Automatic Bucket Crane for Sale, Affordable & Reliable Automation

Automatic bucket cranes offer cost-effective material handling with precision controls, ideal for bulk industries needing smart automation solutions.

Category: Grab Crane

Your Trusted Grab Bucket Automatic Overhead Crane Manufacturer & Supplier

Automatic Bucket Cranes for Sale, Affordable Crane Automation

Grab Buceket Automatic Overhead Crane for Bulk Material Handling

Introduction: Overview of Automatic Bucket Cranes

Automatic bucket cranes are heavy-duty machines designed to handle bulk materials like coal, scrap metal, cement, and waste. These cranes use bucket attachments to scoop, lift, and transport materials efficiently. The "automatic" part means they are controlled with minimal human intervention, making them faster and safer than manual systems.

These cranes are especially useful for industries where large amounts of material need to be moved quickly and precisely. The automation allows for precise control, reducing the chances of human error and improving overall efficiency.

Importance in Industries Like Mining, Steel Manufacturing, Recycling, and Power Generation

Automatic bucket cranes are crucial in industries that deal with bulk materials. In mining, they move raw ores and coal, making extraction and transportation easier. Steel manufacturing relies on them for handling scrap metal, slag, and other materials, reducing manual labor and increasing throughput.

In recycling and waste management, these cranes are used to sort and transport recyclable materials like paper, plastics, and metals. Power generation plants use them for transferring coal from ships or storage to the plant for energy production.

The ability of these cranes to handle a variety of materials safely and efficiently makes them indispensable in these industries.

Why Consider Automatic Bucket Cranes for Sale?

When you're thinking about buying an automatic bucket crane, there are several reasons why it's a smart move.

- Increased Efficiency: Automatic bucket cranes work faster than manual labor. With automated features, they can lift, transport, and dump materials in less time, helping to speed up operations.

- Enhanced Safety: By reducing the need for human intervention, these cranes lower the chances of workplace accidents. Safety features like load sensors, real-time monitoring, and anti-sway systems ensure that everything operates smoothly.

- Reduced Labor Costs: Automation means fewer workers are needed for operating the crane, which can cut down on labor costs. The reduced need for manual labor also means fewer mistakes and less downtime.

These advantages make automatic bucket cranes a wise investment for businesses that want to improve productivity, reduce costs, and enhance safety.

Key Features of Automatic Bucket Overhead Cranes

Crane Design

Double Girder Design for Stability and Higher Load Capacities - Automatic bucket cranes typically feature a double girder design, which provides added stability and supports larger spans. This design is especially important in industries that require handling heavy loads, such as mining and steel manufacturing. The double girder setup helps distribute the load more evenly, making the crane more durable and reliable over time.

Why it matters:

- More stable and durable for heavy-duty applications

- Can handle higher load capacities with minimal strain on the structure

- Ideal for large-scale material handling, especially in harsh environments like steel mills or mining sites.

Bucket Types

Clamshell Buckets for Granular Materials - When it comes to handling granular materials, clamshell buckets are the go-to choice. These buckets have a unique design that opens and closes like a claw, allowing them to scoop and move materials like coal, sand, or grain easily. They are efficient in loading and unloading bulk, lightweight materials and are commonly used in industries like mining and agriculture.

Ideal for:

- Loose and granular materials

- Bulk handling of lightweight goods

- Materials with inconsistent or uneven shapes

Orange Peel Buckets for Heavy, Irregular Materials - For heavier, irregularly shaped materials like scrap metal and industrial waste, orange peel buckets are the best option. These buckets have multiple jaws that can grab and hold onto bulky, uneven materials, making them perfect for operations in places like recycling plants or steel mills.

Perfect for:

- Scrap metal, waste, and industrial components

- Irregularly shaped materials that require a firm grip

- Heavy-duty lifting in harsh environments

Specialized Buckets for Waste Handling, Cement, and Coal - In addition to clamshell and orange peel buckets, automatic bucket cranes also feature specialized buckets designed for specific materials:

Waste Handling Buckets:

- Ideal for moving and handling mixed waste or industrial by-products

- Built to handle sharp or difficult waste materials

Cement Plant Buckets:

- Designed for powdery bulk materials like cement or lime

- Sealed designs prevent spillage

- Equipped to handle abrasive coal and designed for wear resistance.

Each bucket type has been designed for specific materials to improve efficiency, reduce spillage, and ensure long-term durability.

Automation Features

Real-Time Monitoring Systems, Load Sensors, and Anti-Sway Control

One of the biggest advantages of automatic bucket cranes is the integration of automation features that enhance both safety and efficiency. These cranes come equipped with real-time monitoring systems to track critical metrics like the bucket fill rate, load weight, and operational speed. Load sensors ensure that the crane doesn't exceed its weight limits, while anti-sway control helps minimize the swinging of heavy loads, improving precision during material handling.

Key benefits:

- Load sensors prevent overloading

- Anti-sway control reduces material spillage

- Real-time data helps operators adjust crane operations on the fly

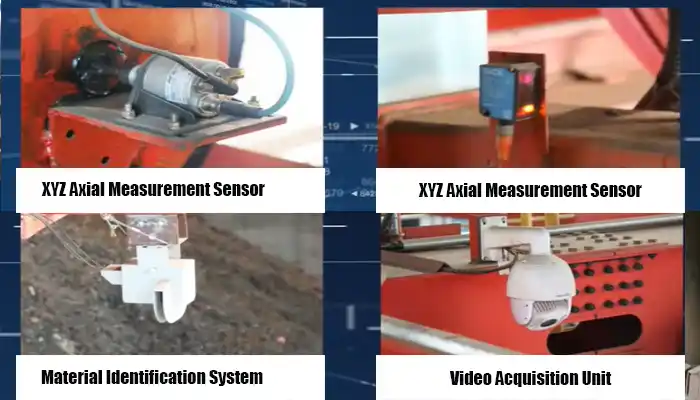

grab bucket automatic overhead crane

Load stbility control and efficiency system for grab bucket overhead crane automation

axial measurement sensor, material handling identifiation system, and video acquisition unit

remote communication network, wireless receiver, smart edge secrurity protector, operator console prcessor

Smart Control Systems and Integration with Warehouse Management Software

Many automatic bucket cranes come with smart control systems, which allow for remote operation and monitoring. These systems can be linked to warehouse management software (WMS), allowing cranes to work seamlessly with other parts of your operations. For example, if the crane is moving materials from one section to another, the WMS can adjust the flow of goods automatically, optimizing the overall workflow and reducing downtime.

Smart controls offer:

- Remote operation and monitoring

- Integration with other systems to optimize workflow

- Increased efficiency and automation across the facility

By integrating automation features, these cranes allow for better management, safety, and control, making them a smart choice for modern industrial operations.

crab crane remote control platform

large screen display system

Benefits of Buying Automatic Bucket Cranes

Improved Efficiency

Faster Operations and Reduced Downtime - One of the key benefits of automatic bucket cranes is their ability to speed up operations. With automation, tasks that once took a lot of time are completed much faster. These cranes are designed to work continuously with minimal interruptions, which leads to reduced downtime. Since the process is automated, there's less chance of delays due to human error or fatigue, ensuring that the crane runs at peak efficiency throughout its lifecycle.

Key advantages:

- Continuous, uninterrupted operation

- Faster handling of materials

- Increased productivity without sacrificing quality

Enhanced Safety

Reduced Human Intervention and Fewer Accidents - Safety is always a top concern in any industrial setting, and automatic bucket cranes excel in this area. By reducing the need for human intervention, the risk of accidents and injuries is significantly minimized. These cranes come with built-in safety systems such as overload protection, emergency stop functions, and automated load monitoring. This means less risk of operational errors and better overall safety in hazardous environments like mining or steel manufacturing.

Key safety benefits:

- Fewer human operators needed

- Automated safety features prevent accidents

- Reduced human error, leading to a safer work environment

Cost-Effectiveness

Lower Labor and Maintenance Costs - While the upfront cost of an automatic bucket crane may be higher than a manual system, the long-term savings are significant. Reduced labor costs are one of the most noticeable benefits, as automation limits the number of operators needed to handle materials. In addition, the integrated maintenance monitoring systems help detect issues before they become major problems, reducing expensive repairs and downtime. Predictive maintenance also ensures that the crane is in good condition, maximizing its lifespan and minimizing costly breakdowns.

How it saves you money:

- Reduced labor costs due to automation

- Lower maintenance expenses with predictive diagnostics

- Long-term savings through efficient performance

Precision Handling

Minimizing Spillage and Material Damage - Automatic bucket cranes offer exceptional precision when handling materials. With features like real-time monitoring and advanced control systems, these cranes can place materials accurately and without unnecessary movements. This precision reduces the likelihood of material spillage and damage, ensuring that your materials are handled efficiently and safely. Whether it's scrap metal, cement, or coal, you can trust automatic bucket cranes to minimize waste and improve material recovery rates.

Benefits of precision handling:

- Accurate bucket control to avoid spillage

- Reduced material loss and damage

- Higher material recovery rates for cost savings

By investing in an automatic bucket crane, you're not just improving operations, but also boosting safety, cutting costs, and achieving higher precision in every move.

automatic bucket hoist crane

material identification system for precise and efficient material handling

Types of Automatic Bucket Cranes Available for Sale

When you're looking to buy an automatic bucket crane, there are several types to choose from, depending on your specific material handling needs. Here's a breakdown of the most common types:

General Purpose Cranes

Ideal for Bulk Materials - General purpose automatic bucket cranes are versatile and designed for a variety of standard bulk material handling tasks. They're typically used in industries like mining, construction, and power generation. These cranes are great for handling materials such as coal, cement, and sand. Their flexible design and moderate load capacities make them suitable for handling materials that don't require specialized buckets or extreme conditions.

Key Features:

- Handles granular bulk materials like coal and sand

- Ideal for medium-weight materials

- Standard bucket designs for easy maintenance

Heavy-Duty Cranes

Built for Tough Materials - Heavy-duty automatic bucket cranes are designed to tackle heavy, abrasive, and dense materials that are commonly found in industries like steel manufacturing, mining, and scrap handling. These cranes are perfect for moving scrap metal, ores, slag, and other large or tough materials. With higher load capacities, reinforced buckets, and stronger structures, these cranes are built to last and operate in challenging environments.

Key Features:

- Handles heavy, abrasive materials

- Reinforced bucket designs for tougher materials

- High load capacities (20 tons and above)

Specialized Cranes

Tailored for Specific Applications - Specialized automatic bucket cranes are built for unique material handling needs that require custom solutions. These cranes are ideal for industries dealing with specialized materials like waste, coal, or cement. They are often equipped with corrosion-resistant coatings, heat-resistant buckets, and custom grab designs to handle the challenges of specific environments. Whether you're dealing with molten slag, hazardous waste, or fine-grained materials, these cranes are designed to meet the demands of those specialized applications.

Key Features:

- Custom buckets for specific materials like coal and waste

- Corrosion-resistant coatings for harsh environments

- Heat-resistant buckets for handling molten materials

- Specialized designs for applications like scrap handling or waste management

Choosing the right type of automatic bucket crane depends on the materials you'll be handling and the specific operational requirements of your facility. Whether you need a general purpose crane for bulk materials, a heavy-duty crane for tough jobs, or a specialized crane for unique conditions, there's a solution available for every need.

Factors to Consider Before Buying Automatic Bucket Cranes

Before purchasing an automatic bucket crane, it's important to consider several key factors that will affect both its performance and long-term efficiency in your operation. Here's a closer look at the most important considerations:

Load Handling Capacity

Know Your Material Handling Needs - The load capacity of the crane is one of the most critical factors to consider. It's essential to understand the weight and density of the materials you'll be handling. Automatic bucket cranes come in a range of capacities, from light-duty cranes for handling small loads to heavy-duty cranes for larger, bulk materials.

Example Capacities:

- 5 tons – For light, bulk materials like sand or grains

- 20 tons – For handling heavier materials like coal or scrap metal

- 50 tons – For extremely heavy materials like ores, molten slag, and large scrap

Ensure the crane you choose is appropriately sized for your material handling needs to optimize performance and prevent overloading.

Bucket Design and Customization

Choosing the Right Bucket for Your Material - The bucket design plays a significant role in how efficiently the crane will handle your specific materials. Buckets are often customizable, depending on the type of material. For instance, clamshell buckets are great for granular materials like coal, while orange peel buckets are better suited for scrap metal and irregular materials.

Types of Buckets:

- Clamshell Buckets – Best for granular materials (e.g., coal, sand)

- Orange Peel Buckets – Suitable for handling scrap metal and irregular materials

- Specialized Buckets – For materials like molten slag, cement, or waste

Make sure to select the right bucket type, size, and design features that match your material characteristics.

Crane Dimensions and Space Requirements

Fit the Crane to Your Facility - Before you invest in an automatic bucket crane, assess your facility's space. It's essential to ensure that the crane will fit within the available area and that it can operate efficiently in the designated workspace. Consider the span, height, and clearance requirements.

Key Considerations:

- Ceiling Height – Ensure there's enough vertical clearance for safe crane operation.

- Span – The width of the crane's girder system must be suitable for the workspace.

- Runway Length – Ensure the crane has enough space to move across the area.

It's critical that the crane integrates seamlessly with the layout of your facility for maximum efficiency.

Automation and Control Systems

Evaluate Automation Capabilities - Automation is one of the key benefits of an automatic bucket crane. Look for smart control systems and automation features that improve operational efficiency. Consider how the crane will integrate with your existing systems, such as warehouse management software, and the level of control you need. Automation features like load sensors, anti-sway control, and real-time monitoring can enhance precision, safety, and productivity.

Automation Features to Consider:

- Real-time monitoring for better control and safety

- Smart sensors for load and position monitoring

- Remote control options for ease of operation

- Integration with facility systems (e.g., warehouse management software)

The right automation system can significantly enhance crane performance and reduce the need for manual intervention.

Durability and Maintenance

Ensure Longevity and Lower Operating Costs - Look for cranes that are built to last, with durable components and features that minimize wear and tear. High-quality materials, like wear-resistant coatings and reinforced steel, can extend the crane's lifespan and reduce the frequency of repairs. Additionally, consider the maintenance requirements and whether the crane has easy access points for regular inspections and repairs.

Durability Features:

- Corrosion-resistant coatings for longer life in harsh environments

- Wear-resistant materials for parts like buckets, ropes, and hoists

- Regular maintenance schedules to ensure crane efficiency

Investing in a durable crane will save you money in the long run by reducing downtime and repair costs.

Where to Buy Automatic Bucket Cranes

When it comes to purchasing an automatic bucket crane, choosing the right supplier is crucial for ensuring both quality and reliability. Here's a guide on where to buy these cranes and what to consider when selecting a trusted manufacturer or supplier.

Trusted Manufacturers and Suppliers

Why Trust Matters - The best place to buy automatic bucket cranes is from manufacturers who have a proven track record in delivering high-quality products. Look for suppliers who specialize in cranes and material handling equipment and have a strong reputation in the industry.

Key Indicators of a Trusted Supplier:

- Proven Experience: Established companies with years of experience in crane manufacturing.

- Quality Assurance: Manufacturers who use high-quality materials and maintain strict production standards.

- Reputation: Read reviews and case studies from previous clients to gauge customer satisfaction.

Certifications Matter - When purchasing a crane, it's essential to ensure that the manufacturer complies with international standards. ISO (International Organization for Standardization) and CE (Conformité Européenne) certifications are important indicators that the crane meets safety, performance, and environmental standards.

Why Certifications Matter:

- ISO Certification ensures that the manufacturer follows consistent and quality management practices.

- CE Certification guarantees that the product complies with EU safety and environmental requirements.

A supplier with these certifications provides additional peace of mind that you're investing in a reliable, safe, and high-performance crane.

Factors to Evaluate Suppliers

Customer Support and Warranty - Before making a purchase, ensure that the supplier offers strong customer support. This can be vital for troubleshooting, maintenance, and assistance during the installation process. Additionally, check if the supplier offers a comprehensive warranty to cover any defects or issues with the crane.

What to Look For:

- Responsive Customer Support: Access to a knowledgeable support team for troubleshooting.

- Comprehensive Warranty: Covers parts, labor, and repairs for a reasonable period.

- Post-Sales Service: Availability of after-sales service for ongoing maintenance and support.

Customization Options - Every operation is different, so the ability to customize an automatic bucket crane is a significant factor. Whether it's the bucket design, crane dimensions, or automation systems, ensure the supplier offers customization to meet your specific operational needs.

Customization Features to Consider:

- Bucket Size and Design: Tailored to handle specific materials (e.g., coal, scrap, cement).

- Crane Configuration: Options for different girder types, trolley systems, and hoists.

- Automation Features: Real-time monitoring, load sensors, and control systems tailored to your workflow.

Delivery Timelines - The lead time for receiving your crane is an important factor. If your operations are on a tight schedule, you'll want a supplier who can meet delivery deadlines. Ensure that the supplier can commit to reasonable delivery timelines and inform you of any potential delays upfront.

Finding the right place to buy automatic bucket cranes is about more than just price. Choose a reliable manufacturer with a solid reputation and relevant certifications like ISO and CE to ensure quality and safety. Be sure to evaluate factors like customer support, warranty, customization options, and delivery timelines before making a decision. By focusing on these aspects, you'll be better positioned to purchase a crane that meets your operational needs and delivers lasting performance.

Price Range and Budgeting

When purchasing an automatic bucket crane, it's crucial to understand the price range and factors that influence the overall cost. Proper budgeting ensures that you get a crane that meets your needs without breaking the bank. Below, we'll explore the key cost factors and how to approach budgeting for your purchase.

Understanding the Price Range

The cost of an automatic bucket crane can vary widely based on several factors. Below are the primary elements that influence pricing:

- Load Capacity - The weight that the crane can handle directly affects the price. Higher load capacities (e.g., 20 tons or more) require more powerful motors, robust structural components, and specialized design features, which can increase the cost.

- Bucket Type - The type of bucket used in the crane also impacts the price. Custom-designed clamshell buckets, orange peel buckets, or specialized buckets for handling scrap metal or coal typically cost more than standard buckets. Customizations for specific materials may also add to the cost.

- Automation Features - Cranes with advanced automation systems—such as real-time monitoring, anti-sway controls, and smart control systems—will cost more than those with basic manual or semi-automated functions. Automation increases precision, reduces labor, and enhances efficiency, but it also contributes to the price.

- Customization - If you need a crane designed to fit unique space constraints, specific load requirements, or environmental conditions (e.g., corrosion-resistant coatings), expect to pay a premium. Customization options tailored to your facility's needs often add additional costs to the base price.

Average Price Range:

- Low-Capacity Cranes (5-10 tons): $10,000 to $30,000

- Medium-Capacity Cranes (10-20 tons): $30,000 to $60,000

- Heavy-Capacity Cranes (20 tons and above): $60,000 to $150,000+

Note: Prices can vary depending on location, supplier, and specific customization requests.

How to Budget for Your Automatic Bucket Crane

Budgeting for an automatic bucket crane involves more than just considering the upfront cost. Here are a few tips to help align your budget with your material handling needs:

- Evaluate Your Material Handling Requirements - Start by clearly defining the material types and volumes you need to handle. For example, if you're handling heavy scrap metal or molten slag, you'll need a high-capacity crane with durable features, which will likely cost more. Understanding your operational needs upfront will help you choose a crane with the appropriate features without overspending.

- Account for Long-Term Costs - Beyond the initial purchase price, factor in long-term costs, including maintenance, electricity consumption, and potential upgrades (e.g., future automation systems). A cost-effective crane should not only meet your current needs but also remain efficient and reliable for years to come.

- Consider Future Expansion - If your operations may expand or evolve, plan for potential upgrades to your crane's capacity or automation features. Purchasing a crane with future scalability options may cost more initially but could save money in the long run.

- Get Multiple Quotes - Don't settle for the first price you see. Request quotes from several reputable suppliers, and be sure to compare prices, warranties, and service agreements. Suppliers may offer different pricing based on their own procurement and production processes, so shopping around is crucial.

Financing Options and Payment Terms

Many suppliers offer flexible financing and payment terms to make the purchase of an automatic bucket crane more manageable. Here are some common options:

- Leasing - Some suppliers offer leasing options where you pay a fixed amount over a set period. This can be a great way to spread out the cost, especially if you don't have the capital for an outright purchase.

- Installment Plans - Payment can often be split into monthly or quarterly installments, making it easier to manage cash flow. Be sure to ask about interest rates and fees associated with installment plans.

- Trade-in Programs - Some manufacturers allow you to trade in older cranes or equipment to offset the cost of a new purchase. If you have older equipment that is no longer efficient, this can reduce the total purchase price.

- Government and Industry Grants - Depending on your location and industry, there may be government grants or incentive programs available to support investments in automated equipment. Be sure to check for any relevant opportunities.

Purchasing an automatic bucket crane is a significant investment, but with the right budgeting and understanding of the price range, you can ensure that you're making a smart choice for your business. Focus on key factors like load capacity, bucket type, and automation features, and don't forget to plan for long-term costs and potential upgrades. Finally, explore financing options and payment plans to help manage your purchase effectively. By carefully considering these factors, you'll be able to invest in a crane that delivers long-term value and boosts your operational efficiency.

Customer Reviews and Case Studies

When buying an automatic bucket crane, customer feedback and real-world success stories play a crucial role in helping you make an informed decision. Seeing how other businesses have benefited from these cranes can provide valuable insight into the performance, reliability, and cost-effectiveness of the equipment. Below, we'll dive into customer testimonials and success stories to highlight how automatic bucket cranes have made a difference in material handling operations across various industries.

Customer Testimonials

Hearing directly from companies that have already invested in automatic bucket cranes can give you a clearer picture of what to expect. Here are some testimonials from different sectors that use these cranes:

- Mining Industry -

"We've been using an automatic bucket crane for over a year to handle our raw ore and coal. The efficiency of the crane has drastically reduced downtime, and the automation features have helped us avoid costly accidents. The real-time monitoring system provides us with the peace of mind that the crane is always working at optimal capacity."

— Mining Operations Manager, Australia - Steel Manufacturing -

"The automatic bucket crane we purchased has transformed our scrap metal handling process. The anti-sway technology has made lifting and placing metal scrap a lot smoother. We've reduced accidents on the floor and lowered labor costs. Plus, it's incredibly durable, even in our harsh environment."

— Production Supervisor, Steel Mill, USA - Waste Management -

"With our old system, we struggled to handle industrial waste efficiently. Since we switched to an automatic bucket crane, we've been able to sort and move waste materials much faster and more accurately. The crane's customized bucket design has proven effective for dealing with a variety of waste types."

— Waste Management Director, UK

Success Stories

Real-world case studies provide deeper insight into how automatic bucket cranes have improved operations. Here are a few success stories from businesses that have seen significant improvements:

Case Study 1: Steel Mill Efficiency Boost - Client: Large Steel Mill in China

Challenge: The steel mill needed to improve its scrap metal handling process, reduce labor costs, and increase safety.

Solution: The steel mill installed a heavy-duty automatic bucket crane with clamshell buckets designed for scrap metal handling. The crane was equipped with advanced automation features, including load sensors and anti-sway control systems.

Results:

- Reduced scrap metal spillage by 30%

- Decreased labor costs by 25% through automation

- Increased overall efficiency in material handling by 40%

- Improved safety record with fewer manual interventions

Testimonial:

"The automatic bucket crane has completely changed the way we handle scrap metal. The added safety and efficiency are game-changers. We're now able to handle more material with less labor." — Steel Mill Operations Manager

Case Study 2: Coal Handling Efficiency in Power Plant - Client: Coal-Fired Power Plant in India

Challenge: The plant was experiencing frequent delays in coal unloading and transfer, which led to production bottlenecks. The existing system was slow and prone to breakdowns.

Solution: The plant upgraded to an automatic bucket hoist crane with open winch trolleys for faster lifting speeds and better control. The crane was equipped with real-time monitoring systems and predictive maintenance technology.

Results:

- Increased coal unloading speed by 35%

- Reduced downtime by 20% due to predictive maintenance

- Improved coal storage and handling efficiency

- Enhanced safety with automated systems and reduced manual intervention

Testimonial:

"Upgrading to the automatic bucket crane has significantly sped up our coal handling process. The integration with our monitoring systems has also allowed us to minimize unplanned downtime, keeping our plant running efficiently." — Plant Manager

Case Study 3: Waste Handling in Recycling Facility - Client: Recycling Plant in Germany

Challenge: The plant struggled to handle a variety of recyclable materials, including metals, plastics, and paper. The existing cranes were not efficient enough to meet growing demand.

Solution: The plant installed an automatic bucket crane with specialized orange peel buckets for handling metal waste and clamshell buckets for paper and plastic materials. The crane was equipped with anti-sway technology and smart control systems.

Results:

- Increased material sorting efficiency by 50%

- Reduced waste contamination by 15% due to precise material handling

- Improved overall productivity by 30%

- Lowered maintenance costs due to the durable design and advanced monitoring systems

Testimonial:

"The automatic bucket crane has made a world of difference in how we handle recyclable materials. We're able to process a larger volume with better accuracy and far less downtime." — Recycling Operations Supervisor

Lessons Learned

From these testimonials and case studies, it's clear that automatic bucket cranes offer significant benefits across various industries. Some common lessons from these real-world applications include:

- Customization Matters: Tailoring the bucket type and crane features to suit specific material handling needs can lead to substantial improvements in efficiency and safety.

- Automation Is Key: Cranes with advanced automation and real-time monitoring systems offer superior control, precision, and reduced labor costs.

- Durability Is Crucial: Investing in a crane with high-quality, durable components leads to lower long-term maintenance costs and better performance, especially in harsh environments.

Customer reviews and success stories show that automatic bucket cranes provide tangible benefits, from enhanced efficiency to improved safety and cost savings. Whether you're in mining, steel manufacturing, or waste management, investing in these cranes can dramatically improve your material handling operations. By learning from the experiences of other companies, you can better understand how an automatic bucket crane can meet your specific needs and optimize your operations.

Conclusion

In summary, automatic bucket cranes are a powerful investment for any business involved in bulk material handling. These cranes improve operational efficiency and safety through automation, real-time monitoring, and precise material handling. Whether you're dealing with heavy-duty scrap metal in steel manufacturing or fine-grain materials in mining, these cranes offer significant advantages in terms of speed, safety, and cost-effectiveness.

Key benefits of purchasing automatic bucket cranes include:

- Increased Efficiency: Automation minimizes downtime and maximizes material handling speed.

- Enhanced Safety: Reduced human intervention lowers the risk of accidents and improves workplace safety.

- Cost Savings: Lower labor costs and predictive maintenance reduce long-term expenses.

Why Choose Automatic Bucket Cranes for Your Business

Investing in automatic bucket cranes can be a game-changer for your business, improving productivity while lowering operational costs. These cranes not only streamline material handling but also ensure precise control over the load, reducing material wastage and damage. With features like load sensors, anti-sway control, and customized bucket designs, these cranes offer flexibility for a variety of industries, from steel mills to recycling facilities.

Choosing automatic bucket cranes means investing in cutting-edge technology that positions your business for long-term growth and success. It's the right move for any company looking to stay competitive and efficient in today's fast-paced industrial environment.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch