40 Ton Explosion-Proof Crane Germany: Quality Inspection Report

Comprehensive inspection report ensuring safe, reliable operation of a 40-ton explosion-proof overhead crane offered for sale in Germany.

Category: Featured

Your Trusted Overhead Crane Manufacturer & Supplier

40 Ton Explosion-Proof Crane Sale Germany: Quality Inspection Report

Introduction:Purpose of the Inspection

The main goal of this inspection is to make sure the 40-ton explosion-proof bridge crane meets all safety and quality requirements. We check that the crane is built correctly, works well, and is safe to operate in hazardous environments. This helps prevent accidents and ensures the crane lasts long without problems.

Overview of the Explosion Proof Crane 40 Ton

This crane is designed to handle loads up to 40 tons. It is a bridge-type crane with a span of 22 meters. The crane works mainly indoors and has an explosion-proof rating of EXDIIAT3, which means it is safe to use in environments where flammable gases may be present.

Key features include:

- Rated lifting capacity: 40 tons

- Working level: A3 for the whole machine, M3 for mechanisms

- Explosion-proof design to prevent sparks or ignition

- Hoisting height of 18 meters

- Main structure made of strong steel plates and components

- Equipped with safety devices like limit switches and braking systems

Applicable Standards and Specifications

This crane is built and inspected according to national and industry standards to guarantee quality and safety. The main standards followed are:

- GB/T3811-2008: Design rules for bridge cranes, ensuring mechanical strength and stability.

- GB/T14405-2011: Manufacturing standards that cover quality control and assembly requirements.

General Crane Specifications

Rated Load Capacity

This crane is designed to safely lift and carry loads up to 40 tons. This capacity suits heavy industrial tasks, especially in environments where safety is critical.

Span and Dimensions

The crane has a span of 22 meters, meaning the distance between the main supporting beams is 22 meters. This wide span allows it to cover large work areas, making it flexible for various lifting needs.

Key size details include:

- Bridge base distance: 5.2 meters

- Trolley gauge (distance between trolley wheels): 3 meters

- Hoisting height: 18 meters

- Maximum wheel load: 315 kN

- Left/right extreme positions: 1000mm / 1300mm

These dimensions are important for proper installation and smooth operation.

Working Level

The crane's working level is classified as:

- A3 for the entire machine, which means moderate to heavy use in general industrial settings.

- M3 for the lifting and running mechanisms, indicating medium duty but reliable performance.

Explosion-Proof Grade

The crane is rated EXDIIAT3, which is a strong explosion-proof classification. This means it is safe to use in areas where flammable gases or dust might be present. The crane's electrical parts and motors are sealed and designed to prevent sparks or heat that could cause ignition.

Main Structure and Materials

The main frame of the crane is a box-type structure. This design provides high strength and stability while keeping weight reasonable.

Materials used are high-quality structural steel:

- Steel grade Q235B is used for main beams and plates.

- Plate thicknesses vary, for example, the main beam cover plate is 14 mm thick and the web plate is 6 mm thick.

This combination ensures the crane can handle heavy loads and tough working conditions without deformation or failure.

Materials Inspection

Main Load-Bearing Structural Parts

The crane's main load-bearing parts are made from Q235B steel. This type of steel is commonly used because it offers good strength and toughness. It is suitable for the main beams, plates, and other key components that carry heavy loads.

Main Load-Bearing Structural Components Materials

| No. | Main Load-Bearing Structural Part | Material Basic Information |

|---|---|---|

| Structural Part Name | Structural Part No. | |

| 1 | Main Beam Cover Plate | — |

| 2 | Main Beam Web Plate | — |

Chemical Composition of Materials (%)

| No. | C | Mn | Si | P | S | Remarks |

|---|---|---|---|---|---|---|

| 1 | 0.16 | 0.33 | 0.18 | 0.013 | 0.014 | See attached material list |

| 2 | 0.14 | 0.34 | 0.17 | 0.02 | 0.005 | See attached material list |

Mechanical Properties of Materials and Bending Test

| No. | Tensile Strength (Rm) MPa | Yield Strength (Re) MPa | Elongation After Fracture (A %) | Impact Test (V) | Hardness | Bending Angle | Bending Radius Diameter |

|---|---|---|---|---|---|---|---|

| Temperature (ºC) | Impact Energy (J) | ||||||

| 1 | 492 | 387 | 34 | — | — | — | — |

| 2 | 475 | 396 | 30 | — | — | — | — |

Chemical Composition Analysis

To ensure the steel quality, we check its chemical makeup. Important elements include:

- Carbon (C): Around 0.14% to 0.16%

- Manganese (Mn): About 0.33% to 0.34%

- Silicon (Si): Approximately 0.17% to 0.18%

- Phosphorus (P): Very low, less than 0.02%

- Sulfur (S): Also very low, less than 0.015%

These levels help confirm the steel's strength and weldability. Low phosphorus and sulfur are especially important to avoid brittleness.

Mechanical Properties

The steel's mechanical tests show it meets required performance:

- Tensile strength (Rm): Around 475 to 492 MPa, meaning it can withstand strong pulling forces.

- Yield strength (Re): About 387 to 396 MPa, indicating the stress at which steel starts to deform permanently.

- Elongation after fracture (A%): Between 30% and 34%, showing good ductility and ability to stretch without breaking.

- Impact energy: Tested to ensure toughness, confirming steel won't crack easily under sudden shocks.

These properties guarantee the crane structure is strong, flexible, and safe for heavy lifting.

Compliance with Standards

All materials used fully comply with relevant standards. This means the steel matches the quality and safety rules in place for cranes of this type. Compliance helps avoid structural failures and supports long-term reliability.

Main Components Inspection

| No. | Component Name | Part No. | Model/Specification | Remarks |

|---|---|---|---|---|

| 1 | Bridge Wheel Set | — | Φ700 | 8 sets |

| 2 | Trolley Wheel Set | — | Φ400 | 4 sets |

| 3 | Drum Assembly | — | Φ650 × 2500 mm | 1 set |

| 4 | Pulley Assembly | — | 40 tons | 1 set |

| 5 | Hook Assembly | — | 40 tons | 1 set |

| 6 | Bridge Travel Motor | — | 4 kW | 2 units |

| 7 | Trolley Travel Motor | — | 2.2 kW | 1 unit |

| 8 | Hoisting Motor | — | 15 kW | 1 unit |

| 9 | Hoisting Gearbox | — | ZQD850-163.38-3CA | 1 unit |

Bridge and Trolley Wheel Sets

- Bridge wheels: 8 sets, each with a diameter of Φ700 mm

- Trolley wheels: 4 sets, each with a diameter of Φ400 mm

All wheels were checked for smooth rotation, surface finish, and tight fit on the axles. No cracks or wear beyond limits were found. The wheel materials and heat treatment also meet required standards.

Drum and Pulley Assemblies

- Drum size: Φ650 × 2500 mm

- Pulley set: Rated for 40 tons

The drum is well-centered and has no deformation. The wire rope grooves are smooth and correctly spaced. The pulley blocks rotate freely, and the sheaves show no signs of cracks or sharp wear edges.

Hook Assembly

- Rated capacity: 40 tons

- Type: Standard forged hook with safety latch

The hook has passed the required non-destructive testing (NDT) to ensure there are no internal defects. It also comes with a valid certification showing it's rated for 40-ton lifts. The hook latch is intact and moves freely.

Motors and Gear Reducers

- Main hoist motor: 15 kW

- Bridge drive motors: 2 × 4 kW

- Trolley drive motor: 2.2 kW

- Hoisting reducer: Model ZQD850-163.38-3CA

All motors were checked for nameplate data, proper insulation, and smooth operation. Gearboxes were opened for visual inspection. Gears, shafts, and oil seals are in good condition, and oil levels are within the normal range.

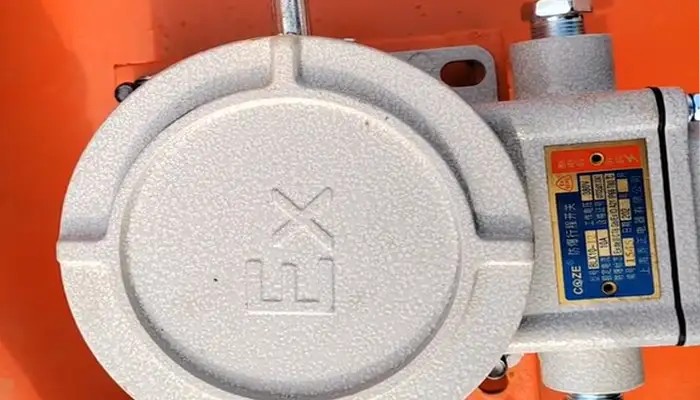

Explosion-Proof Equipment

- Explosion-proof grade: EXDIIAT3

We confirmed all electrical motors, control cabinets, and junction boxes meet this explosion-proof rating. Explosion-proof markings are clearly visible on each device. The cable entries and sealing fittings are secure and match explosion-proof design rules. This ensures safe operation in flammable environments.

Welding Quality Inspection

Welding is one of the most important parts of the crane's structure. Good welds mean safe operation and long service life. In this inspection, both visual and non-destructive tests were done to ensure the crane meets all safety and quality requirements.

| Inspection Item | Inspection Details | Inspection Result | Conclusion |

|---|---|---|---|

| Visual Inspection | Checked all major welded joints: main girders, end beams, trolley frame, and hook blocks. Surface examined for cracks, undercuts, slag, and poor bead formation. | Weld beads smooth and even. No defects observed. Throat thickness met design. | Pass |

| Non-Destructive Testing (NDT) | UT and MT performed on high-stress zones: girder joints, hook mounts, and lifting lugs. | No internal defects found. All results met Class I NDT criteria per GB/T 11345 and GB/T 3323. | Pass |

| Welding Standards Compliance | Welding met GB/T 985, JB/T 5000.3 for appearance and seam size. Testing in line with GB/T 3323 and GB/T 11345. Certified welders and documented procedures were verified. | All documentation and quality control records in place. | Pass |

Remarks:

- Welding processes were conducted by qualified personnel using approved filler materials.

- All inspection records are traceable, and results confirm structural weld integrity.

Visual Inspection of Welds

- All major welded joints on the main girders, end beams, trolley frame, and hook blocks were checked.

- Surface checks were done to spot cracks, undercuts, slag inclusions, or uneven welds.

- Weld beads were found to be smooth, with proper shape and width.

- There were no signs of rust, porosity, or burn-through.

- Fillet welds were measured, and the throat thickness met the design values.

Non-Destructive Testing (NDT) Results

To go deeper, ultrasonic testing (UT) and magnetic particle testing (MT) were carried out on key stress areas:

- Main girder-to-end beam joints

- Hook suspension points

- Lifting lugs and high-load areas

Test results:

- No internal cracks or voids were found.

- All tested sections passed Class I NDT standards (as per GB/T 11345 and GB/T 3323).

This confirms that the crane's main structural welds are free from hidden defects that could cause failure in the future.

Compliance with Welding Standards

All welding work was carried out in line with Chinese national standards:

- GB/T 3323 for radiographic inspection

- GB/T 11345 for ultrasonic testing

- GB/T 985 and JB/T 5000.3 for welding seam size and finish

Welding processes, filler materials, and pre-weld surface treatments were documented and checked. Welders were certified for the required process types, and welding records were complete and traceable.

In short, the welding inspection shows that both the visible and hidden welds meet quality expectations. The crane is safe and strong where it matters most.

Working Mechanism Inspection

The crane's three main mechanisms—hoisting, bridge travel, and trolley travel—were inspected to confirm they work smoothly, safely, and within specified parameters. Each part was checked for performance, power, and reliability.

| Mechanism | Inspection Details | Inspection Result | Conclusion |

|---|---|---|---|

| Hoisting Mechanism | - Motor: 15 kW explosion-proof motor- Lifting speed: 5–8 m/min (confirmed within rated range)- Brake: BYWZ4-300/45 electromagnetic brake with quick response and reliable holding- Reducer: Model ZQD850-163.38-3CA, smooth operation, low noise- Drum size: Φ650×2500 mm, smooth rotation without vibration- Passed load and no-load performance tests | All parameters met design and safety requirements | Pass |

| Bridge Travel Mechanism | - Motor power: 4 kW × 2 units- Travel speed: Smooth, matches design speed- Braking: Electric motor brake tested for emergency stop and hold- Wheels: Φ700 mm, no visible wear or misalignment after testing- Stable motion under full load without skewing or vibration | Stable and reliable operation confirmed | Pass |

| Trolley Travel Mechanism | - Motor power: 2.2 kW- Travel speed: Smooth, responsive at all speeds- Brake: Electric motor braking, no slippage- Wheels: Φ400 mm, proper alignment, clean rolling- Movement controlled easily, no abnormal noise or friction | All tests within expected performance range | Pass |

| Wire Rope Quality and Fixation | - Rope condition: No fraying, corrosion, or kinking- Correct diameter for 40-ton capacity- Firm fixation at drum and hook-end- Pulley grooves matched to rope diameter to prevent wear- Safety devices installed to prevent slipping | Rope condition and fixation fully compliant | Pass |

All key mechanisms operate smoothly and safely. Performance meets the design specs for speed, power, and braking. The crane's working parts are ready for reliable use in hazardous, explosion-risk environments.

Hoisting Mechanism

This is the heart of the crane. It directly handles the load.

- Motor model: 15 kW explosion-proof motor

- Lifting speed: Tested and confirmed to be within the rated range (typically 5–8 m/min, depending on gearbox ratio)

- Brake: Equipped with BYWZ4-300/45 electromagnetic brake

- Brake response was quick, with reliable holding during full load testing.

- Reducer: ZQD850-163.38-3CA model, tested for smooth gear shifting and low noise

- The drum size is Φ650×2500 mm, and the rotation was smooth without vibration.

The hoisting unit passed both load and no-load tests, confirming it performs well under operating conditions.

Bridge Travel Mechanism

The bridge moves the whole crane across the span of the workshop.

- Motor power: 4 kW × 2 units (one for each end)

- Travel speed: Confirmed to match design speed; movement was smooth and well-balanced.

- Braking: Electric brake integrated in motor; tested for emergency stops and start-hold operation.

- Wheels: Φ700 mm; showed no visible wear or misalignment after repeated travel cycles.

The bridge motion remained stable, even under full load, with no sign of skewing or vibration.

Trolley Travel Mechanism

This mechanism moves the trolley (with the hoist) across the crane bridge.

- Motor power: 2.2 kW

- Travel speed: Smooth and responsive at low and rated speeds

- Brake system: Electric motor braking with no slippage

- Wheels: Φ400 mm; aligned properly and rolled cleanly along rails

No unusual noise or friction was observed. The movement was easy to control during forward and reverse runs.

Wire Rope Quality and Fixation

The wire rope is a critical safety part. We took extra care checking this.

- Rope condition: No signs of fraying, corrosion, or kinking

- Correct diameter used, suitable for 40-ton lifting capacity

- Fixation at both drum and hook-end was firm and properly clamped

- Pulley grooves matched rope diameter to prevent uneven wear

All rope ends were fitted with safety devices to prevent slipping during operation.

In summary, all working mechanisms functioned well during inspection. They met speed, load, and braking requirements. Everything is ready for reliable use in an explosion-risk environment.

Electrical and Control System Inspection

The electrical system is critical for both safety and performance. This section checks the protection level, wiring quality, and the function of safety devices. Since this is an explosion-proof crane, all components must meet strict safety standards.

| Inspection Item | Details | Inspection Result | Conclusion |

|---|---|---|---|

| Protection Level of Electrical Components | - All electrical enclosures meet EXDIIAT3 explosion-proof rating- Verified dust- and moisture-proof design- Seals intact, casing screws tight- No loose or damaged parts found | Protection level meets explosion-proof standards | Pass |

| Wiring and Cable Quality | - Wiring neat, color-coded, secured in trays and junction boxes- Cable insulation intact, no damage- Flexible cables used in moving parts (trolley, hoist)- Firm terminal connections with clear labels- Wiring layout avoids stress and sharp bends | Wiring installation complies with standards | Pass |

| Emergency Stop and Safety Switches | - Non-automatic reset emergency stop switch installed and tested- Immediate power shutdown on activation- Travel limit switches (model BLX11-22) tested and functional- Electrical isolator switches checked for correct operation | Safety switches function as required | Pass |

| Explosion-Proof Electrical Components Check | - Explosion-proof motors, brakes, and terminal boxes visually and functionally inspected- Spark-proof seals and joints confirmed- Clear and compliant EX markings- No oil leaks, rust, or loose fittings- Hoist and travel motors, electrical panel labeled with EX marks | All explosion-proof devices comply with requirements | Pass |

The electrical and control system is well protected and installed correctly. Safety devices work reliably, and all explosion-proof components meet the highest safety standards. The system is fit for operation in hazardous environments with flammable gas or dust.

Protection Level of Electrical Components

- All electrical enclosures and components were rated to match EXDIIAT3 explosion-proof standard.

- Dust- and moisture-proof designs were verified. Seals were intact and casing screws tight.

- There were no loose or damaged components found during the inspection.

This ensures the system can operate safely in hazardous environments with flammable gas or dust.

Wiring and Cable Quality

- Wiring was neat, color-coded, and well-secured in cable trays and junction boxes.

- Cable insulation was tested—no signs of wear, cuts, or exposure.

- Flexible cables were used in moving areas like the trolley and hoist to prevent breakage.

- All terminal connections were firm, with proper labeling for easy maintenance.

Wiring layout also followed standard installation rules—no excessive bending or stress on connectors.

Emergency Stop and Safety Switches

- A non-automatic reset emergency stop switch was installed on the control panel.

- It responded immediately during testing and shut down power to the hoisting mechanism as expected.

- Travel limit switches for bridge and trolley were tested (model BLX11-22). Both units triggered correctly to stop motion.

- Electrical isolator switches were checked for proper operation and compliance.

These features ensure the crane can stop safely in case of malfunction or operator error.

Explosion-Proof Electrical Components Check

- Explosion-proof motors, brakes, and terminal boxes were visually and functionally checked.

- Seals and joints were confirmed to be spark-proof. Markings were clear and compliant.

- No oil leakage, rust, or loose fittings were found.

- The hoist motor, travel motors, and electrical panel were all labeled with EX marks.

All explosion-proof devices passed the factory check and meet the rated zone requirements.

Safety Protection Devices Inspection

Safety devices are key to safe crane operation. This section covers all major protection systems installed on the 40-ton explosion-proof bridge crane.

| Inspection Item | Details | Inspection Result | Conclusion |

|---|---|---|---|

| Operation Limiters | - Running limiters for bridge and trolley: model BLX11-22 (two sets installed and tested)- Hoisting height limiter: model BLX10-D, stopped hook correctly- Load limiter: BQX-40T installed, calibrated, triggered accurately during overload test | Operation limiters functioned as designed | Pass |

| Buffer Devices | - Bridge end beams fitted with four JHQ-C-10 rubber buffers- Trolley ends equipped with JHQ-A-6 buffers- Buffers securely mounted, no cracks or aging- Compression tests confirmed energy absorption | Buffers in good condition, effective shock absorption | Pass |

| Brake System Condition | - Main hoist uses two BYWZ4-300/45 electromagnetic brakes- Brakes engaged and released smoothly during lifting tests- No slippage or abnormal noise- Travel mechanisms have reliable motor brakes- Brake wear within limits | Brake system reliable and well maintained | Pass |

| Limit Switches (Bridge, Trolley, Hook) | - All limit switches tested and triggered promptly- Each limiter stopped motion at correct position- Proper mounting and clean contacts confirmed | Limit switches perform correctly | Pass |

| Interlock Protection Devices | - Electrical interlocks prevent conflicting operations (e.g., hoisting and lowering simultaneously)- Circuits passed function checks | Interlocks function as intended | Pass |

| Other Safety Devices | - No anti-wind devices needed indoors- Thermal overload protection built into motors, no overheating observed- Protective covers on moving parts- Maintenance platform and safety railings installed | Other safety features properly installed | Pass |

All safety protection devices were correctly installed and functioned perfectly during inspection. They effectively prevent mechanical damage, ensure operator safety, and maintain smooth crane operation. No faults or omissions were found.

Operation Limiters

- Running limiters for the bridge and trolley are model BLX11-22. Two sets were installed and tested.

- The hoisting height limiter (model BLX10-D) stopped the hook at the set maximum height.

- A load limiter (BQX-40T) was installed and calibrated. It triggered accurately during test overload.

These devices help prevent collisions, over-lifting, and overloading — all essential for safe use.

Buffer Devices

- The bridge end beams had four JHQ-C-10 rubber buffers installed.

- The trolley was equipped with JHQ-A-6 buffers on both ends.

- Buffers were securely mounted, with no signs of cracks or aging.

- Compression tests showed effective energy absorption during simulated impact.

These reduce the shock when movement reaches the limit, protecting both structure and components.

Brake System Condition

- The main hoist brake uses two BYWZ4-300/45 electromagnetic brakes.

- Brakes engaged and released smoothly during lifting tests.

- No brake slippage or abnormal sounds were found.

- The travel mechanisms (bridge and trolley) also include reliable motor brakes.

Brake wear was within acceptable range, and performance met operational needs.

Limit Switches (Bridge, Trolley, Hook)

- All limit switches for bridge travel, trolley travel, and hoisting were tested.

- Switching actions were crisp and timely.

- Each limiter stopped the corresponding motion at its end point without delay.

- Mounting positions were correct, and contacts were clean and intact.

Interlock Protection Devices

- Electrical interlock systems prevented simultaneous conflicting operations.

- For example, hoisting and lowering could not occur at the same time.

- Interlock circuits were tested and passed function check.

- This avoids accidental misuse that could damage the crane or endanger workers.

Other Safety Devices

- Anti-wind devices were not required in this indoor setup.

- Thermal overload protection is built into motors. No overheating occurred during trial runs.

- Moving parts had protective covers to prevent accidental contact.

- A maintenance platform and safety railings were installed for access and repair.

All protection devices were installed correctly and tested to be functional. Each system plays a role in preventing mechanical failure, protecting the structure, and keeping workers safe. Nothing was missing or out of order.

Dimensional and Structural Integrity Inspection

| Inspection Item | Measured Value | Standard / Tolerance | Result |

|---|---|---|---|

| Span | 22.000 m | Deviation ±0.005 m | -0.002 m (Within tolerance) |

| Bridge Base Distance | 5.202 m | Deviation ±0.005 m | +0.002 m (Within tolerance) |

| Trolley Gauge | 3.001 m | Deviation ±0.005 m | +0.001 m (Within tolerance) |

| Bridge Frame Camber | 30 mm | 0.9 ~ 1.4 × S/1000 (S=span length) | Within required range |

| Bridge Frame Bending | Within S/2000 limit | S/2000 (allowable) | No sagging or distortion detected |

| Diagonal Difference of Wheel Mounts | 3 mm | ≤ 5 mm | Proper squareness confirmed |

| Trolley Track Joints Level Difference | ≤ 1 mm | ≤ 0.0015 × Wc (trolley base width) | Welding and leveling good |

| Main Beam Flatness (Web) | 3–4 mm | < 0.7δ (flatness limit) | Within acceptable limits |

| Main Beam Straightness (Flange) | No bulges or dents | Visual/manual inspection | Pass |

| Wheel Skewness (tgΦ) | 0.0010 | ≤ 0.0015 | Well aligned |

| Wheel Gauge Deviation | Within ±2 to +7 mm | Standard range | Within allowable range |

Key Dimensional Checks

- Span: Measured at 22 meters. Deviation was within tolerance at -0.002m, which is acceptable.

- Bridge base distance: Measured 5.2 meters, with +0.002m deviation — also within limits.

- Trolley gauge: Confirmed to be 3.0 meters, with only +0.001m deviation.

These dimensions match design drawings and ensure proper rail and movement fit.

Camber and Bending of Bridge Frame

- Camber (bridge arch) was measured at 30 mm, which fits the required range of (0.9~1.4)S/1000 for a 22 m span.

- No sagging was observed in the middle section.

- Main beam horizontal bending was under the allowed S/2000 value.

The bridge structure holds shape well, with no signs of distortion or over-weld stress.

Diagonal Difference of Wheel Mounts

- Measured at 3 mm.

- This is below the ≤5 mm limit and indicates proper squareness.

- Equal diagonal distances ensure even wheel load and smooth end carriage travel.

Trolley Track Joint and Level Differences

- Joints of the trolley track were properly welded with no height differences or gaps.

- Level difference at joints was negligible — welding passed visual and straight-edge tests.

- Height difference at same cross-section was 1 mm, well below the limit of 0.0015Wc (where Wc = trolley base).

Main Beam Flatness and Straightness

- Local flatness of the main girder web was checked.

- Results: 3 mm and 4 mm deviations, which are under the standard limit of 0.7δ and 1.2δ.

- Beam flange was visually and manually inspected — no bulging or dents.

Skewness and Alignment of Wheels

- Wheel skew value was 0.0010, which is better than the max allowable tgΦ ≤ 0.0015.

- Proper alignment avoids side wear on wheels and rails, extending service life.

- Wheel gauge deviation was also within the allowed range of ±2 ~ +7 mm.

All critical dimensions and structural tolerances passed the inspection. The frame is stable, aligned, and ready for load-bearing use.

Lubrication and Maintenance Devices Inspection

Lubrication is important for keeping the crane parts running smoothly. Poor lubrication leads to faster wear.

| Inspection Item | Details and Observations | Result |

|---|---|---|

| Lubrication of Friction Parts | - All moving joints including pulley shafts, drum bearings, and wheel hubs were fully lubricated. - Grease fittings and oil cups were present and accessible. - Smooth motion observed in trolley and hoisting mechanisms without dry friction noises. | Satisfactory lubrication confirmed. |

| Condition of Lubricants and Devices | - Factory-installed grease was clean and appropriate for the application. - No grease hardening or contamination found. - Seals showed no leakage; grease distributed evenly during operation. - Brake pivot joints properly lubricated. | Lubricants in good condition and functioning well. |

| Accessibility for Maintenance | - Walkways, platforms, and handrails installed near maintenance points. - Lubrication points clearly marked and easily reachable without safety hazards. - Adequate clearance around gearbox, motor, and wire rope drum for safe inspection and maintenance. | Maintenance access is safe and convenient. |

Lubrication of Friction Parts

- All moving joints like pulley shafts, drum bearings, and wheel hubs were lubricated.

- Grease fittings and oil cups were in place and reachable.

- The trolley and hoisting mechanisms showed smooth motion with no dry friction noise.

Condition of Lubricants and Devices

- Factory-installed grease was clean and of proper type.

- No hardening or contamination was found.

- Seals were not leaking. Grease spread evenly during trial operation.

- Brake systems also had correct lubrication in the pivot joints.

Accessibility for Maintenance

- Walkways, platforms, and handrails were provided around key maintenance points.

- Lubrication points were marked and reachable without risk.

- Enough space around the gearbox, motor, and wire rope drum allows safe inspection.

Lubrication was well-prepared. Devices are easy to service, and no faults were found. Maintenance staff can work safely without much difficulty.

Final Test and Performance Verification

| Test Category | Details and Observations | Result |

|---|---|---|

| Load Test Results | - Full-load test performed using a certified 40-ton test weight. - Crane lifted, held, and lowered the load smoothly without abnormal noises, vibrations, or overheating. - Beam deflection remained within permissible limits and returned to normal after unloading. - No permanent deformation or slipping occurred. | Passed load test with stable performance. |

| Functional Tests of All Mechanisms | - Hoisting system operated smoothly at both normal and slow speeds; brakes held the load securely when stopped. - Bridge travel moved steadily along the full span with no jerking or resistance. - Trolley travel was smooth and properly aligned on rails. - All limit switches (hoisting height, bridge, trolley) activated correctly and reliably. - Emergency stop switch responded immediately and stopped all motions. - Overload limiter activated appropriately when exceeding rated capacity. | All mechanisms functioned correctly and safely. |

| Overall Operational Performance Under Load | - Crane operated smoothly and maintained balance throughout lifting operations. - Electrical and mechanical systems coordinated seamlessly and showed no instability. - Load swings were minimal; wire rope showed no signs of twisting or strain. - Control inputs from pendant and remote control were precise and responsive. - Safety systems (emergency stop, overload protection, limiters) worked as designed during tests. | Operational performance verified and compliant with safety standards. |

Load Test Results

- A full-load test was carried out using a certified 40-ton weight.

- The crane successfully lifted, held, and lowered the load without any abnormal sounds, shaking, or overheating.

- Beam deflection stayed within the standard limits and returned to normal after unloading.

- No permanent deformation or slipping was observed.

Functional Tests of All Mechanisms

- The hoisting system worked smoothly. It lifted and lowered at both normal and slow speeds, and the brake held the load firmly when stopped.

- The bridge travel mechanism ran steadily across the entire span. There was no jerking or extra resistance.

- The trolley moved without issues and stayed properly aligned on the track.

- All limit switches activated as expected. Hoisting height, bridge travel, and trolley limits were tested and passed.

- The emergency stop switch functioned correctly, stopping operations immediately.

- The overload limiter responded when the load exceeded rated capacity.

Overall Operational Performance Under Load

- The crane operated smoothly and stayed well-balanced while lifting.

- All systems — electrical and mechanical — were coordinated and stable.

- The load did not swing excessively, and there was no twisting in the wire rope.

- Control commands from both pendant and remote control were accurate and responsive.

- All safety systems activated during simulation and testing.

Inspection Conclusion

This section summarizes all the inspection work and results, confirming the overall condition of the crane.

Summary of Inspection Results

- Structural, mechanical, and electrical components were all checked.

- All critical measurements, test results, and functions met the design and safety standards.

- The crane completed both no-load and full-load testing with good performance.

Compliance with Applicable Standards

The crane meets the requirements of:

- GB/T3811-2008 (Design of cranes)

- GB/T14405-2011 (General specifications for bridge cranes)

- Explosion-proof equipment standard EXDIIAT3

Identified Defects or Issues

- No defects or abnormal findings were recorded.

- All values measured during testing were within the acceptable ranges.

Recommendations for Corrections or Improvements

- Regular maintenance is recommended, especially for lubrication points.

- Periodic checks of safety limit switches and brake systems should be done to ensure long-term safety.

- Operators should be trained on how to safely handle and use explosion-proof cranes.

The 40 ton explosion proof crane passed all required inspections and performance tests. It is approved for delivery and ready for installation and commissioning at the customer's site.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch