Economical Explosion-Proof Crane Kits , 40 Ton Kit No Main Girder

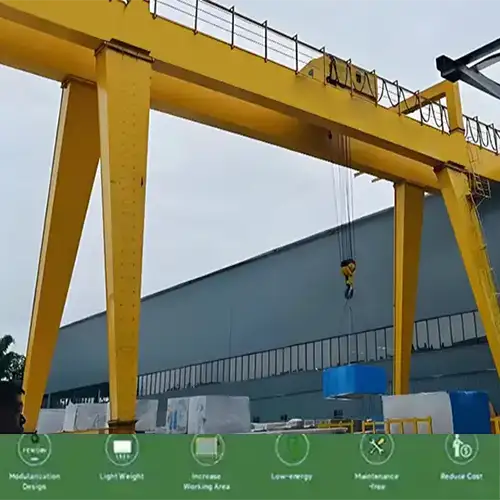

40 ton overhead crane kit for Pakistan. A case study showing how a Pakistan client secured a 40-ton explosion-proof crane kit affordably & efficiently.

Category: 40 Ton Overhead Crane

Your Trusted Explosion Proof Overhead Crane Manufacturer & Supplier

Economical Way to Buy Explosion-Proof Crane Kits

40 Ton Explosion Proof Overhead Crane Kit without Main Girder for Sale Pakistan

Overview of the Case of 40 TonOverhead Crane Kit

This case study centers around a project we worked on in Pakistan, where a client in a hazardous environment needed a reliable and safe overhead crane. The client operates in an industry that handles combustible materials, making safety a top priority. Our job was to supply a 40-ton explosion-proof crane kit designed specifically for their needs.

The purpose of this 40-ton crane kit was to safely lift heavy loads in an environment with explosive risks. Because of the hazardous atmosphere, the crane had to meet explosion-proof standards. Our team customized the kit to ensure it met these strict safety requirements, helping the client operate safely and efficiently.

Crucial Need for Explosion-Proof Equipment

In industries that deal with flammable materials or work in explosive atmospheres, explosion-proof equipment is non-negotiable. These cranes are specifically designed to prevent sparks, heat, or electrical components from causing an explosion. Without the proper explosion-proof design, the risks are too high—potential accidents could result in severe damage, injuries, or worse. That's why ensuring the crane kit met the highest safety standards was critical for this project.

For this project, we provided a 40-ton overhead crane kit but excluded the main girder. This part would be fabricated locally by the client. The reason for this was to reduce costs and allow the client to control the fabrication process. Our kit included all the essential components—the explosion-proof hoist trolley, electrical control cabinets, safety devices, and more—ensuring that the crane would be fully functional once the local girder was installed. This approach provided the client with flexibility and efficiency, saving time and money on shipping.

Client Background

Client's Industry

The client operates in the petrochemical industry in Pakistan, a sector known for handling volatile substances and dealing with flammable gases and liquids. This makes it crucial for them to have equipment that minimizes the risk of sparks, heat, or any other form of ignition that could cause an explosion. Their work environment demands equipment that can meet explosion-proof standards to ensure the safety of both their workers and their facilities.

Why They Needed a 40 Ton Explosion-Proof Crane Kit

In the petrochemical industry, the potential for explosive atmospheres is high, as workers often handle flammable chemicals. A spark from a regular crane could trigger an explosion, resulting in catastrophic damage. The need for a 40-ton explosion-proof crane kit was clear: the crane needed to safely lift and move heavy loads without introducing any risk of ignition. The explosion-proof design ensures that the crane's electrical components, motor, and any exposed parts do not spark or overheat, protecting the environment and maintaining operational safety.

Location and Challenges

The client's facility is located in a remote area of Pakistan, which posed some logistical challenges. Due to its location, sourcing equipment and coordinating delivery required careful planning. Additionally, the local infrastructure was a bit limiting when it came to certain resources, making it harder to get large, pre-assembled crane systems. The client also had to adhere to local regulations for explosion-proof equipment, which meant all components had to meet national safety standards, as well as international certifications.

Why the Client Chose a Crane Kit

Instead of purchasing a fully assembled crane system, the client opted for a crane kit. There were several key reasons for this decision:

- Local Fabrication of the Girder: By excluding the main girder from the kit, the client could have it fabricated locally. This saved on shipping costs and gave them flexibility in terms of design and production.

- Cost-Effectiveness: The crane kit allowed the client to save money, as it didn't require the purchase and shipment of larger, bulkier components.

- Easier Installation: A crane kit is often easier to install, as it comes with detailed instructions and fewer large components to handle. The client had the technical expertise to handle the assembly and was confident they could install it smoothly once they received all the parts.

Choosing the kit gave the client more control over the process, ensuring they had the right equipment at a lower overall cost.

Project Requirements

Technical Specifications

The client's project had specific requirements to ensure the crane kit would meet both operational needs and safety standards. These technical specifications were designed to accommodate the hazardous environment and the nature of the client's work:

- Lifting Capacity: The crane had to handle a 40-ton lifting capacity, suitable for the heavy loads the client frequently handles in their facility.

- Span Size: Two different span sizes were requested for flexibility in various parts of the facility:

14 meters

7.5 meters

- Lifting Height: The crane needed a lifting height of 10.5 meters to ensure it could reach the necessary areas in the client's operations.

- Explosion-Proof Standards: Given the hazardous environment, the crane had to comply with strict explosion-proof standards. This included ensuring that all components, from the electric hoist trolley to the electrical control cabinets, would be designed to prevent any sparks or ignition that could trigger an explosion. All parts needed to meet both local regulations and international safety standards for such environments.

- Power Supply: The crane kit had to be compatible with the local 400V, 50Hz, 3-phase power supply, ensuring seamless integration with the existing electrical system.

- Local Fabrication: The client specifically requested the exclusion of the main girder from the kit. This would be fabricated locally, allowing them to reduce shipping costs and customize the girder according to their specific facility needs.

Payment and Delivery Terms

We agreed on the following terms with the client:

- 90% Payment Upon Order: The client made an initial payment of 90% when placing the order to confirm the project.

- 10% Payment Upon Delivery: The remaining 10% was paid after the crane kit was delivered and inspected on-site.

- CFR Shipping Terms: The delivery was arranged under CFR (Cost and Freight) terms, meaning we were responsible for the cost and transportation to the agreed-upon port in Pakistan. However, the client handled the local import duties and delivery from the port to their site.

Other Special Requirements

- Integration with Existing Systems: The crane kit was designed to integrate seamlessly with the client's existing lifting systems, ensuring minimal disruption to their operations.

- Additional Safety Features: The client also requested extra safety devices, such as overload protection and limit switches, to further ensure safe operation in a hazardous environment.

These specifications and requirements ensured the crane kit was perfectly suited for the client's needs, providing both safety and functionality in their hazardous operational environment.

Customized Crane Kit Solution

Components Included in the Crane Kit

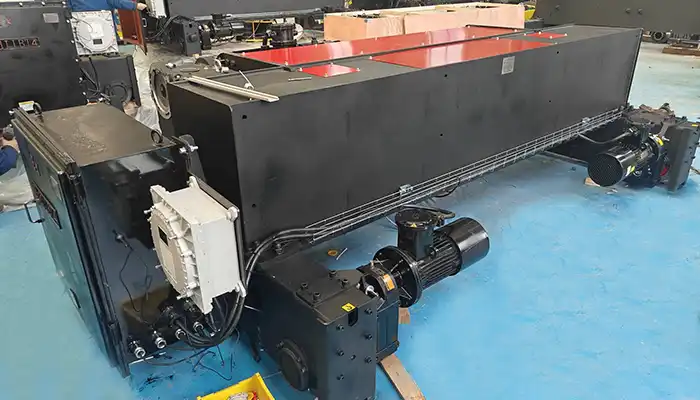

The 40-ton explosion-proof crane kit we provided was carefully tailored to meet the client's specific needs, especially for the hazardous environment in which it would operate. Below are the key components included in the kit:

- Explosion-Proof Electric Hoist Trolley: This hoist trolley is designed to prevent any sparks or heat generation that could ignite the surrounding atmosphere. It meets the necessary explosion-proof standards, ensuring safe operation in hazardous conditions.

- Trolley Frame: The trolley frame was built to support the electric hoist, ensuring smooth and stable movement of heavy loads. Its design ensures durability and safety when lifting or lowering heavy items in volatile environments.

- End Carriages with Motors and Wheels: These are essential for the crane's movement along the tracks. The end carriages come equipped with explosion-proof motors and wheels that are designed to handle heavy loads while ensuring safety in the presence of explosive gases or dust.

- Explosion-Proof Electrical Control Cabinets: The control cabinets contain all the necessary electrical components for crane operation, including switches, fuses, and other safety features. These cabinets are designed to prevent any electrical sparks or overheating, ensuring they remain safe to use in a hazardous atmosphere.

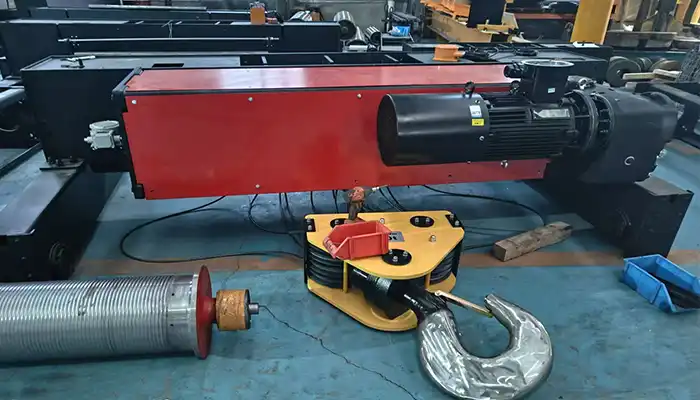

- Hook Assembly: The hook assembly is built to handle up to 40 tons of lifting capacity. It is robust, reliable, and designed to be compatible with the rest of the explosion-proof system, making sure no part of the crane could potentially cause ignition.

- Safety Devices (Limit Switches, Overload Protection): Safety is a top priority in hazardous environments. The crane kit includes limit switches to prevent overtravel of the crane and overload protection to stop lifting beyond the crane's maximum capacity. These devices ensure smooth and safe operations under all conditions.

Exclusion of the Main Girder

The main girder was excluded from the kit for several reasons:

- Cost Efficiency: Excluding the main girder reduced both the shipping costs and overall price of the crane kit. The client was able to handle the fabrication of the girder locally, which was more cost-effective.

- Local Fabrication Flexibility: By fabricating the girder locally, the client had more control over its design and manufacturing. This allowed them to tailor the girder to fit their specific operational needs and constraints within their facility.

- Easier Customization: The exclusion of the girder gave the client the flexibility to adjust dimensions or modify designs as needed, based on their unique installation site.

Custom Features

In addition to the standard components, we worked with the client to include some custom features that would further support their operational needs:

- Integration with Existing Systems: The crane kit was designed to work seamlessly with the client's existing lifting systems, making it easier for their operators to manage and use without disruption to their workflow.

- Enhanced Safety Features: The client requested extra safety features such as automatic safety brakes and emergency stop buttons. These were added to ensure the crane would operate with the highest levels of safety, even under the most demanding conditions.

These tailored components and custom features helped ensure the crane kit met the specific needs of the client, providing both safety and efficiency in their hazardous environment.

Key Challenges and Solutions

Every project has its unique hurdles. For this 40-ton explosion-proof overhead crane kit in Pakistan, we encountered a few key challenges. Here's how we handled them to make the project a success.

Explosion-Proof Compliance

- The Challenge: Meeting international explosion-proof standards was critical. The client operates in a hazardous environment where safety is non-negotiable.

- Our Solution: We used certified explosion-proof components across the crane kit, including the hoist trolley, motors, and control cabinets. All parts were selected based on their ability to perform safely in environments with combustible gases or dust. Materials were flame-resistant, and all wiring was sealed to prevent spark risks.

Electrical and Cable Integration

- The Challenge: The crane's electrical system needed to match the local infrastructure in Pakistan, which can vary depending on the site.

- Our Solution: We confirmed the client's power supply requirements—400V, 50Hz, 3-phase—early in the planning stage. Then we customized the control system and cables to match this standard. We also supplied labeled wiring diagrams to support local technicians during installation.

Client's Local Fabrication

- The Challenge: Since the main girder was not included in the crane kit, it had to be fabricated locally. Ensuring it matched our design specifications was essential to avoid any mismatch during assembly.

- Our Solution: We provided complete girder fabrication drawings and clear assembly instructions. Our technical team remained available to assist the client's engineers and checked in regularly to verify that the local fabrication stayed on track with our design.

Communication and Customization

- The Challenge: Coordinating all the details with an overseas client, including custom specifications, required clear and constant communication.

- Our Solution: We assigned a dedicated project manager to handle all communication. Frequent updates, quick replies, and shared documents helped us stay aligned. We also held several video calls to review design drawings and discuss modifications.

Solutions and Results

Thanks to proactive planning and open collaboration, every challenge was handled effectively:

- The crane kit met all explosion-proof safety standards.

- Electrical systems were perfectly compatible with the local grid.

- The client's locally fabricated girder fit seamlessly with our supplied components.

- Customization was handled smoothly, and the final delivery matched the client's expectations.

In the end, the client got a safe, cost-effective, and tailored crane kit ready for heavy-duty use in a hazardous environment.

Explosion proof wire rope electric hoist and explosion proof electrical control cabinet

Electric hoist trolley with explosion proof motor

explosion proof motor for explosion proof hoist

40 ton explosion proof hook of 40 ton overhead crane kit

Explosion proof electric hoist trolley frame

Explosion proof electric control box

End carriages for electric overhead crane 40 ton

electric overhead bridge crane kit - 40 ton end carriages

explosion proof circulater breaker

explosion proof overload limiter

safety devices

40 ton overhead crane kit -parts and components

end carriages, suppliy line and motors

Explosion proof motors ,end carriages of 40 ton double girder overhead crane kit for sake Pakistan

40 ton ovverhead bridge crane kit without main girder

Main parts and components of 40 ton top running double girder crane kit without main girder, economical solution

40 ton explosion proof overhead bridge crane kit for sale

Shipping and Delivery

Once the production was complete, we moved on to one of the most important phases—making sure the crane kit was packed, shipped, and delivered safely to our client in Pakistan. Here's how we handled it step-by-step.

Packing and Shipping Preparation

Every component in the crane kit was packed carefully. This wasn't just about putting parts in boxes—it was about making sure everything would arrive in perfect condition.

- Each explosion-proof component, especially the electrical cabinets and hoist trolley, was wrapped and cushioned with protective materials.

- The hook assembly, end carriages, and trolley frames were secured on reinforced pallets or steel racks to prevent movement during transport.

- All packages were labeled clearly for easy identification during unloading and installation.

This helped avoid damage and made unpacking and installation faster for the client.

CFR Shipping Terms

We shipped the crane kit under CFR (Cost and Freight) terms. That means:

- We covered all shipping and freight charges to the destination port in Pakistan.

- The client only needed to handle import duties and customs clearance after arrival.

This arrangement made the process easier and more cost-efficient for the client, especially since international freight can get complicated.

Delivery Timeline

Time matters—especially when a heavy-duty crane is essential to a client's operations. We followed a clear schedule:

- Order Confirmation: Once all specifications were approved and the 90% payment received, production started right away.

- Manufacturing and Assembly: All components were completed and tested on time.

- Shipping and Arrival: The containers were dispatched and reached the client's port within the agreed time frame.

The entire process, from order to delivery, was smooth and on schedule.

Pre-Shipping Inspection

Before anything left our facility, a full inspection was done. This included:

- Checking all electrical and mechanical components for quality and compliance.

- Testing the explosion-proof features to make sure they matched the required standards.

- Verifying that all items listed in the packing list were included and labeled properly.

Only after passing this inspection were the goods cleared for shipping. The client also received photos, test reports, and packing lists in advance, so they could prepare for receiving the goods.

In the end, everything arrived safely, with no missing parts or damage. It was a smooth delivery process that gave the client peace of mind—and a solid start to installation.

Client Feedback and Results

After the crane kit was installed and put into operation, we gathered feedback from the client. Here's how the 40-ton explosion-proof crane performed and how the client felt about the whole process.

Client's Satisfaction with Product Quality

The client was very satisfied with the quality of the crane kit.

- Explosion-proof features met all required standards, and the client appreciated the robust build of the hoist trolley, end carriages, and control systems.

- The materials used in the kit were top-notch, designed to perform reliably in harsh, hazardous environments. The crane's components were designed to last and hold up to the demanding conditions of the client's operations.

Compatibility with Locally Made Girders

The main girder, fabricated locally by the client, was a crucial part of the project.

- The crane kit, which excluded the girder, was designed to fit perfectly with the client's locally fabricated girder.

- All the components, from the end carriages to the trolley frame, were adjusted for easy integration. This helped ensure smooth installation and the crane operated as intended without delays.

The client expressed their satisfaction with how easily the parts came together during the final installation.

Installation Process

The installation was a collaborative process.

- The client appreciated the detailed instructions we provided for assembling and installing the crane kit.

- Our technical support team was available to answer questions and guide them through any challenges during installation.

- The crane's design, which excluded the main girder, simplified the assembly and reduced the time it took to set up. The client was able to get the crane operational quickly, minimizing downtime.

Overall Performance

Once up and running, the crane performed exceptionally well in the hazardous environment.

- It lifted heavy loads reliably, meeting the client's operational demands without any issues.

- The explosion-proof features performed exactly as expected, ensuring the crane could be safely operated in an environment with combustible materials.

The client was confident in the crane's ability to perform safely under challenging conditions.

Safety and Efficiency

Safety was a key concern, and the client was highly impressed with the crane's safety features.

- Overload protection prevented the crane from lifting more than its maximum capacity, safeguarding both the crane and the loads.

- Limit switches ensured the crane's movements were restricted to safe zones, preventing overtravel.

- The overall safety and efficiency of the crane meant that the client was able to operate it with peace of mind, knowing they were reducing the risk of accidents or failures.

The client appreciated these features, as they significantly improved the overall safety and efficiency of their operations.

Overall, the client was extremely satisfied with both the performance and safety of the crane. The customized kit provided everything they needed for safe and efficient lifting in their hazardous environment, and they are looking forward to more projects together in the future.

Conclusion

This project was a great success from start to finish. We provided the client with a customized 40-ton explosion-proof crane kit, perfectly suited for their hazardous environment. All key requirements were met, including:

- High-quality components, designed for explosion-proof performance.

- Seamless compatibility with the locally fabricated girder, ensuring smooth installation.

- Timely delivery and efficient installation, with all challenges along the way successfully overcome.

The crane has now been successfully implemented and is performing reliably, meeting the client's operational needs safely and efficiently.

We specialize in providing cost-effective, tailored explosion-proof crane kits for clients in hazardous environments. If you're looking for a crane solution that meets international safety standards, we are here to help.

- Whether you need a 40-ton overhead crane kit or a customized solution, we can provide exactly what you need.

- Our flexible and practical crane kits offer a more cost-effective solution compared to full crane systems, especially for clients looking to locally fabricate some parts.

Send Us Your Request Now to Get Your Price on an Explosion-Proof Crane Kit!

Contact us today for a tailored solution that fits your specific requirements. Let's make sure your operations are both safe and efficient.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch