Single Girder EOT Crane & Double Girder EOT Cranes Doha Qatar

Check reliable single girder eot crane & double girder EOT cranes in Doha Qatar, designed for diverse lifting needs across industries & workshops.

| Crane Typ | Overhead Crane |

| Crane Capacity | 3 ton to 320 ton |

| Crane Span | As your request |

| Lifting Height | Customized. |

Category: Qatar

Your Trusted Overhead EOT Crane Manufacturer & Supplier

Eot Crane for Sale Qatar

Single Girder & Double Girder EOT Cranes for Sale in Doha, Qatar

Why Overhead Cranes Are Becoming a Necessity in Doha

Doha has seen a huge surge in industrial activity over the years. From commercial towers and road networks to prefab yards and repair stations, the city is constantly expanding. With that growth comes the need for equipment that can keep up—especially when it comes to lifting and moving heavy loads safely and efficiently.

Supporting Local Workshops, One Lift at a Time

For many businesses in Doha, floor space is tight, time is limited, and material handling can't afford delays. A well-chosen overhead crane allows operators to lift heavy parts, transport them across the workshop, and place them exactly where needed—all without disrupting the work below.

But here's the catch: not every crane suits every situation. Some shops need something small and flexible; others need a crane that can lift 20 tons across a wide span. So knowing what's available—and what actually fits your working environment—is a smart first step.

Everyday lifting tasks made easier with the right crane:

- Transporting precast elements in construction-related yards

- Moving industrial parts for repairs and installations

- Loading heavy equipment and machinery in logistics or warehousing zones

- Handling steel structures in fabrication plants

What This Guide Is Built to Do

If you're in the market for an overhead crane in Doha—whether you're upgrading or buying for the first time—this guide is here to help you make a confident decision.

Here's what you'll get from it:

- A clear explanation of the difference between single girder and double girder cranes

- Insights into which type matches your lifting needs and workspace layout

- An overview of commonly used crane systems in Doha's industries

- Tips on choosing the right crane setup based on lifting capacity, frequency of use, and your working environment

- Advice drawn from real project experience in local workshops and prefab facilities

In short, we'll walk you through practical options—not just technical specs. You'll see what works, where it works, and how to get the right crane for your specific needs in Doha. Let's begin by exploring what types of cranes are in demand locally.

Market Background: Overhead Crane Demand in Doha

Dominant Industries in Doha Using Overhead Cranes

In Doha, overhead cranes aren't just used in large factories—they're now found in a variety of industries that require efficient material handling. As the city continues its rapid development, the need for reliable lifting systems is growing across several key sectors.

Commercial Construction

Doha is constantly adding new towers, office complexes, and retail centers. These sites require efficient handling of steel beams, precast concrete panels, scaffolding frames, and other large building materials.

- Crane systems are often used in site-adjacent workshops to assemble or modify large components before lifting them into position.

- Mobile gantry cranes or small EOT cranes are useful in temporary on-site warehouses for loading/unloading tasks.

Infrastructure Projects

Projects like bridges, the Doha Metro, highways, tunnels, and sports stadiums often involve massive structural parts that must be preassembled or handled with care.

- Overhead cranes in prefab yards handle long steel elements and heavy concrete sections.

- These cranes reduce the manual labor needed and improve accuracy when handling oversized components.

Machinery Repair and Service

From road construction machines to industrial generators, many service centers in Doha rely on compact cranes to lift and reposition heavy parts during disassembly and repair.

- Most of these urban repair shops use 1–5 ton cranes mounted inside low-ceiling workshops.

- Jib cranes and small single girder EOT cranes with electric hoists are especially popular for tight work areas.

Prefabrication Yards

Prefab yards are critical to Doha's large-scale construction industry. These facilities produce ready-to-install concrete slabs, steel frames, columns, and even fully built modules.

- Double girder overhead cranes are widely used here due to their ability to carry heavy and long-span loads.

- Lifting equipment must be precise and durable, especially when dealing with repetitive lifting in outdoor conditions.

Typical Company Types & Sizes Using Cranes in Doha

Overhead crane users in Doha range from small workshops with just a few employees to large-scale industrial contractors. Whether it's a start-up maintenance shop or a global construction firm, the need for efficient material handling is the same—they just require different setups.

Construction Contractors

These companies often operate both on-site and in off-site support facilities. Their lifting needs vary greatly depending on the project stage.

- Temporary gantry cranes are used for logistics and loading.

- Medium-duty EOT cranes handle support frame assembly and material preparation.

Equipment Leasing and Rental Companies

They manage large inventories of construction tools, vehicles, and parts.

- Overhead cranes help them load/unload machinery in warehouses or storage yards.

- 5 to 10-ton single girder cranes are common for lifting compact equipment.

Steel Structure Fabricators

These fabricators prepare beams, frames, trusses, and other metal parts used in large buildings.

- Precision lifting is key to assembling frames.

- They typically use both single and double girder cranes depending on the workshop span and material sizes.

Repair Stations and Local Maintenance Shops

Smaller companies serving HVAC systems, pumps, motors, or vehicle parts need practical lifting systems for daily service work.

- Low-capacity cranes (1–3 tons) are commonly installed on workshop ceilings.

- Wall-mounted jib cranes are also favored for lifting motors or gearboxes at individual workbenches.

Common Workshop Environments in Doha

Overhead cranes are used in many types of workshop environments in Doha, each with different space limitations, lifting needs, and workflow setups. The type of crane that fits one space may not suit another—even if the lifting capacity is similar. Understanding the layout and daily operation of your workspace is a critical part of choosing the right crane.

Urban Site Support Factories (Temporary and Compact)

These are small, often temporary facilities built near large project sites. They handle on-site steel cutting, minor prefab work, and storage.

- These spaces usually have low ceilings and limited access.

- Lightweight single girder cranes, wall-mounted jib cranes, and small gantry systems are commonly used.

- Ease of installation and relocation are key factors here.

Compact Repair Workshops with Limited Headroom

Scattered throughout Doha's industrial zones, these workshops perform equipment and motor repairs, fabrication of small parts, or light assembly tasks.

- Ceiling height is often less than 5 meters, which limits crane selection.

- Underslung cranes, chain hoists, and wall-traveling jib cranes are a good match.

- The focus is on maneuverability and precise handling rather than raw lifting power.

Standard Steel Structure Factories (Medium to Large Scale)

These are purpose-built facilities for steel fabrication, assembly work, or long-term production.

- Designed with sufficient height for crane runways and maintenance access.

- Ideal for top-running single or double girder cranes with 5–20 ton capacities.

- These spaces support higher lifting frequencies and longer spans, making them suitable for handling beams, machine bodies, and bulky components.

Common Lifting Materials Handled with Overhead Cranes

Cranes in Doha workshops aren't just lifting steel coils or bricks—they handle a wide variety of materials depending on the industry. Each type of load brings its own challenges, such as shape, surface condition, and lifting frequency. Knowing what you'll be lifting helps determine the right lifting mechanism and crane configuration.

Precast Concrete Panels, Steel Beams, Scaffolding Frames

These are typical in construction and prefab applications. They tend to be long, heavy, and awkward to balance.

- Often lifted with clamps, spreader beams, or slings.

- Require cranes with smooth, stable motion and proper safety margins.

- Double girder EOT cranes are common in prefab yards for this purpose.

Motors, Electrical Assemblies, Mechanical Spare Parts

Used across many industries—from MEP contractors to repair workshops.

- These are medium-weight items, often lifted frequently throughout the day.

- Chain hoists or wire rope hoists on single girder cranes are ideal.

- In tight spaces, a jib crane offers efficient point-to-point lifting.

Fully Assembled Construction Machinery Components

These include pumps, generators, compact construction vehicles, or assembled modules.

- Loads can be heavy and bulky, with uneven weight distribution.

- Requires precise lifting and placement during loading, testing, or repair.

- Commonly handled by 5 to 10-ton overhead cranes with anti-sway control or fine-speed hoists.

Typical Lifting Capacity Needs in Doha's Workshops and Yards

When it comes to choosing an overhead crane, one of the first questions is: "How much weight do you really need to lift?" It sounds straightforward, but the answer can vary quite a bit depending on your industry and your daily tasks.

In Doha, most workshops and prefab yards fall into the light to medium lifting range. That means cranes between 3 to 20 tons are the most commonly requested. And while higher capacities do exist, they're usually reserved for specialized industrial facilities.

Here's a breakdown of what most businesses actually use on a regular basis:

Most Common Capacities: 5-ton and 10-ton Cranes

These two sizes are the workhorses across Doha's industrial landscape. They offer a balance between lifting power and cost, and they're flexible enough to handle a variety of jobs.

- Used in repair stations, steel structure factories, and logistics warehouses

- Ideal for handling steel frames, equipment parts, or fully built machinery units

- Often configured with single girder or top-running double girder designs

Light-Duty Needs: Under 5 Tons

Small workshops, especially those focused on maintenance or assembly, don't need a large crane. Instead, they need something compact and easy to operate.

- Typical in motor repair shops, HVAC service centers, and compact metal workshops

- Wall-mounted jib cranes and chain hoists are popular for localized lifting

- Hoists are often manually operated or electrically powered for precision work

Medium-Duty Range: Up to 20 Tons

In prefab yards or medium-sized production plants, loads start getting heavier. These facilities often move large concrete parts or long steel structures several times a day.

- Requires stronger double girder cranes with durable wire rope hoists

- May need longer spans and more frequent duty cycles

- Often installed in outdoor or semi-enclosed environments for better access

Knowing your typical load range isn't just about matching tonnage. It affects everything—from your hoist selection and girder type to motor power and structural support. If you're unsure, it's safer to size slightly above your average load—while staying within the limits of your workshop layout and budget.

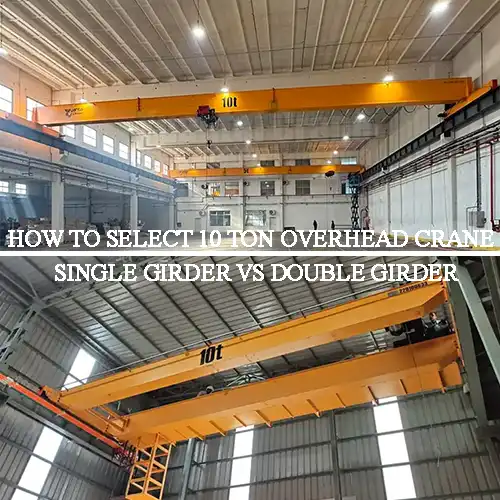

EOT Cranes: Single Girder vs. Double Girder for Sale in Doha

What Is an EOT Crane?

An Electric Overhead Traveling (EOT) crane is one of the most common lifting systems used inside workshops, warehouses, and industrial yards. Its job is simple but essential: move heavy loads horizontally and vertically along a fixed track system.

In Doha's industrial areas, EOT cranes are used for everything from loading raw materials to positioning finished products during fabrication. They are electrically powered and can be operated in several ways depending on the application.

Common operating methods include:

- Pendant control: A simple wired controller attached to the crane

- Wireless remote control: Offers more flexibility and visibility during load movement

- Control cabin: Used in larger cranes where visibility and precise handling are critical

These cranes are mounted on either a single or double girder structure—and choosing between the two depends heavily on your workshop space, lifting weight, and job frequency.

Single Girder EOT Cranes

Single girder cranes are a popular choice for small to medium-sized workshops in Doha. They feature just one main beam across which the hoist travels. Simple, cost-effective, and versatile—these cranes are well-suited for day-to-day lifting tasks that don't exceed 10 tons.

Key features and benefits:

- One main girder supports the load; the hoist runs along the bottom flange

- Lower weight and easier installation, especially in existing buildings

- Economical option for workshops with moderate lifting needs

- Ideal for capacities between 3–10 tons, which covers most routine jobs

- Suitable for compact spaces or areas with limited headroom

This type of crane is widely used in repair workshops, storage buildings, fabrication sheds, and other indoor spaces where the lifting load is moderate and the layout is tight.

Double Girder EOT Cranes

When the lifting tasks get heavier—or when your operation requires longer spans and higher precision—a double girder crane becomes the smarter choice. These cranes feature two parallel beams, with the hoist mounted on top, allowing more space under the hook and greater lifting capacity.

Why many prefab yards and heavy-duty workshops prefer double girder cranes:

- Two girder beams provide enhanced strength and load stability

- The hoist is placed on top of the girders, giving more lifting height (higher hook travel)

- Capable of handling 10 to 20+ tons without stress on the crane structure

- Better suited for longer spans, larger workshops, and outdoor use

- Can accommodate auxiliary features like walkways, service platforms, or maintenance rails

In Doha's prefab yards and large-scale metal structure factories, double girder EOT cranes are often a standard requirement due to the size and weight of the materials being handled.

Side-by-Side Comparison: Single Girder vs. Double Girder EOT Cranes

If you're stuck between choosing a single girder or a double girder crane, a simple side-by-side comparison can help clarify things. While both perform the same basic job—lifting and moving loads—their structure, performance range, and suitability differ quite a bit.

Here's a practical comparison table that breaks down the core features:

| Feature | Single Girder | Double Girder |

|---|---|---|

| Load Capacity | Up to 10 tons (typical) | 10–100+ tons |

| Crane Span | Short to medium | Medium to long |

| Hoist Placement | Suspended under the girder | Mounted on top between the girders |

| Installation Ease | Faster and simpler to install | Requires stronger support and more planning |

| Workshop Fit | Compact spaces, low ceiling clearance | Larger facilities, wide and tall workshops |

| Price Range | More affordable and budget-friendly | Higher investment, more structural demand |

What This Means for Buyers in Doha

- If your lifting needs are modest, and your space is limited, a single girder crane is the better fit. It's easier to install and maintain, and it can handle most tasks in light to medium-duty workshops.

- If you're dealing with heavy loads or long spans, especially in prefab yards or large-scale production plants, go for a double girder crane. It gives you more height, more strength, and better stability over longer distances.

Always match the crane not just to the weight of the load—but to the actual layout and working conditions of your site. That's what ensures smooth lifting, safe operations, and fewer headaches down the line.

Other Types of Overhead Cranes Available in Doha

Top Running Overhead Cranes

Top running overhead cranes are a common sight in many of Doha's larger industrial buildings. They are designed to handle heavy loads and operate smoothly over long distances, making them ideal for standard steel structure factories and large prefab yards.

- These cranes run on rails fixed above the workshop floor, usually mounted on the building's main structure.

- They support long spans, sometimes stretching over 30 meters or more.

- Designed for frequent operation, they can handle multiple lifts throughout the day without overheating or wearing out quickly.

- Perfect for environments where heavy, bulky materials like steel beams or concrete panels need to be moved reliably.

Underslung (Suspended) Overhead Cranes

Underslung cranes are a clever solution when ceiling height is limited or when you want to maximize usable space below the crane. Instead of running on rails above the building structure, these cranes are suspended from the roof trusses.

- Ideal for compact repair workshops or smaller manufacturing units in Doha where headroom is tight.

- They allow equipment and materials to be moved horizontally without interfering with floor space.

- Typically used for lighter loads, but can be customized for medium-duty lifting.

- Installation is often simpler when compared to full top running systems, especially in retrofit situations.

Explosion-Proof Overhead Cranes

In Doha's oil & gas facilities, chemical plants, and other hazardous environments, safety is the top priority. Explosion-proof cranes are specially designed to operate safely in areas with flammable gases, dust, or vapors.

- These cranes are built to prevent sparks or electrical discharges that could ignite hazardous atmospheres.

- They come with strict certifications and comply with local and international safety standards.

- Typically found in oil refineries, petrochemical workshops, and gas processing plants.

- Require specialized maintenance and inspection regimes to ensure ongoing safety.

Portable Gantry Crane Systems

Portable gantry cranes offer flexibility and mobility—qualities that are especially valuable on construction sites or temporary yards in Doha. Unlike fixed overhead cranes, these gantries can be moved around and set up quickly wherever lifting is needed.

- Commonly used for loading and unloading prefab components like concrete slabs, steel sections, and machinery parts.

- They can be assembled and disassembled on-site with relative ease.

- Available in various sizes and lifting capacities, from small 1-ton systems to heavier-duty models.

- Perfect for projects where permanent crane installation is not feasible or cost-effective.

Jib Cranes (Column-Mounted or Wall-Mounted)

Jib cranes are the go-to solution for localized lifting in workshops, assembly lines, or maintenance areas. Whether mounted on a column or attached to a wall, jib cranes help workers lift, position, and move parts within a specific radius.

- Ideal for lifting smaller loads repeatedly in machine shops, repair bays, and assembly stations.

- Easy to operate and maintain, often equipped with electric hoists or manual chain hoists.

- Column-mounted jibs offer 360-degree rotation, while wall-mounted jibs save floor space and operate within a limited arc.

- These cranes improve productivity by reducing manual handling and speeding up workflows.

Applications in Doha's Key Industries

Construction & Prefab Yards

In Doha's booming construction sector, handling large, heavy materials is a daily challenge. Prefabrication yards, in particular, rely heavily on strong and reliable cranes to move precast concrete beams, steel frameworks, and heavy machinery safely and efficiently.

- Double girder EOT cranes are the preferred choice here because they can handle heavier loads and longer spans without strain.

- These cranes help lift and position massive precast panels quickly, speeding up production and reducing manual labor.

- On active construction sites, temporary gantry crane systems are often brought in to assist with assembly, loading, and unloading. These portable cranes provide flexibility where permanent installations aren't possible yet.

- This setup ensures materials can be moved safely from delivery trucks to staging areas or directly into place with minimal downtime.

Compact Repair Workshops

Doha's repair workshops tend to be smaller spaces with limited ceiling height, yet they still face the need to lift and maneuver heavy parts regularly. Here, the focus is on cranes that fit well within tight layouts but don't compromise on lifting efficiency.

- Single girder cranes, combined with chain hoists or wire rope hoists, are commonly installed to handle loads up to 5 tons.

- These cranes allow workshop staff to lift motors, gearboxes, or other mechanical parts smoothly and safely.

- In very tight or highly localized areas, wall-mounted jib cranes provide a handy solution. They offer a limited lifting radius but excel at repetitive, precise lifting tasks right at the workstation.

- Such cranes save valuable floor space and improve workflow by reducing the need for manual handling or moving heavy equipment around.

Equipment Suppliers & Dealers

Equipment suppliers and dealers in Doha require cranes that can help them efficiently load and unload machinery, spare parts, and equipment from trucks and storage areas.

- Medium-duty cranes, often in the 5 to 10-ton range, are typical here to manage a variety of machinery sizes.

- Many prefer modular, easy-to-install cranes that can be adapted to different warehouse layouts or moved between sites if needed.

- These cranes speed up loading operations, reduce damage risk, and improve overall handling safety.

- Whether unloading construction equipment or heavy spare parts, having a reliable crane system streamlines daily logistics.

Key Selection Factors for Crane Buyers in Doha

Building Height and Runway Structure Availability

Before anything else, you need to look at your workshop or factory layout. How high is the ceiling? Is there an existing runway structure or steel framework to support the crane?

- If your building has limited headroom, single girder or underslung cranes might be your best bet.

- For taller buildings with strong runway beams, double girder cranes can provide greater lifting height and capacity.

- In some cases, you might need to reinforce or add new runway structures, which adds to the project timeline and cost.

Load Types and Frequency of Lifting

Not all loads are created equal. Knowing what you'll be lifting and how often makes a big difference in crane selection.

- Are the loads heavy and bulky like precast concrete, or lighter but frequent like motors and assemblies?

- If lifting is frequent and continuous, investing in a crane with higher duty ratings and better control systems pays off.

- For occasional, light-duty lifts, simpler and more economical cranes will do just fine.

Required Span and Travel Distance

The span is the distance the crane needs to cover from one side of the workshop to the other, while travel distance is how far it needs to move along the runway.

- Longer spans generally require stronger, double girder cranes for stability.

- Shorter spans and limited travel can be managed with single girder cranes or jib cranes.

- Understanding these dimensions upfront prevents costly mistakes in ordering the wrong size crane.

Environment (Indoor/Outdoor, Dust, Heat Exposure)

Doha's climate and workshop conditions also affect crane performance and longevity.

- For outdoor or semi-covered yards, choose cranes with weatherproof coatings and components rated for dust and heat.

- Indoor cranes in dusty or dirty environments may need special sealing or explosion-proof features if hazardous materials are present.

- Heat exposure in Doha means electrical components and motors should have cooling features or be designed to handle higher temperatures.

Power Supply Compatibility and Control Method

The crane's power source and control system must match your facility's electrical setup and operator preferences.

- Confirm your available power supply voltage and phase (e.g., 380V/3-phase) before selecting motors and controls.

- Consider control options such as pendant control, wireless remote, or operator cabins depending on safety and precision needs.

- Simpler control methods may be sufficient for light-duty cranes, while complex sites might benefit from automated or remote systems.

Budget Constraints and After-Sales Service Availability

Cost is always a factor, but it shouldn't be the only one.

- Balance upfront purchase price with long-term maintenance costs and crane lifespan.

- Choosing a local or regional supplier in Doha who can provide fast after-sales support, spare parts, and maintenance saves headaches down the road.

- Investing a little more initially for reliable service and quality parts often reduces downtime and repair expenses.

Why Choose a Certified Crane Supplier in Qatar

When investing in an overhead crane, choosing a certified and experienced supplier is crucial—especially in Qatar’s fast-growing industrial market. Here’s why working with a reputable supplier makes a big difference:

- Compliance with CE/ISO and Qatar’s Regulatory Requirements

Certified suppliers ensure that all cranes meet international safety and quality standards, as well as local regulations. This protects your investment and guarantees safe operation on your site. - Strong Local Presence for Installation, Commissioning, and Service

A supplier with a solid presence in Qatar can provide timely installation and start-up support, reducing delays. They also offer quick access to maintenance, spare parts, and emergency repairs. - Customizable Solutions Tailored to Site Dimensions and Lifting Needs

Every workshop or yard is different. Experienced suppliers design cranes specifically for your building’s layout, load requirements, and operating conditions—making sure the crane fits perfectly. - Experience in Handling Regional Industries and Construction Projects

Working with a supplier familiar with Qatar’s key industries means you get practical advice based on real-world applications. They understand your challenges and can recommend the best crane types and features for your sector.

Conclusion & Send Us An Inquiry

Recap of Key Points

- Single girder EOT cranes are a great fit for small workshops and moderate lifting needs, offering cost-effective and space-saving solutions.

- Double girder EOT cranes excel in heavy-duty and large-scale operations, providing higher capacity, longer spans, and greater durability.

- Matching the crane type to your actual working conditions in Doha is essential for maximizing efficiency, safety, and long-term value.

Get Your Tailored EOT Crane Solutions

Don’t guess when it comes to overhead cranes. Reach out to a professional supplier who understands Doha’s unique industrial landscape.

- Get free layout suggestions tailored to your workshop or yard.

- Receive technical proposals designed around your exact lifting needs.

- Request a quotation and expert guidance without any obligation.

Contact us today and let’s find the perfect crane solution that helps your business lift smarter and work safer.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch