Fixed-Height Aluminum Portable Gantry Crane: A User's Guide

Learn how to safely set up, operate, maintain & troubleshoot your fixed-height portable aluminum gantry crane 1 to 5 ton with this practical user guide.

Category: Featured

Your Trusted Portable Gantry Crane Manufacturer & Supplier

Fixed-Height Aluminum Portable Gantry Crane Guide

etup, Safety & Success – An Essential User Manual

Introduction

What Is a Fixed-Height Aluminum Gantry Crane?

A fixed-height aluminum gantry crane is a portable lifting system made mostly from aluminum. It consists of two upright support legs connected by a horizontal I-beam at the top. This beam holds a hoist and trolley, which are used to lift and move heavy items along the beam.

The "fixed-height" part means the vertical supports do not adjust. The height is set and doesn't change during use. This design gives the crane added stability while keeping the structure lightweight.

Unlike large overhead cranes that are fixed in one place, this type of gantry crane is mobile. You can wheel it to where you need it and use it right away.

These cranes come in different capacities—many models lift anywhere from 500 kg to 3 tons—and are ideal for short-term jobs or locations where installing permanent equipment isn't possible.

Who Should Use This Guide?

This guide is made for people who work with lifting tasks in various settings. Whether you're in a shop, a factory, or out in the field, this crane can help make your job easier.

Here are some typical users:

- Workshop users

Mechanics or technicians who need to lift engines, gearboxes, or other machinery. - Facility maintenance teams

Workers responsible for maintaining large equipment, HVAC systems, or electrical cabinets in factories or commercial buildings. - Field service technicians

People who go to different sites to repair or install heavy parts, especially when larger cranes aren't available. - Rental users or first-time buyers

Those who rent or purchase a gantry crane for occasional use and need a basic understanding of how to use it safely.

Even if you've never used a gantry crane before, don't worry—this guide breaks it all down in simple steps.

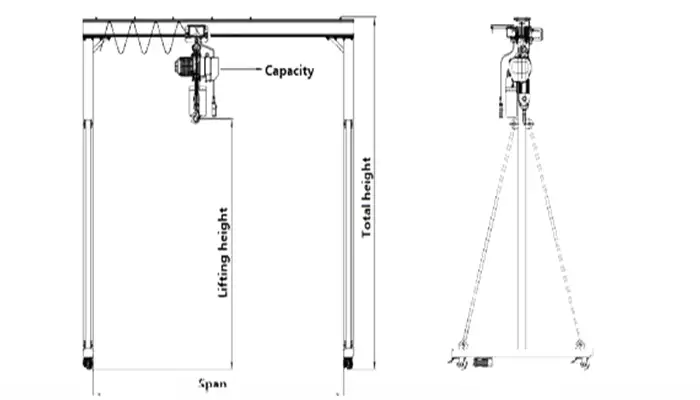

Fixed-Height Aluminum Portable Gantry Crane Drawing

Why Choose a Fixed-Height Aluminum Gantry Crane?

There are many reasons this crane is a favorite for professionals in different industries. Here's why people like it:

- Lightweight, yet strong

Aluminum makes the crane much easier to handle than steel models. But it's still strong enough to lift heavy items like motors, pumps, or dies. - Portable and mobile

Most models come with wheels (casters), so you can roll the crane around a shop or job site. It fits through standard doorways, and in some cases, even into service vans. - Quick setup and teardown

You don't need special tools or skills to assemble it. Many users can put it together in 15–30 minutes. When you're done, you can take it apart and store it without taking up much space. - Works in tight spaces

Because it doesn't need a permanent foundation or extra floor supports, you can use it in garages, service bays, or small warehouses. - Cost-effective

Compared to permanent cranes, this type is much more affordable. It's a good option if you need flexible lifting but don't want to invest in expensive infrastructure.

If you need a crane that's easy to move, simple to use, and doesn't take much to set up, this might be the right one for you.

| Item No. | Rated Load (ton) | Total Height (mm) | Max. Lifting Height (mm) | Outside Span (mm) | Inner Span (mm) | Height (mm) |

|---|---|---|---|---|---|---|

LT-1 Fixed Height Aluminum Gantry Crane | 0.5 | 3000 | 2420 | 2000 | 1880 | 460 |

| 0.5 | 3000 | 2420 | 3000 | 2880 | 460 | |

| 0.5 | 4000 | 3420 | 3000 | 2880 | 460 | |

| 0.5 | 4000 | 3420 | 4000 | 3880 | 460 | |

| 1 | 3000 | 2470 | 2000 | 1880 | 410 | |

| 1 | 3000 | 2470 | 3000 | 2880 | 410 | |

| 1 | 4000 | 3470 | 3000 | 2880 | 410 | |

| 1 | 4000 | 3470 | 4000 | 3880 | 410 | |

| 2 | 3000 | 2215 | 2000 | 1800 | 535 | |

| 2 | 3000 | 2215 | 3000 | 2800 | 535 | |

| 2 | 4000 | 3215 | 3000 | 2800 | 535 | |

| 2 | 4000 | 3215 | 4000 | 3800 | 535 | |

| 3 | 3000 | 2122 | 2000 | 1800 | 685 | |

| 3 | 3000 | 2122 | 3000 | 2800 | 685 | |

| 3 | 4000 | 3122 | 3000 | 2800 | 685 | |

| 3 | 4000 | 3122 | 4000 | 3800 | 685 |

Fixed-height Aluminum Gantry Crane Components

Before you start using your fixed-height aluminum gantry crane, it's important to know what each part does. Understanding how everything fits together helps with setup, safety, and long-term use.

Here's a breakdown of the main components you'll find on a typical fixed-height aluminum portable gantry crane.

main girder of Aluminum Gantry Crane 1 ton

Aluminum Girder of Small Gantry Crane 1 ton

Supporting legs of Aluminum Gantry Crane 1 ton

Ground beam and rollers of aluminum portable gantry crane 1 ton

Side Frames

These are the vertical legs on each end of the crane. They're the main supports that hold up the entire structure.

- What they do: Side frames hold the I-beam at a set height and provide the base for the wheels or casters.

- Construction: Most are made of aluminum, with bracing or cross-supports for added strength and stability.

- Note: Some side frames come in foldable or knock-down designs to make transport and storage easier.

I-Beam or Cross Beam

This is the horizontal beam that spans across the top between the side frames. It's the part that carries the load.

- What it does: The trolley (which carries the hoist) runs along this beam. The beam must be strong and straight.

- Material: Typically aluminum to keep the crane lightweight.

- Important tip: The beam size affects how much weight the crane can lift and how far the trolley can travel.

Casters or Wheels

Each leg usually has a caster wheel at the bottom, making the crane mobile.

What they do: Casters allow you to roll the crane into position.

Features to look for:

- Swiveling wheels for better maneuverability

- Locking brakes to keep the crane steady while lifting

- Non-marking wheels for indoor use on finished floors

Trolley and Hoist (if applicable)

These parts may come with your crane or be sold separately.

- Trolley: This is a wheeled device that rolls along the I-beam. It carries the hoist and allows the load to move side to side.

- Hoist: The lifting mechanism. It can be manual (chain block), electric, or pneumatic.

- Note: Be sure the trolley and hoist are rated for the crane's capacity and beam size.

Connection Hardware and Safety Pins

These are the bolts, pins, and locking parts that hold everything together.

What they do: They connect the I-beam to the side frames and lock the structure into place.

Why they matter: Without these secure connections, the crane may be unsafe.

Typical items include:

- Bolts and nuts

- Safety locking pins

- Washers or brackets to keep parts aligned

Always double-check that every pin and bolt is in place and tightened before using the crane.

Optional Accessories and Add-Ons

Depending on your work and environment, you may choose to add a few extras to get better performance or convenience.

- Adjustable trolleys – To fit different beam widths

- Lifting slings or spreader bars – To handle wider or awkward loads

- Leveling jacks – For use on uneven floors or outdoors

- Grounding straps – For working in sensitive or spark-risk environments

- Push or powered trolleys/hoists – For faster or easier lifting

- Storage kits or travel cases – To keep parts organized when the crane is not in use

Each of these parts plays a key role in keeping your crane safe, stable, and easy to use. In the next section, we'll walk through the setup process step by step—so you can get started with confidence.

Safety Guidelines Before Setup

Before setting up your fixed-height aluminum gantry crane, safety should be your top priority. It's crucial to ensure both the equipment and environment are prepared to avoid accidents or damage. Here's a checklist to guide you.

What Personal Protective Equipment (PPE) to Wear

Always wear the appropriate protective gear when working with cranes. Safety is key!

- Safety boots with steel toes to protect your feet from heavy objects.

- Hard hats to protect your head from falling objects or accidental bumps.

- Gloves to give you a better grip on the crane parts and prevent hand injuries.

- High-visibility clothing if you're working in a busy area, so you're easily seen by others.

- Eye protection if you're handling or installing parts that could cause debris or dust.

Proper PPE minimizes the risk of injury, especially when lifting and moving heavy loads.

Understanding Load Limits and Rated Capacity

Each gantry crane has a specific load capacity that shouldn't be exceeded. Exceeding this weight can cause equipment damage or even failure.

- Rated Capacity: This is the maximum weight the crane can safely lift. Make sure you know the exact weight rating of your crane.

- Spread the load evenly: Always distribute the weight across the entire crane to prevent tipping or stressing the frame.

- Know the load before lifting: Weigh or estimate the load carefully before you start lifting.

- Avoid overloading: Never try to lift anything that exceeds the rated capacity of the crane, even if it seems manageable.

Checking for a Flat and Stable Surface

A solid foundation is essential for safe operation.

- Level ground: The crane should be placed on a flat surface to avoid tipping. Use a spirit level to check if the ground is even.

- Stable surface: Ensure that the surface can support the crane's weight. Concrete or hard-packed dirt is usually ideal. Avoid soft or uneven ground.

- Surface condition: Check for cracks or holes that could affect stability, especially when the crane is in motion.

A firm, level surface prevents accidents and ensures smooth movement of the crane.

Reviewing the Environment for Wind, Weather, or Obstructions

Your work environment can affect crane performance and safety. Before setting up, evaluate the area carefully.

- Wind: Wind can affect stability, especially when lifting heavy or suspended loads. Avoid using the crane in strong winds (check your local wind conditions).

- Weather: Don't operate the crane in wet conditions where the surface is slippery. Rain, snow, or ice could make the crane unstable or affect traction.

- Obstructions: Clear the area of any obstacles or hazards like overhead wires, walls, machinery, or people. Make sure there's enough space to safely move the load.

- Power lines: Always ensure the crane doesn't come too close to electrical wires, as they can cause electrical hazards. Maintain a safe distance.

Checking the environment beforehand ensures safe and smooth operation.

Step-by-Step Setup Instructions

Setting up your fixed-height aluminum gantry crane correctly is essential for safe operation. Follow these simple steps carefully to get your crane ready for use.

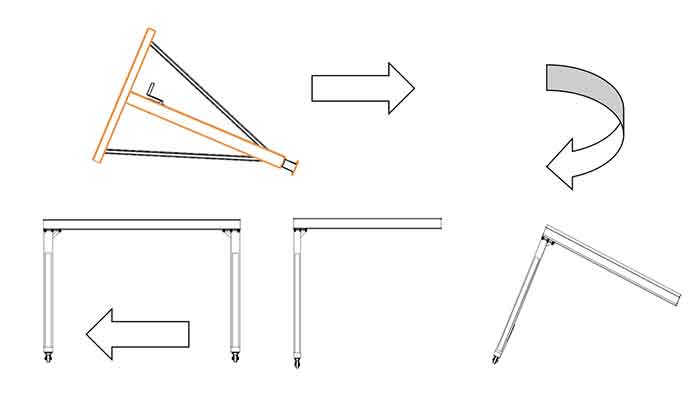

small gantry crane assembly method 1

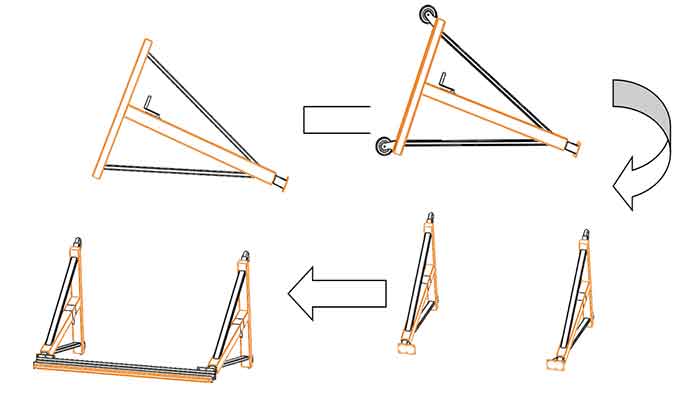

assembly method 2 of small aluminum gantry crane

How to Unpack Your Crane Properly

Unpacking your crane is the first step to ensure all components are intact and ready for assembly.

- Check the packaging: Look for any visible damage to the box or packaging before opening. If you see any signs of damage, report it to the supplier immediately.

- Unbox carefully: Cut the packing straps or tape and remove the packaging. Take care not to damage any of the crane parts with sharp objects.

- Lay out the components: Spread out all parts in a clear, organized area. You should have:

Side frames, I-beam or cross beam,Casters/wheels,Trolley and hoist (if included),Connection hardware and safety pins, etc. - Check the inventory: Use the parts list or assembly manual to confirm that all components are present. If anything is missing, contact the supplier immediately.

Assembling the Crane Frame by Positioning the Side Legs

Now, let's start with the frame assembly.

- Position the side frames: Lay the side frames on the ground, ensuring they're oriented correctly according to the assembly instructions.

- Align the legs: Each leg should be placed in its corresponding position to create a stable base. The side frames typically have pre-drilled holes for easy attachment.

- Attach the crossbars: If your crane has crossbars, secure them to connect the side frames and form the basic frame structure. Tighten the bolts or screws firmly to avoid any wobbling.

- Double-check alignment: Make sure the side frames are evenly spaced and aligned, so the crane stands straight.

Attaching and Securing the I-Beam

Next, you'll attach the I-beam (also known as the cross beam), which is crucial for lifting operations.

- Position the I-beam: Lift the I-beam onto the top of the side frames. Make sure the beam is centered between the side frames.

- Secure the I-beam: Attach the I-beam to the side frames using the provided bolts or pins. Ensure they're tightly secured to prevent any movement during lifting.

- Tighten all connections: Double-check all nuts and bolts holding the I-beam in place. Use a wrench to tighten them to the specified torque to ensure they're firmly in place.

Locking the Casters and Checking Overall Stability

The casters or wheels are important for mobility, so you must secure them properly.

- Attach the casters: Depending on your crane model, the casters may need to be attached to the bottom of the side frames. Position them securely and use bolts or pins to fasten them.

- Lock the casters: Once the casters are in place, lock them to prevent unwanted movement during operation. Most casters have a locking mechanism that prevents rolling.

- Check stability: Before moving the crane, ensure it is stable. Push gently on each side to confirm it stands evenly and doesn't tip. If it feels wobbly, adjust the caster locks.

Attaching the Trolley and Hoist (if Included)

If your crane comes with a trolley and hoist system, now's the time to install them.

- Position the trolley: Place the trolley onto the I-beam, ensuring the wheels sit evenly on the beam's track.

- Secure the trolley: Lock the trolley in place using the provided hardware. Some trolleys come with adjustable features to fine-tune the fit.

- Attach the hoist: If you have a hoist, lift it and secure it onto the trolley. Follow the manufacturer's guidelines to connect the hoist to the trolley properly.

- Check movement: After securing the hoist and trolley, test the movement along the I-beam. It should glide smoothly without resistance. If there's any jerking or uneven motion, recheck the installation.

Final Safety Inspection Before First Use

You're almost ready to use your crane! But before lifting anything, perform a thorough safety check.

- Check all bolts and connections: Go over every bolt, pin, and connection on the crane, including the frame, I-beam, casters, and hoist system. Ensure everything is tight and secure.

- Inspect the load limits: Confirm that the weight of any loads you plan to lift is within the rated capacity of the crane.

- Test the movement: Move the trolley and hoist up and down along the beam to make sure everything operates smoothly.

- Look for any damage: Inspect the crane for any signs of damage during assembly, such as bent beams or cracked parts. If you find any issues, do not use the crane until repairs are made.

- Final check of safety pins and locking mechanisms: Make sure all safety pins are in place, and any locks are secure.

- Ensure the area is clear: Before lifting, double-check that the workspace is free of obstructions or people.

With your crane fully assembled and safety checks complete, you're ready to begin lifting safely and efficiently. Always remember, safety first!

Operating the Crane

Operating a fixed-height aluminum gantry crane requires care and attention. Let's break down the key points to keep in mind for safe and efficient operation.

Moving the Crane Safely

Unloaded Crane:

- Unlock the casters and move the crane to the desired location.

- Tip: Push in the direction of the wheels for smoother movement. Avoid dragging it sideways to prevent damaging the wheels.

Crane with Load:

- Don't push the crane when it's under load. Always use the trolley to move the load along the beam.

- Locking casters: Ensure the casters are locked before lifting a load. This will prevent unwanted movement while the load is suspended.

Remember: Move slowly and cautiously, especially when the crane has a load suspended. Always keep the load balanced.

Lifting and Lowering Heavy Items

Lifting:

- Check the load: Make sure the load doesn't exceed the crane's rated capacity.

- Smooth, steady lift: Lift the load slowly to avoid sudden jerks that could destabilize the load.

- Tip: Gently engage the hoist and avoid sharp movements when raising the load.

Lowering:

- Lower the load slowly to prevent any sudden drops or damage.

- Check load alignment: Keep the load centered and aligned while lowering it to avoid tilting or swinging.

- Tip: Never drop the load quickly. Always take your time to ensure safe lowering.

Keeping Loads Centered and Balanced

- Positioning: Make sure the load is directly under the center of the beam.

- Use a spreader bar: For wider loads, a spreader bar can help distribute the weight evenly and maintain balance.

- Check frequently: As the load rises, make sure it stays centered. If it shifts, lower the load and adjust it before lifting again.

Key Point: Keeping the load centered minimizes strain on the crane and ensures safer lifting.

Preventing Swinging or Tilting

- Steady movements: Avoid sudden starts or stops while lifting or lowering the load. Jerking the crane could cause the load to swing uncontrollably.

- Slow travel: When moving with a suspended load, keep the movement slow and controlled. This prevents the load from swaying or tilting.

- Stop if swinging: If the load starts to swing, stop the crane and wait for the load to settle before continuing.

Remember: Always ensure the load remains stable and never allow it to swing or tilt during operation.

Special Care for Outdoor Use

Weather Conditions:

- Wind: Strong winds can make it difficult to control the load. Always avoid using the crane when the wind is too strong.

- Rain and snow: Wet conditions can make surfaces slippery. Make sure the area is dry and clear of ice before use.

Surface Considerations:

- Check the ground: Ensure the ground is level and stable, whether it's gravel, grass, or pavement. An uneven surface can cause instability.

- Lock the casters: When not moving, lock the casters in place to prevent accidental movement, especially in outdoor environments.

Protect the Crane:

- Cover the crane: If the crane is exposed to harsh weather, use a protective cover to shield it from rain, snow, or sunlight.

- Regular inspection: Outdoor exposure can cause wear over time. Make sure to regularly inspect the crane for any damage or wear from the elements.

Best Practices and Common Mistakes

When operating a fixed-height aluminum gantry crane, safety and smooth operation are paramount. Let's go over the key things you should always do and also highlight some common mistakes to avoid.

Best Practices for Safety and Smooth Operation

Regular Inspections:

- Before each use, always inspect the crane to make sure all components are in good condition, including the frame, casters, and hoist mechanism.

- Check the trolley and hoist for smooth operation and ensure there are no obstacles that could interfere with the movement.

Secure the Load:

- Always center the load on the beam to keep the crane balanced.

- Use proper lifting techniques, such as starting slowly to ensure the load is stable before lifting or lowering.

- Tie-downs: If the load is not stable, consider using tie-downs to secure it.

Limit Load Weight:

- Never exceed the crane's rated capacity. This is crucial for preventing accidents and damage.

- Use the crane's load chart to ensure you're within the safe lifting limits.

Proper Use of Casters:

- Lock the casters whenever the crane is in use. This prevents accidental movement, especially when lifting or lowering loads.

- When moving the crane, make sure you unlock the casters only when necessary and push the crane slowly.

Clear the Area:

- Always ensure that the area around the crane is clear of obstructions. This includes both overhead and ground-level obstacles.

- Keep the work zone free of people and objects that could be in the crane's path.

Common Mistakes Users Should Avoid

Exceeding Load Capacity:

- Don't overload the crane. This is the most dangerous mistake you can make. Always check the rated capacity before lifting anything.

- Even if the load seems manageable, the crane's stability is compromised when you exceed its limits.

Using on Uneven Ground:

- Never operate the crane on uneven or unstable surfaces. It can lead to tipping or destabilizing the crane.

- Always check for level ground and make sure the crane stands firm. If the ground is uneven, adjust the crane's positioning or find another place with a stable surface.

Ignoring Safety Gear:

- Don't skip wearing PPE (personal protective equipment) like gloves, hard hats, and safety shoes when operating the crane.

- Safety equipment helps protect you from potential accidents, especially when lifting heavy items.

Not Checking Wind Conditions:

- Don't operate the crane in strong winds. Wind can cause the load to swing, making it harder to control.

- Always check weather conditions before using the crane outdoors. If the wind picks up unexpectedly, it's safer to stop operation until it calms down.

Rushing the Operation:

- Take your time. Rushing through the setup, operation, or lowering of the load can lead to mistakes.

- Always make sure every step is performed carefully. A calm, methodical approach ensures better safety and smoother operations.

Forgetting Final Checks:

- Always conduct a final safety check before lifting the load, even if everything seems in order.

- Check the load's stability, the trolley movement, and make sure all locking mechanisms are secure.

Maintenance and Inspection

To keep your Fixed-Height Aluminum Gantry Crane in excellent working condition and ensure safety during use, regular maintenance and inspections are key. Here's what you need to know about how to care for your crane.

Recommended Inspection Schedule

A solid inspection routine is essential to ensure your crane operates smoothly and safely.

Daily Inspections: Before every use, do a quick visual check of the crane's main components:

- Side frames for cracks or damage.

- Wheels to ensure they are intact and turn smoothly.

- Trolley and hoist mechanism for smooth operation.

Weekly Inspections: Perform a more thorough inspection weekly or after heavy use:

- Check bolts, fasteners, and connection hardware for tightness and wear.

- Inspect casters and lock mechanisms to ensure they function properly.

- Lubricate the wheels and moving parts to prevent rust and ensure smooth motion.

Monthly Inspections: Once a month, take a deeper look:

- I-beam: Check for any signs of bending or wear.

- Inspect the trolley rails for any misalignment or obstacles that could interfere with the movement.

- Look for signs of corrosion on all parts, especially if the crane is used in outdoor environments or high-humidity areas.

Annual Inspections: At least once a year, have a professional technician perform a detailed inspection to check for:

- Stress fractures or damage to the frame or structural components.

- Thoroughly check all safety pins and load-bearing components.

- Ensure overall alignment and load limits are within safe operating range.

Parts to Check Regularly

Regular inspection of key components will ensure the crane remains safe and functional. Here's what to pay attention to:

- Ensure that the wheels rotate smoothly and show no signs of excessive wear or cracking.

- Check the locking mechanisms on the casters to ensure they work effectively, especially when the crane is in use.

Bolts and Fasteners:

- Tighten any loose bolts, nuts, or screws to prevent the frame from shifting during use.

- Regularly check for any signs of rust or corrosion that could weaken these parts.

Connections and Safety Pins:

- Inspect safety pins and quick release pins to ensure they are secure and functional.

- Check that all connections (like beams and legs) are properly aligned and securely fastened.

I-Beam and Rails:

- Make sure the I-beam is free of dents or cracks that could compromise its strength.

- Look for any misalignments in the rails, which could affect the movement of the trolley.

Trolley and Hoist:

- Check for smooth operation and test the lifting mechanism to ensure it isn't blocked or malfunctioning.

- Inspect the hoist chain or rope for signs of wear, and replace it if fraying is evident.

Cleaning Tips and How to Store the Crane Properly

To prolong the life of your gantry crane, it's important to clean and store it correctly:

Cleaning the Crane:

- Dust and dirt: Wipe down all parts with a soft cloth or brush to remove dirt, dust, or debris.

- Avoid harsh chemicals that could damage the finish or corrode components.

- For metal parts, use a gentle non-abrasive cleaner. If used outdoors or in high-humidity areas, inspect for signs of rust and treat with anti-corrosion spray if necessary.

Storing the Crane:

- When not in use, store the crane indoors in a dry, well-ventilated area to prevent corrosion.

- Avoid stacking heavy objects on top of the crane, as it could cause damage to the frame or casters.

- If storage outdoors is unavoidable, cover the crane with a weather-resistant tarp to protect it from rain, snow, or direct sunlight.

Signs That Professional Service May Be Needed

While regular maintenance and inspections can address many issues, some problems may require professional service:

- Excessive Wear or Damage: If you notice significant damage to any major components like the side frames, I-beam, or trolley that cannot be fixed through regular maintenance, it's time to call a technician.

- Unusual Noises or Movements: If the crane starts making strange sounds or the trolley moves unevenly, this may indicate mechanical issues that require professional attention.

- Inconsistent Lifting Performance: If the crane begins to struggle lifting the rated capacity or shows sluggish movement, it may point to internal issues with the hoist mechanism or the trolley system.

- Frame Instability: If the crane feels unstable during use, even after ensuring it's on a level surface, it's important to have a professional check the structural integrity of the frame and connections.

- Visible Cracks or Structural Damage: Any cracks, bends, or deformations in the frame or beam structure should be inspected immediately by a qualified technician. Using the crane under such conditions could lead to dangerous failure.

Maintaining your fixed-height aluminum gantry crane is essential for ensuring its longevity and safe operation. By sticking to a regular inspection schedule, paying close attention to key components, cleaning and storing the crane correctly, and knowing when to seek professional service, you'll keep the crane in excellent shape for years to come.

Troubleshooting: Solving Common Crane Issues

Crane issues can happen, but with the right steps, they're easy to handle. Here's a breakdown of common problems and how to fix them.

Crane Doesn't Roll Properly

Possible Causes & Solutions:

Wheels or Casters:

- Dirt and Debris: Clean the wheels to remove any blockage.

- Wear and Tear: Inspect wheels for cracks or damage. Replace if necessary.

- Lubrication: Apply lubricant to stiff wheels for smoother movement.

Surface Issues: Ensure the crane is on a flat and smooth surface. Uneven ground could make rolling difficult.

Locking Mechanisms:Check if the casters lock properly. A malfunctioning lock could hinder movement. Test and adjust as needed.

Hoist Isn't Lifting Properly

Possible Causes & Solutions:

Power Issues:

- Electric Hoist: Confirm that the power cable is plugged in and the breaker is on.

- Battery-Powered Hoist: Ensure the battery is charged and connected.

Hoist Mechanism:

- Inspect the chain or rope for tangles or damage. A blocked or damaged mechanism may prevent lifting.

- Look for any signs of overheating in the lifting motor.

Overloaded Hoist:

- Verify that the load is within the hoist's rated capacity. Exceeding capacity can cause malfunction or damage.

- Balance the load before lifting to avoid strain on the hoist.

Limit Switch:

- If the hoist is not reaching full height, the limit switch might be stuck. Adjust or replace if necessary.

Crane Sways or Misaligns

Possible Causes & Solutions:

- Uneven Surface:Ensure that the crane is placed on a flat, stable surface. This helps avoid instability and swaying.

- Load Balance:Double-check that the load is centered and balanced. Misaligned or uneven loads can cause swaying.

- Trolley Alignment:Ensure the trolley moves smoothly along the I-beam. Misalignment can cause the crane to sway or misbehave.Check rails for debris or obstructions. Realign the trolley if needed.

- Wind & Environmental Factors:If using the crane outdoors, strong winds can make the crane sway. In high winds, consider postponing use or adding extra security.

- Connection Points:Inspect the I-beam, side frames, and casters. Loose connections can lead to instability. Tighten any loose bolts or nuts to keep everything secure.

Quick Tips:

- Regularly check for wear and tear to avoid breakdowns.

- Always ensure the crane is used within its rated capacity to prevent damage.

- Clean and lubricate parts as needed to keep them moving smoothly.

- Pay attention to the environment: Wind or uneven ground can cause issues with stability.

- Tighten all bolts and connections to ensure a secure setup before use.

Frequently Asked Questions

Can this crane be used outside?

Yes, this crane can be used outdoors, but there are a few important things to keep in mind:

- Ensure that the ground is flat and stable to prevent tipping.

- If the crane is used in windy conditions, be extra cautious, as strong gusts can affect stability.

- Weatherproofing: Make sure that any electrical components, if present, are properly protected from moisture to avoid damage.

- Always check the manufacturer's guidelines for outdoor use recommendations specific to your model.

Is the height adjustable?

No, this is a fixed-height gantry crane. The height is set during assembly and cannot be changed after setup. If you require an adjustable height crane, you may need to look into other models designed for variable height settings.

How long does assembly take?

Assembly time typically ranges from 30 minutes to 1 hour, depending on the size of the crane and your familiarity with the process. Having a second person to help can speed up the process. The steps mainly involve:

- Positioning the side frames.

- Attaching the I-beam.

- Securing the casters and the trolley/hoist.

- Performing a final safety check.

Make sure to follow the step-by-step instructions in the manual to ensure everything is set up properly.

What kind of hoist can be attached?

This crane is compatible with most standard electric hoists, manual hoists, and chain hoists. The hoist should match the crane's weight capacity and intended load for safe operation.

- Electric Hoists: Best for lifting heavier loads with minimal effort.

- Manual Hoists: Ideal for lighter loads and more hands-on work.

- Chain Hoists: Suitable for varied applications, offering great flexibility and ease of use.

Check the hoist's weight and lifting capacity to ensure it aligns with the crane's specifications.

Final Reminders

Summary of Safe Usage Tips

To ensure safe and efficient use of your fixed-height aluminum gantry crane, keep these key points in mind:

- Never exceed the crane's rated load capacity. Always check the weight of your load before lifting.

- Always use personal protective equipment (PPE), including gloves, safety shoes, and a hard hat, when operating the crane.

- Make sure the crane is set up on a level, stable surface to avoid any accidents.

- Avoid lifting loads that are not balanced. Keep the load centered to prevent tipping or swaying.

- Keep a safe distance from the load during operation and avoid walking under suspended loads.

- Don't use the crane in extreme weather conditions like high winds, rain, or snow, unless specified by the manufacturer.

Importance of Regular Inspection and Maintenance

Regular inspection and maintenance are critical to ensure your crane operates safely and efficiently:

- Inspect the crane regularly for signs of wear, especially the wheels, bolts, connections, and lifting mechanism.

- Lubricate moving parts to ensure smooth operation.

- Check for any signs of rust or corrosion on the metal components, especially if used in outdoor environments.

- Tighten bolts and hardware periodically to prevent loose parts, which can lead to accidents.

- Follow the manufacturer's recommended inspection schedule and replace any worn or damaged parts immediately to avoid malfunction.

Where to Reach Out for Technical Support or Replacement Parts

If you encounter issues that can't be resolved with basic troubleshooting, or if you need replacement parts, don't hesitate to reach out for support:

- Contact the manufacturer's customer service for technical assistance. They can help with any issues you might face.

- Order replacement parts directly from the manufacturer or authorized dealers to ensure quality and compatibility.

- Visit the manufacturer's website for helpful guides, FAQs, and contact details for support.

Keeping the contact information for technical support handy ensures that you can address any issues quickly and keep your crane in top working condition.

Main Projects

Related Products

Supplied three grab bucket crane kits to Indonesia, enhancing garbage handling efficiency with high load capacity and reliable performance.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch