EOT Crane in Qatar: Applications, Selection, and Industrial Use Cases

Check EOT crane demand in Qatar. Learn where and how EOT cranes are used, industry-specific needs, and how to choose the right model.

Category: Qatar

Your Trusted Overhead Crane Manufacturer & Supplier

Overhead Crane for Sale Qatar

EOT Cranes in Qatar – Applications, Types, and Buying Guide

Introduction: EOT Cranes for Qatar's Growing Industrial Needs

The demand for efficient lifting equipment in Qatar's industrial sector is rising, and Electric Overhead Traveling (EOT) cranes are playing a pivotal role in meeting this need. Below, we explore what makes these cranes essential and why they are the right fit for many of Qatar's factories and workshops.

What is an EOT crane (Electric Overhead Traveling crane)?

An EOT crane is a type of overhead crane commonly used in factories and workshops. It consists of a hoist that moves along a trolley, which itself runs across a bridge girder fixed on runways. The entire system moves materials horizontally inside a building or workspace. Simply put, it's a crane mounted on rails above the ground, allowing heavy loads to be lifted and transported safely within a facility. This setup keeps the floor clear and maximizes workspace efficiency.

Core Components of an EOT Crane

To understand how an EOT crane works, it's helpful to know the main parts:

- Hoist: The device that actually lifts and lowers the load, powered electrically for smooth operation.

- Trolley: The platform that carries the hoist along the length of the bridge girder.

- Bridge Girder: The main horizontal beam that spans across the runway rails. The trolley travels on this beam.

- Runway: The rails fixed to the building structure or columns, supporting the bridge girder and allowing it to move along the length of the workshop or factory.

Each component plays a key role in making sure loads can be moved safely, reliably, and efficiently.

Why EOT Cranes Are Essential in Qatari Workshops and Factories

Qatar's industries are growing fast. From steel fabrication to construction and general manufacturing, there is a big demand for equipment that can move heavy materials quickly and safely indoors. EOT cranes fit this need perfectly.

- They free up floor space because the lifting system is overhead.

- They allow precise control when moving loads, which improves workplace safety.

- They can handle a wide range of weights, from small tools to heavy steel beams.

- They help speed up production by cutting down manual handling time.

For workshops and factories in Qatar, where space can be limited and environmental conditions can be harsh, EOT cranes offer a practical, reliable solution to keep operations running smoothly.

Difference Between EOT Cranes and Gantry Cranes

While both EOT and gantry cranes are designed for lifting heavy loads, the main difference lies in their installation and movement:

- EOT cranes are fixed inside buildings and move on runways attached to the building structure. This makes them perfect for indoor use.

- Gantry cranes are free-standing and move on wheels along the ground, often used outdoors in yards or ports.

In Qatar, EOT cranes are preferred in workshops because they don't take up ground space and provide smoother, more controlled movement for materials within confined areas. Gantry cranes, on the other hand, are more suitable for outdoor applications like loading docks or large storage yards.

Types of EOT Cranes Commonly Used in Qatar

Choosing the right type of EOT crane is crucial to meet your workshop's specific lifting needs and space constraints. In Qatar, several common types are preferred depending on the load, application, and building structure.

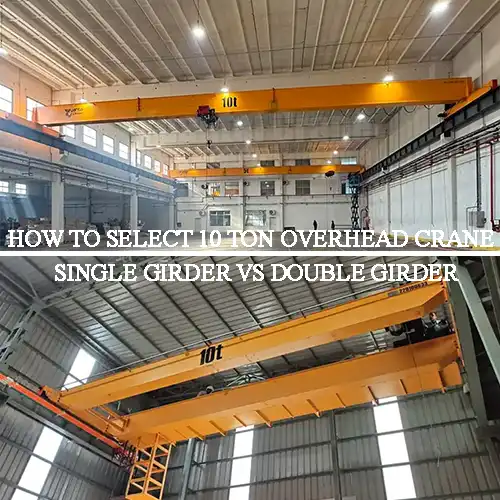

Single Girder EOT Cranes for Light to Medium-Duty Use

Single girder EOT cranes are widely used across workshops and light manufacturing facilities in Qatar. Their simple and compact structure makes them a cost-effective solution for everyday lifting needs. These cranes are designed with a single bridge girder supporting the hoist, which travels along the girder to lift and transport loads.

These single beam EOT cranes are lighter in weight, which reduces structural requirements and installation time. Their lower cost and space-saving design make them especially attractive for facilities that do not require frequent or high-capacity lifting. For businesses seeking reliable handling solutions without overbuilding, single girder EOT cranes offer a practical option.

Key Features- Suitable for lifting capacities up to 10 tons

- Designed for smaller spans and moderate lifting cycles

- Hoist mounted on the bottom flange or side of the girder

- Operated via pendant control or wireless remote systems

- Easy to install and maintain

- Machinery and equipment workshops

- Mold handling in plastic manufacturing

- Light steel component assembly

- Repair shops and service bays

- General material handling in small to medium factories

Double Girder EOT Cranes for Heavy-Duty Lifting

Double girder EOT cranes are engineered for heavy lifting and long-span operations. With two parallel girders supporting the trolley and hoist, these cranes offer superior strength, stability, and performance. They are the preferred choice in industries where lifting heavy loads is a regular requirement.

Built for durability and performance, double girder cranes are essential for operations requiring high lifting capacity and precise load handling. Their ability to support auxiliary equipment such as service platforms, walkways, and magnetic lifters makes them versatile for complex industrial processes. These cranes ensure efficiency and safety in heavy-duty applications.

Key Features- Designed for lifting capacities from 10 tons up to 30 tons or more

- Provides high hook height and better end approach

- Trolley runs on top of the girders, allowing larger hoists

- Stronger structure minimizes deflection and vibration

- Supports a wide range of lifting attachments

- Steel fabrication and metal processing plants

- Precast concrete manufacturing

- Heavy equipment assembly and repair

- Large warehouses and logistics hubs

- Industrial manufacturing with high load demands

Low Headroom EOT Crane

A Low Headroom EOT (Electric Overhead Traveling) Crane is designed specifically for workplaces where vertical space is limited. The main purpose of this crane is to maximize lifting height within a compact structure. This is achieved by positioning the hoist alongside the bridge girder, rather than hanging below it, which significantly reduces the required headroom.

Key Features- Compact and space-saving design for tight vertical clearances

- Hoist integrated closely with the girder to increase effective hook height

- Available in single girder or double girder configurations

- Can be operated with pendant control, remote control, or cabin operation if needed

- Optimized for smooth and safe lifting in low-clearance industrial environments

- Small and medium-sized workshops

- Equipment maintenance facilities

- Old factories with low ceilings

- Warehouses and storage areas with structural height limitations

- Machinery assembly and fabrication plants

Explosion-Proof EOT Crane

An Explosion-Proof EOT Crane is engineered to operate safely in hazardous environments where flammable gases, vapors, or combustible dusts are present. It is designed to prevent ignition sources and ensure operational safety in compliance with national and international explosion protection standards.

Key Features- All electrical components are sealed in flameproof enclosures

- Motors, brakes, junction boxes, and control panels are certified for use in hazardous zones

- Mechanical components like hooks and wheels are made from anti-spark materials

- Optional stainless steel wire ropes and non-sparking bronze wheels depending on environment

- Control systems include explosion-proof pendant stations or wireless remotes

- Chemical and petrochemical plants

- Oil and gas refineries

- Paint and solvent storage areas

- LNG and fuel handling terminals

- Flour mills, grain processing, and coal mining industries

Top Running EOT Cranes

Top running EOT cranes are designed with bridge girders that travel on top of runway rails, which are mounted directly to the building's columns or dedicated gantry structures. This configuration allows for higher lifting capacities, faster speeds, and wider spans, making it suitable for demanding industrial environments.

Key Features- Bridge travels on rails mounted above the crane runway

- Suitable for heavy-duty lifting and large spans

- Offers greater lifting height due to top-mounted design

- Requires strong building columns or crane girders for support

- Ideal for indoor or outdoor installations in robust structures

- Steel service centers and heavy manufacturing

- Precast concrete production and large warehouses

- Equipment assembly plants

- Facilities requiring frequent heavy lifts and long travel distances

Underslung EOT Cranes

Underslung EOT cranes, also known as under-running cranes, feature bridge girders that hang beneath the runway rails. The rails themselves are suspended from the building structure or roof trusses. This type of crane is ideal for workshops where ceiling height is limited or heavy structural support is unavailable.

Key Features- Bridge travels below rails suspended from the building structure

- Suitable for light to medium lifting duties

- Allows for better utilization of limited vertical space

- Requires less structural reinforcement from the building

- Commonly used in low-headroom environments

- Maintenance and repair workshops

- Small manufacturing units and assembly lines

- Warehouses with space constraints

- Locations where floor space and ceiling height are limited

European Standard EOT Cranes

European standard EOT cranes are designed and manufactured according to advanced engineering principles and internationally recognized standards such as FEM (European Federation of Materials Handling) and DIN (German Institute for Standardization). These cranes emphasize safety, precision, and long service life.

Key Features- Designed in accordance with FEM and DIN specifications

- Equipped with modular hoists, frequency inverters, and intelligent control systems

- Compact structure with optimized wheel loads and hook approaches

- High-quality components ensure smooth, quiet, and efficient operation

- Engineered for long-term reliability and minimal wear

- High-precision assembly plants

- Automated production lines

- Facilities with continuous or high-duty lifting operations

- Projects requiring energy-efficient, low-maintenance solutions

Conventional EOT Cranes

Conventional EOT cranes are designed based on widely accepted industrial practices and general design standards. They are robust and cost-effective, making them a common choice for a variety of basic lifting tasks in workshops and factories.

Key Features- Built using traditional design principles and general fabrication methods

- Components are generally easier to source and replace locally

- Control systems are simpler and often use contactor-based technology

- Typically configured for moderate lifting cycles and standard environments

- Suitable for overhead or gantry crane configurations

- General manufacturing and fabrication shops

- Local repair and maintenance facilities

- Small to mid-sized production plants

- Warehouses and handling operations with standard lifting needs

Why EOT Cranes Are Preferred in Qatar Over Other Crane Types

In Qatar's industrial settings—where workshops are often busy, space is limited, and efficiency is critical—EOT cranes are the preferred choice for many factory owners and engineers. Compared to other lifting equipment like gantry or jib cranes, EOT cranes offer a practical blend of performance, space-saving, and cost control.

Smooth and Controlled Load Travel Across Wide Spans

One of the standout benefits of an EOT crane is its ability to move heavy loads across large working areas without interruption.

- Offers precise control over both vertical and horizontal movement

- Handles long spans of 15 meters or more without compromising safety

- Ideal for workshops handling bulky steel beams, panels, or long equipment

This smooth travel reduces accidents, minimizes damage to goods, and supports faster workflow across workstations.

Ideal for Indoor Workshops with Limited Ground Space

In many Qatari factories—especially those in Doha or Al Rayyan—floor space is at a premium. EOT cranes solve this problem by operating entirely overhead.

- Keeps the floor clear for machinery, pallets, or worker movement

- Eliminates the need for forklifts in certain tasks

- Doesn't interfere with foot traffic or ground operations

This is a big advantage over mobile cranes or gantry cranes, which take up valuable space and may create safety hazards.

More Efficient Than Gantry Cranes for Permanent Facilities

While gantry cranes are suitable for outdoor yards or temporary sites, EOT cranes are better suited for permanent installations.

- No need for floor tracks or supporting legs

- Integrated into the building's structure, making them more stable

- Lower maintenance costs due to fewer exposed moving parts

For long-term use inside a workshop, EOT cranes are a cleaner and more dependable solution.

Cost-Effective in Long-Term Factory Operations

Though the initial cost of an EOT crane may be higher than some alternatives, it quickly pays off in reduced labor, faster handling, and minimal downtime.

- Less need for manual lifting or extra workers

- Reduced risk of product or equipment damage

- Longer working life when properly maintained

In short, for a factory owner in Qatar thinking ahead—especially in sectors like steel, precast, or heavy equipment—a good EOT crane is not just a tool, it's an investment that returns value year after year.

If you're setting up a new facility or upgrading your material handling system, it's worth seriously considering an EOT crane—not just for its lifting power, but for the way it fits naturally into a well-run Qatari workshop.

Where EOT Cranes Are in Highest Demand in Qatar

Different cities and regions have their own industrial strengths, which influence the demand for cranes.

Doha: Hub for Logistics, Equipment Handling, and Urban Development

Doha, the capital and largest city, leads the pack in EOT crane demand. With ongoing urban development projects, warehouses, and a booming logistics sector, the need for efficient material handling solutions is high.

- Handling heavy equipment and construction materials in urban workshops

- Moving supplies quickly in warehouses and distribution centers

- Supporting large infrastructure projects that require precise lifting

If your business is based in or near Doha, having a reliable EOT crane can make all the difference in meeting tight schedules and safety standards.

Al Wakrah: Port Logistics and Marine Fabrication

Al Wakrah's growing port and marine industries drive demand for cranes that can handle shipping containers, steel structures, and heavy fabrication work. This area is critical for:

- Loading and unloading cargo at the port

- Moving heavy materials inside warehouses

- Supporting shipbuilding and marine repair workshops

EOT cranes here need to be robust and often adapted to outdoor or semi-outdoor environments due to proximity to the coast.

Al Rayyan: SME Manufacturing and Repair Facilities

Al Rayyan hosts many small and medium-sized enterprises (SMEs) involved in manufacturing, machinery repair, and workshop operations. These facilities often rely on smaller capacity EOT cranes for:

- Lifting machine parts and components safely

- Assisting with equipment maintenance and assembly

- Handling medium-sized loads in limited space workshops

Flexibility and ease of operation are key factors for cranes used in this region.

Al Khor: Construction and Prefabrication Projects

Al Khor is known for construction contractors and precast concrete plants working on infrastructure projects. The demand for EOT cranes is driven by:

- Moving heavy steel and prefabricated components on-site

- Supporting assembly lines for precast concrete elements

- Assisting with heavy equipment positioning for construction

Cranes in Al Khor need to handle heavier loads and longer spans, often with customized features to suit project-specific requirements.

Top Industries Using EOT Cranes in Qatar

EOT cranes are versatile tools, but certain industries in Qatar rely on them more heavily due to the nature of their work. Let's look at the main sectors driving demand for these cranes.

Steel Fabrication and Metal Structure Factories

Steel fabrication is one of the biggest users of EOT cranes in Qatar. Factories that produce metal structures, beams, and frameworks depend on cranes to:

- Lift and position heavy steel plates and beams safely

- Move raw materials and finished components around the workshop

- Handle cutting, welding, and assembly processes efficiently

Without a reliable EOT crane, handling these large, heavy materials would slow down production and increase safety risks.

General Construction and Infrastructure Developers

The construction sector in Qatar is booming, with many ongoing projects for roads, buildings, and infrastructure. Construction companies use EOT cranes to:

- Transport heavy construction materials like rebar and concrete blocks within workshop areas

- Support onsite prefabrication of components before installation

- Facilitate safe movement of tools and machinery during different phases of construction

EOT cranes help keep construction timelines on track by improving material handling and reducing manual labor.

Cement and Precast Component Producers

Factories producing cement and precast concrete parts also rely on EOT cranes to handle heavy molds and finished products. In these settings, cranes are used for:

- Lifting molds for casting concrete elements

- Moving large precast panels and beams safely for storage or shipment

- Shifting heavy pallets of raw materials or finished goods

Precision and reliability are key here, as mishandling can damage expensive components.

Equipment Repair and Maintenance Workshops

Many workshops dedicated to repairing heavy machinery and equipment in Qatar use EOT cranes daily. The cranes assist in:

- Lifting heavy machine parts for inspection and repair

- Moving engines, gearboxes, and other components safely within the workshop

- Assisting with assembly and disassembly processes

For these workshops, a compact but strong EOT crane often fits best, allowing for smooth handling in tighter spaces.

Plastic Molding and Light Manufacturing

Even lighter manufacturing industries such as plastic molding plants benefit from EOT cranes. Here, the cranes typically handle:

- Moving molds and dies used in injection molding machines

- Transporting raw material containers and finished products

- Supporting assembly lines with material lifting

Though the loads are lighter, precise and smooth crane operation is still essential to avoid damage and maintain workflow.

Common Applications of EOT Cranes in Qatari Workshops

In Qatar, EOT cranes are widely used across various workshop environments—from steel processing plants to maintenance facilities. Their practical design and overhead installation make them ideal for handling heavy and bulky items in a controlled and efficient way. Below are some of the most common daily applications.

Lifting Structural Steel, Rebar, and Steel Beams

Many fabrication and construction support workshops rely on EOT cranes to handle raw steel and structural materials. These items are often long, heavy, and awkward to move manually.

- Lifting long rebar bundles from storage racks to cutting or bending stations

- Hoisting steel beams for welding or assembly

- Transferring fabricated structures between workstations or to transport trucks

This reduces the need for forklifts, cuts down on manual labor, and speeds up production.

Moving Equipment and Machinery During Maintenance

In machinery repair and maintenance workshops—especially those servicing construction or industrial equipment—EOT cranes are essential.

- Lifting heavy motors, gearboxes, and machine parts for disassembly

- Supporting overhead access to under-maintained areas of equipment

- Re-positioning machines or components during installation or repair

This allows for safer and faster turnaround during routine maintenance or emergency servicing.

Handling Molds, Dies, and Workshop Tools

Plastic molding and light manufacturing workshops in Qatar often handle high-precision tools like molds and dies. These components, while not always very large, are typically heavy and require careful handling.

- Loading and unloading molds into molding machines

- Transporting dies to and from storage areas

- Moving tool sets between production lines or stations

Using an EOT crane minimizes the risk of damage and injury, especially when handling expensive or delicate tooling.

Storing and Shifting Precast Concrete Components

Precast concrete production is growing in Qatar, especially for urban infrastructure and housing projects. EOT cranes are used in these workshops to manage:

- Movement of concrete slabs, blocks, and wall panels from casting bays to curing areas

- Transferring components to storage or shipping zones

- Lifting molds used in the casting process

Because these items are heavy and often shaped awkwardly, a top-running double girder EOT crane is usually the best fit for this application.

Practical Design Tips for EOT Cranes in Qatar

Designing an EOT crane for use in Qatar requires more than just choosing the right capacity. Workshop size, building structure, and environmental conditions all play a role in how well your crane will perform. Here are some practical considerations to help you get it right the first time.

Adapting Crane Design to Low Ceiling Heights

Many workshops in Qatar—especially those built for small and medium-sized businesses—have limited vertical clearance. This can be a challenge when choosing an overhead lifting system.

- Use low-headroom hoists to maximize lifting height in restricted spaces

- Consider underslung EOT cranes when top-running cranes don't fit

- Plan hoist and trolley dimensions carefully to prevent collision with the ceiling or equipment

Even just 30 cm of lost hook height can limit what you're able to lift or where it can be moved.

Choosing Optimal Span and Lifting Height for Narrow Workshops

Some Qatari workshops are long but narrow, which affects how you design the crane span and lifting height.

- Don't oversize the bridge span—this adds cost and may not fit the building layout

- Choose a lifting height that's enough for your tallest equipment, but not excessive

- If you're planning to expand later, consider modular designs that allow future runway extensions

Oversizing wastes money; undersizing creates bottlenecks. Balance is key.

Designing for Outdoor Use in High-Temperature and Dusty Environments

If your EOT crane will operate partially or fully outdoors—as is common in precast or steel storage yards—Qatar's climate can't be ignored.

- Use dust-proof enclosures and sealed electrical components

- Choose motors and gearboxes with heat resistance (ambient up to 50°C)

- Apply anti-corrosion paint or galvanized coatings on steel structures

- Add sunshades or covers for electrical panels and control stations

Environmental stress shortens crane life if not addressed early in the design.

Considerations for Runway Beam Length and Column Spacing

A common mistake is underestimating how much support your runway beams need. Qatar's construction practices vary, so this must be planned properly with the builder or installer.

- Standard column spacing is often 6 meters, but verify it against your crane's wheelbase

- Reinforce runway beams based on load class and frequency of use

- Account for expansion joints in longer runways to deal with steel expansion from heat

Improper spacing or support can cause rail misalignment or even structural failure over time.

Popular Lifting Capacities of EOT Cranes in Qatar

Not every crane needs to lift 50 tons. The right capacity depends on your materials, processes, and how frequently you lift. In Qatar, EOT crane buyers often follow a pattern based on typical factory needs. Here's a closer look at the most commonly used lifting capacities and where they're applied.

3 Ton EOT Cranes – For Workshop and Light-Duty Use

These are ideal for smaller tasks, where precision and ease of use matter more than heavy lifting.

- Perfect for small repair shops and maintenance facilities

- Used for lifting pumps, motors, small tools, and light parts

- Often built with underslung or single girder configurations to fit lower ceilings

These cranes are easy to install, affordable, and don't require reinforced building structures.

5 Ton EOT Cranes – Versatile for Small Factories

The 5-ton capacity hits a sweet spot. It's one of the most requested sizes in Qatar because of its wide usability across sectors.

- Common in plastic molding, packaging, light steel fabrication, and storage facilities

- Can lift larger dies, bundles of material, or machinery components

- Still compact enough for narrow workshops or light-duty operations

This size is often chosen for first-time crane buyers or expanding production lines.

10 Ton EOT Cranes – Popular in Steel and Mechanical Workshops

If you're handling steel profiles, fabricated parts, or machinery assembly, the 10-ton crane is a practical option.

- Widely used in mid-sized steel structure plants and heavy equipment workshops

- Suitable for top-running single or double girder designs

- Lifts medium steel beams, large motors, structural assemblies

It balances strong lifting capability with manageable installation requirements.

20–30 Ton EOT Cranes – For Heavy Loads and Industrial Plants

When lifting gets serious, these cranes are used in larger workshops and production facilities.

- Common in precast concrete yards, foundries, and steel fabrication centers

- Can lift full-size precast wall panels, large tanks, or heavy rebar bundles

- Require double girders, strong foundations, and professionally designed runways

These cranes are typically custom-engineered for each facility based on layout and load patterns.

Over 30 Ton EOT Cranes – Used in Fabrication Yards and Precast Plants

In Qatar's heavy-duty operations, some facilities require even more lifting power. These cranes handle bulky, oversized loads that smaller systems can't manage.

- Essential in modular building factories, large fabrication workshops, and offshore equipment plants

- Lift oversized concrete segments, industrial containers, or steel structures

- Often paired with dual hoists or tandem operation for safe handling of large items

Due to their size and cost, these cranes are less common—but critical where needed.

How to Choose a Reliable EOT Crane Supplier in Qatar

Investing in an EOT crane is not just about buying a product — it's about finding the right partner who understands your workshop, your workflow, and Qatar's working conditions. Whether you're purchasing your first crane or expanding your operations, choosing a reliable supplier can make or break your project.

Compare Local Agents and Chinese Manufacturers

Both local agents and international suppliers — especially Chinese crane manufacturers — are active in the Qatari market. Each has its pros and cons.

- Local agents may offer quicker on-site support, local installation teams, and shorter communication times

- Chinese manufacturers often provide better pricing, advanced technology, and more flexible customization options

Tip: If working with a Chinese supplier, make sure they have experience exporting to the Middle East, and can provide clear documentation and local references.

Ensure Customized Design for Qatar's Workshop Conditions

Not every crane design suits every building. Qatar's workshops often deal with high ambient temperatures, dust, and low ceilings. So don't settle for an off-the-shelf model.

- Ask for custom girder heights to match your ceiling limits

- Request IP-rated motors and electrical parts for dust and heat resistance

- Consider crane painting or galvanization to resist corrosion in coastal areas

A good supplier will request your building layout and offer drawings before you sign the deal.

Look for Delivery, Installation, and After-Sales Service Support

Buying the crane is just the beginning. You'll need support for shipping, customs clearance, assembly, testing, and future maintenance.

- Does the supplier offer turnkey installation or work with a local service partner?

- Can they assist with runway beam fabrication and alignment?

- Is remote technical support or on-site troubleshooting available?

These services can save you time and trouble later — especially if something needs adjustment after installation.

Confirm CE, ISO Certifications and Third-Party Inspections

Crane safety and compliance are non-negotiable. Your EOT crane must meet recognized international and regional standards.

- Ask for CE (European Conformity) marking for electrical and mechanical safety

- Ensure the manufacturer has ISO 9001 for quality management

- Request third-party inspection reports or factory test certificates before shipping

This documentation not only protects your investment but is often required for insurance or regulatory compliance.

Conclusion: Invest in the Right EOT Crane for Long-Term Productivity

An EOT crane is more than just lifting equipment—it's a key tool that supports the smooth operation of your entire workshop. From steel fabrication to machinery maintenance, the right crane helps you get work done faster, safer, and with fewer disruptions.

- It improves safety by reducing manual handling and lowering the risk of injury

- It increases efficiency by speeding up material transfers between workstations

- It enhances material flow, especially in busy or space-limited workshops

Fit-for-Purpose Solutions Offer Better Value

In Qatar, industrial conditions vary by sector and location. That's why a crane that's properly designed for your specific needs—not just based on lifting capacity—delivers better long-term performance.

- A well-sized crane reduces downtime caused by limitations or overuse

- Maintenance is easier when the crane matches the demands of your application

- Energy and operating costs remain lower when the system is optimized for your building layout

Get Expert Help with Your EOT Crane Selection

Whether you're starting a new factory or upgrading an existing one, it's important to choose a supplier who understands both the technical side of cranes and the practical needs of Qatari workshops.

Get in touch with our team for a free consultation. We'll help you design and select an EOT crane system that fits your facility, your budget, and your production goals.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch