Buying CNEX Explosion-Proof Cranes from China

Buying Explosion-Proof Cranes from China: What Buyers Need to Know About CNEX Cranes

Most Important Takeaway

CNEX-certified explosion-proof cranes from China are technically safe and reliable, fully compliant for domestic hazardous-area projects in China, and can serve as supporting technical evidence for some export projects—but buyers must carefully evaluate local regulatory requirements like ATEX or IECEx for international installations.

Key Takeaways

- CNEX certification ensures real explosion-proof safety for cranes and components.

- CNEX is legally sufficient in China, but has limited international recognition.

- CNEX can be combined with ISO, CE, and third-party inspection for added buyer confidence.

- For export to EU, Middle East, or other regulated markets, ATEX or IECEx certification may still be required.

- Buyers must assess: installation location, hazard classification, supplier credibility, and potential future relocation.

- CNEX cranes from China are cost-effective, customizable, and technically robust, especially for industrial plants, mining operations, and workshops.

What Is CNEX Certification and Why It Matters

CNEX stands for the China National Supervision and Inspection Center for Explosion Protection. It is China's main authority for testing and certifying equipment used in hazardous environments, such as cranes in chemical plants, steel mills, coal plants, and powder-handling workshops. CNEX certification is based on GB 3836 standards, China's national standards for explosion-proof equipment. These standards cover design, manufacturing, and testing processes. When a crane or its components carry CNEX certification, it means they have undergone thorough checks to ensure they operate safely in hazardous conditions.

Main Areas CNEX-Certified Cranes Are Tested For

- Explosion Containment (Ex d, Ex e, Ex i, etc.)

CNEX evaluates whether a component can safely contain an internal spark or ignition without spreading to the surrounding environment. Different protection types are used depending on the gas or dust hazard in the area. - Electrical Safety in Hazardous Zones

Electrical components such as motors, control panels, limit switches, and wiring are inspected to ensure there's no risk of sparks, overheating, or short circuits that could trigger an explosion. This is essential for cranes operating in gas or dust zones. - Mechanical Reliability Under Industrial Conditions

Cranes are also tested for mechanical durability, including the hoist, moving parts, structural components, and load-handling mechanisms. CNEX ensures cranes perform reliably under demanding conditions like lifting heavy materials in steel mills or coal plants.

Why CNEX Matters for Buyers

- CNEX certification guarantees real explosion-proof safety, not just a label.

- In China, it is fully recognized by local authorities and inspectors.

- For international projects, CNEX alone may not satisfy EU, Middle East, or other ATEX/IECEx requirements, so additional certification might be necessary.

Practical Tips for Buyers

Before purchasing a CNEX-certified crane:

- Verify which components are actually covered by the certification; sometimes only motors or hoists are certified, not the full crane system.

- Request detailed CNEX test reports to ensure compliance with your project's hazard classification.

- If exporting, confirm whether CNEX is sufficient for local regulations or if ATEX/IECEx certification will also be required.

Who Can Buy CNEX-Certified Explosion-Proof Cranes from China

CNEX-certified cranes are designed for hazardous industrial environments, but not every buyer or project requires them. Understanding who can safely and legally buy these cranes helps prevent mistakes, compliance issues, and project delays. Buyers can generally be divided into domestic and international groups.

Domestic Buyers in China

CNEX certification is fully recognized by Chinese authorities, making it a practical choice for industrial projects across China. Typical domestic buyers include:

Chemical Plants, Coal Plants, Steel Mills, and Powder-Handling Workshops

These facilities often work with flammable gases, combustible dust, or powders, creating high-risk environments. CNEX-certified cranes help ensure safe lifting and movement of materials in these zones.

- Confirm that the crane's lifting capacity and span fit your plant's operations.

- Check the duty cycle to ensure continuous or heavy use will not cause excessive wear.

- Ensure the crane layout matches hazardous-area zoning to comply with safety regulations.

Local EPC Contractors and Plant Engineers

EPC (Engineering, Procurement, and Construction) contractors, as well as in-house plant engineers, often require cranes that are legally compliant to pass inspections. CNEX simplifies this process.

- Use CNEX certificates to document compliance with GB 3836 standards.

- Streamline project approvals and reduce delays caused by safety verification.

- Rely on CNEX test reports to design crane layouts safely for complex facilities.

International Buyers

For buyers outside China, CNEX certification is technically credible but may not fully satisfy local legal requirements in regions like Europe, the Middle East, or parts of Asia. Many international buyers use CNEX as a technical reference or as a cost-effective solution for projects where ATEX or IECEx certification is not strictly required.

Industrial Projects in Southeast Asia, Africa, and Latin America

CNEX-certified cranes are popular for smaller or cost-sensitive industrial facilities, where full ATEX/IECEx certification might be unnecessary.

- Examples include private steel workshops, medium-sized chemical plants, mineral processing facilities, and small-scale mining operations.

- CNEX certification gives buyers confidence in design quality, electrical safety, and mechanical reliability.

- Important: Always confirm local regulations to determine whether CNEX alone is acceptable, or if additional documentation or inspection is needed.

Private Plants or Workshops with Internal Safety Verification

Some facilities have internal safety engineers or auditors who can independently assess CNEX certification. This allows them to approve cranes without requiring full international certification.

- Using CNEX-certified cranes in these facilities can reduce costs compared to ATEX or IECEx cranes.

- Provides a way to use technically safe cranes without complex international approvals.

- Ideal for plants that manage their own compliance and inspection processes.

EPC Contractors Evaluating Suppliers for Export Projects

For international projects that may eventually require ATEX or IECEx, CNEX certification can serve as a first-step evaluation tool.

- Contractors can verify the crane's technical quality, safety, and design before committing to dual certification.

- Helps in budget planning, timeline estimation, and risk management, ensuring safety while preparing for future regulatory requirements.

- Speeds up supplier selection and reduces initial evaluation costs.

Practical Tips for International Buyers

- Confirm whether the CNEX certificate covers the full crane system or only individual components.

- Verify local regulatory acceptance—some countries only allow CNEX for technical reference.

- Consider adding ISO certification, CE marking, or third-party inspections to strengthen compliance.

- Keep detailed technical documentation to support inspections or approvals in export markets.

Benefits of Buying CNEX Cranes from China

CNEX-certified explosion-proof cranes offer more than just compliance—they provide practical advantages for buyers in both domestic and some international projects. Below are the main benefits, broken down with clear subheadings.

Lower Cost Without Sacrificing Safety

CNEX cranes from China are generally more affordable than European or ATEX/IECEx-certified cranes.

- Cost savings allow buyers to invest in installation, training, or spare parts while maintaining explosion-proof safety.

- Especially attractive for budget-sensitive industrial projects in Southeast Asia, Africa, and Latin America.

Proven Safety and Reliability

Safety is the core advantage of CNEX certification.

- Cranes and components are tested for explosion containment (Ex d, Ex e, Ex i), electrical safety, and mechanical durability.

- CNEX cranes can safely operate in hazardous zones with flammable gas or dust, giving buyers confidence in daily operations.

Faster Delivery and Project Approval in China

For domestic projects, CNEX certification allows quicker procurement and approval.

- Local authorities accept CNEX documentation, reducing inspection and commissioning time.

- Buyers avoid long delays associated with international certifications like ATEX or IECEx.

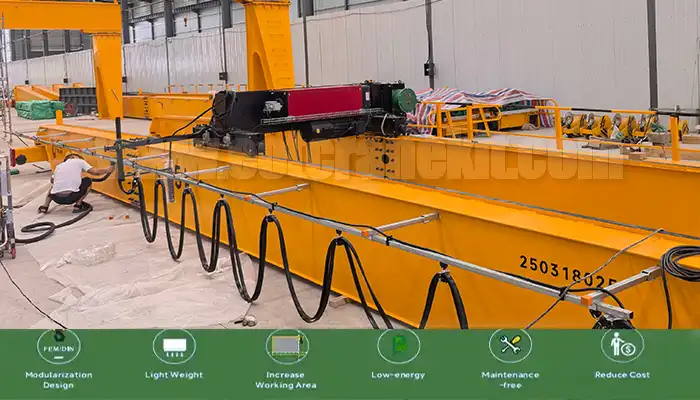

Flexible and Customizable Solutions

Chinese suppliers often offer tailored crane designs to meet specific plant requirements.

- Buyers can select lifting capacity, span, hoist type, and duty cycle to fit workflow and materials handling needs.

- Suitable for light-duty or heavy-duty industrial applications, providing maximum operational efficiency.

Added Confidence with Complementary Certifications

CNEX certification can be enhanced with other marks to boost buyer assurance.

- ISO certification ensures quality management and consistent manufacturing standards.

- CE marking supports export compliance where general product safety is required.

- Third-party inspections provide independent verification of crane safety and performance.

Practical Tips for Buyers

- Verify that CNEX certification covers the entire crane system, not just individual components.

- Ensure customizations are tested and certified under CNEX standards.

- For international projects, confirm whether additional ATEX/IECEx certification or inspection is required.

- Check delivery timelines, warranty terms, and maintenance support to ensure long-term safe operation.

Limitations of CNEX-Certified Cranes

CNEX certification guarantees real explosion-proof safety, but buyers—especially international ones—should be aware of its practical limitations. Understanding these issues helps prevent compliance problems, delays, and unexpected costs.

Limited International Recognition

CNEX is recognized in China, but its acceptance outside China is limited.

For regions such as the EU, Australia, or markets that require ATEX or IECEx, CNEX alone may not meet regulatory standards. Buyers cannot assume CNEX certification automatically grants approval in foreign countries, and installing cranes without accepted certification could lead to inspection delays or fines.

- Verify local regulations before purchase.

- Consider whether additional certification (ATEX or IECEx) is needed for your target market.

- Understand that CNEX is primarily recognized as a technical safety standard, not a legal requirement internationally.

System-Level Certification Requirements

Some export projects demand full crane system certification, not just component-level approval.

CNEX sometimes only covers motors, hoists, or electrical parts, rather than the entire crane assembly. If your project requires a fully certified system, you may need dual certification or additional testing to comply with international standards.

- Check which parts of the crane are covered under CNEX.

- Plan ahead to avoid re-certification or redesign costs.

- Ensure documentation clearly shows compliance for all critical components.

Supplier Capability

Not all Chinese crane suppliers can provide dual-certified (CNEX + ATEX/IECEx) solutions.

While many suppliers offer CNEX-certified cranes, only some have the experience and resources to deliver dual-certified or export-ready cranes. Choosing the wrong supplier can lead to project delays, compliance issues, or extra costs.

- Confirm supplier's ability to provide dual certification if needed.

- Review past export projects and certifications completed by the supplier.

- Ensure clear communication about delivery timelines, documentation, and support.

Project Risk and Compliance Verification

Installing CNEX-certified cranes outside China requires careful compliance planning.

Even though CNEX-certified cranes are technically safe, local authorities may require additional proof or certification. Failing to verify compliance in advance can result in inspection delays, fines, or forced modifications. Consulting with local safety engineers or inspectors before purchase helps reduce these risks.

- Always verify whether CNEX is sufficient for local regulations.

- Plan for potential extra inspections or certification needs.

- Keep detailed CNEX documentation to support approvals or audits.

Practical Takeaways

- CNEX guarantees safety but may not replace ATEX or IECEx for global projects.

- Confirm system-level coverage and component certifications.

- Verify supplier's capability for dual certification or export compliance.

- Plan in advance to avoid project delays or legal issues in international markets.

What Buyers Should Notice Before Purchasing CNEX-Certified Cranes

Before purchasing a CNEX-certified explosion-proof crane, buyers need to carefully review several critical factors. This ensures the crane meets safety requirements, operational needs, and potential export regulations.

Project Location

The location of your project directly affects which certifications are required.

Some countries or regions, such as the EU or Australia, may mandate ATEX or IECEx certification, even if the crane is CNEX-certified. Knowing your project location in advance helps avoid compliance issues or installation delays.

- Verify local laws regarding explosion-proof equipment.

- Determine if CNEX alone is sufficient or if dual certification is necessary.

- Factor in potential inspection or approval timelines.

Hazard Classification

Different hazardous areas require different crane specifications.

- Identify whether your plant deals with flammable gases, combustible dust, or a combination.

- Hazard classification (Zone 0, 1, 2 for gas; Zone 20, 21, 22 for dust) impacts crane design, protective features, and certification requirements.

- CNEX certification will cover specific zones—ensure the crane matches your site's classification.

Certification Needs

Buyers must confirm which certifications are required for safety, legal compliance, and export purposes.

- CNEX certification ensures technical explosion-proof safety.

- CE marking supports general safety compliance for export.

- ISO certification guarantees manufacturing quality and management standards.

- Third-party inspections add an extra layer of verification.

- ATEX or IECEx may be required for certain export destinations.

Supplier Credibility

Not all suppliers provide full documentation or reliable quality.

- Request CNEX certificates, ISO documents, and third-party inspection records.

- Confirm that the supplier has experience with international shipments if you plan to export.

- Ensure documentation covers all critical components, not just hoists or motors.

Future Relocation or Export Plans

Think ahead if your facility may move or if you plan to export the crane.

- Future relocation may require ATEX or IECEx certification even if CNEX is sufficient for domestic use.

- Planning early prevents additional costs or re-certification delays.

- Suppliers can advise on dual-certified cranes suitable for both domestic and international markets.

Technical Limitations

Each crane has specific operational constraints that must be reviewed carefully.

- Check maximum lifting weight, span, and duty cycle to ensure it meets your operational demands.

- Consider environmental conditions such as temperature, humidity, and exposure to corrosive or dusty atmospheres.

- Confirm that customizations or special requirements are compatible with CNEX certification.

Practical Tips for Buyers

- Make a checklist of project location, hazard type, and certification requirements before requesting a quote.

- Always request detailed documentation from suppliers to verify compliance.

- Consider future export needs when choosing CNEX-certified cranes.

- Ensure technical specifications match real-world plant conditions for safe and reliable operation.

CNEX vs ATEX vs IECEx – Quick Buyer Comparison

When buying an explosion-proof crane, understanding the differences between CNEX, ATEX, and IECEx certifications is essential. Each has its strengths, limitations, and practical implications for domestic and international projects.

Safety

All three certification systems ensure high levels of explosion-proof safety, but the approach differs slightly.

- CNEX: Tested under GB 3836 standards, ensures reliable protection in hazardous areas within China.

- ATEX: Complies with European Union directives for gas and dust zones, recognized legally in the EU.

- IECEx: Offers global recognition with strict testing and documentation for explosion-proof equipment.

Key point: Safety is high in all three, but CNEX focuses on domestic compliance, while ATEX and IECEx are more internationally oriented.

Domestic Recognition

The country or region where your project is located determines which certification is accepted.

- CNEX: Fully recognized within China ✅

- ATEX: Limited acceptance outside the EU ❌

- IECEx: Limited acceptance without local adoption ❌

Tip: Domestic buyers in China can rely on CNEX, but international buyers need to confirm whether local authorities accept CNEX.

International Recognition

If your crane might be exported or relocated, international recognition is important.

- CNEX: Limited outside China ❌

- ATEX: Accepted in the EU and some aligned countries ✅

- IECEx: Globally recognized, ideal for export projects ✅

Advice: For export or multinational operations, ATEX or IECEx is often required. CNEX can serve as a technical reference but may not satisfy legal inspection requirements.

Cost

Cost differences are significant and often influence buyer decisions.

- CNEX: Lower cost, good for domestic or cost-sensitive projects.

- ATEX: Higher cost due to strict EU testing and documentation.

- IECEx: Highest cost because of global compliance and system-level approval.

Practical tip: CNEX offers savings, but dual certification or international projects may require ATEX or IECEx, increasing overall costs.

Certification Complexity

Complexity affects project timelines and supplier selection.

- CNEX: Moderate complexity; certification is mostly component-level.

- ATEX: High complexity; requires detailed documentation and EU-specific approvals.

- IECEx: Very high complexity; system-level approval, global standards, and rigorous testing.

Note: Plan for certification timelines when budgeting or scheduling your project.

System-Level Approval

Some projects require entire crane systems to be certified, not just individual parts.

- CNEX: Partial system approval; may only cover motors, hoists, or electrical panels.

- ATEX: Full system approval required for export to EU markets.

- IECEx: Full system approval required for global compliance.

Tip: Always verify whether CNEX certification covers the entire crane system before purchase, especially for export projects.

Potential Markets for CNEX-Certified Cranes

CNEX-certified explosion-proof cranes are primarily designed for hazardous industrial environments. While widely used in China, certain international markets also present opportunities—especially for cost-sensitive projects or private plants with internal safety verification.

Domestic China

CNEX is fully recognized in China, making it the easiest and most straightforward market.

- Typical buyers include chemical plants, coal facilities, steel mills, and powder-handling workshops.

- CNEX ensures compliance with GB 3836 standards, which is mandatory for hazardous zones in China.

- Domestic buyers benefit from fast approval, lower costs, and reliable safety documentation.

Southeast Asia

Countries like Vietnam, Thailand, the Philippines, and Indonesia often have cost-sensitive industrial projects.

- CNEX-certified cranes offer real explosion-proof safety at a lower price compared with ATEX or IECEx cranes.

- Suitable for private steel workshops, medium-sized chemical plants, or mineral processing facilities.

- Buyers should confirm local regulations as CNEX is usually treated as a technical reference rather than a legally recognized certificate.

Africa

Markets like South Africa, Egypt, and Nigeria include private plants and industrial workshops where CNEX cranes can be used safely.

- Often applied in mining, steel, and chemical facilities with internal safety procedures.

- CNEX certification can reduce costs while ensuring technical safety.

- Always verify national safety and compliance requirements before importing.

Latin America

Countries such as Brazil, Mexico, and Chile are potential markets for CNEX-certified cranes.

- Popular for private industrial projects, including small-to-medium manufacturing plants.

- CNEX is often used as a technical reference for internal safety verification.

- Buyers may consider complementary certifications (ISO, CE, third-party inspection) if the crane is exported across borders.

Middle East

Countries like the UAE and Oman have private industry projects where CNEX-certified cranes are useful.

- Suitable for facilities with internal safety engineering teams who can verify CNEX compliance.

- CNEX provides cost-effective explosion-proof solutions without waiting for international approvals.

- Ideal for medium-scale chemical, steel, or powder-handling workshops.

Practical Tips for Target Markets

- Confirm local regulations to determine whether CNEX alone is acceptable.

- Consider ISO certification, CE marking, or third-party inspection to strengthen credibility in export markets.

- Assess the project size, hazard classification, and operational needs to match the right crane model.

- CNEX is most effective in cost-sensitive or technically verified projects, not in markets requiring strict ATEX/IECEx compliance.

Conclusion: Making the Right Choice with CNEX-Certified Cranes

CNEX-certified explosion-proof cranes from China offer a practical combination of safety, reliability, and cost-effectiveness. They are ideal for domestic hazardous-area projects and certain export markets with internal safety verification processes. Buyers should consider key factors to ensure operational and regulatory compliance.

Key Considerations for Buyers

Evaluate these points before making a decision:

- Project Location and Local Regulations

Determine whether ATEX or IECEx certification is required in your country. CNEX alone may not satisfy legal inspection requirements in some regions. - Hazard Classification

Identify the type of hazardous area—gas, dust, or mixed zones—to ensure the crane design and CNEX certification match the risk level. - Supplier Credibility and Documentation

Request CNEX certificates, ISO documentation, CE marking, and third-party inspection reports to confirm supplier reliability and crane quality. - Future Relocation or Export Plans

If the crane may be relocated or exported, consider whether dual certification or additional documentation is needed to comply with international standards.

Reducing Risk and Ensuring Safe Operation

By combining CNEX certification with ISO, CE, and third-party inspection, buyers can:

- Reduce compliance and operational risks.

- Ensure safe and reliable crane operation in hazardous areas.

- Make informed purchase decisions for both domestic and international projects.

- Balance cost-effectiveness with safety and quality, avoiding unnecessary expenses.

Final Takeaway

CNEX-certified cranes from China are a practical solution for buyers who need reliable, technically safe, and affordable explosion-proof lifting equipment. Proper planning, supplier verification, and attention to certification requirements make it possible to confidently use these cranes in domestic projects and select international markets.

Questions Solved

This article is designed to help buyers make informed decisions when considering CNEX-certified explosion-proof cranes from China.

1. What is CNEX certification, and does it ensure safety?

CNEX is the China National Supervision and Inspection Center for Explosion Protection, based on GB 3836 standards.

- CNEX-certified cranes are tested for explosion containment, electrical safety, and mechanical reliability.

- While CNEX ensures real technical safety, its recognition is mostly domestic, and international acceptance is limited.

2. Who can buy explosion-proof cranes from China?

Both domestic and international buyers can purchase CNEX-certified cranes, depending on local regulations and safety verification.

- Domestic buyers include chemical plants, coal plants, steel mills, and powder-handling workshops.

- International buyers include Southeast Asia, Africa, Latin America, and Middle East projects, especially cost-sensitive facilities or plants with internal safety verification.

3. What are the benefits and limitations of CNEX cranes?

CNEX-certified cranes offer cost-effective, safe, and customizable solutions, but buyers must understand practical limitations.

Benefits:- Lower cost compared to ATEX or IECEx cranes

- Technically safe and reliable

- Faster approval in China

- Flexible customization options

- ISO, CE, and third-party inspection can add extra assurance

- Limited international recognition

- Partial system-level certification

- Not all suppliers can provide dual-certified solutions

- Export projects require verification of local compliance

4. How does CNEX compare to ATEX and IECEx certifications?

CNEX, ATEX, and IECEx all provide high levels of explosion-proof safety, but recognition, cost, and complexity differ.

| Feature | CNEX | ATEX | IECEx |

|---|---|---|---|

| Safety | High | High | High |

| Domestic Recognition | China ✅ | Limited ❌ | Limited ❌ |

| International Recognition | Limited ❌ | EU ✅ | Global ✅ |

| Cost | Lower | Higher | Higher |

| Certification Complexity | Moderate | High | Very High |

| System-Level Approval | Partial | Required | Required |

- CNEX is ideal for domestic projects or technically verified export projects.

- ATEX and IECEx are necessary for full international legal recognition.

5. What should buyers notice before purchasing a CNEX crane for domestic or international projects?

Before buying, evaluate:

- Project location and local regulations – ATEX or IECEx may be required internationally.

- Hazard classification – gas, dust, or mixed hazardous zones.

- Supplier credibility – request CNEX certificates, ISO, CE, and third-party inspection records.

- Future relocation or export plans – dual certification may be needed.

- Technical limitations – maximum lifting weight, span, duty cycle, and environmental conditions.