How to Match Goliath Crane Capacity to Your Site Conditions

Practical guide for buyers to choose Goliath crane capacity safely, efficiently & cost-effectively based on real site conditions. Get right goliath crane!

How to Match Goliath Crane Capacity to Your Site Conditions — A Practical Buyer's Guide

Introduction: Why Capacity Matching Matters

When planning to buy a Goliath crane, one of the first questions to settle is the lifting capacity. But it's not just about how much weight the crane can pick up. The real question is — how much weight can it handle safely and efficiently in your actual working environment? Choosing the right capacity is about finding the balance between safety, cost, and long-term performance.

Many buyers tend to go for a higher capacity "just in case." It feels safer at first, but an oversized crane can mean unnecessary expenses — heavier structures, larger motors, higher power consumption, and a more complex foundation. On the other hand, underestimating capacity could lead to strain on the crane, frequent breakdowns, or even safety risks. The ideal choice sits in between — a crane that matches your daily lifting tasks, site conditions, and future needs.

Here's why getting the capacity right really matters:

- Prevent structural overloads and ground issues: Goliath cranes put heavy loads on rails and foundations. If the soil bearing capacity or concrete base isn't strong enough, it can cause uneven settlement or rail misalignment over time.

- Avoid wasting money on excess capacity: Every extra ton in rated capacity adds cost — not just to the crane itself but also to the installation, energy use, and maintenance. There's no sense in paying for lifting power you'll never use.

- Ensure stable performance under real conditions: Factors like strong coastal winds, extreme temperatures, or dust can reduce the crane's effective capacity. A properly matched crane considers these environmental loads and still operates safely.

- Plan ahead for expansion: If your production or material size might increase in a few years, it's smart to allow a small margin for growth. That way, you won't need to rebuild or replace your crane system later.

In short, capacity matching is a practical decision, not just a technical one. It affects the crane's service life, the reliability of your operations, and your total investment cost. By carefully evaluating your site and lifting requirements early, you can choose a Goliath crane that performs well today and stays dependable for years to come.

Evaluating Your Site Conditions Before Crane Selection

Ensure your Goliath crane performs safely and reliably by assessing environmental, structural, and operational site conditions.

Environmental Factors

The operating environment affects crane strength, maintenance needs, and long-term reliability. Ignoring these factors can shorten lifespan or cause downtime.

- Average and peak wind speeds: High winds add stress on long-span cranes. Consider storm-locking devices, windproof anchoring, or automatic wind alarms for stability.

- Coastal exposure: Salt air and humidity accelerate corrosion. Choose cranes with marine-grade coatings, sealed electrical systems, and stainless steel components.

- Temperature range and humidity: Extreme cold affects motors and lubrication; high heat may shorten electrical insulation life. Confirm motors, brakes, and gearboxes are climate-rated with suitable ventilation or heaters.

Ground and Structural Conditions

The crane's weight exerts significant load on the ground. Weak soil or foundations can cause misalignment, vibration, or uneven rail settlement.

- Foundation or rail support type: Decide between embedded rails, concrete pads, or mobile wheel tracks, as each requires a different installation approach.

- Soil bearing capacity: Verify that soil can support crane weight plus dynamic loads; consult a geotechnical engineer if needed.

- Overhead and lateral clearance: Measure available height and distances from walls, buildings, or power lines to ensure full travel and lifting range.

Operational Constraints

Daily usage and load patterns determine the ideal crane capacity and duty class. Continuous or heavy use demands more robust design than occasional light lifts.

- Frequency of lifting: Determine if the crane is in constant operation or used periodically; adjust motor and gearbox duty class accordingly.

- Load profile: Assess whether loads are uniform and predictable or irregular and off-centered; this affects hoist type, hook design, and safety margin.

- Available movement area: Review full travel paths and staging zones; limited space may require narrower span or customized leg design.

Understanding Crane Capacity Ratings in Real Terms

Learn how rated capacities translate to real-world operations and choose the right girder and crane type for your site.

Rated Load vs. Actual Working Load

Rated capacity is the maximum safe load under ideal conditions, but real operations often introduce dynamic loads that affect performance.

- Compare nominal and peak load: Ensure the crane capacity exceeds your highest expected working load.

- Include a safety margin: Add 20–30% allowance for shock, sway, or irregular handling.

- Check duty class (A3–A8): Choose based on usage frequency and load intensity to avoid motor or gearbox wear.

Single Girder vs. Double Girder Goliath Cranes

The girder configuration affects cost, load handling efficiency, and suitability for your site conditions.

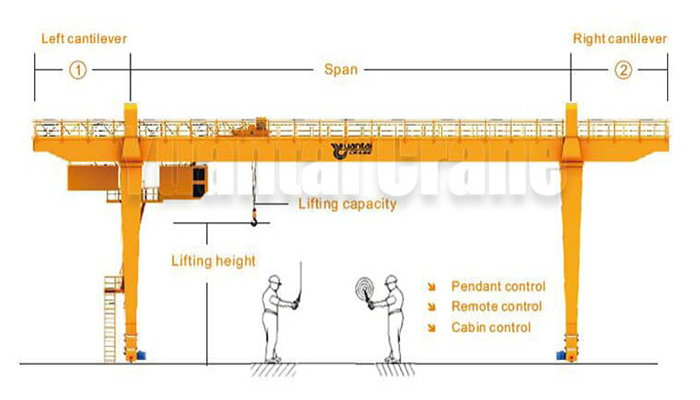

- Single girder goliath gantry cranes : Economical, lighter design, typically <20 tons and shorter spans; ideal for small workshops and light industrial yards.

- Double girder goliath gantry cranes: Built for heavier loads, larger spans, and higher lifting heights; common in shipyards and steel plants.

- Practical tip: Verify wheel load and foundation capacity before deciding; ground conditions may limit double girder use.

Double Girder Gantry Crane & Goliath Crane, Rail Travelling Gantry Crane for Indoor & Outdoor Uses

Single Girder Goliath Crane, Box Girder Gantry Crane +European style Electric Hoist 3 Ton to 20 Ton

Portal Crane vs. Standard Goliath Gantry

Site layout often dictates whether a portal-type or standard gantry crane is the best fit.

- Portal cranes: One side supported by rail/track, the other open; ideal for narrow spaces or long corridors.

- Standard Goliath gantries: Supported on both sides; suitable for open yards, ports, or heavy-lift areas with high stability.

- Consider workflow: Portal cranes offer space efficiency, while full gantry cranes provide more lifting power and balance in open sites.

Matching Crane Capacity to Actual Operations

Ensure your Goliath crane is sized correctly for real-world loads, environmental factors, and existing site infrastructure.

Step-by-Step Evaluation

Follow a structured process to match crane capacity to operational needs, avoiding both under-sizing and overspending.

- Identify maximum expected load and frequency: Account for typical and peak weights; rate the crane slightly above peak for flexibility.

- Add handling accessories: Include spreaders, magnets, grabs, or hooks, which can add 5–10% to total lifting mass.

- Consider simultaneous operations: Calculate combined load distribution if two cranes handle one piece, avoiding overloading a single crane.

- Leave margin for future growth: Allow 10–15% extra capacity for increasing project demands.

Adjusting for Environmental Load

Natural forces like wind, temperature, and moisture reduce effective lifting capacity; manufacturers provide derating guidelines for safe operation.

- High-wind areas: Reduce rated capacity as recommended; use storm locks or wind anchors for idle cranes.

- Coastal projects: Use IP65 enclosures, marine-duty motors, stainless steel fittings, and maintain coatings to combat corrosion.

- Extreme temperatures: Ensure motors, brakes, and electrical systems are rated for local temperature extremes to maintain reliability.

Integration with Site Infrastructure

Proper integration ensures smooth workflow and safety, avoiding delays, bottlenecks, or operational conflicts.

- Rail and foundation alignment: Confirm rail distance, level, and length match crane design to prevent wheel wear or structural strain.

- Working area and access width: Measure space for crane movement, truck entry, and staging for efficient operations.

- Compatibility with existing systems: Ensure crane span and travel paths align with trucks, container rows, storage areas, or berths for consistent material flow.

Safety and Compliance for Goliath Gantry Cranes

Ensure reliable crane operation by following local and international standards, applying safety factors, and maintaining skilled operators.

Conform to Local and International Standards

Crane design and components must meet recognized industrial codes to ensure structural integrity and electrical safety.

- Follow ISO and FEM standards for design, classification, and testing.

- Refer to GB/T (China) and EN (Europe) standards for materials, control systems, and performance.

- Obtain factory inspection certificates, CE/ISO compliance reports, and load test records before shipment.

Apply Practical Safety Factors

Site conditions can introduce extra stress; apply suitable safety factors for environmental and operational loads.

- Wind load: Equip outdoor cranes with storm locks, rail clamps, and windproof devices.

- Shock load: Consider sudden start/stop motions or uneven load pickup.

- Operating class: Match duty class (A3–A8) to lifting frequency and intensity.

Maintain Regular Inspection and Lubrication

Routine maintenance ensures the crane operates at rated capacity and prevents unexpected downtime.

- Follow manufacturer's inspection intervals for hoisting, traveling, and electrical systems.

- Use recommended lubrication grades suitable for local temperature and humidity.

- Record maintenance history for traceability and warranty support.

Train Operators and Enforce Safe Procedures

Skilled operators are crucial for accident prevention and efficient material handling.

- Train operators to monitor load indicators and avoid exceeding rated capacity.

- Review wind shutdown procedures and restrict operation under strong gusts.

- Test limit switches and emergency stops before each shift.

Decision-Making and Supplier Coordination

Ensure your Goliath crane investment is safe, economical, and reliable by balancing cost, supplier quality, and long-term planning.

Cost vs. Risk Balance

Oversizing or undersizing a crane impacts both safety and cost; balancing the two ensures efficient operations.

- Load-risk assessment: Analyze lifting frequency, peak loads, and environmental factors like wind to determine realistic safety margins.

- Cost-benefit review: Compare single vs. double girder options for upfront cost, span, lifting height, and long-term durability.

Supplier and Quality Check

Supplier quality is critical; a reputable manufacturer ensures smooth installation, reliable operation, and long-term support.

- Certifications: Verify CE, ISO, or other recognized third-party certifications.

- Duty-class calculation sheet: Request documentation showing crane performance under your load cases, duty cycles, and site conditions.

- After-sales service and spare parts: Ensure reliable support, fast delivery, and technical guidance from the supplier.

Maintenance and Lifecycle Planning

Planning maintenance and lifecycle costs upfront prevents unexpected expenses and keeps the crane operating at rated performance.

- Annual inspection budget: Allocate resources for yearly checks on hoist, travel motors, rails, and electrical systems.

- Spare part scheduling: Plan for replacements of motors, brakes, wheels, and wire ropes to avoid downtime.

- Upgrade paths: Consider future automation, remote operation, or capacity increases to save on full replacements later.

Conclusion: Send Us An Inquiry

Selecting the right Goliath crane is more than picking a number off a specification sheet. It's about understanding your actual loads, site environment, and operational demands. A well-matched crane keeps your team safe, operations smooth, and costs under control, while also providing flexibility for future growth.

Key takeaways for crane buyers:

- Match crane capacity to real conditions: Consider the actual weight of loads, site layout, ground strength, and environmental factors such as wind or humidity.

- Avoid over-specification: Oversized cranes increase cost and energy consumption without adding real value. Focus on efficient capacity that meets operational needs.

- Plan for the future: Factor in potential increases in load, production scale, or environmental stress. A small capacity margin now can prevent costly upgrades later.

- Partner with experienced suppliers: Work with manufacturers who can analyze your site and simulate real load conditions before delivery, ensuring your crane is correctly sized and configured.