EOT Crane Buying Guide for Riyadh from Budget to Runway Layout

EOT Crane Buying Guide for Riyadh, Saudi Arabia — From Budget Planning to Crane Runway Layout

A practical guide covering budget, power, runway design & certifications for selecting EOT cranes in Riyadh's industrial projects.Get tailored eot crane!

Introduction: Why a Buying Guide for Riyadh’s Urban Crane Projects?

Overhead cranes aren’t just for large-scale steel plants or ports anymore. In Riyadh, demand is growing across a wide range of industries—modular construction, steel structure fabrication, logistics hubs, and even municipal maintenance depots. Urban industrial growth is steady, and more companies are starting to realize they need lifting equipment that fits both their workflow and the tight spaces they operate in.

But here’s the thing—not every crane fits every building. Especially in urban Riyadh, where many facilities are built with preexisting roofs, narrow access points, and mixed-use utility lines. This makes buying and installing an EOT (Electric Overhead Traveling) crane more complicated than it looks.

So, why this guide? Because we’ve seen too many buyers jump in based on capacity alone—10 ton, 20 ton, 50 ton—without considering the runway beam fit, electrical supply, or the documentation needed to meet Saudi regulations. If you’re responsible for sourcing a crane in Riyadh, this guide is written for you.

Here’s what we’ll walk through:

- Cost planning- Understand what affects crane prices, from span and lifting height to installation and local fabrication options.

- Electrical setup- Know what power supply is standard in Riyadh’s industrial zones and how to match it to your crane’s requirements.

- Crane runway layout- Learn how to make the best use of your building’s layout, including ceiling height and column spacing.

- Certifications and documentation- Ensure your crane meets CE and SASO standards—especially important if your project involves government or oil-sector contracts.

- Supplier selection- What to look for in a crane provider who can deliver, install, and support your crane within Saudi Arabia’s regulatory and operational framework.

Overhead EOT Cranes for Riyadh, Saudi Arabia Applications

When we talk about EOT cranes, we mean Electric Overhead Traveling cranes. These cranes run on rails fixed to the building’s structure and move loads horizontally across the workspace. They are widely used because of their efficiency and ability to handle heavy materials safely. We have types of eot cranes for sale Saudi Arabia. If you have any need, please feel free to contact us.

There are two main types you’ll encounter:

- Single girder EOT cranes- These have one main beam that carries the hoist. They’re usually lighter, easier to install, and cost less. They work well for capacities up to around 20 tons and shorter spans. Ideal for workshops or factories where the lifting needs are moderate and space is limited.

- Double girder EOT cranes- These use two main beams, allowing for heavier loads and longer spans. They’re suited for capacities ranging from 20 tons up to 100 tons or more. Double girder cranes offer better stability and can carry larger hoists or multiple hooks, which is important in larger Riyadh steel fabrication shops or heavy equipment plants.

We offer a full range of overhead bridge cranes for sale in Saudi Arabia, from 1 ton light-duty cranes to 320 ton heavy-duty cranes. Our product line includes single girder, double girder, gantry, and specialized bridge cranes, providing the perfect solution for workshops, factories, warehouses, and industrial plants worldwide.

- 1 ton overhead crane, 2 ton overhead crane, 3 ton overhead crane,

- 5 ton overhead crane, 10 ton overhead crane, 15 ton overhead crane, 20 ton overhead crane,

- 40 Ton Overhead Crane, 50 Ton Overhead Crane , 50 Ton above to 550 Ton Overhead Crane

In Riyadh, the most common load capacities fall between 5 tons and 50 tons. For example:

- 5 ton and 10 ton cranes are often found in small to medium workshops, assembly lines, and logistics centers.

- 20 ton cranes are popular for steel structure fabrication plants and modular building production.

- 50 ton and above are used in heavy machinery manufacturing and some petrochemical facilities where very large or bulky components must be moved.

These cranes fit Riyadh’s industrial landscape because:

- They maximize the use of vertical and horizontal space in often compact buildings.

- EOT cranes reduce manual handling, improving safety and efficiency.

- They can be customized to fit specific workshop layouts, which is essential in urban settings where ceiling height and column placement vary.

- The electric operation means precise control, which is critical when working in busy, multi-use facilities.

Overall, EOT cranes strike a good balance between lifting power and flexibility. For Riyadh’s growing industries, they provide reliable and adaptable solutions for material handling without requiring massive structural changes to existing buildings.

Budget Planning for Overhead Crane Projects in Riyadh

Getting your budget right is crucial when buying an overhead crane. In Riyadh, projects often have tight schedules and specific needs, so knowing what affects the cost can save you a lot of trouble later on. It’s not just about the crane’s lifting capacity — several factors play a role.

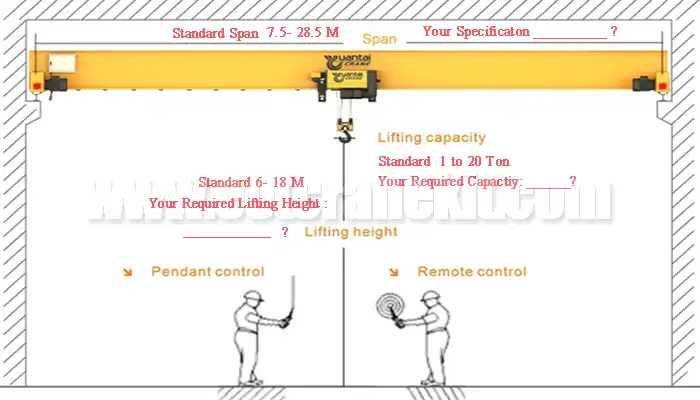

single girder eot crane specification drawing, main specifications required to get price

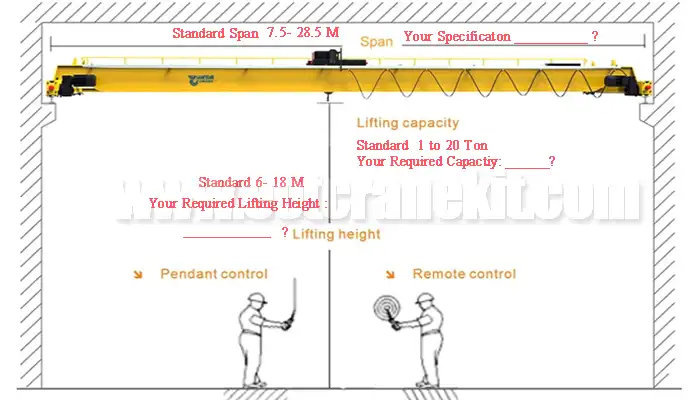

double girder eot crane specification drawing, main specifications required to get price

Here are the main things that affect how much your crane will cost:

- Crane span (the distance between the runway beams): The wider the span, the stronger and heavier the crane has to be. This means bigger girders, more steel, and stronger motors — all of which add to the price.

- Lifting height: The higher you need to lift, the more powerful the hoist needs to be, and the longer the wire ropes. Taller lifts also need extra safety features and space, which can increase costs.

- Control type: Do you want a simple pendant control, a remote control, or a cabin operator? Remote controls are convenient but add cost. Cabins are more expensive but useful for bigger cranes or complicated jobs.

- Customization: Special features like explosion-proof parts, weather-resistant paint, or anti-sway technology can add to the price. Sometimes you need these to meet safety or environment requirements.

Now, let’s talk numbers. While exact costs vary by project, here are some rough price ranges you can expect in Riyadh:

- 5 ton single girder crane: Usually between $15,000 and $25,000. Great for smaller workshops or light lifting.

- 10 ton single girder crane: Around $25,000 to $40,000, suitable for medium workshops or assembly lines.

- 20 ton double girder crane: Typically $40,000 to $70,000. Used in steel fabrication and modular building plants.

- 50 ton double girder crane: Between $70,000 and $120,000, ideal for heavier manufacturing.

- 100 ton double girder crane: Starts at $120,000 and goes up, mostly for very heavy-duty operations.

If you want to save money without cutting corners, here are some smart tips:

- Use crane kits: Buying a crane kit means you get all the mechanical and electrical parts except the main beams. You can get the beams made locally, saving shipping costs and speeding up installation.

- Source runway beams locally: Instead of importing heavy steel beams, fabricating them in Riyadh can be cheaper and more flexible for your building’s needs.

- Stick to standard sizes: Standard cranes are less expensive than fully custom ones because they’re quicker to make and easier to maintain.

But watch out for extra costs that sometimes catch buyers by surprise:

- Electrical system upgrades: Your current power supply might not be enough for the crane. You may need transformers, new wiring, or safety devices, which adds cost.

- Runway beam work: Making and installing runway beams is a big job. If your building needs extra support or modifications, expect the budget to rise.

- Logistics and installation: Moving heavy crane parts and putting everything together on-site requires skilled workers and special equipment — this isn’t cheap and takes time.

To sum up, your budget should cover more than just the crane itself. Think about everything from structure and power to installation. Chat openly with your supplier so you know all costs upfront and avoid surprises down the road. That’s the best way to keep your project on time and on budget.

Power Supply Requirements in Riyadh Industrial Zones

One of the first things to check when buying an EOT crane for a Riyadh project is the power supply. Without the right electrical setup, even the best crane won’t work properly. Riyadh’s industrial areas generally have standard power systems, but you still need to make sure everything matches up with your crane’s needs.

Here’s a quick look at the typical power supply specs in Riyadh and nearby cities: most industrial zones use a 380 to 400-volt, three-phase, 50 Hz power supply. This is fairly common for heavy machinery and overhead cranes. But depending on your exact location and building, voltage levels might vary a little.

Your crane’s motors and control systems must be compatible with this power supply. For example, if your crane’s motor is designed for 400V, three-phase power, and your site has something different, you’ll need transformers or converters. Otherwise, the crane won’t operate efficiently or safely.

Indoor cranes might have different power requirements compared to outdoor cranes. Outdoor cranes sometimes need special protection for electrical components because of dust, heat, or humidity. This can affect the type of wiring, insulation, and control panels used.

Before you finalize your purchase, here are some key power-related questions to ask your supplier or electrical engineer:

- What is the exact voltage and frequency available at my site?

- Is the power supply stable and reliable enough for continuous crane operation?

- Will the crane controls and motors match the local power specs, or will transformers be needed?

- Are there any special electrical protections required, like surge protectors or circuit breakers?

- For outdoor cranes, are the electrical components rated for harsh environments?

- Does the power system have enough capacity to handle future crane upgrades or additional equipment?

Confirming these details early on will save you from costly electrical modifications later. Plus, it ensures your crane runs smoothly from day one, without unexpected power issues slowing down your operations.

Crane Runway Beam Design and Fit for Urban Workshops

A crane runway beam is basically the “track” that the overhead crane travels on. It’s a critical part of your crane system because it supports the entire weight of the crane and the load it carries. Without a properly designed runway, the crane won’t run smoothly, and safety could be compromised.

There are a few common ways to support runway beams, especially in urban workshops where space and building structure limit your options:

- Bracket-mounted runways: The beams are attached directly to the walls or columns of the building using brackets. This saves floor space but requires strong walls and careful load calculations.

- Column-supported runways: Here, vertical columns are installed inside the workshop to hold up the beams. This works well if the building’s existing structure can’t handle the loads or if you need to spread the weight evenly.

- Floor-mounted runway systems: In some cases, such as, the freestanding bridge cranes, the runway beams rest on beams or supports anchored to the floor. This is less common indoors but can be used in special situations or where ceiling height is very limited.

Urban workshops in Riyadh often have low ceilings or narrow widths, so runway design must adjust accordingly. For example, low ceilings mean your crane’s hook height and lifting capacity need to fit without hitting the roof or other overhead equipment. Small spans require lighter girders but can limit the crane’s coverage area.

It’s essential to make sure the runway beams are compatible with the building structure and can safely carry both the crane and its maximum load. This means checking beam sizes, materials, and support spacing carefully. A strong runway beam reduces vibrations and prevents structural damage over time.

Some common mistakes to avoid in runway beam layout include:

- Installing beams without considering existing building columns or utilities, which can cause conflicts later.

- Using undersized beams that can’t handle the crane’s wheel loads, leading to premature wear or failure.

- Poor alignment between runway beams on either side, causing crane trolley binding or uneven travel.

- Neglecting to check the runway straightness, which can affect crane safety and maintenance costs.

Getting the runway design right is often more complicated than people expect, especially in older buildings or tightly packed urban workshops. Working with an experienced crane supplier or structural engineer familiar with Riyadh’s local conditions can help avoid costly mistakes and delays.

Choosing the Right EOT Crane Supplier in Riyadh, Saudi Arabia

Choosing the right supplier for your EOT crane is very important. A good supplier makes the whole process easier—from buying to installing and maintaining the crane.

Look for suppliers who know the rules and standards in Saudi Arabia, like CE and SASO certifications. This way, you know your crane will meet safety requirements and pass inspections without problems.

It’s also important to find a supplier who offers local installation and service in Riyadh. If something goes wrong, having someone nearby to fix it quickly saves time and money.

Every workshop is different, so your crane may need some changes to fit your space and work needs. Make sure your supplier can customize the crane’s size, capacity, controls, and other features to match your project.

Before you decide, ask your supplier these simple questions:

- Have you worked with customers in Riyadh before?

- Can you provide installation and service locally?

- How do you handle custom requests, and how long does it take?

- Are your cranes certified with CE and SASO?

- What kind of warranty and support do you offer?

- Can you help with planning things like runway beams and electrical setup?

Picking a supplier who can answer these clearly will help your project run smoothly. Take the time to find a partner who understands your needs and will support you beyond just selling the crane.

Case Study: 20 Ton EOT Crane Installed in a Riyadh Steel Workshop

A steel workshop in Riyadh needed a 20-ton EOT crane to improve lifting and handling of heavy steel components. The goal was to install a reliable crane that would boost efficiency and safety in daily operations.

Project Challenges

The project had several challenges that required careful planning:

- Low ceiling height limited the crane’s overall size and hoisting equipment.

- Tight deadlines meant the crane had to be delivered and installed quickly to avoid downtime.

- The workshop handled irregularly shaped loads that needed special attachments for safe lifting.

Customized Solution

To address these issues, the supplier worked closely with the client to design a customized crane:

- A compact hoist was selected to fit the limited headroom without sacrificing lifting capacity.

- Simplified control systems helped operators get trained quickly and use the crane safely.

- Pre-assembly and off-site testing sped up the installation process, reducing disruption.

- Special lifting attachments were provided to safely manage irregular loads.

Key Takeaways and Recommendations

This project offers useful lessons for similar Riyadh workshops:

- Always verify ceiling height and workspace dimensions before finalizing crane specs.

- Consider pre-assembling crane components to meet tight schedules.

- Customize hoists and attachments to fit your specific load types.

- Choose suppliers who communicate well and offer flexible solutions tailored to your needs.

Conclusion: Build the Right Crane for Riyadh’s Industrial Needs

Choosing the right EOT crane for your project in Riyadh takes careful thought and planning. You need to consider not just the crane’s lifting capacity, but also how it fits into your building, the power supply available, and the local regulations. Your budget should cover more than just the crane — runway beams, installation, and ongoing support matter just as much.

Working with a certified supplier is key. A supplier who understands Saudi standards like CE and SASO will help you avoid compliance issues. Confirming all technical details early—such as power compatibility, runway design, and safety features—will save you from costly changes down the line.

If your project is in a tight urban space, don’t hesitate to seek expert advice. Specialists who know the local conditions can recommend the best crane type and layout, making sure the equipment fits safely and works efficiently.

Ready to get started? Contact a trusted supplier to request a tailored EOT crane proposal that fits your Riyadh project’s unique needs. This way, you can be confident you’re investing in the right crane for your facility and workflow.

Final Checklist for EOT Crane Buyers in Riyadh, Saudi Arabia

Essential pre-purchase checks to ensure your crane fits your facility, operates safely, and arrives on time.

1. Have you confirmed the power supply compatibility?

Verify that your site's voltage, phase, and frequency match the crane's motor and control system. Power mismatches can lead to startup issues or damage to electrical components.

2. Is the runway beam properly designed and reviewed?

Ensure the runway beam is engineered to handle the crane's rated load and dynamic forces. Have structural engineers verify layout, spacing, and load-bearing capacity before installation.

3. Are your lifting requirements clearly defined?

Document the heaviest load, typical lifting height, and operational frequency. Choose a crane that meets or exceeds these needs with an adequate safety margin.

4. Have you verified all certifications and documents?

Check that your crane has valid CE and SASO certifications. Ensure all manuals, test reports, and drawings are provided and approved before shipping.

5. Is your project timeline and installation plan realistic?

Coordinate manufacturing, delivery, and installation schedules carefully. Make sure trained personnel and the required tools are ready when the crane arrives.

6. What is the typical lead time for a crane in Riyadh?

Lead times generally range from 6 to 12 weeks, depending on crane size and customization. Early planning ensures timely delivery and avoids project delays.

7. Can the crane be customized for tight or existing spaces?

Yes. We offer low-headroom hoists, compact runways, and special control systems for installations where space is limited or building structure cannot be modified.

8. How should cranes be maintained in Riyadh's environment?

Perform regular cleaning, lubrication, and visual inspections. Using protective covers, heat-resistant components, and specialized coatings helps extend crane lifespan in high-temperature, dusty conditions.

9. Is on-site installation included in the package?

Most reliable suppliers include on-site installation services in Riyadh. Confirm the scope of work in advance — such as wiring, testing, and operator training — to avoid delays.

10. What's the best way to finalize your crane purchase?

Review all technical specifications, confirm site readiness, and finalize certifications before placing the order. This ensures smooth delivery, installation, and safe operation from day one.