How to Run 3-Phase Electric Crane in Single-Phase Workshop

Learn practical ways to operate a 3-phase electric crane using single-phase power safely, efficiently, and without overloading motors.

Introduction

3-phase electric cranes are everywhere for a reason. They lift heavier loads, run smoother, and the motors last longer. If you’ve worked with cranes, you know a good three-phase crane can save a lot of time and headaches compared to a single-phase model.

The challenge: many small workshops or older buildings only have single-phase power. That means a standard 3-phase powered crane won’t run properly—or at all—without some extra equipment.

The solution: there are practical ways to make a 3-phase crane work on single-phase power. These methods can help small workshops use reliable cranes without rewiring the entire building.

Important:

- These tips are for practical guidance only.

- Always consult your crane supplier before making any decisions. They’ll ensure the solution matches your crane’s motor, load capacity, and duty cycle.

Why 3-Phase Electric Cranes Are Preferred

When it comes to electric cranes, three-phase models are the standard in most workshops and factories. Even if your crane is small, like 3–5 tons, a three-phase motor can make a noticeable difference in performance and reliability. Here's why these cranes are preferred:

Why this matters:

- Saves you money by avoiding the wrong installation.

- Prevents motor damage and ensures your crane operates safely.

- Helps you plan the right setup for your workshop’s power limitations.

Higher Efficiency

Three-phase electric cranes lift loads faster and run smoother. The motors waste less energy, which can lower electricity costs over time. Smooth operation also reduces jerking movements, which helps protect both the crane and the load.

- Faster lifting speeds compared to single-phase cranes

- Smooth, steady operation for precise handling

- Lower energy loss, saving power and money

Better Durability

Three-phase cranes are built to handle medium-to-heavy loads and continuous operations. The motors are stronger, and the crane structure is designed to last longer under regular use.

- Handles heavier loads safely

- Built for repetitive, daily lifting

- Reduces the risk of motor overheating or mechanical failure

Lower Maintenance

Because the motors and components operate more efficiently, three-phase cranes generally need less maintenance. This means fewer breakdowns, less downtime, and longer overall lifespan.

- Less wear and tear on motors and gears

- Longer service life for the crane

- Reduces costs and time spent on repairs

Even Small Cranes Benefit

Even light-duty cranes, like 3–5 ton electric cranes, gain advantages from three-phase motors. They operate more reliably, have smoother control, and are less likely to overheat compared to single-phase models.

- More consistent performance for small cranes

- Better suited for workshops that occasionally lift heavier or awkward loads

- Enhances overall safety and reliability

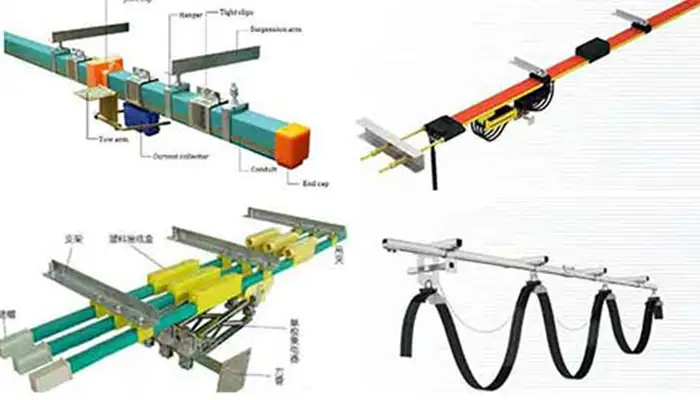

4 types of electric crane power supply busbur - Electric Overhead Cranes Guide: Types, Safety, Power Supply & Design

Methods to Operate a 3-Phase Electric Crane on Single-Phase Power

If your workshop only has single-phase electricity, you don’t have to give up on a 3-phase electric crane. There are practical ways to make it work. The most common methods are Rotary Phase Converters (RPC), Static Phase Converters, and Variable Frequency Drives (VFDs).

Important ClarificationThe methods discussed—RPC, static converters, and VFDs—are meant to give you practical ideas for running a 3-phase powered crane in a single-phase workshop. They can help smaller workshops make the most of available power without completely rewiring the facility.

Key points to remember:

- These solutions are not universal; what works for one crane or workshop may not work for another.

- Always consult your crane supplier before making a decision. They can recommend the safest and most effective setup for your electric crane, considering load capacity, duty cycle, and workshop conditions.

- Following professional advice helps avoid motor damage, downtime, and safety risks, ensuring your crane operates efficiently for years.

Practical tip: Think of these methods as ideas to explore with your supplier—not a DIY guarantee. Proper guidance ensures safety and performance.

1. Rotary Phase Converter (RPC)

A rotary phase converter takes your single-phase power and converts it into three-phase electricity using a motor-generator system. This allows your 3-phase electric crane to operate almost as if it were connected to a standard three-phase supply.

Where it works best:

- Medium to heavy cranes

- Continuous-duty operations

- Suitable for overhead cranes, gantry cranes, and large jib cranes

Benefits:

- Provides full crane capacity

- Reliable for heavy loads and continuous use

- Smooth operation for both lifting and trolley movement

Limitations / Considerations:

- Requires more space for the equipment

- Higher initial investment compared to other methods

- Needs maintenance to keep the system running efficiently

- May not be cost-effective for small, light-duty cranes

Practical tip: For workshops running large or frequently used cranes, RPC is usually the safest choice. It handles the load better than static converters and avoids motor overheating.

2. Static Phase Converter

A static phase converter uses capacitors to start a three-phase motor with single-phase electricity. Once the motor is running, it can operate the crane, though usually at reduced power. This is a simple and affordable option for smaller workshops.

Where it works best:

- Light-duty or small cranes (1–3 tons)

- Occasional lifting or intermittent use

- Small jib cranes or portable gantry cranes

Benefits:

- Compact and doesn’t take much space

- Inexpensive compared to rotary converters

- Easy to install and set up

Limitations / Considerations:

- Runs the motor at reduced power (around 70–80%), so lifting heavy loads may be slower

- Not suitable for continuous operation—motors can overheat if used too often

- Performance may be inconsistent under varying load conditions

Practical tip: Static converters are great for workshops that only lift occasionally and don’t need full crane capacity. If you plan to use the crane frequently or for heavier loads, consider a rotary converter or VFD instead.

3. Variable Frequency Drive (VFD)

A Variable Frequency Drive (VFD) is a versatile device that converts single-phase power into three-phase power while also allowing you to control the crane motor’s speed. This makes it ideal for cranes that need frequent starts and stops or precise positioning of loads.

Where it works best:

- Medium or light electric cranes with frequent start/stop cycles

- Operations requiring precise load positioning

- Jib cranes, small to medium overhead cranes, and some gantry cranes

Benefits:

- Efficient: Converts power with minimal loss, saving energy

- Compact: Takes up less space than a rotary converter

- Precise motor control: Allows smoother lifting and trolley movement

Limitations / Considerations:

- Must be properly sized for the crane motor to avoid overheating or underperformance

- Higher upfront cost compared to static converters

- Limited by the maximum motor size the VFD can handle, so it may not work for very heavy cranes

Practical tip: VFDs are excellent for workshops that need control and efficiency rather than just brute lifting power. They are especially useful for precision lifting tasks or when energy efficiency is important. For larger or continuous-duty cranes, a rotary phase converter might be more suitable.

Practical Considerations

Running a 3-phase electric crane on single-phase power isn’t just about picking a converter or VFD. You also need to think about your crane type, motor size, and how often you use it. Skipping these checks can lead to motor damage, unsafe lifting, or wasted money.

Motor Capacity Check

Before buying any converter or VFD, make sure it matches your crane’s motor rating. If it’s too small, your crane won’t lift at full capacity and motors can overheat.

Tips:

- Check the kW or HP rating of your crane motor

- Compare it to the rated capacity of the converter or VFD

- When in doubt, ask your crane supplier—they can help size it correctly

Duty Cycle

Not all cranes are used the same way. A light jib crane used a few times a day is very different from a gantry crane running continuously.

Guidelines:

- Heavy-use or continuous-duty cranes: use RPC or VFD

- Occasional or light lifting: static converters may be enough

- Always consider how often the crane will run each day

Crane Type

The type of crane matters because of load and motor size differences.

Guidelines:

- Small jib cranes and portable gantry cranes: static converters can work

- Large overhead cranes or gantry cranes: need RPC or VFD for reliable operation

Safety & Installation

Your installation must follow local electrical codes and manufacturer recommendations. Improper wiring or sizing can cause electrical hazards and motor damage.

Tips:

- Hire a licensed electrician if you’re unsure

- Make sure converters and VFDs are correctly grounded

- Keep equipment well-ventilated to avoid overheating

Cost vs. Performance

Cheaper isn’t always better. You need to balance the initial investment with long-term efficiency, reliability, and maintenance costs.

Considerations:

- RPC is more expensive but reliable for heavy-duty use

- Static converters are cheap but limit performance

- VFDs cost more but offer speed control and precision

Limitations and Cautions

While the methods we discussed—RPC, static converters, and VFDs—can help you run a 3-phase electric crane on single-phase power, they aren’t a one-size-fits-all solution. The right approach depends on your crane type, load capacity, and how often it’s used.

Key Limitations

- Not suitable for all cranes: Heavy-duty overhead or gantry cranes may exceed the capacity of static converters or even some VFDs.

- Continuous operation: If your crane runs all day, a dedicated three-phase supply is often the safest option. Converters may overheat or reduce lifting performance under long hours.

- Motor size matters: Large crane motors may require specialized equipment; undersized converters can cause overheating, motor damage, or slow operation.

Practical Advice

- Always consult your crane supplier before making a choice. They can help you select the method that is safe, reliable, and matched to your specific crane and workshop setup.

- Consider the long-term costs: a cheap converter might save money upfront but can cause higher maintenance or downtime later.

- Check local electrical codes and ensure all installations are done properly to prevent hazards.

Remember: These methods are meant to provide practical options, but professional guidance is essential to ensure safety and efficiency.

Conclusion

Running a 3-phase electric crane in a single-phase workshop is possible, but it takes careful planning. Choosing the right method—whether a rotary phase converter, static converter, or VFD—depends on several factors, including crane capacity, how often you use it, duty cycle, and budget.

The key is to match the solution to your crane and workshop setup. Small, occasional-use cranes may get by with a static converter, while larger, heavy-duty cranes usually need an RPC or VFD to operate safely and reliably.

Most importantly: always consult your crane supplier or an electrical professional. They can guide you to the safest, most effective setup, ensuring your crane runs efficiently and lasts for years. After all, it’s better to invest a little time and advice upfront than deal with costly downtime or motor damage later.

Takeaway: With the right approach and guidance, your workshop can safely run a 3-phase electric crane—even on single-phase power—without sacrificing performance or safety.