Right-Sizing Your Overhead Bridge Crane

Discover how to right-size your overhead bridge crane, ensuring safety, efficiency, and cost savings by buying only what you truly need.

Category: Featured

Your Trusted Overhead Bridge Crane Manufacturer & Supplier

Right-Sizing Overhead Bridge Cranes: Smart, Safe, Cost-Effective

Tips Before You Buy an Overhead Crane – How to Save Money and Get the Right Crane

Why Properly Sizing Your Overhead Bridge Crane Matters

Choosing the right overhead bridge crane isn’t just about picking the heaviest or the biggest one on the market. Many plants make the mistake of assuming “bigger is better,” only to find themselves paying more upfront, using more energy, and dealing with higher maintenance costs. On the other hand, undersized overhead cranes can slow down your workflow, increase the risk of accidents, and sometimes even require a costly replacement sooner than expected.

Getting the sizing right from the start ensures that your indoor overhead crane—or any overhead crane you install—is efficient, safe, and cost-effective for your specific operation. It’s all about matching your crane to the actual needs of your plant, not to some theoretical maximum.

Why Oversized Cranes Can Be a Problem

- Higher Purchase Cost: A larger crane requires more steel, stronger motors, and often more expensive hoists.

- Increased Installation Requirements: Bigger cranes may need reinforced runway beams or higher ceilings, adding to construction costs.

- Energy Waste: Overpowered cranes use more electricity, which adds up quickly over time.

- Maintenance Burden: More components and higher loads mean more frequent servicing.

Risks of Undersized Cranes

- Workflow Bottlenecks: Lifting too little weight per cycle or having a slow hoist can slow production.

- Safety Concerns: Operating close to maximum capacity constantly increases the risk of mechanical failure or accidents.

- Frequent Upgrades: You may end up needing to replace or supplement the crane sooner than planned, leading to higher long-term costs.

The Sweet Spot: Right-Sized Overhead Cranes

- Meets your plant’s load and span requirements without excess.

- Operates efficiently with optimal energy use.

- Minimizes maintenance and reduces downtime.

- Provides flexibility for future changes in production or layout.

Investing time in figuring out the correct overhead bridge crane size—whether it’s for an indoor overhead crane or a larger production facility—pays off in safety, efficiency, and cost savings. A crane that fits your operation just right works harder, lasts longer, and keeps your team moving without frustration.

Assessing Your Lifting Requirements for Overhead Cranes

Before you even start looking at models or suppliers, you need a clear picture of what your bridge crane will actually be lifting. This step is all about understanding the demands of your operation—what you lift, how often, and under what conditions. Skipping this step can lead to buying a crane that either struggles to keep up or costs way more than necessary.

Maximum Load Capacity

The first question is simple: how heavy is the heaviest item your crane will lift? But here's the thing—it's not just about the single heaviest load. You also need to consider:

- Safety margins: cranes should handle slightly more than the heaviest load, usually 10–20% extra.

- Combined loads: if multiple items are lifted at once, include their total weight.

- Attachments: hooks, magnets, or lifting clamps add extra weight that matters.

Knowing your exact load requirements ensures your overhead cranes—or your indoor overhead crane—won't be underpowered or overbuilt.

Lifting Frequency and Duty Cycle

Not all lifts are equal. Some items are lifted once a day; others are moved dozens of times per hour. This affects the crane's duty cycle, which is basically how hard the crane works over time.

- High-frequency lifting: choose a crane with a robust motor and hoist rated for continuous use.

- Low-frequency lifting: you might save money by picking a lighter-duty bridge crane.

- Speed considerations: lifting speed impacts workflow. Faster hoists can improve productivity but may cost more upfront.

Future Growth

Your production needs might change over time. Maybe your plant will start handling heavier materials, or you'll need to move more items simultaneously. Thinking ahead can save you a lot of trouble later.

- Consider cranes that can be upgraded with stronger motors or additional trolleys.

- Plan runway layouts that can accommodate a slightly larger span if needed in the future.

- Don't oversize unnecessarily—right-sizing with future flexibility is the key.

Material Characteristics

Different materials behave differently when lifted. Your bridge crane needs to handle them safely and efficiently. Consider:

- Shape: long slabs, coils, or irregular machinery might require special hooks or clamps.

- Temperature: hot or cold materials may need heat-resistant components.

- Surface condition: oily, wet, or rough surfaces affect gripping methods.

- Fragility: delicate items require precise handling to avoid damage.

Taking all these factors into account ensures your overhead cranes meet real operational needs. It's not just about lifting weight—it's about lifting smartly, safely, and efficiently.

Selecting the Right Type of Overhead Bridge Crane

Once you know what you need to lift and how often, the next step is choosing the right type of overhead bridge crane. The right choice affects installation costs, workflow efficiency, maintenance, and long-term reliability. Let’s break down the main options.

Single Girder vs. Double Girder

Indoor overhead cranes come in single and double girder designs, and each has its strengths.

- Ideal for lighter loads, typically up to 20 tons.

- Less expensive to purchase and install.

- Lower maintenance due to fewer components.

- Easier to install in buildings with lower ceilings.

- Better for heavy loads, often exceeding 20 tons.

- Offers higher lifting heights, thanks to trolley riding on top of the main girders.

- More stable and durable under frequent heavy-duty operations.

- Slightly higher initial cost and more complex installation.

Choosing between the two depends on your load, lifting height, and available building space.

Top-Running vs. Under-Running Overhead Cranes

The way your crane moves along the runway affects installation and maintenance.

- Wheels ride on top of the runway beams.

- Typically used for larger spans and heavier loads.

- Require stronger runway structures.

- Wheels run under the runway beams.

- Easier and cheaper to install in smaller workshops.

- Usually limited to lighter loads and shorter spans.

Decide based on your building structure, load, and space constraints.

Specialty Cranes

Sometimes your operation has unique needs. Specialty cranes can handle challenging environments:

- Explosion-Proof Cranes: For hazardous indoor areas with flammable gases or dust.

- Outdoor Cranes: Built to withstand rain, wind, and temperature fluctuations.

- Customized Cranes: Designed for unusual loads or confined spaces.

These cranes can cost more upfront, but they keep your operation safe and efficient.

Trolley and Hook Options

The way you lift and move materials depends on trolley and hook configuration:

- Single Hook: Suitable for general-purpose lifting of standard loads.

- Multiple Hooks or Dual Trolleys: Allows lifting multiple items at once or very long loads.

- Special Attachments: Magnets, clamps, or spreader bars can improve handling efficiency.

Choosing the right trolley and hook setup ensures smooth workflow and reduces unnecessary handling time.

Selecting the right type of overhead bridge crane for your indoor operation isn’t just about picking a model from a catalog. It’s about matching the crane type to your load, workshop space, and workflow needs. When done right, it saves money, increases safety, and keeps your operation moving without interruptions.

Common Mistakes When Buying Overhead Cranes

Even experienced plant managers sometimes make costly mistakes when purchasing overhead cranes. Knowing what to avoid can save you time, money, and headaches down the road.

Oversizing the Crane

Many buyers think that a bigger crane automatically means safer and more capable operations. That’s not always the case. Oversizing can lead to:

- Higher upfront costs: Larger motors, girders, and hoists increase purchase and installation expenses.

- Higher energy consumption: Bigger cranes use more power even for standard lifts.

- Structural upgrades: Your building or runway may need reinforcement to handle the extra weight, adding construction costs.

A right-sized bridge crane meets your operational needs without unnecessary extras.

Excessive Span or Lifting Height

Buying a crane with a longer span or higher lifting capacity than needed might sound “future-proof,” but it often turns into wasted investment:

- Increased material costs for girders and trolleys.

- More complex installation and alignment.

- Unnecessary stress on the building structure.

Measure your workspace carefully and design the crane to match actual operational requirements.

Ignoring Maintenance Requirements

Some buyers focus only on the initial price and overlook long-term upkeep. Complex cranes can lead to:

- Increased downtime: More moving parts mean more potential failures.

- Higher service costs: Special components and hoists may require expensive repairs.

- Shortened crane lifespan: Poorly planned maintenance reduces efficiency and reliability.

Selecting a simpler, right-sized crane often results in lower maintenance needs and smoother day-to-day operation.

Avoiding these common mistakes ensures your overhead cranes deliver the performance you need without unnecessary costs or risks. The key is balance: choose a bridge crane that fits your operation, not the one that looks “impressive” on paper.

Cost-Saving Strategies for Overhead Bridge Cranes

Buying an overhead bridge crane is a big investment, so it's smart to think beyond the sticker price. A well-planned purchase can save you thousands over the crane's lifetime. Here's how to make the most of your budget while getting the right crane for your operation.

Use Accurate Load Calculations

Don't guess when it comes to weight. Base your crane's capacity on actual loads, not estimates.

- Include the heaviest single item and any combined loads.

- Factor in lifting attachments like hooks, clamps, or spreader bars.

- Add a safety margin—usually 10–20% above your maximum load.

Accurate calculations prevent oversizing, save money, and ensure safe operation for your overhead cranes.

Choose Modular or Standard Indoor Overhead Cranes

Modular and standard designs are often more cost-effective than fully customized cranes.

- Less expensive upfront due to standardized components.

- Easier and faster to install.

- Maintenance is simpler because spare parts are widely available.

This approach works especially well for indoor overhead cranes with predictable lifting needs.

Plan for Future Scalability

Your needs may grow, but that doesn't mean buying the largest crane now.

- Design runways and building space to allow for future upgrades.

- Select cranes that can handle slight increases in load or span without a full replacement.

- Focus on flexibility, not maximum possible capacity.

Compare Quotes Carefully

The lowest price isn't always the best deal. Look at the full package:

- Installation costs and time.

- Warranty coverage and duration.

- Availability of service packages and spare parts.

A slightly higher initial cost can save money over time if the crane is easier and cheaper to maintain.

Evaluate Total Cost of Ownership

Think beyond the purchase price. Long-term costs include:

- Energy consumption: heavier cranes use more electricity.

- Maintenance: labor, spare parts, and downtime.

- Operational efficiency: slower or underpowered cranes can impact productivity.

By focusing on total cost of ownership, you ensure your overhead bridge crane delivers value for years to come.

Pre-Purchase Checklist for Your Overhead Bridge Crane

Buying an overhead bridge crane is more than just picking a model and signing a purchase order. A careful pre-purchase review helps avoid costly mistakes and ensures your crane meets the demands of your facility. Whether it’s an indoor overhead crane or a heavier industrial bridge crane, taking the time to confirm critical details upfront can save headaches down the line.

Before you finalize your order, check the following key points:

- Confirm maximum load and safety margin

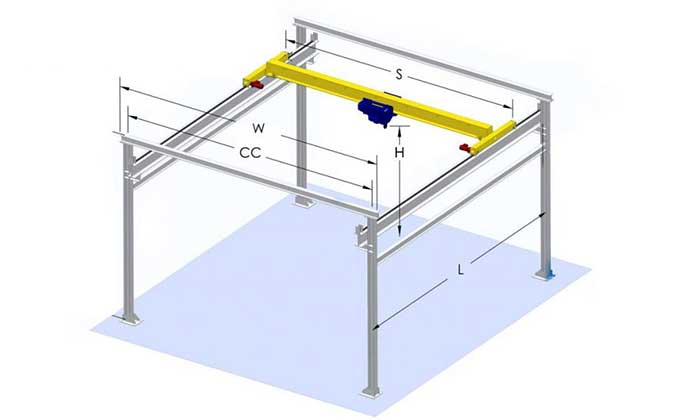

Always calculate the heaviest item your crane will lift, including any attachments such as hooks, clamps, or spreaders. A safety margin—typically 10–20% above your maximum load—is essential to protect your operators and extend the life of the crane. - Verify span, runway length, and hook requirements

Make sure the crane covers the entire work area without obstruction. Check that the runway length allows smooth travel and that the hook height and reach can handle all lifting points safely. Proper measurements prevent operational bottlenecks and reduce the risk of accidents. - Check power supply compatibility and control system options

Confirm that voltage, phase, and frequency match your facility’s power setup. Consider the most efficient and safe control method for your workflow, whether it’s a pendant, radio remote, or cabin control system. This ensures the crane operates reliably and safely from day one. - Inspect installation conditions (indoor vs. outdoor, environmental factors)

Environmental conditions can affect crane performance and durability. Indoor overhead cranes may need dust or moisture protection, while outdoor cranes require weatherproofing. Ensure your building structure—including ceiling height and runway beams—can safely support the crane. - Ask about warranty, service, and spare parts availability

Long-term support matters. Clarify warranty terms, coverage, and duration. Confirm service packages, technician availability, and spare part accessibility to minimize downtime and keep operations running smoothly.

Going through this checklist carefully helps you select an overhead bridge crane that fits your operational needs, maximizes efficiency, and reduces unexpected costs. A well-matched crane not only performs better but also lasts longer, making your investment more worthwhile over time.

Conclusion

Choosing the right overhead bridge crane is about more than just lifting capacity or flashy specifications. Buying the biggest crane “just in case” often leads to unnecessary costs, higher energy use, and more complex maintenance. The smartest approach is to select a crane that fits your actual operational needs—whether it’s an indoor overhead crane in a compact workshop or a larger overhead crane for heavy industrial loads.

Key Takeaways:

- Buy the Right Crane, Not the Biggest: Focus on matching crane capacity, span, and features to real workflow requirements.

- Consult Crane Specialists: Expert guidance helps confirm proper sizing, duty classification, and attachment options for safe and efficient operation.

- Prioritize Safety, Efficiency, and Long-Term Savings: A well-sized overhead bridge crane reduces operational risks, minimizes energy consumption, and lowers maintenance costs over time.

Investing time and planning into the selection of your overhead cranes ensures your facility runs smoothly, safely, and cost-effectively. Right-sizing isn’t just a smart choice—it’s the foundation for reliable performance and long-term return on investment.

Related Products

Affordable 10 ton double girder overhead crane with CD/MD hoist trolley, built for U.S. standards, ideal for construction and industrial lifting

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch