Complete Overview of Industrial Overhead Cranes in Qatar

Check tailored EOT, gantry, jib, and low headroom cranes designed for handling loads from 3 to 40 tons in Qatar.

| Crane Type | Overhead material handling cranes |

| Crane Capacity | 3 ton to 320 ton |

| Crane Span | As your request |

| Lifting Height | Customized. |

Category: Qatar

Your Trusted Overhead Crane Manufacturer & Supplier

Comprehensive Guide to Industrial Overhead Cranes for Qatar:

Customized EOT, Gantry, Jib & Low Headroom Cranes for 3 to 40 Ton Load Handling

Industrial Overhead Cranes in Qatar: Built for the Way You Work

In Qatar, overhead cranes aren't just tools—they're an essential part of how materials move, projects progress, and factories function. Whether it's a 5-ton jib crane in a small maintenance bay or a 40-ton gantry crane handling cargo in an outdoor yard, the right lifting solution keeps everything running smoothly. And as industries grow, so do the demands placed on crane systems. Not every crane fits every job. What works for a steel structure plant in Al Wakrah may be completely wrong for a repair workshop in Doha. That's why crane solutions must be customized—not just to the load, but to the workspace, the workflow, and the working conditions.

Why Customization Matters in Qatar's Industrial Environment

Different industries in Qatar face different lifting challenges. Some factories work in tight, low-ceiling spaces. Others handle heavy, bulky steel under the desert sun. A crane that's too basic may slow things down or become a safety risk. One that's overbuilt wastes money and space. That's why tailored cranes aren't a luxury—they're a practical need.

Crane buyers in Qatar need to think about:

- Workshop layout: low headroom, narrow bays, or wide spans all impact crane design.

- Work frequency: daily heavy lifting or occasional component handling? The difference matters.

- Outdoor vs. indoor use: Dust, wind, and sun exposure affect crane structure and motor protection.

- Load type: Pipes, steel coils, rebar cages, motors—each needs a different lifting approach.

Types of Cranes and Available Capacities: 3 to 40 Tons, Covered

From small-scale maintenance to heavy industrial use, Qatar's industries rely on a range of crane types. Each type is designed to solve a particular kind of lifting problem, and each is available in a range of capacities to fit different workloads.

Common crane types used in Qatar include:

- EOT Cranes (Electric Overhead Traveling): Ideal for large indoor workshops with medium to high lifting frequency. Often used in steel fabrication and assembly workshops.

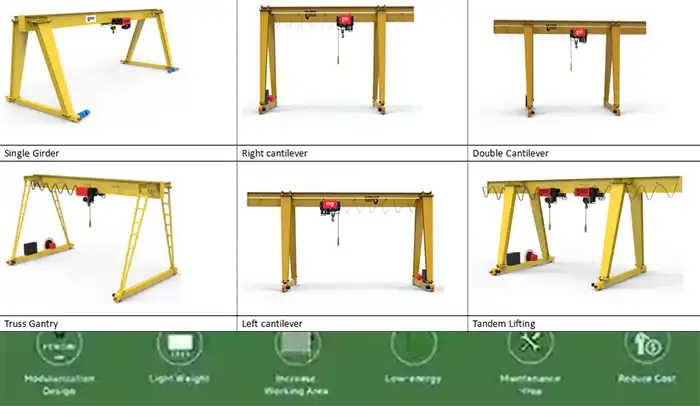

- Gantry Cranes: Suited for outdoor yards, construction zones, or areas where a full runway system isn't practical.

- Jib Cranes: Best for flexible, localized lifting near workbenches, machinery, or inside compact service areas.

- Low Headroom Cranes: Used in facilities with limited vertical clearance where standard crane systems would not fit.

Typical lifting capacities range from:

- 3 to 10 tons: Suitable for small workshops, maintenance, or construction support.

- 10 to 20 tons: Mid-range lifting for production and assembly.

- 20 to 40 tons: Heavy-duty loads in steel, port, or infrastructure-related industries.

Whether it's a 3-ton chain hoist for tool handling or a 40-ton double girder crane for lifting steel beams, there's a solution for every job—you just have to build it right for the work you do.

Overview of Crane Types Used in Qatar's Industrial Plants

Matching Cranes to Industry Needs

In Qatar's industrial sector, cranes are more than just lifting equipment—they're an essential part of day-to-day production. Depending on the plant layout, load type, and work frequency, different crane types are used across steel fabrication workshops, logistics yards, construction sites, and service areas. Below is a practical look at the main types of cranes commonly used and where they fit best.

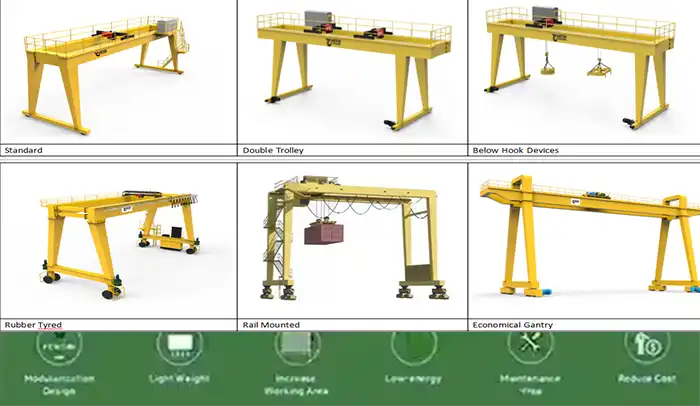

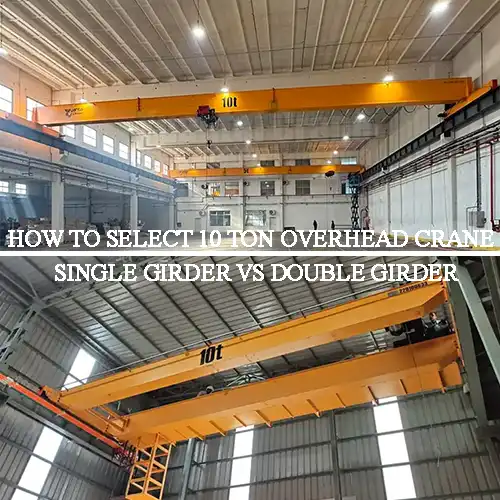

- Electric Overhead Traveling (EOT) cranes are the most widely used in large indoor factories, especially where heavy lifting happens frequently. Running along runway beams fixed to the building structure, these cranes are ideal for steel fabrication, mechanical assembly, and handling precast components. With capacities ranging from 5 to 40 tons, EOT cranes can also be equipped with dual hoists for synchronized lifting when needed.

- Gantry cranes are the go-to choice for outdoor or semi-covered work areas where installing overhead beams isn't feasible. You'll find them in logistics yards, ports, and construction zones—anywhere large or heavy items need to be moved across open ground. Gantry cranes are freestanding and come in full or semi-gantry designs, typically handling loads from 10 to 40 tons.

- Jib cranes are compact and perfect for localized lifting near machinery, workbenches, or service areas. These cranes are commonly found in maintenance workshops and assembly lines where mobility and quick lifts are needed. They can be wall-mounted or fixed to the floor and are most effective for lighter loads, typically ranging from 0.5 to 15 tons.

- Low headroom cranes are specifically designed for factories or workshops with limited vertical clearance. In older buildings or spaces that weren't originally designed for overhead lifting, these cranes help maximize hook height without altering the structure. They're commonly used in compact industrial units and maintenance bays and are best suited for lifting capacities between 3 and 20 tons.

Each of these crane types is built to solve specific challenges. Choosing the right one depends on your workspace layout, the material you need to lift, and how often the crane will be in use.

Tailored EOT Cranes for Qatar's Industrial Demands

Every factory has its own lifting challenges. Some need to lift large steel frames daily. Others need to move delicate components a few times a week. A standard crane can't always handle these differences efficiently. That's where a customized EOT crane becomes the right solution—it's built around your workflow, not the other way around. In Qatar, where factory layouts vary widely and many buildings face space or environmental constraints, customization isn't just helpful—it's necessary.

Why Go Custom?

Every factory has its own lifting challenges. Some need to lift large steel frames daily. Others need to move delicate components a few times a week. A standard crane can't always handle these differences efficiently. That's where a customized EOT crane becomes the right solution—it's built around your workflow, not the other way around.

In Qatar, where factory layouts vary widely and many buildings face space or environmental constraints, customization isn't just helpful—it's necessary.

What Makes a Customized EOT Crane Stand Out?

When an EOT crane is custom-built for your site, every feature is purposeful. You're not just adding options—you're making the crane easier to use, safer to operate, and more productive over time.

Practical features commonly customized:

- Single or double girder options depending on load weight and span requirements

- Optimized hook approach and travel distance to reach tight corners of your workshop

- Remote or pendant controls chosen based on workspace layout and safety distance

- Speed control and soft start systems for better handling of sensitive loads

- Built-in maintenance walkways or access platforms for ease of inspection

You get exactly what your operation needs—nothing more, nothing less.

Capacity and Size Options to Match Your Load

Customized EOT cranes come in a wide capacity range. Whether lifting small machinery parts or handling oversized steel structures, there's a build that fits the job.

Typical lifting capacities:

- 3–5 tons: for light-duty service areas or small fabrication jobs

- 10–20 tons: the most common range for general industrial lifting

- 30–40 tons: heavy-duty systems, used for steel, logistics, and construction sectors

Span range:

Designs can accommodate various bay widths, from 8 to 35 meters, depending on your building structure and runway system.

Built for Qatar's Workspaces and Working Conditions

In Qatar, heat and dust are part of the job. That's why EOT cranes here need more than just lifting power—they need resilience.

Custom design features to suit local needs:

- Dust-sealed motors and controls for dusty fabrication shops

- Heat-protected electrical components to withstand high ambient temperatures

- Compact low-headroom designs for workshops with height restrictions

- Weatherproof options for semi-open yards or coastal locations

Each system is tailored not only for the load but for the long-term conditions it will face.

Where These Cranes Are Used in Qatar

Custom EOT cranes are trusted across many industrial zones in Qatar, especially where lifting is frequent, and downtime is costly.

Typical applications by sector:

- Steel fabrication – Handling beams, plates, and welded assemblies

- Mechanical assembly plants – Lifting frames, enclosures, or assembled modules

- Logistics hubs and warehouses – Moving crates, equipment, or packaged goods

- Construction support yards – Transporting mold components, formwork, and rebar cages

From design to delivery, a customized EOT crane supports how your business works—right from the first lift.

Gantry Cranes for Outdoor and Heavy-Duty Applications in Qatar

Across Qatar's key industrial zones—from the precast yards of Al Khor to the steel storage zones in Al Wakrah and the port operations in Doha—gantry cranes play a central role in outdoor material handling. Unlike EOT cranes that require runway beams fixed to a building, gantry cranes stand on their own legs and move along floor tracks or rubber tires. This independence makes them perfect for open yards and construction sites where covered infrastructure is limited or intentionally avoided. Given Qatar's climate, with intense heat, dust, and periodic humidity near the coast, these cranes are especially favored for their durability and adaptability in outdoor use.

Why Gantry Cranes Are Ideal for Qatar's Open-Site Industries

In Qatar, many workshops and plants are designed with open-air storage or production zones. Whether in logistics, precast production, or steel fabrication, there's often a need to move heavy items across wide, unobstructed areas—without the constraints of walls or columns.

Advantages:

- No reliance on building structures: Perfect for precast yards and equipment depots

- Resistant to heat and dust: Outdoor-rated motors and components handle harsh Gulf conditions

- Customizable height and span: Fits varied workshop sizes from compact logistics yards to large-scale fabrication areas

- Cost-effective for long-term or temporary use: Can be relocated as projects move or expand

- Handles irregular loads: Ideal for precast molds, rebar bundles, or containerized cargo

Single Girder vs. Double Girder Gantry Cranes: What Works Where

Qatar's industries use both single and double girder gantry cranes, depending on the type of material, required height, and frequency of use.

Single Girder Gantry Cranes:

- Often used in construction supply yards or light fabrication zones

- Handle loads from 10 to 20 tons

- Lower profile, easier to install and maintain

- More mobile, sometimes used with rubber wheels in temporary job sites

Double Girder Gantry Cranes:

- Common in steel yards, precast plants, and port terminals

- Built for 25 to 40 ton loads, or heavier

- Allow for higher lifting height and larger spans

- Better suited for daily, repetitive heavy-duty use

Typical Capacities and Materials Lifted in Qatar

Qatari industries often handle bulky and dense materials that forklifts or indoor cranes can't manage efficiently. Gantry cranes step in as the outdoor workhorses.

Usual lifting capacities and their tasks:

- 10–20 tons: Moving rebar cages, machinery crates, portable generators, or tool pallets

- 25–40 tons: Lifting precast slabs, steel coils, molds, or heavy cargo for export

These cranes often work in tandem with transport systems, loading and unloading from trailers or flatbeds in storage zones and shipping areas.

Industry Applications Across Qatar

Gantry cranes are a key asset in several of Qatar's industrial sectors that rely on outdoor operations and frequent lifting of large-scale items.

Where they are most commonly used:

- Port logistics in Doha and Al Wakrah: Container positioning, steel coil loading, and cargo staging

- Precast concrete yards in Al Khor and Umm Salal: Transporting precast panels, wall elements, and large molds

- Steel and fabrication storage zones in Al Daayen: Lifting long steel beams, box girders, and structural frames

- Construction supply areas and contractor depots: Moving formwork systems, scaffolding, and large machinery parts

Gantry cranes in Qatar aren't just an optional tool—they're a critical part of outdoor industrial workflows. When buildings can't support overhead runways or when heavy loads must move under the open sky, a well-built gantry crane is the practical choice. And with configurations built for both temporary jobs and permanent installations, these cranes are as flexible as the projects they support.

Jib Cranes for Flexible and Precise Lifting Needs in Qatar

In many industrial workshops across Qatar—especially in cities like Doha, Al Rayyan, and Al Khor—space is limited, but the need for reliable lifting remains. That's where jib cranes prove their worth. These compact, localized lifting systems are perfect for handling small to mid-sized loads where large cranes would be excessive or simply wouldn't fit. Whether installed next to a machine or at a workstation, jib cranes bring lifting power exactly where it's needed—without interrupting the rest of the operation.

Compact Lifting Solutions for Tight Industrial Spaces

In Qatar's manufacturing and service sectors, two main types of jib cranes are used depending on the workshop layout:

Floor-Mounted Jib Cranes (Pillar Type):

- Installed directly on the workshop floor with a fixed column

- Provides 270° to 360° rotation

- Suitable for open spaces in mechanical repair bays or fabrication stations

Wall-Mounted Jib Cranes:

- Mounted on structural walls or building columns

- Rotates 180° or more, depending on design

- Ideal for narrow bays or when floor space is limited

These cranes are often seen in equipment service shops, panel assembly lines, pump maintenance areas, and repair garages across Qatar's industrial estates.

Load Capacities and Typical Use Scenarios

Jib cranes in Qatar usually handle lighter loads, but precision and frequency are high. Most units fall within the 0.5 to 5-ton range, with some reaching up to 15 tons for heavier workshop components.

Common lifting tasks include:

- 2-ton wall jib cranes in equipment repair workshops (Doha, Al Rayyan) for pumps, motors, and gearboxes

- 1-ton floor-mounted units in plastic or mechanical assembly areas for small tools and fixtures

- 5 to 10-ton units used in steel structure workshops for supporting welding stations or component handling

Why Jib Cranes Make Sense for Qatari Workshops

In Qatar, where many factories and workshops are modular, space-saving solutions are key. Jib cranes deliver just that—efficient lifting without the need for runway beams or structural changes.

Advantages that suit local needs:

- Minimal space requirement – fits into small bays or next to machines

- Quick installation – easy to add to existing facilities

- Precise control – ideal for positioning parts, tools, or assemblies

- Cost-effective – lower investment than full EOT or gantry systems

- Durable for local environments – coated designs resist dust and humidity

Jib cranes are especially practical in service-heavy industries where components need to be frequently lifted, rotated, or precisely aligned. From small-scale repair shops to industrial production cells, these cranes are quietly doing the heavy lifting—without taking up the whole shop.

Low Headroom Cranes for Space-Constrained Workshops in Qatar

In many of Qatar's industrial areas—particularly Doha Industrial Area, Al Rayyan, and older light manufacturing zones in Al Wakrah—factories and service workshops often face space limitations. These buildings were not always designed with overhead cranes in mind. Ceiling heights are restricted, equipment layouts are dense, and floor space is too valuable to waste. That's exactly where low headroom cranes make a real difference. Designed with a compact hoist and trolley system that fits snugly beneath the beam, these cranes allow for maximum hook height, even in tight vertical spaces. They are especially valued by companies where every meter counts—whether for lifting a motor, repairing a pump, or handling small components near the ceiling.

Key Design Advantages for Qatari Workshops

In Qatar's high-density workshops, it's not uncommon to find factories operating out of repurposed buildings or custom-built sheds with limited vertical clearance. These environments call for lifting equipment that does the job without demanding a redesign of the building.

How low headroom cranes support local workshop conditions:

- Compact structure allows the hook to lift closer to the ceiling

- Ideal for retrofitting in existing buildings without major structural changes

- Enclosed hoists with dust-resistant features suit Qatar's dusty conditions

- Reduced clearance requirements are perfect for tight mezzanine levels and short-span bays

These features are especially helpful in smaller mechanical shops, equipment servicing zones, and fabrication units where full-size EOT cranes won't fit or are not cost-effective.

Common Capacity Range: 3 to 20 Tons for Practical Indoor Use

Most low headroom cranes installed in Qatar fall within the 3 to 10-ton range, although larger systems up to 20 tons are also used in more specialized industrial bays, such as for steel part assembly or pump testing areas.

Typical lifting capacities and use examples:

- 3–5 tons: For tool and parts handling in repair garages (Doha, Al Rayyan)

- 5–10 tons: For equipment lifting in HVAC and electrical service centers

- 15–20 tons: For compact steel beam welding zones or hydraulic machinery workshops in Al Daayen

These capacities meet most internal lifting requirements while keeping the crane system efficient and minimally invasive.

Workshop Applications and Real Use Cases Across Qatar

Low headroom cranes are actively used in sectors where lifting is necessary but space is constrained. These include both production and service-based industries.

Common applications by location and industry:

- Maintenance workshops in Doha Industrial Area: For hoisting motors, valves, and compressors

- Mechanical service stations in Al Rayyan: For removing and replacing pump units and machine parts

- Light fabrication workshops in Al Wakrah and Umm Salal: For lifting small assemblies and steel parts during welding

- OEM and spare parts centers in Al Khor: For lifting packaged goods, hydraulic assemblies, and repair tools

Maximizing Efficiency in Tight Indoor Spaces

When space is limited, workflow efficiency becomes even more critical. Low headroom cranes improve workspace organization by reducing reliance on floor-based lifting tools and freeing up more usable floor area.

Key benefits for Qatari workshops:

- Minimize obstruction in low-bay buildings

- Enhance safety by avoiding manual lifting or crowded forklift use

- Increase productivity in repetitive lifting zones without structural expansion

- Easy integration with short-span rails or ceiling supports

For many Qatari businesses working in compact or repurposed industrial spaces, low headroom cranes offer a smart, space-saving lifting solution that fits the environment without compromise. Whether you're maintaining equipment or fabricating components in a confined workshop, this type of crane lets you lift more—without needing more room.

Load Capacity Considerations and Selection Guide for Qatar's Industrial Cranes

Choosing the correct crane capacity is one of the most important decisions for any business in Qatar's industrial sectors. Whether you're running a steel fabrication workshop in Al Wakrah or a maintenance facility in Doha, selecting a crane that matches your actual lifting needs prevents costly mistakes and downtime. Start by closely examining the types of loads you handle regularly—their weight, size, and how often they need moving. Overestimating capacity leads to unnecessary expenses, while underestimating risks safety and productivity.

Factors to Consider When Selecting Capacity

Before making a choice, here are the key points every buyer should consider:

Load Type and Weight

Understand the kinds of materials you'll be lifting and their maximum weights. For example:

- Steel mills deal with heavy beams and plates weighing up to 40 tons.

- Maintenance workshops lift motors, pumps, or machine parts between 0.5 and 10 tons.

- Logistics yards handle containerized cargo, often 10 to 40 tons.

Make sure to add a safety margin of 20-30% above your heaviest expected load for unexpected situations.

Multi-Point Lifting and Synchronization for Complex Loads

When your loads are large, bulky, or irregularly shaped, simple lifting won't cut it. Here's why multi-point lifting systems matter:

- Balanced Load Support: Multi-point lifting prevents the load from twisting or slipping, protecting both the crane and the item.

- Component Safety: Delicate or fragile parts are less likely to be damaged when lifted evenly.

- Smooth, Coordinated Movement: Synchronization features in cranes allow operators to lift with precision, which improves safety and handling.

Dual hoists and synchronized controls are particularly popular in Qatar's steel and mechanical assembly plants for these reasons.

Safety Margins and Operational Efficiency

Operating safely and efficiently requires paying attention to several practical factors:

- Duty Cycles: Consider how frequently your crane will operate daily, as heavy use demands stronger, more durable cranes.

- Dynamic Loads: The forces during lifting, starting, and stopping can be greater than the static load weight, so factor these into your capacity.

- Environmental Conditions: Qatar's wind, dust, and heat can affect crane operation and should influence design choices.

For operational efficiency:

- Choose lifting speeds that match your workflow without compromising safety.

- Select control systems that fit your workspace and operator visibility—manual pendant or remote control options.

- Maintain a regular inspection and maintenance schedule to avoid unexpected downtime.

Quick Tips for Qatar-Based Crane Buyers

To wrap it up, here are practical recommendations for selecting the right crane capacity tailored to Qatar's industries:

- Work with Local Experts: Choose suppliers experienced with Qatar's specific industrial and climate conditions.

- Provide Detailed Load Information: Clearly communicate your heaviest loads, load shapes, and lifting frequency to get accurate crane sizing.

- Plan for the Future: Anticipate growth in your lifting needs to avoid costly upgrades later.

- Use Proper Accessories: Consider spreader bars, load monitoring, or other specialized equipment for handling complex loads safely.

By carefully considering these points, Qatar-based businesses can select cranes that maximize safety, efficiency, and long-term value.

Industry-Specific Applications in Qatar

Qatar's industrial landscape features a diverse range of sectors, each with unique lifting demands shaped by their operations and workshop setups. Understanding the typical industrial features and workshop conditions helps in choosing the right crane solutions tailored to local needs.

Steel Structure Fabrication Plants (5–40 Tons)

Steel fabrication is a major industry in Qatar, especially around Al Wakrah, Al Daayen, and Doha Industrial Area. These plants typically have large workshops with multi-bay steel structures designed for heavy and repetitive lifting.

Workshop Features:

- High ceilings with wide spans to accommodate large double girder cranes

- Multiple lifting points and heavy-duty crane rails to handle large beams, box girders, and welded assemblies

- Open floor plans to allow movement of oversized steel sections

- Frequent multi-point lifting for long, heavy components requiring synchronized hoisting

Typical Applications:

- Lifting H-beams, steel plates, and fabricated structural components

- Transporting assemblies between welding, machining, and painting stations

- Handling raw steel deliveries and finished product loading

Port Logistics and Storage Facilities (10–40 Tons)

In Qatar's major port zones such as Hamad Port and Al Wakrah logistics areas, heavy-duty gantry and EOT cranes serve the dynamic needs of container handling, bulk cargo, and storage yard operations.

Workshop and Yard Features:

- Large open outdoor storage yards with extensive track systems for gantry cranes

- Heavy-duty runway beams for double girder cranes in semi-covered loading zones

- Equipment designed for harsh outdoor conditions including dust, heat, and coastal humidity

- Integration with transport and stacking equipment for efficient cargo flow

Typical Applications:

- Loading and unloading containers, steel coils, and heavy machinery crates

- Stacking and sorting bulk cargo and pallets

- Supporting customs inspection and cargo staging operations

Construction and Infrastructure Sites (3–15 Tons)

Temporary and semi-permanent workshops near construction sites in Doha, Al Khor, and Al Rayyan require cranes that can be quickly installed and relocated. These sites handle materials needed for infrastructure projects such as road building, bridges, and urban development.

Workshop Features:

- Smaller, often low-height prefabricated sheds or open yards

- Mobile or light-duty gantry cranes and jib cranes to accommodate changing site layouts

- Limited structural support, requiring cranes that don't rely heavily on building infrastructure

- Focus on flexibility and ease of installation

Typical Applications:

- Lifting precast concrete elements, rebar bundles, and formwork

- Moving construction equipment and tooling

- Supporting assembly and installation of temporary structures

Machinery Maintenance and Assembly Workshops (0.5–20 Tons)

Maintenance shops and assembly lines scattered around industrial hubs in Doha Industrial Area, Al Rayyan, and Al Wakrah focus on the upkeep and assembly of mechanical and electrical equipment.

Workshop Features:

- Compact indoor spaces with low to medium ceiling heights

- Floor-mounted jib cranes and low headroom overhead cranes for localized lifting

- Organized layout with dedicated bays for pump repair, motor servicing, and component assembly

- Emphasis on precision lifting and maneuverability rather than heavy loads

Typical Applications:

- Lifting motors, pumps, gearboxes, and hydraulic units

- Positioning machinery components during assembly or repair

- Handling spare parts and small equipment in confined spaces

Additional Customization and Integration Options for Qatar's Industrial Cranes

In Qatar's diverse industrial environment, cranes must often be customized beyond basic specifications to fit existing infrastructure, withstand local conditions, and meet operational demands. Understanding these customization needs helps businesses get the most from their crane investment.

Seamless Integration with Existing Runway Systems and Factory Infrastructure

Many factories and workshops across Qatar—especially older facilities in Doha Industrial Area and expanding plants in Al Wakrah or Al Daayen—already have runway beams or steel frameworks in place. Customized cranes can be designed to fit these existing systems, minimizing downtime and avoiding costly structural changes.

Key integration features include:

- Adaptation to current runway beam dimensions and load ratings

- Matching crane span and travel length to existing workshop layouts

- Compatibility with installed power supply and control wiring

- Structural reinforcements where needed for heavier loads or updated standards

This ensures a smooth upgrade path and faster crane commissioning.

Weather and Dust Protection for Outdoor Cranes

Qatar's outdoor industrial sites, like port yards and open storage areas, face intense sun, frequent dust storms, and coastal humidity. Cranes used outdoors must be robustly protected to ensure reliability and reduce maintenance costs.

Common protective measures:

- Weatherproof paint coatings and corrosion-resistant materials

- Dust-tight enclosures for motors, electrical panels, and control devices

- Sealed bearings and heavy-duty gearboxes designed for dusty conditions

- UV-resistant cables and protective covers on moving parts

These enhancements extend crane life and keep operations running smoothly in Qatar's harsh environment.

Automation and Remote Control Options for Enhanced Efficiency

As Qatar's industries modernize, automation and remote operation become increasingly important for safety and productivity. Customized cranes can be equipped with features such as:

- Remote control systems to operate cranes from safe distances, improving operator safety in hazardous zones

- Programmable lifting sequences for repetitive tasks in assembly or logistics

- Load monitoring and anti-sway devices to protect loads and enhance precision

- Integration with factory automation systems for seamless workflow coordination

These technologies help Qatar-based plants reduce downtime and increase lifting accuracy.

Compliance with Qatar and International Standards (CE, ISO)

Ensuring cranes meet local regulations and international quality standards is crucial for safety, reliability, and insurance purposes in Qatar's industrial sector.

Certification and standards include:

- Compliance with Qatar Civil Defense requirements for industrial machinery safety

- Adherence to CE marking for European conformity where applicable

- Alignment with ISO 9001 quality management and ISO 45001 occupational health and safety standards

- Customized documentation and inspection reports for Qatari regulatory approval

Choosing cranes that meet these standards helps businesses avoid regulatory issues and ensures long-term operational confidence.

Conclusion

Qatar's industrial landscape demands crane solutions that are both robust and adaptable. From steel fabrication plants in Al Wakrah to port logistics in Doha, each sector has unique lifting needs shaped by workshop layouts, load types, and environmental conditions. Choosing cranes tailored to these specific factors ensures smoother operations and better long-term value.

Customized crane design isn't just a luxury—it's essential for maximizing efficiency, enhancing workplace safety, and making the most of limited space or challenging outdoor conditions common across Qatar's industrial zones. Properly matched cranes reduce downtime and improve productivity by fitting perfectly into your facility's workflow.

If you're looking to improve your material handling or expand your lifting capabilities, don't settle for off-the-shelf options. Reach out today for expert advice, detailed needs analysis, and a personalized crane solution designed specifically for your Qatar-based operation. Our team is ready to help you find the right crane with the right features and capacity—tailored to your unique industrial demands.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch