Inquiry Checklist for UAE Fabricators: Key Pre-Quote Confirmations

Crane Inquiry Checklist for UAE Fabricators: What to Confirm Before You Request a Quote

In the UAE steel fabrication industry, overhead cranes are part of daily work. Whether you're lifting steel plates, beams, or finished structures, you need a reliable crane system that fits your workshop setup and workload. Many fabrication shops in Dubai, Abu Dhabi, Sharjah, and other industrial zones rely on cranes to keep production running smoothly and safely.

When you're planning to buy a new crane—or get a quote from a supplier—it helps a lot to prepare some basic technical details in advance. Why? Because the more accurate your information is, the faster and more suitable your quotation will be.

Here’s why this matters:

- Faster quotations – Suppliers won’t need to keep asking follow-up questions like “What’s your span?” or “Is the crane indoor or outdoor?”

- Fewer mistakes – If your site has a low ceiling or limited runway length, it’s better to mention that early, not after the design is done.

- Better price match – When your specs are clear, the supplier can offer the right design—not something too big or underpowered.

Many buyers in the UAE are busy running jobs and don’t always have time to prepare a full list—but a short checklist can make a big difference. This guide will walk you through the main points to confirm before asking for a crane quote. It’s based on real situations we've seen with fabrication plants, welding shops, and steel service centers across the Emirates.

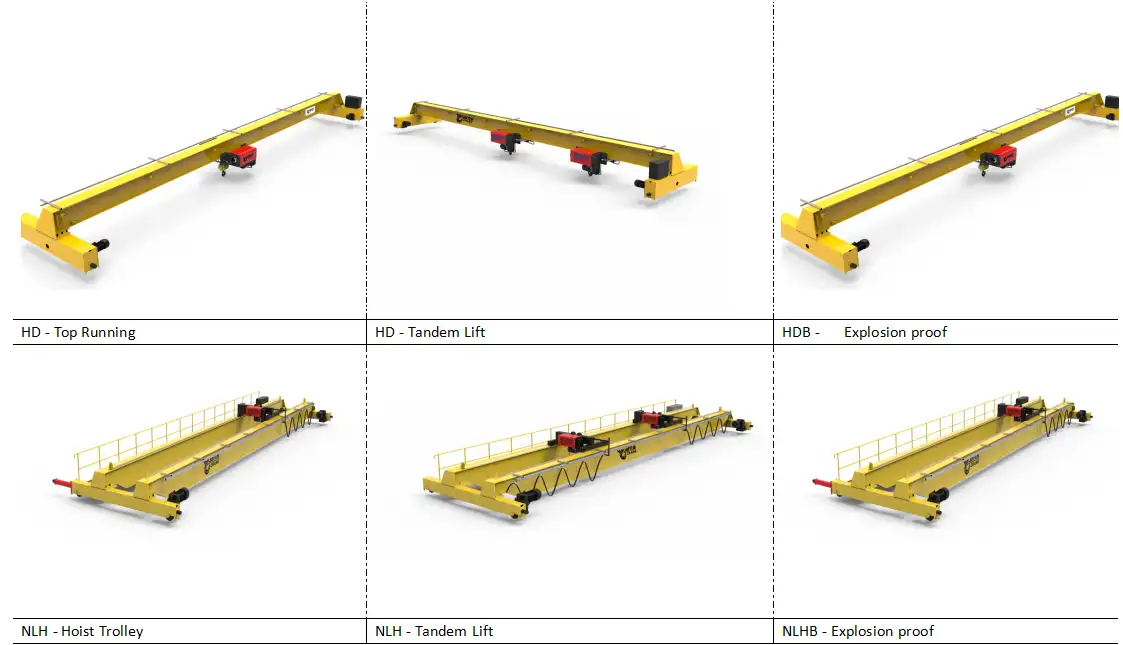

Crane Type and Application

Before asking for a quote, first be clear about what kind of crane you need and how you plan to use it. This helps the supplier choose the right design and avoid delays later.

Ask yourself the following:

What type of crane do you need?

- Overhead crane: Fixed to the building, runs on runway beams—best for indoor use.

- Gantry crane: Stands on legs and runs on ground rails—often used outdoors or in open yards.

- Jib crane: Small crane fixed to a column or wall—good for local workstations.

Will the crane be used indoors or outdoors?

- Indoor cranes are protected from weather but need to fit your ceiling height and layout.

- Outdoor cranes need protection against sun, dust, and high temperatures (common in the UAE).

Is the crane for one area or the whole factory?

- Some cranes stay in one spot (like near a cutting table).

- Others travel the full length of the building to handle different jobs.

The Crane Type Affects...

The crane type affects how it's built, where it's installed, and what kind of protection it needs. If you choose the wrong type, you might face changes, extra costs, or delays later on. Starting with the right one saves time and trouble.

Load Details: Weight, Shape, Frequency

Knowing exactly what you plan to lift is one of the most important parts of your crane inquiry. The weight, shape, and how often you lift directly affect the crane's hoist size, working class, and overall design. It's not just about the maximum weight—the details really matter.

Here's what to confirm:

What's the heaviest load the crane needs to lift?

- Give the maximum weight in tons (not just average). For example, "We lift 8 tons most of the time, but sometimes up to 12 tons."

- This ensures the hoist and structure can safely handle peak loads with enough safety margin.

How often will the crane be used?

- Is it for occasional lifting (a few times a day), or continuous use (multiple lifts per hour, every shift)?

- This helps decide the crane's duty class (A3 to A7). In fabrication workshops, A5 or A6 is often used.

What are you lifting?

- Be specific: Steel plates, I-beams, coils, fabricated structures, machines, or containers.

- If loads are long, wide, or uneven, mention that too. Some loads need special lifting beams or adjustable spreaders.

Why Load Details Matter

These details decide the size and strength of the hoist, motor power, brake system, and even the hook type. If the crane is too weak, it risks failure. If it's too strong, you may be overpaying. Getting the load specs right helps the supplier build a crane that fits your work—not just any crane.

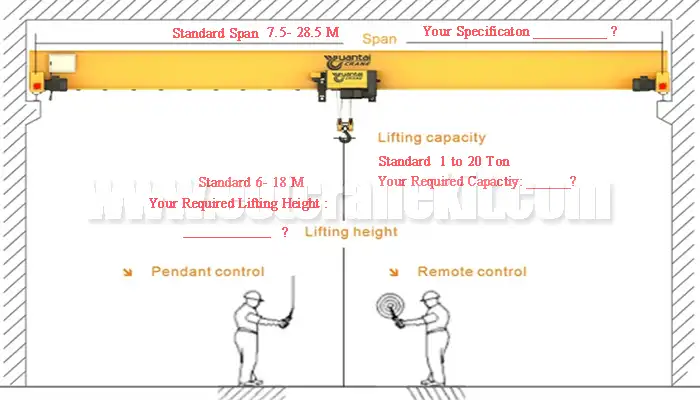

Crane Span and Runway Length

Crane span and runway length are basic but critical measurements that must be confirmed before quoting. These numbers define the size of the crane structure and how far it can travel across your workshop or yard.

Here's what to confirm:

What is the crane span?

- This is the distance between the two runway rails, measured from center to center.

- For example, if your workshop is 15 meters wide and the rails are mounted on both sides, your crane span is likely close to 15 meters.

- If unsure, check your building drawing or measure the clear space between the rails.

What is the total runway length?

- This is how far the crane needs to travel along the length of your workshop or yard.

- For instance, if your workshop is 60 meters long and the crane needs to reach from one end to the other, then the runway length is 60 meters.

- If the crane only serves part of the building, mention that too (e.g., "only 40m travel needed out of total 80m shop length").

Why Span and Runway Length Matter

The crane span affects the main girder size and wheelbase, while the runway length affects the travel motor size and cable arrangement. If the supplier doesn't have the correct measurements, the quote might be off—or worse, the crane won't fit when it arrives. Getting these numbers right helps avoid costly changes later.

Lifting Height (Hook Travel)

Lifting height refers to how high the hook needs to go when it's fully raised. It's a simple but very important detail. If the hook doesn't go high enough, you won't be able to lift your loads properly. And if there's too much unused height, the crane may be overdesigned—and overpriced.

Here's what to confirm:

What is the required lifting height?

- Measure from the floor to the highest point the hook needs to reach.

- For example, if you're lifting steel frames that are 2.5 meters tall and need some clearance, your lifting height might be around 4 meters.

Are there any height limitations inside your building?

- Check for low ceilings, overhead beams, ventilation ducts, lighting fixtures, or mezzanines that might limit crane height.

- If space is tight, a low-headroom hoist or compact girder design may be needed.

Why Lifting Height Matters

Lifting height affects the hoist model, trolley configuration, and main girder profile. In workshops with limited space, a standard crane might not fit. Knowing your true lifting needs helps the supplier pick the most efficient and space-saving design.

Power Supply Specifications (UAE Standards)

Crane systems run on heavy-duty electrical power, so confirming your power supply is essential for choosing the right motors, control systems, and safety devices. In the UAE, most industrial areas follow a standard power setup—but it's still important to check.

Here's what to confirm:

What is your site's power supply?

- The common standard is 415V, 50Hz, 3-phase, especially in UAE industrial zones like JAFZA, KIZAD, and Sharjah Industrial Area.

- Still, confirm with your onsite electrician—some sites, especially older buildings or rural areas, may vary slightly.

Are there any known power issues?

- Mention if your site has voltage drops, fluctuations, or long cable distances that could affect performance.

- If your location is remote or uses a generator, you may need special transformers or surge protection.

Why Power Supply Matters

Using the wrong voltage or unprotected systems can damage crane motors and panels. Confirming your power specs early ensures the motor, VFD (variable frequency drive), and control panel are correctly configured for safe, smooth operation.

Operating Environment in the UAE

The working environment in the UAE is tough—especially during the summer. Heat, sand, dust, and humidity all put stress on your crane's electrical and mechanical parts. So it's important to let the supplier know where and how the crane will be used. This helps them design a system that can handle the local conditions without frequent breakdowns.

Here's what to confirm:

Will the crane be used indoors or outdoors?

- Indoor cranes are usually protected from weather but may still deal with heat and dust.

- Outdoor cranes need protection from direct sunlight, rain, and blowing sand—especially in open yards or near coastal areas.

What environmental factors are present?

- Is there exposure to dust, humidity, sandstorms, corrosive fumes, or welding smoke?

- For example, steel fabrication yards near the sea may need anti-rust treatment or stainless components.

What's the expected temperature range?

- In summer, outdoor temperatures in the UAE can reach 48–50°C.

- Mention if cranes will be working during peak heat or in poorly ventilated buildings.

Why Operating Environment Matters

High heat and airborne particles affect motor cooling, brake performance, and electrical safety. Confirming environmental conditions helps the supplier choose proper IP-rated enclosures, cooling fans, UV-resistant paint, and other protective features. It reduces the risk of overheating or failure in real working conditions.

Crane Control Method

How you plan to operate the crane is another key factor. The control system must suit your workflow, safety needs, and operator convenience. Some UAE workshops prefer simple push-button control, while others need wireless remotes or even automation.

Here's what to confirm:

Which type of control do you prefer?

- Pendant control (wired to the hoist): Simple and cost-effective; good for short travel distances.

- Wireless remote control: Offers more flexibility and safety; ideal when the operator needs to walk with the load.

- Cabin control: Used for larger cranes with long travel distances or heavy loads—common in large fabrication yards.

Do you need automation or semi-automation?

- If you're handling repetitive lifting (e.g., loading/unloading steel plates), automation can improve speed and accuracy.

- Let the supplier know early if you're exploring these options so they can offer suitable control systems and sensors.

Why it matters:

The control method affects the electrical layout, safety features, and overall cost of the crane. For example, remote control systems may need additional receivers and safety relays, while cabin controls require platforms and cab wiring. Choosing the right method makes your crane easier—and safer—to use in daily operations.

Installation Site and Support Structures

The physical setup of your site plays a big role in the crane design and installation process. Whether you're building a new facility or installing a crane in an existing workshop, your supplier needs to know what's already in place—and what you expect them to provide.

Here's what to confirm:

Do you need the crane only, or also the supporting structure?

- Some buyers only need the crane and will build the runway beams and columns locally.

- Others prefer a full package, including steel support structure, crane rails, and anchor bolts.

Is there an existing support structure at your site?

- If yes, provide drawings or basic measurements (column spacing, rail height, beam specs).

- If not, mention whether you need help designing or fabricating it.

Is your site accessible for installation?

- Share information about access roads, overhead clearance, crane unloading area, and working space for erection.

- Let the supplier know if your facility is still under construction or already in use.

Do you require certification or third-party inspection?

- Common requests include CE marking, ISO 9001, or inspection by SGS, Bureau Veritas, or similar agencies.

- These are often needed for international projects or to meet your client's specifications.

Are there any local authority approvals required?

- For example, if you're supplying to ADNOC, DEWA, or a government project, they may have specific requirements for electrical components, testing, or safety documentation.

- Also, check if your facility is in a free zone (like JAFZA or KIZAD), as they may require registration or technical approvals.

Why it matters:

If compliance needs are not shared early, the crane design might miss key specs—leading to redesigns, delays, or even non-approval during final inspection. Clear communication upfront helps the supplier prepare the correct documents, use compliant components, and coordinate with the right inspectors to keep your project on track.

Delivery Schedule and Budget Constraints

When you're ready to request a quote, it's important to be clear about your timeline and budget. These details help the supplier plan and tailor their offer to fit your project's needs.

Here's what to confirm:

What is your target delivery or installation date?

- Let the supplier know if you have a fixed deadline or a flexible schedule.

- For urgent projects, they may offer faster production or prioritize your order.

Do you have a budget range or cost limits?

- Sharing your budget helps the supplier recommend the best options within your price range.

- It also avoids surprises later if the initial quote is outside what you expected.

Why it matters:

Knowing your schedule and budget helps the supplier design a crane that meets your priorities—whether that's speed, cost-efficiency, or extra features. It also allows them to allocate resources and give you a realistic timeline for delivery and installation.

Conclusion: Be Prepared, Get Quoted Faster

Providing all the technical details before asking for a crane quote makes the whole process smoother. When you come prepared with clear information about your crane type, load, site conditions, and budget, suppliers can respond quickly with accurate prices and suitable designs.

For fabricators in the UAE, taking a little time to document your needs in advance means fewer delays, better communication, and a crane that truly fits your workshop. Use this checklist to gather the right info, and you’ll get your quote—and your crane—much faster.