How to Measure Crane Span Like a Pro: Practical Guide for Buyers

Learn simple, accurate methods to measure overhead, gantry, and jib crane spans for safe installation and efficient operation.Get right overhead crane!

Category: Featured

Your Trusted Overhead Crane Manufacturer & Supplier

How to Measure Crane Span Like a Pro

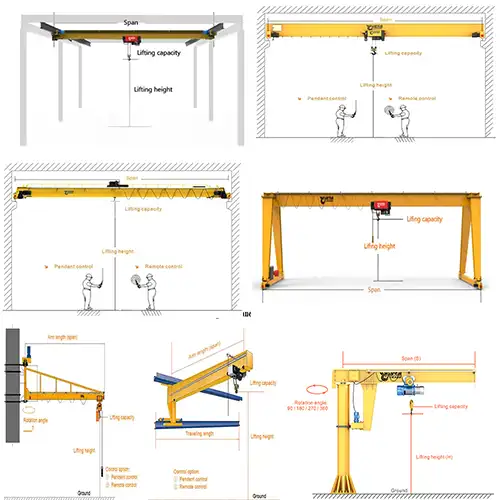

A Practical Guide for Overhead Crane , Gantry Crane, and Jib Cranes

Introduction

Why Accurate Crane Span Measurement Matters

When you're planning to buy or install a crane—whether it's an overhead bridge crane, a gantry crane, or a jib crane—one of the first and most crucial details you need to figure out is the span. This measurement may seem simple, but it plays a big role in whether the crane will fit your workshop, operate smoothly, and avoid extra costs during installation.

A correctly measured span ensures the crane aligns with your building's layout and functions the way it's supposed to. If you get it wrong, you might end up with a crane that can't be installed without structural changes—or worse, one that can't be installed at all. That's not something you want to discover after signing the contract.

Here's why span measurement needs your attention:

- It directly affects the crane's compatibility with your existing building or layout

- An incorrect span can lead to expensive modifications, delays, or return shipping

- It helps determine the type and model of crane you can actually use in your space

A Common Source of Confusion for Buyers

If you're a first-time buyer or a project manager handling crane selection for the first time, span might not be on your radar. Many people focus on capacity—how many tons the crane can lift—but forget to ask: Will it actually fit into the workshop?

And even when span is discussed, the terms used—like "runway rail center distance" or "effective boom radius"—can sound technical. But the truth is, it's not complicated once you break it down by crane type.

Some common confusions include:

- Mistaking building width for crane span

- Assuming all cranes use standard sizes (many don't)

- Not considering obstacles or clearance on either side of the runway

What This Guide Covers

This guide is here to walk you through how to measure crane span properly based on the type of crane you're dealing with. We'll go into practical detail for:

- Overhead bridge cranes – the kind that runs on rails along the top of building columns

- Gantry cranes – typically found in open yards or indoor factories with no runway beams

- Jib cranes – used for smaller lifting jobs near workstations or along walls

No fluff, just straightforward information you can use to make better decisions before you place your order.

What Is Crane Span?

Simple Definition, Big Impact

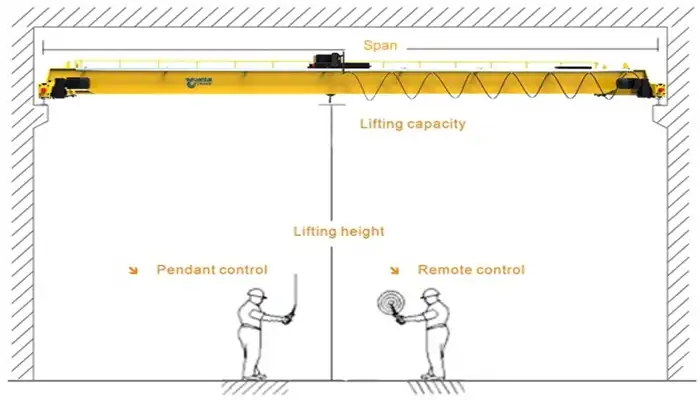

Crane span is the horizontal distance between two fixed points that define the crane's movement area. For overhead bridge cranes and gantry cranes, it refers to the distance between the centerlines of the two runway rails—essentially the width the crane needs to run properly. For jib cranes, it's a little different. The span usually means the working radius—from the center of the column or wall mount to the furthest point the boom can reach.

So yes, it's just one number. But it affects nearly everything that comes after in your project.

Standard Marking and Units

Crane span is typically labeled as "S" in design drawings or technical quotes. It's always measured in meters (m), and rounding accuracy is important—don't guess. Even a 100 mm (0.1 m) mistake can create serious alignment problems during installation.

You'll often see it written like:

- Span (S): 10.5 m

- Or simply: S = 10.5

Keep this in mind when comparing technical specs from different suppliers.

Why You Can't Afford to Get It Wrong

An incorrect crane span throws a wrench into everything—from engineering calculations to on-site assembly. And once steel structures are fabricated or delivered, fixing that mistake isn't cheap.

Here's why accurate span measurement is so important:

- Ensures the crane fits the available building space

A crane that's too wide won't install; one that's too narrow might wobble or become unsafe. - Avoids clashes with columns, walls, or other overhead equipment

You need to think beyond just width—how much space is actually usable? - Keeps the crane system structurally sound

Mismatched spans can cause stress or imbalance in the bridge girder, rails, or end carriages. - Reduces modification and rework costs

If you get the span wrong, the remedy could mean custom shims, extra supports, or worse—returning components to the factory for rework.

In short, don't treat span as just another checkbox. It's one of the foundation measurements that defines whether the crane can do its job, and do it safely. Accurate from the start—that's the goal.

Measuring Span for Overhead Bridge Cranes

Where to Measure

When determining the span for an overhead bridge crane, the correct method is to measure the horizontal distance between the centerlines of the two runway rails or beams. These rails are typically mounted on top of columns on both sides of the workshop.

It's important to note that this span is not the full width of the building or the space between walls or columns. Only the center-to-center distance between the rails should be used. Measuring from the wrong reference points can lead to crane components not fitting during installation.

Standard Factory Spans and Corresponding Crane Spans

Many industrial workshops follow standard bay widths based on national or industry construction norms. The crane span is typically set slightly shorter than the bay width to allow for safe side clearances, proper hook travel, and installation tolerances.

For general-purpose cranes with a lifting capacity of 3 to 50 tons, the most commonly used combinations are:

- A 9-meter bay width corresponds to a 7.5-meter crane span

- A 10.5-meter bay width matches a 10.5-meter crane span

- A 12-meter bay width fits a 13.5-meter crane span

- A 15-meter bay width uses a 16.5-meter crane span

- A 18-meter bay width corresponds to a 19.5-meter crane span

- A 21-meter bay width matches a 22.5-meter crane span

- A 24-meter bay width fits a 25.5-meter crane span

- A 27-meter bay width uses a 28.5-meter crane span

For workshops with a 30-meter bay width or other non-standard sizes, crane spans can be customized depending on project requirements and equipment design.

Crane Spans for Heavier Capacities (80–250 Tons)

For larger bridge cranes handling heavy loads—typically between 80 and 250 tons—the crane span is often selected from round numbers. These spans are based more on specific structural and lifting requirements than on standard factory bay widths.

Common span sizes for heavy-duty cranes include:7 meters, 10 meters, 15 meters, 20 meters,

These are determined according to load distribution, required lifting height, and the supporting structure's capacity.

Practical Tip

Before finalizing any crane span, always confirm the actual building measurements. For standard buildings, refer to structural drawings. For older or custom-built workshops, a site survey or field measurement is strongly recommended.

Even a small miscalculation in span—just 100 to 200 mm—can lead to serious issues during crane installation, including misalignment of the end trucks or interference with structural elements. Getting the span right from the start helps avoid expensive delays and ensures your crane will fit and function properly.

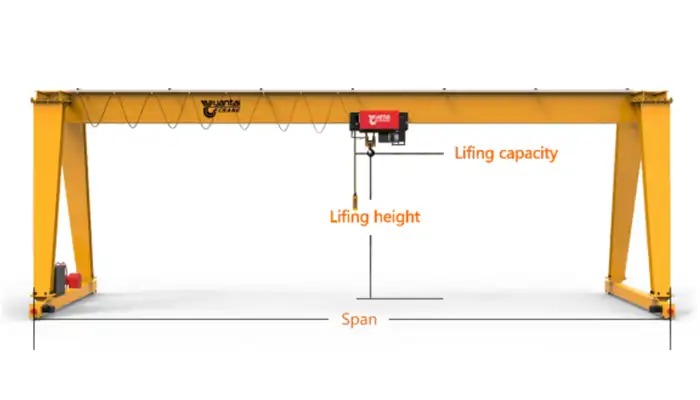

Measuring Span for Gantry Cranes

Where to Measure

For gantry cranes, the span is the distance between the rails on the ground or the inner sides of the crane's legs if it's a leg-supported type. This measurement defines the width the crane needs to move smoothly along its path.

If the rails are already installed, measure the distance between the rail centerlines. If the rails are embedded in concrete or haven't been laid yet, confirm the planned rail gauge with your supplier or builder to ensure accuracy.

Additional Factors to Consider

When measuring the span for a gantry crane, keep in mind several important factors that can affect the final crane design:

- Overhang: Some gantry cranes have legs or beams that extend beyond the rails on one or both sides. This overhang affects clearance and support requirements.

- Rail Positioning: If the rails are embedded or flush with the ground, the exact centerline might be harder to measure, so use precise drawings or a site survey.

- Indoor vs. Outdoor Use: Outdoor gantry cranes may require wider spans to clear obstacles or allow for uneven terrain. Indoor cranes need to fit within workshop clearances.

Why Accurate Span Measurement Matters for Gantry Cranes

- Ensures the crane's legs and wheels properly align with the rails for smooth travel

- Prevents rail or wheel wear caused by misalignment

- Helps avoid collisions with structures, vehicles, or materials near the rails

- Supports safe operation under load and reduces maintenance issues

Always coordinate with your crane supplier to verify rail gauge, expected overhang, and site conditions before finalizing the gantry crane span. Accurate measurement helps avoid costly adjustments and keeps your crane running reliably.

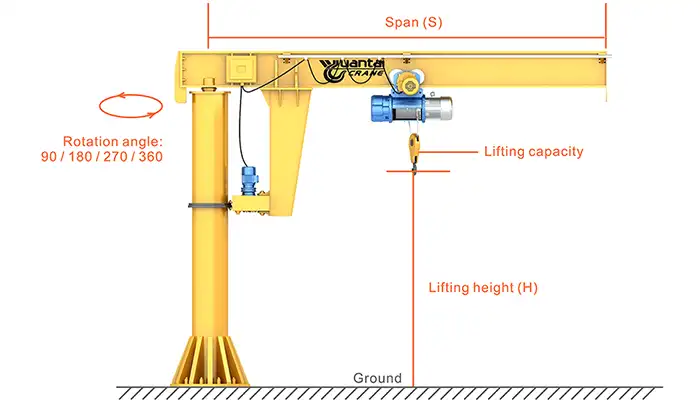

Measuring Span for Jib Cranes

What Defines the Span for a Jib Crane?

Unlike overhead or gantry cranes, the span of a jib crane is based on the length of its boom arm, which determines how far the crane can reach horizontally. This reach is often called the effective working radius.

The boom arm length directly affects how much area the jib crane can cover and where the hook can travel.

Crane span of wall jib crane including wall mounted jib crane and wall travelling jib cranes

Types of Jib Cranes and Their Span Measurement

- Wall-Mounted Jib Cranes:

For these, the span equals the horizontal length of the boom arm extending from the mounting wall to the outermost hook position. - Column-Mounted Jib Cranes:

Here, the span is the radius measured from the center of the supporting column to the furthest point the hook can reach during operation.

Important Factors to Keep in Mind

When measuring or specifying the span for jib cranes, consider:

- Swing Angle:

How far the jib can rotate left and right affects the usable coverage area. - Rotation Limits:

Some jib cranes have physical stops that restrict rotation to prevent collisions with walls, equipment, or other cranes. - Obstructions:

Check for any floor or ceiling obstacles such as pipes, lighting, or ventilation ducts that may limit boom movement or hook travel.

Accurate measurement of the jib crane span ensures you get the right boom length to cover the intended work area safely and efficiently without wasted space or interference. Always assess the installation environment carefully before finalizing span requirements.

Practical Tips for Crane Buyers

Verify Building Standards

Before deciding on a crane span, check whether your workshop or facility follows national or industrial building standards. Standardized factory bay widths make it easier to choose crane spans that fit well and avoid surprises during installation.

For Custom or Non-Standard Workshops

If your building has a custom layout or unusual dimensions, don't rely solely on drawings or assumptions. Instead, arrange for a site visit by your crane supplier or provide them with accurate and up-to-date layout drawings. This ensures the crane span matches your actual conditions.

Important Factors to Consider

- Hook Approach Clearance:

Make sure the crane's span and hook position allow safe and easy access to the load without hitting walls, columns, or other obstacles. - Future Expansion or Upgrades:

Think ahead. If you plan to add more equipment or increase lifting capacity later, choose a span and crane configuration that can accommodate those changes without needing a complete redesign.

Work with Experienced Suppliers

Choosing the right crane span and setup can be complex, especially for larger or custom projects. It pays to work with crane manufacturers or suppliers who have experience and technical knowledge. They can:

- Help interpret your building dimensions

- Recommend suitable crane types and spans

- Avoid costly mistakes during ordering and installation

A knowledgeable partner saves time and money, making sure your crane fits and functions perfectly from day one.

Conclusion

Measuring the crane span might seem tricky at first, but it becomes straightforward once you understand the specific requirements for each type of crane—whether it's an overhead bridge, gantry, or jib crane.

Getting the span right is essential. Accurate measurements lead to smoother installations, safer and more reliable crane operation, and better value over the crane's lifetime.

To avoid costly mistakes and ensure the best fit, work closely with experienced crane manufacturers or suppliers. Their expertise can guide you through custom sizing and help tailor the crane to your exact needs.

Related:

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch