- Cons: Require a fixed runway or beam to operate, limited mobility

- Applications: Used in manufacturing plants, warehouses, and other industrial settings for moving heavy loads along a fixed path.

- Features: Have a vertical mast with a horizontal boom that can rotate 360 degrees

- Pros: Ideal for lifting loads in a small area, can be operated remotely or manually

- Cons: Limited lifting capacity, limited range of motion

- Applications: Used in manufacturing plants, workshops, and other industrial settings for lifting and moving loads in a small area.

- Feature: Freestanding gantry crane design, with rollers, requiring no foundations, providing high flexibility and versatility.

- Pros: Ideal for material handing in various working sites

- Cons: Limited lifting capacity, with standard capacity of 500kg -10 ton

- Applications: Used in various industrial applications, such as injection workshops, warehouse, and various applications and workstations, for either indoors or outdoors on leveled concrete ground.

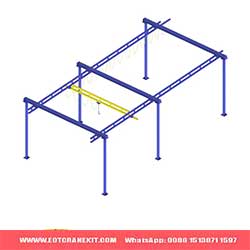

Workstation bridge crane for maintenance

Workstation bridge cranes for maintenance are specialized overhead cranes that are designed for use in maintenance and repair applications.

Workstation bridge cranes are commonly used in a variety of industrial sectors, including:

- Manufacturing: Workstation bridge cranes are widely used in manufacturing facilities for lifting and positioning of materials and equipment in production lines.

- Automotive: Workstation bridge cranes are commonly used in automotive manufacturing facilities for handling of parts and equipment in assembly areas.

- Warehousing and logistics: Workstation bridge cranes are used in warehouses and logistics facilities for loading and unloading of materials, as well as for positioning of materials on shelves or racks.

- Maintenance and repair: Workstation bridge cranes are ideal for use in maintenance and repair workshops, where they can be used for lifting and positioning of machinery and equipment.

Overall, workstation bridge cranes are a versatile and efficient solution for a wide range of lifting and positioning tasks, making them a popular choice in many industrial sectors.

Elecric overhead jib crane for maintenance

Jib cranes are a type of overhead crane that are designed to lift and move heavy loads within a limited area. They consist of a horizontal arm, called a jib, that is mounted on a vertical pillar or wall. The jib is equipped with a hoist and trolley system that can move along the length of the arm and lift and move loads.

Jib cranes for maintenance work are specialized cranes that are used in maintenance and repair applications. They are designed to provide easy access to equipment and machinery for maintenance and repair work.

Articulating jib cranes 0.25- 1000kg

There are several types of jib cranes used for maintenance work, including:

- Wall-mounted jib cranes: These cranes are mounted on a wall or vertical pillar and are ideal for work areas with limited floor space.

- Freestanding jib cranes: These cranes are mounted on a freestanding support column and can be moved to different locations as needed.

- Articulating jib cranes: These cranes have a flexible arm that can be adjusted to reach around obstacles and provide access to hard-to-reach areas.

The typical applications of jib cranes for maintenance include:

Industrial sectors that frequently use jib cranes for repair work include automotive, aerospace, manufacturing, and warehousing/distribution.

- Equipment and machinery maintenance: Jib cranes can be used to lift and move heavy equipment and machinery for maintenance and repair work.

- Vehicle maintenance: Jib cranes can be used in automotive repair shops to lift and move vehicles for maintenance and repair work.

- Aerospace maintenance: Jib cranes can be used in aerospace facilities to lift and move aircraft components for maintenance and repair work.

- General maintenance: Jib cranes can be used in a variety of other maintenance applications, such as in manufacturing facilities, warehouses, and distribution centers.

Portable gantry cranes

Portable gantry cranes are a type of maintenance crane that are designed to be easily moved and set up, making them ideal for use in temporary or changing workspaces. These cranes are typically used for lifting and positioning of equipment and machinery during maintenance and repair work.

Pros of portable gantry cranes:

- Easy to move and set up: Portable gantry cranes can be easily moved and set up in different locations as needed, making them highly versatile.

- Cost-effective: Portable gantry cranes are generally less expensive than fixed gantry cranes, making them a more cost-effective solution for many applications.

- No installation required: Portable gantry cranes do not require any installation, which can save time and money compared to fixed gantry cranes.

Cons of portable gantry cranes:

- Lower weight capacity: Portable gantry cranes typically have a lower weight capacity than fixed gantry cranes, which may limit their use in some applications.

- Less stable: Portable gantry cranes are generally less stable than fixed gantry cranes, which may affect their suitability for certain tasks.

There are several different types of portable gantry cranes that can be used for maintenance and repair work, including:

- Adjustable height gantry cranes: These cranes feature adjustable height legs, allowing them to be used in different workspaces with varying ceiling heights. They are ideal for use in maintenance and repair workshops.

- Aluminum gantry cranes: These cranes are lightweight and easy to move, making them ideal for use in temporary or changing workspaces. They are often used in construction or outdoor settings.

- Steel gantry cranes: These cranes are more durable and have a higher weight capacity than aluminum gantry cranes, making them ideal for use in heavy-duty applications such as manufacturing or warehousing.

Typical applications of portable gantry cranes for repair work include:

- Lifting and positioning of machinery and equipment during maintenance and repair work

- Loading and unloading of materials in temporary or changing workspaces

- Handling of tools and parts in maintenance workshops

Industrial sectors that commonly use portable gantry cranes include:

- Manufacturing: Portable gantry cranes are widely used in manufacturing facilities for lifting and positioning of materials and equipment in production lines.

- Construction: Portable gantry cranes are often used in construction sites for lifting and positioning of materials on site.

- Warehousing and logistics: Portable gantry cranes are used in warehouses and logistics facilities for loading and unloading of materials, as well as for positioning of materials on shelves or racks.

- Maintenance and repair: Portable gantry cranes are ideal for use in maintenance and repair workshops, where they can be used for lifting and positioning of machinery and equipment.

In-factory gantry cranes are easily transported from one work area to another for quick maintenance and repair, which is arguably one of their greatest benefits. Depending on the size of the gantry and the load, one or two workers can simply roll the entire crane to a new location within the shop and lift materials as needed. They are equipped with polyurethane tires for easy indoor movement and can even be track mounted for manual or motorized travel over a fixed route. However, because most maintenance and repair applications require workflow changes, portable or re-locatable gantry cranes are a more practical option.

There are several gantry models for in-shop and outdoor maintenance and repair, depending on the needs of the operation.

Engine or Electrical Maintenance and Repair

An adjustable steel gantry crane is an ideal solution for facilities that perform equipment maintenance and repairs on vehicles and/or machinery. Workers often have to pull an engine or transmission from inside a vehicle, whether it be an automobile, light rail, or transit vehicle. Lifting heavy parts from larger vehicles can be impossible without the help of a material handling solution. Even smaller parts weighing 50-100 pounds can require the help of a material handling system to avoid putting unnecessary physical stress on workers.

Adjustable gantries are often adjustable in height, span, and tread, making them easy to maneuver and extremely versatile. For applications like these, adjustability and portability are key. A three-way adjustable gantry crane is a great option for a transit company that needs to pull heavy electrical cables from rail cars because it can be transported to any point around the rail car and adjusted to lift from almost any position.

These gantries are generally engineered for stability, leaving the I-beam free to pivot as it self-centers over the load. The A-frame design helps to eliminate swaying, and the I-beam can be cantilevered to deliver parts through the end of the gantry up to four feet past the end of the beam. This is especially important when reaching into machinery and lifting heavy cables or large engines that are suspended for long periods of time.

HVAC Maintenance and Repair

HVAC applications almost always require the help of a light-lift system. However, HVAC maintenance and repair often requires a system that is extremely portable and lightweight. While many steel gantries can be easily transported by one or two workers on the shop floor, a steel gantry crane cannot be easily lifted from a service truck or work vehicle and carried from one job site to another. For applications like these, an aluminum gantry crane is an excellent option.

Not only can they lift up to three tons, but they can also be easily assembled and disassembled and transported in a work truck or similar vehicle. Aluminum gantries can weigh as little as 116 pounds fully assembled (depending on the capacity) making them an excellent solution for workers who have to maintain and repair HVAC equipment on rooftops or in other precarious locations.

Aluminum gantry cranes are height adjustable for specific lifts, uneven floors, or maneuverability in narrow or tight spaces. Adjustable spans also allow the crane to be shortened for easy transport in tight locations. They can be customized with pneumatic tires for easy outdoor movement and excellent rooftop protection.

Maintenance works in workshop or garage

Portable gantry cranes are ideal for use in garage maintenance applications, as they can be easily moved to different locations as needed. They are commonly used for lifting and moving heavy automotive components, such as engines and transmissions, for maintenance and repair work.

portable gantry cranes are commonly used in car or truck repairing applications. These cranes are designed to be easily moved and set up in different locations, making them ideal for use in garage or automotive repair shop environments.

Portable gantry cranes can be used to lift and move heavy automotive components, such as engines, transmissions, and suspension systems, for maintenance and repair work. They can also be used to lift and move vehicles for inspection, repair, or maintenance purposes.

The high load capacity and versatility of portable gantry cranes make them a popular choice for automotive repair applications, as they can be customized to suit specific needs and can be configured with different hoist and trolley systems, as well as other accessories. Additionally, the improved safety provided by portable gantry cranes can help reduce the risk of injury or damage during automotive repair work.

Injection workshops for Mold repairing and exchanging

Portable gantry cranes are commonly used in injection workshops for repairing and mold exchanging applications. These cranes are designed to be easily moved and set up in different locations, making them ideal for use in injection molding facilities where molds need to be exchanged or repaired.

Portable gantry cranes can be used to lift and move heavy injection molds for maintenance and repair work, as well as for exchanging molds between injection molding machines. They can also be used to move other heavy equipment and components within the injection workshop.

The high load capacity and versatility of portable gantry cranes make them a popular choice for injection workshop applications. They can be customized to suit specific needs and can be configured with different hoist and trolley systems, as well as other accessories. Additionally, the improved safety provided by portable gantry cranes can help reduce the risk of injury or damage during injection molding operations.

Maintenance crane for heavy machinery workshops

As for heavy duty machinery workshops or factory, the maintenance cranes are usually functioned by the material handling crane, including overhead crane and gantry cranes, etc.

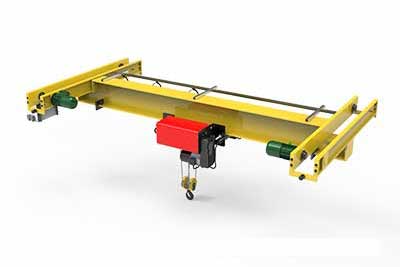

- Features: Have a horizontal beam supported by two end carriages that can move along overhead runway rails.

- Pros: Make advantages of the overhead space to lift and transport heavy loads over a wide area, can be operated remotely or manually. T

- Cons: Require a supporting runway structures to operate, limited mobility

- Applications: Typical used for indoor application such as workshops, warehouse, to lift and move heavy loads or machinery parts over a large area.

- Features: Have a horizontal beam supported by two legs that can move along rails

- Pros: Can lift and transport heavy loads over a wide area, can be operated remotely or manually

- Cons: Require a flat surface to operate, limited mobility

- Applications: Used in shipyards, factories, and construction sites for lifting and moving heavy loads over a large area.

Overhead cranes for various indoor mainteance works

Overhead cranes are a type of maintenance crane that are suspended from a beam or track, allowing them to move along the length of the track. These cranes are typically used for lifting and positioning of heavy equipment and machinery during maintenance and repair work.

Pros of overhead cranes:

High weight capacity: Overhead cranes can have a very high weight capacity, making them ideal for lifting and positioning of heavy equipment and machinery.

- Precise positioning: Overhead cranes can be used to precisely position loads, which is important in many maintenance and repair tasks.

- Space-saving: Overhead cranes are suspended from a beam or track, which means they do not take up floor space in the workspace.

Cons of overhead cranes:

- High cost: Overhead cranes can be more expensive than other types of maintenance cranes, which may limit their use in some applications.

- Installation required: Overhead cranes require installation, which can be time-consuming and expensive.

There are several different types of overhead cranes that can be used for maintenance and repair work, including:

- Single girder overhead cranes: These cranes have one beam that spans the workspace, and are ideal for use in smaller workspaces or where a lower weight capacity is required.

- Double girder overhead cranes: These cranes have two beams that span the workspace, and are ideal for use in larger workspaces or where a higher weight capacity is required.

- Underhung overhead cranes: Thse bridge cranes is monted on the ceiling structrues and roof structures of workshops,which is an economical bridge crane without supporting columns.

Typical applications of overhead cranes for repair work include:

- Lifting and positioning of heavy equipment and machinery during maintenance and repair work

- Loading and unloading of materials in production lines

- Handling of tools and parts in maintenance workshops

Overhead cranes are ideal for use in maintenance and repair workshops, where they can be used for lifting and positioning of machinery and equipment during maintenance and repair work. They can be used for tasks such as lifting engines out of vehicles, positioning heavy equipment for repair work, and moving large components during maintenance tasks.

Goliath gantry cranes for indoor and outdoor heavy reparing work

Goliath gantry cranes are a type of maintenance crane that are similar to gantry cranes, but feature a bridge that is supported by legs on either side of the workspace. These cranes are typically used for lifting and positioning of heavy equipment and machinery during maintenance and repair work.

Pros of goliath gantry cranes:

- High weight capacity: Goliath gantry cranes can have a very high weight capacity, making them ideal for lifting and positioning of heavy equipment and machinery.

- Mobile: Goliath gantry cranes can be moved around the workspace, making them more versatile than fixed cranes.

- Space-saving: Goliath gantry cranes are supported by legs instead of being suspended from a beam or track, which means they do not take up floor space in the workspace.

Cons of goliath gantry cranes:

- Installation required: Goliath gantry cranes require installation, which can be time-consuming and expensive.

- Limited height: Goliath gantry cranes may have limited height due to the height of the legs, which may limit their use in some applications.

There are several different types of goliath gantry cranes that can be used for maintenance and repair work, including:

- Single girder goliath gantry cranes: These cranes have one bridge that spans the workspace, and are ideal for use in smaller workspaces or where a lower weight capacity is required, with lifting capacity no heavier than 20 ton.

- Double girder goliath gantry cranes: These cranes have two bridges that span the workspace, and are ideal for use in larger workspaces or where a higher weight capacity is required, with lifting capacity up to 320 ton.

- Semi goliath gantry crane: With one end of main girder mounted on the overhead runway system and the other end supported by gantry legs, which are travelling on the ground beam.

Typical applications of goliath gantry cranes for repair work include:

- Lifting and positioning of heavy equipment and machinery during maintenance and repair work

- Loading and unloading of materials in production lines

- Handling of tools and parts in maintenance workshops

- Industrial sectors that commonly use goliath gantry cranes include:

Maintenance and repair: Goliath gantry cranes are ideal for use in maintenance and repair workshops, where they can be used for lifting and positioning of machinery and equipment during maintenance and repair work.

How do you choose the right maintenance crane for your facility?

Choosing the right maintenance crane for your facility depends on several factors such as the type of maintenance work that needs to be done, the weight and size of the equipment being lifted, the available space in your facility, and your budget.

Here are some key considerations when choosing a maintenance crane:

- Capacity: Choose a crane that can handle the weight of the heaviest equipment you need to lift.

- Height: Consider the height of your facility and choose a crane that can reach the highest point you need to lift equipment to.

- Span: The span is the distance between the crane's runway rails. Choose a crane with a span that fits your workspace.

- Mobility: Consider whether you need a crane that can move along a runway or one that is stationary.

- Power source: Decide whether you prefer an electric or hydraulic crane based on your power supply and budget.

- Safety features: Ensure that the crane has safety features such as overload protection, emergency stop buttons, and limit switches.

- Maintenance requirements: Consider the maintenance requirements of the crane and choose one that fits your maintenance schedule and resources.

By considering these factors, you can choose the right maintenance crane for your facility that is safe, efficient, and cost-effective.

Double Girder Gantry Crane 40 Ton for sale Kenya for Maintenance - A Case Study

40 ton double girder gantry crane for maintenance works in Geothermal project in Nakuru, Kenya. Check customized goliath crane 40 ton for sale now.

- Crane type European style double girder gantry crane

- Crane specifications 40 ton -8 m span - 8 m lifting height

- Power supply 380V50HZ3P

- Applications The goliath crane is used for maintenance works .

- Project locations Kenya

- The picture on the left is the 40 ton wire rope hoist trolley for the double girder gantry crane for mainteancne works in Kenya.

What safety measures should be taken when using a maintenance crane?

When using a maintenance crane, it is important to take several safety measures to prevent accidents. Here are some important safety tips to keep in mind:

- Always inspect the crane before use to ensure that it is in good working condition.

- Make sure that the crane is on a level surface and that the outriggers are properly extended.

- Use appropriate personal protective equipment (PPE) such as hard hats, safety glasses, and gloves.

- Ensure that the load being lifted does not exceed the crane's weight capacity.

- Use proper lifting techniques to avoid swinging the load and keep it stable during movement.

- Keep a safe distance from the crane when it is in operation.

- Never exceed the crane's maximum operating radius or boom length.

- Follow all manufacturer's instructions and safety guidelines.

By following these safety measures, you can help prevent accidents and ensure that maintenance crane operations are conducted safely and efficiently.

How often should a maintenance crane be inspected and maintained?

Maintenance cranes should be inspected and maintained regularly to ensure their safety and proper functioning. The frequency of inspections and maintenance will depend on various factors such as the type of crane, its usage, and the environment it operates in. Generally, it is recommended that maintenance cranes undergo a thorough inspection and maintenance at least once a year. However, more frequent inspections may be necessary for cranes that are used more frequently or operate in harsh environments. It is important to follow the manufacturer's recommendations and guidelines for maintenance and inspection to ensure the safety of the crane and its operators.