Cost-Saving Tips When Buying a Steel Coil Handling Overhead Crane

Maximize ROI on your 10 ton overhead crane with practical cost-saving tips for steel coil handling operations in PNG. Get your cost-effective eot crane!

Introduction

Handling steel coils in Papua New Guinea workshops and steel processing plants comes with its own set of challenges. Many facilities deal with heavy loads, tight spaces, and humid, tropical conditions that can quickly affect machinery. A 10 ton overhead crane is a significant investment, and if not chosen wisely, it can lead to unexpected maintenance costs, downtime, and even safety risks.

In PNG, business decisions are often rooted in practicality and trust. It is not just about buying equipment—it's about making sure it serves your operation reliably for years. As the local saying goes: "Olgeta samting mas strong na save last longpela taim" – everything must be strong and last long. Choosing a crane that is well-suited to your workshop, climate, and workload can save a lot of money and hassle over time.

Goal of this guide:

- Show how to get the most out of your 10 ton overhead crane for steel coil handling.

- Focus on practical ways to reduce total ownership costs.

- Help you plan for long-term efficiency, uptime, and safety.

Key considerations for PNG business owners:

- Understand the local workshop environment: high humidity, heat, and heavy rain can impact crane lifespan.

- Plan for maintenance: local support and availability of spare parts matter.

- Match crane capacity and features to your typical loads and operations—not just the price.

- Think long-term: small savings on a cheap crane can turn into big expenses later.

Investing in the right steel coil handling crane is not just a purchase—it's a business decision that affects workflow, safety, and profitability. In the following sections, we'll go over practical tips to make sure your crane works efficiently and keeps costs under control in PNG conditions.

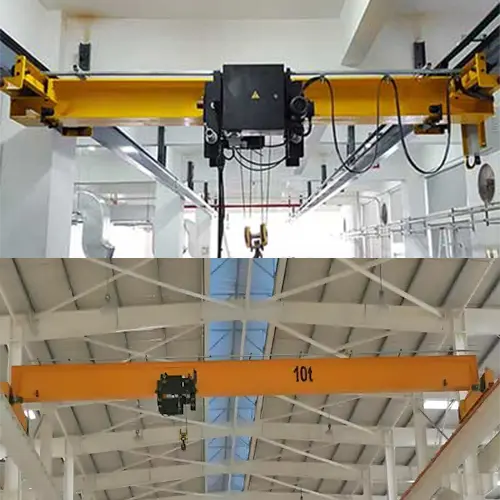

Types of 10 Ton Overhead Cranes

Balancing Purchase Price vs. Long-Term Maintenance

When investing in a steel coil handling overhead crane in PNG, it's easy to focus only on the upfront cost. A lower purchase price may seem attractive, but it can be expensive in the long run. Cheap cranes often require frequent repairs, spare parts may be hard to find, and unexpected downtime can disrupt your operations.

A small extra investment in a reliable 10 ton crane can pay off quickly. It reduces maintenance needs, keeps your production running smoothly, and gives peace of mind that the crane will last for years. As many PNG business owners say: "Noken save go daun long cheap samting, dispela samting bai bagarap kwiktaim" – don't go for cheap stuff, it will fail quickly.

Practical tips for balancing cost and value:

- Look beyond the sticker price: Compare total ownership cost, not just initial purchase.

- Check local support: Ensure spare parts and qualified service are available in PNG to reduce downtime.

- Assess crane quality: Durable materials and well-tested components may cost more upfront but last longer.

- Factor in downtime impact: Calculate the potential losses if a crane fails during critical operations.

- Request maintenance plans: Some suppliers offer preventive maintenance packages—worth considering for long-term savings.

By focusing on lifetime value rather than just purchase price, you protect your operations and make a smarter investment. In PNG, reliability and trust matter as much as cost—choose equipment that keeps your team productive and safe.

Energy-Efficient Hoists and Controls

Modern overhead cranes come with energy-saving hoists and advanced controls, such as variable frequency drives (VFDs). These features allow the crane to use power more efficiently, reduce mechanical stress, and provide smoother lifting operations. For a busy steel coil handling workshop in PNG, this can make a noticeable difference to both operational cost and equipment lifespan.

Energy-efficient hoists don't just save electricity—they reduce wear on motors, brakes, and gears. Over time, this translates into fewer repairs and longer service life. In PNG, where electricity costs can be high, these savings add up quickly. As the saying goes locally: "Sapos yu save kontrol energi, yu save kisim moa profit long bisnis" – if you control energy, you gain more profit.

Practical benefits of energy-efficient cranes:

- Lower electricity bills: Reduces power consumption during lifting and idle periods.

- Reduced maintenance costs: Less stress on mechanical and electrical components extends lifespan.

- Smoother operation: VFDs allow precise speed control, improving safety and efficiency.

- Environmental impact: Consuming less energy helps reduce overall carbon footprint—good for compliance and company reputation.

Example calculation for PNG context:

- Assume a 10 ton crane operates 8 hours/day, 22 days/month.

- Standard hoist: consumes ~15 kWh/day → ~330 kWh/month.

- Energy-efficient hoist with VFD: reduces consumption by ~25% → ~247 kWh/month.

- Monthly electricity savings: 330 − 247 = 83 kWh. At ~PGK 0.60/kWh, savings = ~PGK 50/month. Over a year, that's ~PGK 600—just for one crane.

Even small efficiency gains can have a meaningful impact, especially when multiple cranes are in operation. Choosing cranes with energy-efficient hoists is a practical way to reduce costs while keeping production smooth and reliable.

Maximizing Uptime

For steel coil handling operations in PNG, keeping your 10 ton overhead crane running smoothly is crucial. Downtime not only delays production but also increases costs, disrupts workflow, and affects trust with clients and team members. Maximizing uptime starts with preventive maintenance and proper operator training.

Regular inspections help identify small issues before they become costly breakdowns. Operators who know the crane well can detect unusual noises, vibrations, or signs of wear early. In PNG business culture, reliability and community trust are key. As locals say: "Ol wokman mas save wok gut na mas stap strong" – workers must operate well and keep things strong.

Practical tips to maximize crane uptime:

- Schedule preventive maintenance: Monthly or quarterly checks on hoists, brakes, gears, and electrical components.

- Monitor hoist and trolley wear: Track rope condition, hook integrity, and lifting performance.

- Keep critical spare parts ready: Motors, brakes, fuses, and control components should be stocked locally.

- Train operators: Make sure staff understand proper lifting techniques, emergency procedures, and safety rules.

- Document maintenance: Keep logs for inspections, repairs, and replacements to anticipate future needs.

Long-term benefits of proactive uptime management:

- Fewer unexpected interruptions and production delays.

- Extended lifespan of crane components.

- Safer work environment for operators and other staff.

- Improved confidence among team members and clients, enhancing trust and reliability in your business.

By combining regular maintenance with skilled operation, you ensure your overhead crane performs efficiently, costs stay controlled, and your PNG workshop remains productive and reliable.

Choosing Durable Materials for Tropical Climates

Papua New Guinea's tropical climate can be tough on steel coil handling cranes. High humidity, heavy rain, and coastal exposure all contribute to rust, corrosion, and electrical failures. Choosing durable materials upfront is one of the most effective ways to reduce maintenance costs and extend your crane's lifespan.

Key material considerations:

- Corrosion-resistant paints and coatings: Protect structural steel from rust caused by moisture and salt in coastal areas.

- Stainless steel components: Use for critical parts such as bolts, pins, and hoist components to prevent corrosion.

- UV-protected electrical enclosures: Ensure control panels and wiring stay safe from sun damage, especially in workshops with open sides or outdoor exposure.

Practical example:

Investing in a crane with corrosion-resistant paint and stainless steel hoist parts may cost slightly more initially, but it prevents rust, breakdowns, and extra maintenance costs in the long run. This is especially important for steel coil handling, where downtime can be costly.

In local terms: "Longpela taim, gutpela samting i save stap moa gut long hevi klimut" – good things last longer in harsh climate.

Conclusion

Making smart investment decisions for a steel coil handling crane in PNG is about more than just the price tag. Combining durability, energy efficiency, and preventive maintenance ensures your crane keeps working reliably and safely for years.

Key takeaways:

- Slightly higher upfront costs can result in long-term savings, fewer repairs, and smoother production.

- Durable materials and energy-efficient hoists improve both operational efficiency and safety.

- Regular maintenance and trained operators maximize uptime and protect your investment.

For PNG business owners, reliability and trust matter. Choosing the right crane strengthens not only your operations but also your reputation with staff and clients.

Get Your Overhead Crane Solution Today: Consult reputable suppliers who understand PNG conditions to get a crane solution tailored to your steel coil handling needs.

As a local reminder: "Olgeta samting mas strong, safe, na save wok longpela taim" – everything must be strong, safe, and last long.