Ports & Shipyards Goliath Gantry Cranes Wind Protection Devices

A practical guide for selecting outdoor Goliath cranes, evaluating wind risks, and implementing protection devices for ports and coastal sites.

| value1 | title1 |

| value2 | title2 |

Category: Featured

Your Trusted Overhead Goliath Gantry Crane Manufacturer & Supplier

How to Choose Outdoor Goliath Gantry Cranes in High-Wind Areas

Wind Protection Devices for Ports, Shipyards, and Coastal Projects

Overview

Choosing the right outdoor Goliath gantry crane or portal crane in high-wind areas is more than picking the largest model. You need to understand site conditions, load types, and wind effects on safety and operations. This guide is designed to help engineers, project managers, and decision-makers make practical choices for single girder Goliath cranes and double girder Goliath cranes, while highlighting essential wind protection devices for ports, shipyards, and coastal projects.

- Match Goliath crane specifications to local wind conditions

- Identify suitable wind protection devices for high-wind environments

- Apply practical considerations for coastal and port operations

shipyard gantry crane for sale

Challenges in High-Wind Areas

Operating Goliath gantry cranes or portal cranes in windy conditions comes with unique risks. Even moderate gusts can cause load swings, strain crane structures, and delay work.

Operational Hazards:

- Load swing can damage cargo, cranes, or nearby equipment

- Sudden gusts may force emergency stops

- Manual operation becomes riskier for exposed single girder Goliath cranes

Structural and Safety Considerations:

- Wind stress affects beams, rails, and foundations of both single and double girder cranes

- Repeated exposure can shorten crane lifespan

- Safety systems must be rated for local wind speeds

Economic Impact of Downtime:

- Crane stoppages delay loading and unloading schedules

- Repairs or replacements are costly

- Proper Goliath crane selection and wind protection devices reduce risks and downtime

Key Considerations for Selecting Outdoor Goliath Gantry Cranes

A practical guide to evaluating environmental, operational, design, and regulatory factors for your Goliath crane selection.

Environmental Assessment

Before selecting a Goliath gantry crane or portal crane, assess the site's environmental conditions. Wind, storms, and coastal exposure significantly affect safety and crane longevity.

- Check average and peak wind speeds to ensure safe operation.

- Review seasonal weather patterns and storm frequency for your port or shipyard.

- Consider saltwater exposure and corrosion risk for both single and double girder Goliath cranes.

Crane Design Specifications

Selecting the right type of Goliath crane depends on load requirements and structural demands. Proper design ensures stability and long-term reliability.

- Define load capacity and span requirements for your portal crane.

- Ensure structural stability to resist strong winds and heavy lifting operations.

- Choose materials and coatings suitable for coastal environments to reduce maintenance.

Operational Factors

Daily use and load types influence which Goliath crane is most suitable. Both single and double girder options have strengths depending on operational needs.

- Assess frequency of use and load cycles for efficient crane selection.

- Match crane type to loads: bulk materials, containerized cargo, or irregular shapes.

- Ensure integration with existing infrastructure at ports, shipyards, or coastal projects.

Regulatory & Safety Compliance

Even a well-designed Goliath crane can fail if it doesn't meet safety standards. Compliance protects workers, prevents fines, and ensures smooth operations.

- Follow local building codes and occupational safety regulations for Goliath and portal cranes.

- Consider international standards for crane design, including wind load requirements for single and double girder cranes.

Types of Wind Protection Devices for Outdoor Goliath Gantry Cranes

Explore practical solutions for protecting Goliath gantry cranes from high winds, including structural, crane-mounted, and monitoring systems.

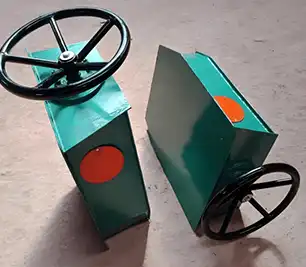

manual rotating goliath gantry crane rail clamp for outdoor use

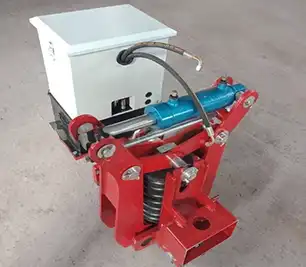

electro-hydraulic rail clamp for outdoor gantry crane

windproof iron wedge brake for outdoor goliath gantry cranes

wheel side brake to ensure safety for outdoor gantry crane in high wind area

electrical rail clamp for outdoor goliath crane in ports and shipyards

wind rope , the safety devices for shipyard gantry crane and port yard gantry cranes

antiwind devices for anchoring gantry cranes with small capacity

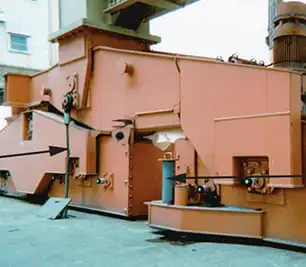

large capacity goliath crane anchore wind devices

Physical Structural Protection

Physical barriers and reinforcements are the first line of defense for Goliath and portal cranes in high-wind areas, protecting both single and double girder cranes.

- Wind shields & barriers: Reduce direct wind pressure on crane structures and loads.

- Anchoring and foundation reinforcement: Prevent tipping or displacement during storms.

Crane-Mounted Wind Control Systems

Modern Goliath cranes often include built-in wind control systems to actively protect loads and improve operational safety.

- Anti-sway systems: Minimize load swing during high winds, especially useful for single girder cranes.

- Braking and locking mechanisms: Secure cranes in place when winds exceed safe limits.

Environmental Monitoring & Automation

Automation and monitoring technologies help operators make informed decisions and avoid unsafe operations in coastal or high-wind environments.

- Anemometers & wind sensors: Automatically stop crane operations when wind speeds exceed safe levels.

- Remote monitoring systems: Provide real-time alerts to operators and maintenance teams.

Additional Coastal Considerations

For cranes operating near saltwater, extra protection is critical to maintain longevity and reduce maintenance costs.

- Corrosion-resistant coatings: Protect metal structures of both single and double girder cranes.

- Drainage and water management systems: Prevent flooding or damage from storm surges.

Port, Shipyard, and Coastal Project-Specific Guidelines

Ports & Container Terminals

Ports and container terminals often rely on Goliath gantry cranes and portal cranes for fast, high-volume operations. Choosing the right crane type—single girder or double girder—can make a big difference in efficiency.

- High-frequency operations require rapid response systems and reliable crane performance

- Integration with automated stacking cranes ensures smooth cargo handling and reduces delays

Shipyards

Shipyard gantry crane for sale, tailored for your needs. Shipyards typically use heavy-duty Goliath cranes for lifting large components during ship assembly. Structural strength and wind protection are critical for safe operations.

- Heavy-lift single girder or double girder Goliath cranes with higher structural tolerance are preferred

- Designed for intermittent, high-load operations typical in ship construction and repair

Coastal & Offshore Installations

Cranes operating near the coast or offshore face additional challenges, including saltwater corrosion, strong gusts, and storm surges.

- Extra attention to corrosion-resistant coatings for both single girder and double girder Goliath cranes

- Reinforced foundations and wind protection systems prevent tipping and structural damage

- Suitable for portal cranes exposed to extreme coastal conditions

Decision-Making Framework for Selecting Outdoor Goliath Gantry Cranes

A structured approach to choosing the right Goliath crane, ensuring safety, efficiency, and long-term reliability in high-wind areas.

Risk Assessment and Cost-Benefit Analysis

Evaluate hazards and weigh costs to make informed decisions for crane selection.

- Assess potential hazards related to wind, load, and site conditions.

- Compare costs of downtime, repairs, and protective measures versus investment in proper crane design.

Matching Crane Specifications with Site Conditions

Choose the crane type that fits your operational and environmental needs.

- Select between single or double girder Goliath cranes based on span, load, and frequency of use.

- Ensure the crane type suits local wind conditions and operational demands.

Selection of Appropriate Wind Protection Devices

Decide on protective systems to maintain safety during high winds.

- Choose physical barriers, anti-sway systems, or automated wind monitoring based on crane type and site exposure.

- Ensure wind protection devices are compatible with both portal cranes and Goliath gantry cranes.

Vendor Evaluation and Certification Considerations

Select reputable manufacturers with proven expertise in high-wind crane installations.

- Verify manufacturer credentials and certifications for high-wind operations.

- Review references for similar installations in ports, shipyards, or coastal projects.

Maintenance and Inspection Planning for Long-Term Reliability

Plan for ongoing inspection and maintenance to ensure crane longevity and safe operation.

- Establish a schedule for inspecting critical components like rails, beams, brakes, and anti-sway systems.

- Factor in corrosion protection and environmental wear, especially for coastal single and double girder Goliath cranes.

Conclusion & Actionable Takeaways

Choosing the right Goliath gantry crane or portal crane for high-wind environments requires careful planning and attention to both crane design and wind protection. Safety, compliance, and operational efficiency should always come first.

- Prioritize safety and compliance: Ensure that both single girder and double girder Goliath cranes meet local and international regulations for high-wind operations

- Combine crane selection with wind protection devices: Physical barriers, anti-sway systems, and monitoring tools are essential for protecting loads, structures, and personnel

- Proactive maintenance and monitoring: Regular inspections, corrosion protection, and automated wind monitoring keep Goliath cranes reliable and minimize costly downtime

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch