What 220 V Overhead Crane Buyers Must Know About Busbar Sizing

What Crane Buyers Need to Know About Busbar (Power Line) Sizing for 220V Overhead Cranes

Learn why correctly sizing busbars for 220V cranes ensures safe, efficient operation & prevents costly electrical issues.Get customized overhead crane!

Introduction: Why Busbar Size Matters for Your Crane Purchase

When you're buying an overhead crane, a lot of attention goes into the crane's lifting capacity, the type of hoist, or even the brand. But one important detail that often gets overlooked is the busbar — or power line — that supplies electricity to the crane. It might seem like just a small part of the whole system, but it actually plays a big role in how well your crane performs and how safe it is to operate.

If the busbar isn't sized correctly, you can run into problems like voltage drops, overheating, or even electrical failures. This not only risks damaging the crane's components but also can lead to downtime or costly repairs. And believe me, fixing electrical problems after installation can be a headache you don't want.

For cranes running on 220V, this issue becomes even more important. Because the voltage is lower, the current flowing through the busbar will be higher compared to cranes running at higher voltages like 380V or 400V. So, you need to pay close attention to how the busbar is sized based on the total power of your crane.

In this section, you'll learn why:

- The busbar size directly affects your crane's electrical performance and safety.

- Many buyers make the mistake of undersizing the busbar by dividing the total power incorrectly.

- For 220V cranes, you should always base the busbar size on the full machine power — not half or any fraction of it.

Note: Any guidance, visuals, illustrations, or details provided here are intended solely for general education and to promote overall safety awareness. They are not a substitute for legal, medical, or other specialized advice or services. Always consult qualified industry professionals for specific guidance. This material is not all-inclusive, and users should obtain expert advice as needed for their particular situation.

European style double girder overhead crane for sale hot sale 20 ton

Electrical Current for 220V Overhead Cranes

When you run an overhead crane on 220 volts, the electrical current it draws is naturally higher than cranes running at higher voltages like 380V or 400V. This happens because the power needed to lift heavy loads stays the same, but since voltage is lower, the current has to increase to deliver that power.

To put it simply, power (measured in kilowatts) equals voltage multiplied by current. So, if voltage drops, current has to rise to keep the same power level. For crane buyers, this means your busbar or power line must be sized to handle that higher current safely.

Why does this matter? Because if your power line isn't thick enough or properly rated for the current, you'll experience issues like:

- Voltage drops along the busbar, which can reduce crane performance

- Excessive heat buildup that can damage electrical components

- Increased risk of power interruptions or electrical faults

All these issues not only affect how smoothly your crane works but can also lead to expensive repairs or safety hazards.

For your facility, it means you need to carefully check that your existing electrical setup can support these higher currents. Sometimes, this might involve upgrading your busbars, cables, or circuit protection devices to avoid surprises after installation.

In summary:

- 220V cranes pull more current to deliver the same power as higher-voltage cranes

- Your power line must be sized correctly to handle this higher current

- Proper sizing helps maintain crane performance, reduce wear, and keep your operation safe

Common Mistakes Buyers Make in Busbar Selection

Dividing Total Crane Power by 2 or More

A common mistake is assuming you can reduce the busbar size by dividing the crane's total motor power—often by 2—especially if the crane has multiple motors or phases. This is incorrect because the busbar must carry the full current based on total power, not a fraction of it. Trying to save money this way leads to undersized power lines that can't handle the load.

Why undersized busbars cause problems:

- Overheating due to excessive current in smaller conductors

- Voltage drops that reduce crane performance

- Frequent unexpected shutdowns or electrical faults

- Damage to insulation and components, increasing fire risk

- Costly repairs and downtime for your operation

Always size busbars based on full total machine power:

- Use the crane's total motor power without dividing it

- This ensures the busbar can safely handle peak current demands

- Helps maintain consistent voltage and crane reliability

- Prevents costly equipment damage and operational interruptions

Never try to cut costs by undersizing your busbar. Using the full machine power for sizing is a small step that protects your investment and keeps your crane running smoothly.

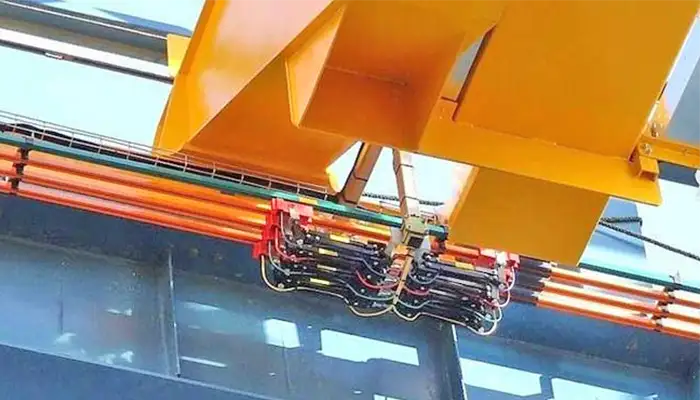

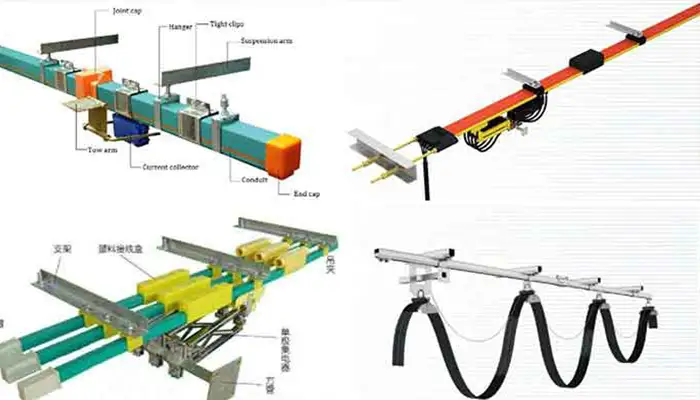

4 types of overhead crane busbar for your selection

How to Calculate the Right Busbar Size for Your Crane

No need for complicated math — just the basics:

When sizing the busbar for your overhead crane, you don't have to get bogged down in complex formulas. The main thing to remember is that your crane's total motor power, measured in kilowatts (kW), indicates how much electrical current it will draw. Since 220V cranes operate at a lower voltage, they require higher current, so your busbar needs to be sized accordingly. Always base your busbar size on the full total motor power.

- Your crane's total motor power (in kilowatts, kW) tells you how much electricity it needs.

- At 220 volts, the current will be higher than at higher voltages, so you must size the busbar accordingly.

- Always use the full total power of your crane when deciding busbar size. Don't divide or reduce this number.

Why use total power directly?

Some buyers make the mistake of dividing the total motor power by 2 or another number, thinking this reduces the current load on the busbar. However, this practice can cause serious problems. If the busbar is undersized, it can overheat, lead to voltage drops, and even cause electrical faults. Using the full power rating ensures your busbar can safely handle the electrical load and keep your crane running smoothly.

- Using the full motor power (for example, 12 kW) ensures the busbar can safely carry the current.

- Dividing or halving the power can lead to an undersized busbar.

- Undersized busbars cause overheating, voltage drops, and potential electrical failures.

Typical busbar sizes for common crane powers at 220V:

To give you a practical idea, here are common busbar sizes recommended for cranes with different motor powers operating at 220 volts. These sizes are typical and will usually meet safety and performance requirements, but always confirm with your supplier or electrician.

| Crane Motor Power (kW) | Recommended Busbar Size (mm²) |

|---|---|

| 5 | 10 |

| 12 | 16 |

| 20 | 25 or larger |

What should you do next?

Once you know the total motor power of your crane, use it to discuss busbar sizing with your supplier or a qualified electrician. Also, check your local electrical codes for any additional rules or requirements. It's always better to choose a busbar that's sized for safe and reliable operation rather than risking problems later by cutting corners.

- Confirm these sizes with your crane supplier or electrician.

- Check local electrical codes for any additional requirements.

- Always prioritize safe and reliable operation over cutting costs on wiring.

Practical Advice: Busbar Sizing Example for Buyers

Example: For a 12 kW overhead crane running at 220V, a 16 mm² busbar is typically recommended

Let's take a real-world example to make this clearer. If your crane's total motor power is 12 kW and it runs on a 220-volt supply, the busbar or power line should generally have a cross-sectional area of around 16 mm². This size is commonly recommended because it can safely carry the current your crane needs without overheating or causing voltage drops.

- For a 12 kW crane running at 220V, a 16 mm² busbar is typically recommended.

How this sizing supports safe, reliable operation without electrical issues

Choosing the right busbar size is more than just following numbers — it's about ensuring your crane runs smoothly and safely every day. The correct busbar size helps prevent electrical problems such as overheating, which can damage equipment or even cause fire hazards. It also reduces voltage drops, keeping your crane operating at full power without interruptions or slowdowns.

- Proper busbar sizing prevents overheating and protects electrical components.

- It minimizes voltage drops, ensuring consistent crane performance.

- It lowers the risk of electrical faults that could lead to costly downtime.

Tips on confirming busbar sizing with your crane supplier or electrician

When buying your crane, don't hesitate to ask your supplier or electrician about the busbar specifications. It's important they verify the busbar size is suitable for your crane's total power and your facility's electrical setup. Make sure they confirm compliance with local electrical standards and consider any site-specific factors like installation environment or future upgrades.

- Ask your supplier or electrician to confirm busbar size based on your crane's total motor power.

- Ensure the sizing complies with local electrical codes and standards.

- Discuss any special site conditions or plans for future expansion that might affect busbar requirements.

Summary: Key Takeaways for Buyers

Always ensure busbar sizing is based on total machine power for 220V cranes

One of the most important points to remember when buying a 220V overhead crane is to size the busbar according to the full total motor power. This approach ensures your power line can safely handle the electrical load and prevents overheating or voltage drops.

- Busbar size must match the total machine power, not a reduced or divided figure.

Don't fall for shortcuts that can lead to undersized power lines and future problems

Some buyers try to save costs by guessing or undersizing the busbar, often by dividing the power rating incorrectly. This shortcut may cause problems down the road, including frequent breakdowns, poor crane performance, and even safety hazards.

- Avoid estimating busbar size without proper calculations or expert advice.

- Undersizing leads to overheating, voltage instability, and expensive repairs.

Work with your crane supplier to verify the correct busbar specification for your specific crane model

Every crane model can have its own power requirements and installation conditions. Collaborating closely with your supplier and an electrician will help ensure the busbar is properly sized for your exact crane and site setup.

- Confirm busbar specs with your crane supplier based on your crane's power and application.

- Involve a qualified electrician to verify installation safety and compliance.

Bonus Tips for Crane Buyers

Check if your site's existing electrical infrastructure supports the busbar size needed

Before purchasing, review your facility's electrical setup. Older or smaller electrical systems might require upgrades to handle the busbar size your crane needs. Planning this early avoids surprises during installation.

- Assess existing cables, circuit breakers, and busbars for compatibility.

- Consider electrical capacity and whether upgrades are necessary.

Consider future upgrades or expansions when selecting busbar capacity

If you expect to add heavier cranes or additional equipment later, it's smart to size the busbar with future needs in mind. This proactive approach can save time and money down the road.

- Choose a busbar size that can handle potential future loads.

- Discuss long-term plans with your supplier to accommodate growth.

Ask your supplier about compliance with local electrical standards and safety regulations

Electrical standards vary by region and are designed to keep your operation safe. Confirm that the busbar and electrical components meet these regulations to avoid legal or safety issues.

- Request documentation proving compliance with local codes.

- Ensure your supplier provides components rated for your location and application.