15 Ton Explosion-Proof Crane for Hazardous Indoor Lifting Nigeria

Safe, reliable 15-ton crane designed for hazardous indoor environments in Nigeria, featuring low-headroom hoist, dual units & explosion-proof compliance.

Category: 15 Ton Overhead Crane for Sale

Your Trusted Overhead Crane Manufacturer & Supplier

15 Ton Overhead Crane for Hazardous Environment

15 Ton Explosion-Proof Crane for Hazardous Indoor Lifting in Nigeria

Safe, reliable 15-ton crane designed for hazardous indoor environments in Nigeria, featuring low-headroom hoist, dual units, and explosion-proof compliance.

Indoor hazardous lifting environments present unique challenges that standard cranes simply cannot handle. In workshops or industrial areas where flammable gases, dust, or vapors are present, even a small spark can create a serious safety risk. At the same time, these facilities often need to move heavy equipment or materials quickly and efficiently to maintain smooth operations. Balancing safety with productivity is a constant concern.

Explosion-proof cranes play a critical role in these settings. Designed to prevent sparks, contain heat, and operate reliably under hazardous conditions, they allow operators to lift and transport heavy loads without compromising safety. Their sturdy design also ensures long-term durability, reducing downtime and maintenance costs.

To address these challenges, a 15-ton, 13-meter span explosion-proof overhead crane was developed. This crane is specifically designed for indoor hazardous environments:

- Safe lifting in gas- or dust-prone areas, meeting strict Ex II 2 G Ex de IIC T4 standards.

- Dual units capability, allowing simultaneous lifting operations in the same facility.

- Low-headroom design with crab trolley, maximizing available lifting height in confined spaces.

- Integrated runway system, ensuring stable and smooth crane travel across the workshop.

This solution combines safety, practicality, and efficiency, offering a reliable lifting system for hazardous indoor environments.

Project Challenges in Hazardous Indoor Environments

Working in hazardous indoor environments comes with a set of challenges that demand careful planning and specialized equipment. Lifting heavy loads is not as simple as using any overhead crane—there are real risks associated with sparks, flammable gases, and combustible dust. Ensuring safety while maintaining productivity is a delicate balance.

Some of the key challenges include:

- Handling heavy loads safely in flammable or explosive conditions

Operating in areas with gas, dust, or vapor requires cranes that prevent sparks and are fully explosion-proof. Even small electrical or mechanical failures could lead to accidents, so the equipment must meet strict safety standards. - Limited headroom or constrained workshop space

Many industrial facilities have low ceilings or tight layouts. A standard crane could reduce the effective lifting height or interfere with workflow. Designing a low-headroom solution while maximizing lifting capacity is essential. - Need for continuous, reliable operation without downtime

Industrial processes cannot afford frequent interruptions. The crane must operate smoothly and consistently, even in tough conditions, to prevent delays and keep operations running efficiently. - Compliance with strict explosion-proof standards (Ex II 2 G Ex de IIC T4)

Adhering to certified explosion-proof standards ensures safety and legal compliance. Every electrical and mechanical component needs to meet rigorous testing to operate safely in hazardous environments.

Addressing these challenges requires a solution that is not only technically capable but also practical for everyday industrial use. The next step is designing a crane system that tackles all these issues effectively, without compromising on safety or productivity.

Exproof Crane Requirements for Hazardous Lifting

To tackle hazardous indoor lifting safely and efficiently, the crane needed to meet a clear set of practical requirements. These specifications ensured not only safe operation in flammable or dust-prone areas but also optimized workflow and lifting capacity for the workshop environment.

The main requirements included:

- Safe lifting in gas/dust-prone areas

Designed to prevent sparks or heat generation, protecting both personnel and equipment. - Lifting capacity: 15 tons

Capable of handling heavy loads reliably and safely. - Crane span: 13 meters

Covering the full workshop width to enable smooth material handling. - Crane Lifting Unit: Explosion proof hoist with low headroom design

- Lifting height: 8.95 meters

Maximizing lifting height despite limited headroom. - Power supply: 400V, 50Hz, 3 Phase

Fully compatible with local electrical infrastructure for safe operation. - Two units for parallel lifting operations

Allowing simultaneous lifts for increased efficiency and reduced handling time. - Complete system including runway beams

Ensuring stability, smooth travel, and seamless integration into the workshop layout. - Explosion-proof compliance: Ex II 2 G Ex de IIC T4

All mechanical and electrical components designed to meet strict explosion-proof standards.

Meeting these requirements was essential to deliver a practical, reliable, and safe crane solution that could operate effectively in a hazardous indoor environment while maximizing productivity and minimizing risk.

Explosion Proof Crane Solution

To meet the challenges of hazardous indoor lifting, a tailored crane solution was developed. The design focused on safety, reliability, and practical usability while ensuring compliance with strict explosion-proof standards.

Crane Design

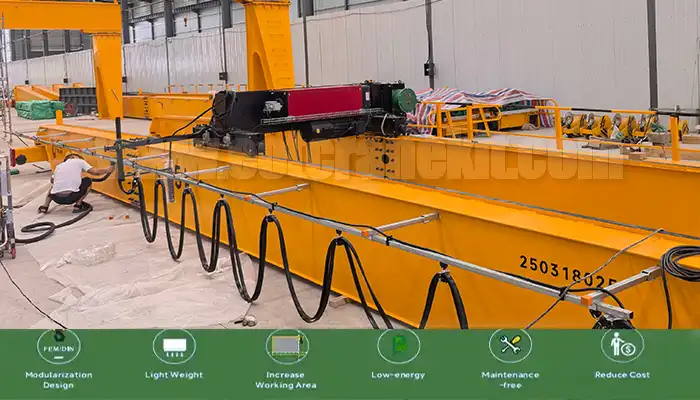

The crane was built as a European-style double girder overhead crane, providing strength and stability for heavy loads.

- Low-headroom hoist and crab trolley: Maximized lifting height even in confined workshop spaces.

- Optimized layout for smooth operation and minimal interference with workshop activities.

Explosion-Proof Configuration

Safety in hazardous environments was a top priority, so all components were carefully selected and certified.

- Electrical and mechanical parts designed for gas- and dust-prone areas.

- Full compliance with Ex II 2 G Ex de IIC T4 standards, ensuring safe operation under all conditions.

Runway System

A well-designed runway system was essential for stability and smooth crane movement.

- Custom-designed runway to fit the workshop layout precisely.

- Ensured stable, safe travel for both cranes during lifting operations.

Project Execution

Delivering a 15-ton explosion-proof crane for hazardous indoor lifting requires careful planning and step-by-step coordination. Each stage of the project was designed to ensure safety, quality, and timely completion.

Key steps in the execution process included:

- Detailed engineering drawings prepared and approved

Every dimension, lifting specification, and layout detail was verified to match the workshop's requirements and safety standards. - Fabrication and factory testing, including load and function checks

The cranes were assembled and tested under real working conditions, ensuring all mechanisms worked reliably before shipment. - Packaging and shipment to Nigeria with protective measures

The cranes and runway beams were carefully packed to prevent damage during transit, including reinforced crates and protective coatings for sensitive parts. - Remote guidance for safe installation and commissioning

Our engineers supported the local team through every step of installation, ensuring the cranes were set up safely and operated correctly from day one.

Results & Benefits

The 15-ton explosion-proof cranes delivered a practical solution for hazardous indoor lifting, combining safety, reliability, and efficiency. The project outcomes clearly demonstrate how tailored design and careful execution translate into real operational benefits.

Key results and benefits included:

- Safe and reliable indoor lifting in hazardous conditions

Operators could handle heavy loads with confidence, knowing the cranes met strict explosion-proof standards. - Space-saving design optimized for low headroom

The low-headroom hoist allowed maximum lifting height in confined workshop spaces. - Reduced downtime due to high-quality explosion-proof protection

Durable construction and certified components minimized maintenance needs and operational interruptions. - Smooth dual-crane operation on integrated runway system

Two cranes working simultaneously improved workflow efficiency and reduced handling time. - Demonstrated practical, reliable solution for hazardous indoor lifting

The system proved that well-designed explosion-proof cranes can deliver both safety and productivity in challenging environments.

Conclusion

The project successfully delivered two 15-ton, 13-meter span explosion-proof cranes with a fully integrated runway system, ready for safe indoor operation in hazardous conditions.

This case highlights the importance of customized, explosion-proof solutions for facilities handling flammable or dust-prone materials, ensuring both safety and operational efficiency.

Industrial facilities looking for reliable lifting solutions in hazardous indoor environments are encouraged to contact experienced suppliers to explore tailored overhead crane options that meet both safety standards and practical workflow needs.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch