How to Get a Tailored Gantry Crane for Stone Handling Operations

How to choose a gantry crane tailored to your stone yard? Assess yard layout, block sizes, lifting needs & customization options for safe & efficient uses.

Category: Featured

Your Trusted Overhead Crane Manufacturer & Supplier

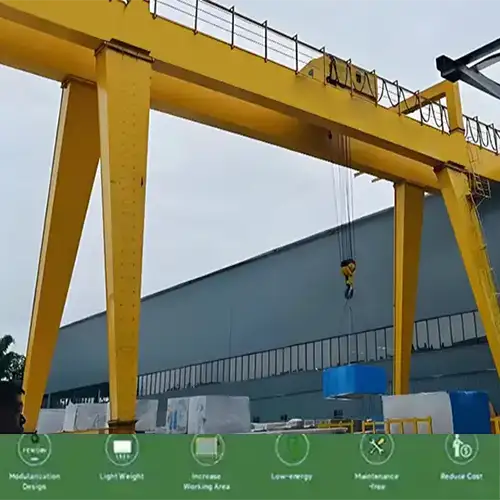

Stone Yard Gantry Cranes for Your Needs

How to Get a Tailored Gantry Crane for Stone Handling Operations

In stone yards, marble workshops, and tile factories, moving heavy blocks safely and efficiently is one of the biggest challenges. Gantry cranes are essential tools in these operations—they allow operators to lift, transport, and position blocks with much less manual effort. Without a crane, handling even medium-sized blocks can be slow, risky, and labor-intensive.

Not all yards are the same, though. Standard, off-the-shelf cranes often don't fit every operation. A narrow workshop, a yard with uneven surfaces, or an operation with unusually large or irregular blocks may require a different setup. Using the wrong crane can lead to inefficiency, material damage, or even accidents.

Tailored gantry cranes solve these problems by matching the crane to your exact yard conditions and lifting needs. Choosing a customized solution can improve workflow, reduce risks, and make operations more productive.

Benefits of a tailored gantry crane include:

- Efficiency: Smoothly handles the blocks you work with every day, reducing delays and rework.

- Safety: Designed for your yard layout and lifting patterns, lowering the risk of accidents or material damage.

- Productivity: Fits your space and block sizes, allowing operators to work faster and with more confidence.

With the right tailored crane, even small or irregular stone yards can handle heavy blocks safely, keep operations moving, and protect valuable materials.

Assessing Your Yard Layout

Before choosing a gantry crane, it's important to take a close look at your yard. The crane you select must fit your workspace, operate safely, and handle the blocks you work with every day. Yard layout plays a big role in determining the crane's span, lifting height, and mobility.

Even small differences in aisle width or available space can make a big difference. For example, a crane that works perfectly in a wide outdoor yard may not fit indoors or in a compact tile workshop. Assessing your yard carefully ensures the crane can operate efficiently without causing bottlenecks or safety issues.

Key considerations when assessing your yard layout:

- Indoor vs Outdoor Operations: Determine whether the crane will work primarily indoors, outdoors, or in both. Outdoor cranes may need weatherproofing, corrosion protection, and stronger foundations.

- Aisle Width and Obstacles: Measure the available space between workstations, walls, or storage areas. This affects crane span and the ability to move blocks without obstruction.

- Available Runway Length and Support Structure: Check how long the crane's rails can be, and ensure the building or yard can support the crane's weight. Concrete foundations, steel beams, or reinforced columns may be required depending on the design.

Examples of layout challenges and solutions:

- Small Workshop: Narrow aisles may require a compact 10-ton gantry crane with a short span and low lifting height.

- Medium-Sized Yard: Space allows for a 15–20 ton crane with moderate span, double girder configuration, and flexible trolley travel.

- Large Outdoor Yard: Long runways and heavy blocks call for a 25–40 ton crane with extended span, high lifting height, and full outdoor protection.

Block Sizes and Dimensions Matters

Stone blocks come in all shapes and sizes, from small decorative marble pieces to massive granite slabs. Understanding the dimensions, weight, and shape of the blocks you handle is critical when designing or selecting a gantry crane. Using the wrong crane for your blocks can slow operations, increase wear on equipment, or even cause accidents.

The size and weight of a block directly influence the crane's span, lifting height, hoist configuration, and trolley design. For example, longer or heavier blocks may require a wider span or multiple rope falls to lift safely, while irregular shapes may need specialized lifting attachments.

Typical block parameters to consider:

- Length, Width, and Height: Measure the maximum dimensions of the blocks you will lift. These determine the crane's clearance, lifting height, and span requirements.

- Weight Distribution and Density: Denser materials like granite weigh more per cubic meter than marble or limestone. Consider uneven weight distribution for irregular blocks.

- Irregular or Tapered Shapes: Some stone blocks are not perfect rectangles and may require slings, clamps, or customized hoists for safe handling.

Before choosing a crane, it's important to understand the range of block sizes you will handle. Blocks can be small decorative marble pieces or massive granite slabs. Their dimensions and density directly influence lifting capacity, hoist selection, and crane span.

| Material | Typical Block Size (L × W × H) | Approx. Weight Range | Notes |

|---|---|---|---|

| Marble | 1.5–3 m × 1–2 m × 0.8–1.5 m | 5–20 tons | Mostly decorative blocks; can be irregular. |

| Granite | 2–4 m × 1–2.5 m × 1–1.5 m | 15–30 tons | Dense and heavy; often for countertops or structural use. |

| Limestone | 2–3.5 m × 1–2 m × 0.8–1.2 m | 10–25 tons | Medium density; used in building materials. |

| Sandstone | 1.5–3 m × 1–2 m × 0.8–1.2 m | 8–20 tons | Softer than granite; easier to handle. |

Notes on irregular shapes: Many blocks are tapered, rounded, or uneven, so lifting attachments like slings, clamps, or spreader beams may be required.

How block dimensions influence crane design:

- Span of the Crane: Wider or longer blocks often need cranes with extended spans to safely lift without swinging.

- Lifting Height: Taller blocks or stacked slabs require higher lifting capabilities to move safely over workstations or storage racks.

- Hoist Type and Number of Rope Falls: Heavy or irregular blocks may need electric wire rope hoists with multiple falls to distribute the load evenly.

- Trolley Design and Positioning: The crane's trolley must accommodate the block size and movement path, ensuring precise placement and minimal risk of collisions.

Careful measurement and analysis of block sizes help ensure your gantry crane can handle every load safely, efficiently, and without interruption to your workflow.

How Dimensions Affect Crane Design

Understanding how block dimensions influence crane design is critical. A crane must have the right span, lifting height, hoist type, and trolley configuration to handle blocks safely. Oversized blocks may need extended spans or multiple hoists, while irregular shapes require specialized lifting attachments.

Span of the Crane

Span of the Crane: Wider or longer blocks require cranes with extended spans to lift safely.

Typical guidance:

- Small blocks (<15 tons): 6–12 m span

- Medium blocks (15–25 tons): 10–18 m span

- Large blocks (>25 tons): 15–25 m span

Lifting Height

Lifting Height: Taller blocks or stacked slabs need higher lifting capabilities.

Typical guidance:

- Small workshops: 4–6 m lifting height

- Medium yards: 6–10 m lifting height

- Large export yards: 10–15 m lifting height

Hoist Type and Rope Falls

Hoist Type and Rope Falls: Small/medium blocks: single electric wire rope hoist or chain hoist is sufficient.

- Heavy/irregular blocks: multiple rope falls with electric wire rope hoist to distribute load evenly.

Trolley Design and Positioning

Trolley Design and Positioning:

- Trolley must travel the full span and accommodate block size.

- Long or heavy blocks may require double trolleys or dual hoists for stability.

Suggested Gantry Crane Capacities Based on Typical Blocks

Once you know the size and weight of your blocks, you can match them to the right gantry crane. Choosing the correct capacity ensures safe lifting and efficient operations.

| Block Weight Range | Suggested Crane Capacity | Configuration | Typical Usage |

|---|---|---|---|

| 5–10 tons | 10-ton gantry crane | Single girder | Small marble workshops, tile cutting yards |

| 10–20 tons | 15–20 ton gantry crane | Single or double girder | Medium marble or limestone yards |

| 15–30 tons | 25-ton gantry crane | Double girder | Granite yards, larger stone processing |

| 25–40 tons | 32–40 ton gantry crane | Box girder, double girder | Large granite export yards, heavy outdoor operations |

Additional Recommendations:

- Anti-sway hoists for delicate or irregular blocks.

- Extended spans for long slabs or truck loading.

- Weatherproofing and corrosion protection for outdoor yards.

By understanding typical block dimensions and weights, you can choose a crane with the correct span, lifting height, hoist type, and trolley configuration. This ensures safe, efficient, and uninterrupted stone handling operations.

Defining Specific Lifting Needs

Once you know your yard layout and block dimensions, the next step is to define your lifting needs. Every stone yard has different daily workloads, and understanding these requirements ensures your gantry crane is safe, efficient, and suitable for your operation.

Daily lifting requirements vary depending on the weight of the blocks, how often they are moved, and the type of lifting attachments used. Ignoring these factors can result in overloading, excessive wear, or inefficient operations.

Key factors to evaluate:

- Maximum Block Weight: Identify the heaviest block you expect to lift. This determines the crane's lifting capacity and hoist configuration.

- Average Load Frequency: Consider how often blocks are lifted per day. High-frequency operations may require more robust cranes and reliable hoists to minimize downtime.

- Types of Lifting Attachments: Determine whether you will use slings, clamps, magnets, or other devices. Attachment choice affects how the load is distributed and can influence hoist selection and trolley design.

Impact on crane configuration:

- Single vs Double Girder: Heavier or longer blocks may require double girder cranes for greater stability and lifting height, while smaller loads may work well with single girder setups.

- Cantilever Options: If you need to load trucks or reach beyond the runway limits, a cantilever design may be necessary.

- Rail-Mounted vs Rubber-Tired: Permanent yards often use rail-mounted cranes for precision, while temporary or mobile operations may prefer rubber-tired cranes for flexibility.

- Movement Paths: Consider the paths the crane will follow to lift and place blocks. Clear, obstacle-free movement reduces accidents and increases efficiency.

By clearly defining lifting needs, you can ensure the gantry crane is correctly sized, configured, and equipped to handle your stone blocks safely and efficiently every day.

Customization Options for Gantry Cranes

Not every stone yard is the same, and a standard gantry crane may not meet all operational needs. Customization allows you to tailor the crane to your yard layout, block sizes, and specific lifting requirements. Choosing the right features can make your daily workflow safer, faster, and more efficient.

Custom features help operators handle blocks carefully, reduce downtime, and extend the crane's lifespan. For small or medium stone yards, these options can make a significant difference in both safety and productivity.

Available customization features:

- Anti-Sway Hoists: Prevents swinging of delicate marble or tile blocks, reducing the risk of cracks or scratches.

- Extended Spans: Allows the crane to cover wider yards or reach trucks for loading, improving flexibility in material handling.

- Cabin or Remote Control: Enhances operator safety and visibility, making precise lifting easier, especially for heavier or irregular blocks.

- Corrosion Protection & Weatherproofing: Essential for outdoor yards, protecting the crane from rain, humidity, and harsh conditions, which extends service life.

Benefits of customization:

- Efficiency: Smooth movement and precise control reduce time spent repositioning blocks.

- Material Protection: Specialized hoists and careful load handling minimize damage to valuable stone blocks.

- Longevity: Features like corrosion protection and proper hoist selection reduce wear and tear, keeping the crane operational for years.

By selecting the right custom options, your gantry crane can match your yard perfectly, improving both operational safety and productivity.

Working with Suppliers

Getting a tailored gantry crane starts with clear communication with your supplier. The more detailed information you provide about your yard and stone blocks, the better the manufacturer can design a crane that fits your operation perfectly. Supplying accurate data upfront saves time, avoids errors, and ensures you get a crane that meets your workflow and safety needs.

Experienced suppliers use the information you provide to suggest optimal configurations, from girder type to hoist selection and control systems. Providing drawings and operational details helps them understand your specific requirements and constraints.

Information suppliers typically need:

- Yard Layout Drawings: Detailed floor plans or yard diagrams showing aisles, storage areas, and runway locations.

- Typical Block Sizes and Weights: Include length, width, height, weight, and density for the majority of blocks you handle.

- Operational Workflow: Explain how blocks are lifted, moved, and placed, including daily lifting frequency and movement paths.

Questions to ask suppliers for tailored solutions:

- Can the crane be customized for my specific block sizes and yard layout?

- What anti-sway, control, or safety features are available?

- Are there options for weatherproofing or corrosion protection for outdoor operations?

- How long will installation take, and what foundation or support structures are needed?

- Can the crane be expanded or upgraded in the future if my yard grows?

By providing accurate information and asking the right questions, you ensure your supplier can design a gantry crane that matches your yard's needs, protects your materials, and improves workflow efficiency.

Projects References

Seeing how tailored gantry cranes perform in real operations helps buyers understand what works best for their own yard. Each stone yard has unique requirements, and the crane must be configured accordingly. Here are some practical examples from around the world:

Small Marble Workshop

- Crane Type: Compact 10-ton gantry crane

- Features: Anti-sway hoist for delicate marble blocks, lightweight structure for narrow aisles

- Benefits: Smooth, precise handling of decorative blocks without taking up too much space

Medium Stone Yard

- Crane Type: 20-ton gantry crane with double girder configuration

- Features: Extended span for wider yard coverage, remote operation for operator safety

- Benefits: Efficient handling of medium-sized marble or granite blocks, improved workflow, and safer operation

Large Granite Export Yard

- Crane Type: 40-ton box girder gantry crane

- Features: Full outdoor protection, high lifting height, long span for truck loading

- Benefits: Handles heavy granite blocks reliably, withstands weather exposure, and supports large-scale export operations

These examples show how choosing the right capacity, configuration, and features allows each yard to maximize productivity, protect materials, and maintain safe operations. Tailored solutions ensure the crane matches your block sizes, yard layout, and operational workflow perfectly.

Conclusion

Choosing a tailored gantry crane is one of the smartest investments a stone yard or marble workshop can make. A crane designed specifically for your yard layout, block sizes, and lifting needs not only improves safety but also ensures a smooth workflow and long-term cost-effectiveness.

Key takeaways for buyers:

- Safety First: Customized cranes reduce the risk of accidents and material damage, especially when handling heavy or irregular stone blocks.

- Smooth Workflow: Tailoring the crane to your yard layout and block dimensions allows operators to move materials efficiently, saving time and labor.

- Long-Term ROI: Investing in a crane that matches your operational needs reduces maintenance, extends lifespan, and minimizes downtime.

- Importance of Customization: Features like anti-sway hoists, extended spans, weatherproofing, or remote control enhance performance and adapt the crane to your unique operation.

- Work with Experienced Manufacturers: A knowledgeable supplier can guide you through layout assessments, block considerations, and the selection of the right features for your yard.

By carefully evaluating your yard, block sizes, and lifting requirements, and collaborating with an experienced crane manufacturer, you can ensure your gantry crane meets your needs now and remains a reliable part of your stone handling operation for years to come.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch