Wire Rope Explosion-Proof Hoists for High Lifts & Heavy Loads

Tailored hoists deliver safe, reliable lifting up to 70 meters high & 63 tons heavy in hazardous environments.Custom wire rope electric hoist for sale!

Category: Wire Rope Hoist Crane

Your Trusted Explosion Proof Hoist and Crane Manufacturer & Supplier

Custom Explosion-Proof Wire Rope Hoists for High Lifts & Heavy Loads

— Up to 70 Meters & 63 Tons of Safe Power

Introduction:What Is an Explosion-Proof Wire Rope Hoist?

An explosion-proof wire rope hoist is a special type of lifting device. It's built to work safely in places where flammable gas or dust is present. These hoists have enclosed motors, spark-proof components, and sealed electrical systems.

They're not just for safety—they're essential. In high-risk industries, one small spark can lead to disaster. That's why these hoists follow strict international standards like ATEX or IECEx.

Why Customized Hoists Matter

Not every job site is the same. Some need to lift loads very high, sometimes up to 70 meters. Others need to lift very heavy loads—up to 63 tons. Off-the-shelf hoists can't always handle these needs.

That's where customization comes in.

We adjust lifting height, speed, motor power, and control methods to fit each project. Even the coating and wiring can be tailored for hot, humid, or corrosive environments.

Think of it this way: a custom hoist doesn't just "work"—it works better, safer, and longer in your specific conditions.

Who Uses These Hoists?

Explosion-proof wire rope hoists are used in many industries where safety is critical. Common users include:

- Oil & Gas: For lifting in refineries, offshore rigs, and tank farms

- Chemical Plants: Where toxic fumes and flammable substances are common

- Mining: For both underground and surface handling in gas-prone areas

- Power Plants: Especially in coal, biomass, or gas-based stations

- Paint & Coating Workshops: Where vapors and solvents create fire risks

- Grain & Feed Processing: Where fine dust can become explosive

Key Custom Features

Lift Higher – Up to 70 Meters

Some facilities require lifting loads over long vertical distances—far more than standard hoists allow. Whether it's a deep pit, tall structure, or a multi-level processing tower, having a hoist with a long lifting height is crucial. Our explosion-proof wire rope hoist can be customized to handle lifts of up to 70 meters, all while keeping the operation smooth and safe.

- Long-lift wire rope design: Precision winding with anti-sway guidance

- Larger drums and reinforced structure: Prevents rope overlap and wear

- Advanced control system: Ensures smooth movement from top to bottom

- Optional rope guide system: For stable lifting at extreme heights

Lift Heavier – Up to 63 Tons

Heavy industrial loads require more than just power—they require control, safety, and strength. Our hoists are engineered to carry up to 63 tons, making them ideal for applications like steel production, large component handling, and pressure equipment assembly.

- Robust hoisting mechanism: High-torque motors and oversized gearboxes

- Double or multi-fall reeving: Distributes load evenly, reduces swing

- Heavy-duty hooks and safety latches: Built for oversized materials

- Built-in overload protection: Prevents damage from accidental excess load

Certified for Hazardous Zones – Explosion-Proof Build

Working in hazardous environments means safety can't be optional. That's why every hoist is built with explosion-proof components—designed to contain internal sparks and resist external hazards. These hoists meet major international safety standards.

- ATEX and IECEx certified: Suitable for Zone 1, Zone 2, and dust areas

- Flameproof motor and brake units: Fully sealed to contain ignition sources

- Explosion-proof limit switches and control panels: With stainless steel covers

- Copper or bronze-coated wheels/hooks (optional): Prevents static discharge

Custom Speed Control – Match Your Operation Needs

Different tasks call for different levels of speed and control. Some jobs need quick lifting, while others require slow, careful movement. We offer three configuration types to match your site's needs and operator comfort.

- Single-speed: Best for straightforward, low-frequency tasks

- Dual-speed: Smooth switching between fast lift and slow positioning

- Variable Frequency Drive (VFD): Allows precise motion, soft starts/stops, and energy saving

- Optional remote or cabin control: Enhances flexibility and keeps operators at a safe distance

Technical Specifications

When selecting an explosion-proof wire rope hoist for your project, it's important to match the technical parameters with your actual working conditions. Below is a breakdown of the key specifications we customize for each order. These ensure safe, efficient, and long-lasting performance in demanding environments.

Lifting Height Range

We offer flexible lifting heights based on your project's layout. Whether you're working in deep shafts or tall buildings, the hoist can be configured to lift up to 70 meters with stable and precise motion.

- Standard range: 6 to 70 meters

- Higher lifting heights include longer wire ropes and specially designed drums

- Rope guides and travel limiters are included for safety and control

Lifting Capacity Range

From light loads to extremely heavy items, we offer a wide capacity range. All units are designed to ensure smooth lifting, reliable stopping, and long-term durability.

- Available from 5 tons to 63 tons

- Custom reeving arrangements for balanced lifting

- Strong hooks, bearings, and load brakes for high-weight operations

Duty Group / Working Class

The duty group defines how often and how intensively the hoist can be used. We follow FEM/ISO classifications to match your lifting frequency and load handling needs.

- Options include M5 (medium-heavy), M6 (heavy), and M7 (very heavy)

- M5 is suitable for moderate use (e.g., 5–10 lifts/hour)

- M6 and M7 are built for frequent use and continuous operation (e.g., steel plants, mines)

Power Supply Customization

We understand that power systems vary by country and facility. That's why we customize the power supply and electrical components to match your exact requirement.

- Voltage options: 220V to 690V, 3-phase, 50Hz or 60Hz

- Controls matched to your local power and safety regulations

- Explosion-proof enclosures and sealed wiring for all voltage levels

Environmental Protection Level (IP Rating)

Tough environments demand tough protection. We offer a range of IP ratings depending on the location of use—whether it's dusty, humid, corrosive, or exposed to rain.

- Standard protection: IP55

- Optional upgrades: IP65 or IP66 for outdoor, chemical, or coastal applications

- Sealed motors, gearboxes, and electrical cabinets prevent moisture and dust intrusion

Technical Specification Summary Table

| Parameter | Available Range / Options |

|---|---|

| Lifting Height | 6 to 70 meters |

| Lifting Capacity | 5 to 63 tons |

| Duty Group (ISO/FEM Class) | M5, M6, M7 |

| Power Supply Options | 220V–690V, 3-phase, 50Hz or 60Hz |

| IP Protection Level | IP55 (standard), IP65/IP66 (optional) |

Safety & Reliability in Hazardous Environments

When working in areas where gas, dust, or vapors may cause explosions, safety is everything. A failure in any part of the lifting system can lead to serious damage—or worse. That's why our explosion-proof wire rope hoists are designed from the ground up to be safe, reliable, and certified for use in hazardous zones.

Explosion-Proof Enclosures for Motors, Brakes, and Controls

The motor, brake, and control box are all sealed inside flameproof housings. These are built to contain any spark or flame that could occur inside and prevent it from escaping into the surrounding environment.

- Enclosures meet ATEX and IECEx standards

- Pressure-tested flameproof housing protects from ignition risks

- Cast iron or aluminum shells with precision sealing surfaces

- Control boxes include explosion-proof push buttons and emergency stops

Flameproof Limit Switches and Wiring

Every electrical connection matters in a hazardous zone. That's why we use flameproof-rated limit switches and wiring systems—ensuring sparks don't escape, even during wear or failure.

- Travel and height limit switches rated for explosive atmospheres

- Fully sealed cable entries with certified glands and connectors

- Wiring in armored or flame-resistant conduits

- Ground fault protection built into control systems

Anti-Sparking Materials and Protective Coatings

Even metal-on-metal contact can generate sparks. To prevent this, we use non-sparking materials and coatings where necessary—especially in the lifting mechanism and moving parts.

- Copper or bronze alloy wheels, hooks, or buffers (optional)

- Anti-static coatings on external parts

- Non-metallic bumpers or guards on trolleys and end stops

- Powder-coated frame with corrosion and spark resistance

Redundant Braking and Control Systems

We don't rely on a single safety feature. In hazardous environments, redundancy is key. Our hoists include backup systems to ensure safe stopping and control—even if one component fails.

- Dual braking system: Motor brake + mechanical load brake

- Overspeed and overwind protection built into the drive system

- Manual emergency lowering device in case of power failure

- Redundant control paths with fail-safe relay logic (if required)

Every detail of our explosion-proof hoist design focuses on real-world risk reduction. If you're operating in a dangerous zone, this is the kind of equipment you can trust day after day.

Applications

Explosion-proof wire rope hoists are not just for any factory. They're built for places where the air itself can be dangerous. If your site handles flammable gases, dust, or chemicals, using standard lifting equipment is a serious risk. That's where these hoists come in. Below are some of the key industries and environments where explosion-proof hoists are essential.

Offshore Oil Platforms

Offshore platforms have a high risk of gas leaks and vapors—especially in confined zones or near pumping units. All lifting equipment must meet strict explosion protection standards.

- Handling drilling tools, pipe spools, or heavy modules

- Exposure to salt air, moisture, and extreme temperatures

- Often used in Zone 1 or Zone 2 hazardous areas

Chemical Processing Plants

Chemical plants work with a wide range of flammable or reactive materials. Lifting equipment must be sealed, spark-free, and corrosion-resistant.

- Used to lift tanks, reactors, pumps, or drums

- High frequency of lifting and precise placement

- Gases or vapors may accumulate in enclosed process areas

Dusty or Flammable Material Warehouses

Dust can be just as explosive as gas in certain conditions. Warehouses storing grain, sugar, wood powder, or even aluminum dust require hoists that won't ignite particles in the air.

- Storage and material handling zones

- Risk from fine combustible dust accumulation

- Equipment often exposed to vibration and airborne particles

Gas Filling Stations

In places where LPG, oxygen, or other gases are filled and stored, even a small spark could be catastrophic. Every movement must be tightly controlled.

- Loading and unloading of gas cylinders

- Filling system maintenance support

- Typically used in enclosed spaces with high gas concentration

Power Stations with Risk of Gas or Dust Ignition

Some power plants burn biomass or coal, creating airborne dust. Others may have methane pockets or gas turbine areas. Explosion-proof lifting is critical in these zones.

- Maintenance hoists in fuel handling areas

- Electrical rooms or battery storage zones

- Systems designed for continuous safe operation in harsh environments

If your facility fits into one of these categories—or if you're unsure—it's always better to ask. We can assess your site conditions and recommend the right explosion-proof lifting system. Safety starts with choosing the right hoist.

Customization Options of Explosion Proof Hoist

Every lifting job has its own unique challenges. That's why our explosion-proof wire rope hoists come with a wide range of customization options. These help you get exactly what your site needs—no more, no less. From the hook to the controls, from the trolley to protective coatings, we tailor the hoist to your specific working conditions.

Hook Type and Reeving Options

Not all loads are the same, and the way you lift them can vary a lot. You might need a single hook for straightforward lifting or multiple reeving lines for heavy or bulky loads. We offer several configurations to optimize safety and efficiency.

- Single hook: Simple, cost-effective for lighter loads

- Double or multiple reeving: Distributes heavy loads, reduces rope tension

- Special hooks: Swivel, latch, or custom shapes for unique handling

- Load blocks: Designed to prevent twisting or swinging during lifts

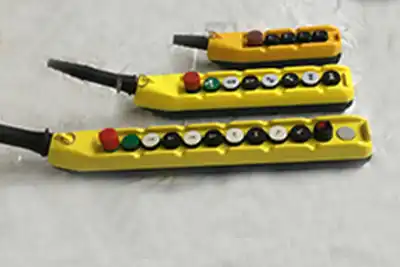

Control Methods

Control and operator safety go hand in hand. Depending on your work environment and operator preferences, we offer several ways to operate the hoist—each explosion-proof and easy to use.

- Pendant control: Classic wired remote with emergency stop

- Wireless remote: Increased mobility and safer operation from a distance

- Cabin control: Enclosed operator cabin for complex or high-risk operations

- Integrated control panels: Custom layout with intuitive buttons and displays

Specialized Trolleys or Crab Units

The trolley or crab unit moves the hoist along the runway beam. Customizing this part can make a big difference in how smoothly and safely your loads travel.

- Low-headroom trolleys: Save vertical space in tight workshops

- Explosion-proof motorized trolleys: For long runway beams or heavy loads

- Side-shift or rotation capabilities: For precise load positioning

- Manual or motorized crab units: Depending on your power source and control needs

Special Coatings and Corrosion Protection

Many explosion-proof hoists work outdoors or near the sea, where moisture, salt, and chemicals can cause rust and damage. We offer protective finishes to extend your hoist's life and keep it looking and working great.

- Marine-grade paint and coatings: Resist saltwater corrosion

- Powder coating: Durable, scratch-resistant, and weatherproof

- Zinc or galvanizing treatment: Extra protection for steel parts

- Custom colors and markings: For safety or branding purposes

Choosing the right customization can improve safety, productivity, and equipment lifespan. We work closely with you to find the best fit for your specific needs, budget, and site conditions.

Why Choose Us?

Choosing the right partner for your explosion-proof wire rope hoist is just as important as choosing the right hoist itself. We understand the stakes are high when working in hazardous environments. Here's why we stand out as a trusted supplier and manufacturer.

Experienced Chinese Manufacturer with CE and ISO Certifications

We are a well-established crane manufacturer based in China with decades of experience. Our products meet the highest international standards.

- CE certification: Ensures compliance with European safety, health, and environmental requirements

- ISO 9001 certified quality management system: Guarantees consistent product quality and continuous improvement

- Skilled engineering and production teams committed to precision and reliability

Proven Project Cases in Explosive Environments

We have successfully delivered explosion-proof hoists to many industries where safety cannot be compromised.

- Completed projects in oil & gas, chemical plants, mining, and power generation

- References and case studies available upon request

- Solutions tailored for specific hazardous zones, with real-world performance verification

Factory-Direct Support with Engineering Consultation

Buying directly from the manufacturer means you get personalized attention and expert advice throughout your project.

- Dedicated engineering team to customize your hoist exactly to your needs

- Assistance with site evaluation, technical specs, and installation planning

- Quick response and direct communication—no middlemen, no delays

Third-Party Inspection & International Shipping

Quality and safety don't stop at our factory door. We offer thorough third-party inspections and support global logistics.

- Independent inspection agencies verify compliance before shipment

- Certificates and test reports provided for your peace of mind

- Reliable international shipping with packaging tailored for safe delivery

Partnering with us means getting a high-quality explosion-proof wire rope hoist built for your toughest challenges. We don't just sell equipment — we deliver safety, reliability, and peace of mind.

Inquiry Checklist for Buyers

To provide you with the best explosion-proof wire rope hoist solution, we need some key details about your application. This checklist will help you gather the important information before contacting us. The more accurate your info, the faster and more precise our offer will be.

Required Lifting Height and Capacity

- What is the maximum lifting height needed (up to 70 meters)?

- What is the heaviest load you need to lift (up to 63 tons)?

- Will you be lifting single items or bundles?

Working Environment and Hazardous Zone Classification

- What type of environment is the hoist used in (oil platform, chemical plant, dusty warehouse, etc.)?

- Do you know the hazardous zone classification? (e.g., Zone 1, Zone 2, Zone 21, Zone 22)

- Are there any special environmental factors like moisture, salt spray, or chemicals?

Power Supply Details

- What voltage and frequency does your site use? (e.g., 380V, 50Hz)

- Is power supply stable or prone to fluctuations?

- Do you require explosion-proof electrical components compatible with your power system?

Frequency of Operation (Duty Cycle)

- How often will the hoist be used per hour/day?

- What is the average load weight during operation?

- Is the operation continuous, intermittent, or occasional?

Control Type Preferences

- Do you prefer pendant control, wireless remote, or cabin operation?

- Any special requirements for control safety features?

- Would you like additional automation or remote monitoring options?

Get a Custom Quote

Getting the right explosion-proof wire rope hoist starts with sharing your specific needs. The more details you provide, the better we can customize your hoist for safety, performance, and cost-efficiency.

Please include all relevant specs such as lifting height, load capacity, hazardous zone classification, power supply, control preferences, and any special requirements. Don't worry if you're unsure about some details—we're here to help clarify and guide you through every step.

When you request a quote from us, expect:

- Fast turnaround times: We understand your projects can't wait. Our team prioritizes prompt and accurate quotations.

- Technical support: Our engineers are available to answer your questions and assist with technical challenges.

- Custom drawings and documentation: We provide detailed layout plans and specs tailored to your site conditions and operational needs.

We aim to make the buying process as smooth and transparent as possible. Just send us your info, and we'll take care of the rest.

Looking for a safe, powerful, and high-lift explosion-proof hoist designed exactly for your tough working environment?

Contact us now for a custom solution that fits your needs perfectly. Let's work together to keep your operations safe, efficient, and reliable—no compromises.

Reach out today and get started with expert advice and a tailored quote!

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch