Why Bulk Purchasing Crane Kits Makes Sense for Manufacturers

Bulk purchasing crane kits saves costs, improves efficiency, and streamlines operations for large-scale manufacturers in various industries.

Category: Featured

Your Trusted Overhead Bridge Crane Manufacturer & Supplier

Why Bulk Purchasing Crane Kits Makes Sense for Manufacturers

Introduction: The Power of Bulk Purchasing for Crane Kits

When it comes to large-scale manufacturing, crane kits are a must-have. But buying these in large quantities—also known as bulk purchasing—can make a huge difference. It’s not just about saving money; it’s about making your operations run more smoothly.

What is Bulk Purchasing for Crane Kits?

In simple terms, bulk purchasing means buying crane kits in large quantities, usually for multiple workshops or production lines. Instead of buying one or two kits here and there, you place a large order at once.

Why Bulk Makes Sense

The real beauty of buying crane kits in bulk is the savings. You get lower prices per unit, which adds up to a significant reduction in costs. Plus, bulk purchasing can simplify your supply chain, reducing the back-and-forth with suppliers. It's a win for manufacturers looking to save money and streamline their processes.

The Key Focus: Saving Money and Improving Operations

For industries like automotive, mining, or steel production, where multiple cranes are needed, bulk purchasing offers both financial and operational benefits. It’s not just about getting the best deal, but also about ensuring that the cranes you need are available when you need them.

- Lower Costs: Bulk buying lowers the price per unit thanks to economies of scale.

- Fewer Delays: Large orders mean fewer shipments and reduced lead times.

- Streamlined Operations: You can better manage your supply chain with a single large order, reducing the hassle of multiple suppliers.

By taking advantage of these benefits, large manufacturers can keep costs down while making sure their operations run smoothly.

overhead bridge crane kit without main girder

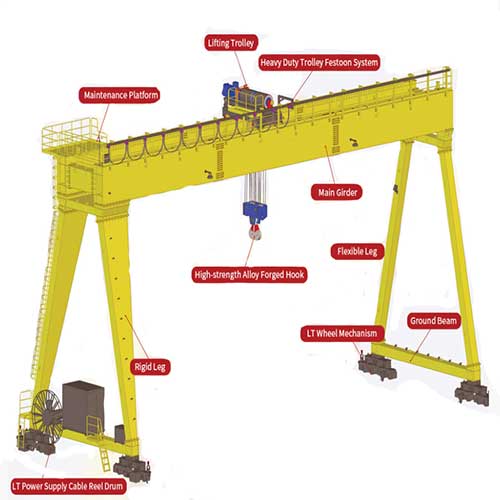

gantry crane kit without steel structure main girder and supporting legs

jib crane kit without steel structure cantilever and column

How Buying in Bulk Saves Money for Large Manufacturers

When you purchase crane kits in large quantities, you’re not just getting more units; you’re also saving money in a big way. Here's how it works:

Cost Reduction: Big Savings on Bulk Orders

- Lower Per-Unit Cost: The biggest advantage of bulk buying is the lower price per unit. When manufacturers place a large order, suppliers can offer discounts. This happens because they can produce and ship a higher volume, which cuts down on the cost to both sides. So, instead of paying full price for every crane kit, you're able to take advantage of economies of scale and get a better deal.

- Bulk Discounts: Suppliers often offer special deals when you buy in bulk, making each crane kit much cheaper than if you were to order just a few. The more kits you buy, the more you save per unit. Simple as that.

Long-Term Savings: Cut Down on Shipping and Handling

- Reduced Shipping Costs: Shipping a large order all at once is far cheaper than shipping smaller orders repeatedly. With bulk purchases, you can negotiate better shipping rates, saving you money on transportation. Fewer shipments also mean less handling, so you save on packaging and related costs.

- Less Frequent Orders: Buying in bulk means you won’t need to reorder as often. This results in lower administrative costs, since you’re not constantly managing smaller shipments.

Supply Chain Efficiency: Streamlining Your Purchasing Process

- Fewer Orders, Less Hassle: Bulk purchases make it easier to manage your inventory. You’re dealing with one big order instead of multiple smaller ones, which simplifies the process. It reduces the time spent on coordinating orders, payments, and deliveries.

- Avoid Inventory Shortages: By buying in bulk, you’re less likely to run into supply chain problems like stockouts. When you have plenty of crane kits on hand, you don’t have to worry about running out when demand spikes. This keeps your operations running smoothly without delays.

In short, buying crane kits in bulk helps manufacturers cut down on costs at multiple levels—from the price per kit to shipping and even inventory management. It's a smart, long-term investment that helps save money and keep things running efficiently.

Industries That Benefit from Bulk Purchases

When it comes to bulk purchasing crane kits, several industries stand to benefit the most. Let’s take a closer look at how different sectors like automotive, mining, and steel production rely on bulk crane kits for their operations.

Automotive Manufacturers and Their Need for Multiple Cranes

High-Volume Lifting

Automotive factories are busy places where parts and materials move constantly along assembly lines. To handle this fast-paced environment, multiple cranes are required. These cranes are used to lift car parts, engines, and components, often repeatedly, to keep the production line running smoothly.

- Why It’s Essential: High-volume lifting needs mean that automotive manufacturers need cranes that can operate continuously without delays.

- Constant Lifting: Every single part has to be moved efficiently—whether it’s heavy engine blocks or car frames.

Types of Cranes

For automotive assembly plants, the most commonly used crane types are:

- Bridge Cranes: Ideal for long, uninterrupted spans across large production areas.

- Jib Cranes: Perfect for smaller, more specific lifting tasks within certain parts of the production line.

Bulk Demand

Automotive manufacturers often have a high demand for multiple cranes. Ordering these crane kits in bulk makes sense because it keeps operations streamlined and consistent. Instead of dealing with multiple suppliers or staggered deliveries, manufacturers can set up their assembly lines quickly, ensuring they stay on schedule and maintain cost control.

Mining Operations and Their High Demand for Heavy-Duty Lifting Equipment

Heavy-Duty Requirements

Mining operations are one of the toughest environments for cranes. These operations need powerful, durable lifting equipment to handle substantial weights, such as extraction machinery, heavy rocks, and minerals. The cranes must be able to lift tons of materials in harsh and sometimes hazardous conditions.

- Rugged Needs: Whether it's moving large mining equipment or handling extracted materials, mining companies need equipment that can bear heavy loads over long periods.

Crane Kit Customization

Bulk purchasing allows mining companies to order heavy-duty crane kits that are customized for their specific needs. These cranes are built to withstand the rough conditions of mining, with reinforced structures, enhanced lifting capacities, and long-lasting materials. Customizations can include:

- Extended lifting capacities

- Corrosion-resistant finishes to withstand tough environmental conditions

- Heavy-duty hoists and winches designed for constant heavy lifting

Cost Savings

Since mining companies need a lot of heavy-duty cranes, buying in bulk makes a big difference in terms of long-term savings. The initial investment in large orders may seem high, but the cost savings over time are substantial. Bulk orders reduce per-unit prices, shipping costs, and the frequency of reordering, making these massive capital expenditures more manageable.

Steel Mills: Handling Multiple Workshops and Heavy Materials

Multiple Workshops

Steel mills are large facilities with multiple workshops, each needing several overhead cranes to move heavy materials such as steel billets, slabs, or coils. These mills rely on cranes to lift and transport materials throughout the facility efficiently.

- Need for Consistency: Steel mills need several cranes, often across various sections of the plant, to handle everything from raw material storage to finished product movement.

Efficiency

Bulk purchases of crane kits are particularly beneficial in steel mills because they ensure consistency in performance across the entire facility. Instead of having cranes with different specifications in each workshop, bulk purchasing allows for standardized crane kits. This consistency leads to:

- Better compatibility across various parts of the operation

- Less downtime due to consistent performance

- Streamlined maintenance and spare parts management

Material Handling

The cranes used in steel mills are typically designed for heavy material handling. These crane kits are built to lift and move large, heavy steel products efficiently. By buying crane kits in bulk, steel mills ensure they get cranes that are:

- Capable of lifting extremely heavy loads with precision

- Built for long-term use, as steel mills require equipment that can handle constant heavy-duty work

- Adaptable to specific steel mill environments, such as high temperatures or corrosive conditions

In summary, industries like automotive manufacturing, mining, and steel production greatly benefit from bulk purchasing crane kits. Whether it’s managing high-volume lifting, customizing heavy-duty equipment, or ensuring efficiency across multiple workshops, buying cranes in bulk helps these industries save money and maintain smooth operations.

Advantages of Bulk Purchases

Buying crane kits in bulk comes with some clear advantages that make it a smart choice for large manufacturers. These benefits not only save money but also streamline operations and improve efficiency. Let's break down these advantages:

Lower Per-Unit Cost, Economies of Scale, and Improved Logistics

Economies of Scale

One of the biggest benefits of bulk purchasing is the lower per-unit cost. When you place a large order, suppliers can offer discounts, which reduces the price for each crane kit. These savings add up quickly, making bulk buying much more cost-effective for large operations.

- How it works: The larger the order, the less you pay per unit. This helps lower overall project costs.

Streamlined Logistics

Bulk purchasing makes your logistics process a lot more efficient. With large orders, you reduce the number of shipments you need to manage. Fewer shipments mean less paperwork, fewer delays, and reduced chances of mistakes during transportation.

- Optimized Supply Chain: You can better coordinate when and where shipments should arrive, helping to keep production schedules on track.

Reduced Lead Time

When you order crane kits in bulk, you benefit from faster turnaround times. Instead of waiting for multiple shipments or dealing with stockouts, you have a large order ready to go when needed.

- Less Waiting: With fewer shipments to manage, you'll receive your crane kits faster, allowing for quicker installation and less downtime.

- More Flexibility: You can quickly add or replace kits without waiting for restocks from suppliers.

Simplified Inventory Management for Large-Scale Operations

Simplified Ordering

Managing a large-scale operation means keeping track of a lot of moving parts. Bulk purchasing helps simplify this process by providing a steady supply of crane kits. With a consistent inventory of crane kits, manufacturers can more easily plan for maintenance and future production needs.

- Easy Tracking: Keeping track of a large stock of crane kits is easier when you order in bulk. You can predict your needs, order ahead, and avoid last-minute panic buys.

Fewer Suppliers

Another advantage of bulk purchasing is the ability to work with fewer suppliers. Dealing with multiple suppliers can lead to confusion, inconsistent quality, and longer delivery times. When you buy in bulk, you can reduce the number of suppliers, making your purchasing process more streamlined.

- Consolidated Orders: Fewer suppliers means you have a more organized procurement process, fewer points of contact, and reduced administrative work.

- Stronger Relationships: Bulk buying allows you to develop better relationships with your suppliers, which can lead to even better pricing and service.

In summary, bulk purchasing crane kits provides advantages like lower per-unit costs, optimized logistics, and simplified inventory management. These benefits help large manufacturers save money, reduce operational complexities, and improve efficiency across their production lines.

How Crane Kits Help Meet the Demands of High-Volume Operations

When dealing with high-volume operations, it’s essential to have equipment that not only performs well but also keeps up with the pace of production. Crane kits are designed to meet these needs, providing quick setup, scalability, and customization options that make them ideal for large manufacturers.

Speed and Flexibility of Crane Kit Assembly

Quick Setup

One of the key benefits of crane kits is their quick assembly and installation. These kits come with all the parts you need, pre-fabricated for easy setup. This reduces downtime and allows manufacturers to get their production lines running faster.

- Less Waiting, More Doing: With crane kits, you can install and get your cranes up and running much faster than waiting for a custom-built crane to be designed and delivered.

- Minimal Disruption: The fast setup ensures that manufacturing operations are minimally disrupted, maintaining productivity.

Scalability

Another major advantage of crane kits is their scalability. As your operation grows, so can your crane setup. You can easily adjust or expand crane systems by adding more kits as needed, without major overhauls or delays.

- Grow with Your Business: Whether you're adding a new workshop or expanding your production capacity, crane kits can be scaled up to fit your evolving needs.

- Flexible Configurations: Kits can be adjusted for higher lifting capacities, larger spans, or even different types of operations.

Customization Options for Bulk Orders

Tailored Solutions

Bulk orders give manufacturers the flexibility to customize their crane kits according to specific needs. When ordering in bulk, you have the ability to select crane kits that match the lifting capacity, size, and design needed for your operations. This ensures that the cranes are perfectly suited to your facility.

- Lifting Capacity: Customize the cranes to handle different weight requirements depending on the materials you're lifting.

- Design Flexibility: Whether you need cranes for high-clearance or low-clearance environments, kits can be tailored to fit.

Adaptability

In industries like automotive, mining, and steel production, each operation has unique demands. Crane kits can be tailored to meet these demands, providing the flexibility manufacturers need.

- Automotive: For automotive plants, cranes might need to be designed to handle car parts and assembly line needs.

- Mining: For mining operations, heavy-duty cranes with specific lifting capacities are necessary to handle rough conditions and heavy equipment.

- Steel Production: Steel mills often need cranes capable of lifting extremely heavy steel billets or coils, which crane kits can be adapted for.

In summary, crane kits offer the speed, flexibility, and customization that high-volume operations need. Whether it’s quickly setting up a new crane system, scaling up as operations grow, or tailoring cranes to meet specific industry requirements, crane kits are an excellent solution for large manufacturers.

Conclusion: Making Crane Kits More Affordable for Large-Scale Operations

In summary, bulk purchasing crane kits brings several key advantages to large-scale manufacturers. By buying in bulk, manufacturers can benefit from:

- Cost Savings: Bulk orders reduce the per-unit price, leading to significant savings over time. These savings are particularly valuable for industries that need many cranes, such as automotive, mining, and steel production.

- Operational Efficiency: Bulk purchases streamline logistics, reduce lead times, and help ensure timely deliveries. Quick assembly and scalability also contribute to minimal downtime and enhanced production flow.

- Simplified Inventory Management: With bulk purchasing, inventory is easier to track and manage. Fewer suppliers mean fewer headaches, and consistent supplies of crane kits help manufacturers stay on top of their needs.

Bulk purchasing crane kits is a practical, cost-effective solution for large-scale manufacturers. It not only reduces operational costs but also improves equipment reliability and scalability. As industries grow and evolve, having a flexible, affordable crane system in place can make all the difference in maintaining smooth, uninterrupted production. For manufacturers looking to optimize operations and save money, bulk crane kits are a smart investment.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch