Mobile Gantry Crane for Sale: 2, 3, 5,10 T Capacity & Price Guide

Affordable mobile gantry cranes 1 ton to 10 ton for sale. Portable, flexible, & cost-effective solutions tailored for your material handling needs.Check!

Category: Mobile Gantry Crane For Sale

Your Trusted Mobile Gantry Crane Manufacturer & Supplier

Mobile Gantry Cranes : Capacity and Price Guide

Mobile Gantry Cranes 2 T, 3 T, 3 T, 5 T for Sale, Find the Perfect Tonnage and Price for Your Business

Affordable mobile gantry cranes 1 ton to 10 ton for sale. Portable, flexible, & cost-effective solutions tailored for your material handling needs.

Mobile Gantry Cranes

What is a Mobile Gantry Crane?

A mobile gantry crane is a portable lifting system that can easily move from one location to another. It's designed to handle materials in various work environments, from small workshops to larger construction sites. These cranes are perfect for businesses that need flexibility and frequent movement of equipment.

- Portable: It doesn't need to stay in one place, so you can move it wherever it's needed.

- Versatile: Whether you're working indoors or outdoors, it fits well in many types of environments.

- Compact: A smaller footprint means it can work in tight spaces, saving room for other activities.

Why Choose a Mobile Gantry Crane?

Mobile gantry cranes are a smart choice for many businesses. They offer several advantages compared to fixed cranes, especially when flexibility and cost are important.

Flexibility

A mobile gantry crane can go wherever the job takes you.

- Can be used in workshops, warehouses, and construction sites

- Easily relocated to different areas as work shifts

- No need for fixed tracks or dedicated installation space

This flexibility allows one crane to serve multiple locations, making it highly practical for changing work environments.

Cost-Effective

You save more than just money on the crane itself.

- No major installation costs or permanent foundations

- Lower maintenance compared to overhead systems

- One crane can be used in multiple locations, reducing the need for duplicates

It's a good option for businesses that want solid lifting power without a large upfront investment.

Easy to Use

These cranes are designed for fast, simple operation.

- Quick setup with no special tools or skills required

- Easy to roll into place and lock for safe lifting

- Ideal for quick jobs, occasional lifting, or use by different teams

Whether you're moving small equipment or parts, mobile gantry cranes let you handle tasks smoothly and efficiently.

Mobile Gantry Crane Capacities

Choosing the Right Capacity for Your Needs

Selecting the right lifting capacity is one of the first and most important steps when buying a mobile gantry crane. The capacity should match the typical load you handle. Here's a practical breakdown based on common applications.

Small Capacity: 0.25 ton, 0.5 ton to 1 ton mobile gantry crane

This range is ideal for simple, light-duty operations where lifting heavy items isn't necessary.

- Best for use in tool rooms, garages, electronics workshops, and small assembly lines

- Can lift light machine parts, toolboxes, molds, and small pallets

- Easy to roll and reposition, even by one person on a smooth floor

- Useful for maintenance work or shifting loads between workbenches

Medium Capacity: 2 tons, 3 tons, 5 tons mobile gantry crane

If you're working with moderate-weight materials or equipment, this capacity is a solid choice. It gives you more power without being oversized.

- Commonly used in mechanical workshops, metal fabrication, and mid-sized production facilities

- Suitable for lifting pumps, engines, steel frames, mechanical parts, and shipping containers

- Often used for loading and unloading delivery trucks

- Can be moved around a workshop or yard without needing a fixed track

Larger Capacity: 10 tons mobile gantry crane

For heavy-duty jobs, a 10-ton mobile gantry crane is a strong and reliable choice. This size is built for industrial settings.

- Ideal for lifting large dies, molds, heavy structural components, or construction equipment

- Used in outdoor construction sites, steel yards, and large fabrication shops

- Requires a flat surface and adequate turning space due to its size

- Typically paired with a motorized hoist to ease the lifting of heavy loads

How to Determine the Right Capacity

Choosing the right crane capacity isn't just about picking the biggest one available. It's about matching the crane to your actual workload and work environment—so you don't overspend or overbuild.

Know Your Load

Start with the weight of your typical lifting tasks.

- Identify the heaviest item you'll lift regularly

- Don't oversize "just in case" — if your load is under 1 ton, a 1-ton crane is enough

- Lifting lighter loads with a heavier crane only adds unnecessary bulk and cost

Understand Your Work Environment

Your workspace impacts the size and type of crane you need.

- Measure your ceiling height and working space

- Consider the height of your workbench or platform

- A longer span or higher lift increases crane size and cost

Match the crane's specs to your actual layout to avoid wasted space or reduced mobility.

Think About Frequency of Use

The more often you use the crane, the more robust it should be.

- For occasional lifts, a light-duty or manual gantry may be enough

- For daily use, choose a more durable frame and electric hoist

- Consider motorized movement if you'll move the crane frequently

Balance Power and Portability

More lifting power usually means a heavier crane. That can limit how easy it is to move.

- Choose a crane that lifts what you need without being oversized

- A lighter model is easier to move, especially on smooth shop floors

- Think about how often and how far the crane will be moved

Safety First

Always build in a safety margin for regular lifting tasks.

- Avoid operating at maximum rated capacity all the time

- If your typical load is 2 tons, choose a 3-ton crane

- This protects your equipment and ensures longer service life

Getting the right capacity helps you stay efficient, safe, and within budget. It's worth taking the time to plan it out carefully.

This section provides practical guidance for crane buyers by focusing on real-world applications and helping them avoid over- or under-buying based on capacity needs.

Pricing for Mobile Gantry Cranes

Affordable Options for Every Budget

Mobile gantry cranes are available in a wide range of capacities and sizes, making them suitable for businesses of all scales. Prices vary depending on how much weight you need to lift, the span, and how high the crane needs to go. Here's a clear breakdown to help you compare:

| Capacity | Span (m) | Lifting Height (m) | Price Range (USD) |

|---|---|---|---|

| 0.25 ton | 2 ~ 12 | 1 ~ 9 | $900 ~ $9,000 |

| 0.5 ton | 2 ~ 12 | 1 ~ 9 | $1,200 ~ $12,000 |

| 1 ton | 2 ~ 12 | 1 ~ 9 | $1,500 ~ $15,000 |

| 2 ton | 2 ~ 12 | 1 ~ 9 | $2,000 ~ $20,000 |

| 3 ton | 2 ~ 12 | 1 ~ 9 | $3,000 ~ $30,000 |

| 5 ton | 2 ~ 12 | 1 ~ 9 | $4,500 ~ $46,000 |

| 10 ton | 2 ~ 12 | 1 ~ 9 | $7,000 ~ $65,000 |

Factors That Affect the Price of Mobile Gantry Cranes

Mobile gantry crane prices vary depending on several key factors. Understanding these helps you make the right investment and avoid paying for features you don't need.

Lifting Capacity

The higher the weight your crane needs to lift, the stronger and more expensive the crane will be.

- Heavier capacities require thicker steel and reinforced frames.

- Larger hoists and more durable components drive up manufacturing costs.

- A 5-ton crane will cost more than a 1-ton crane, even if the other specs are the same.

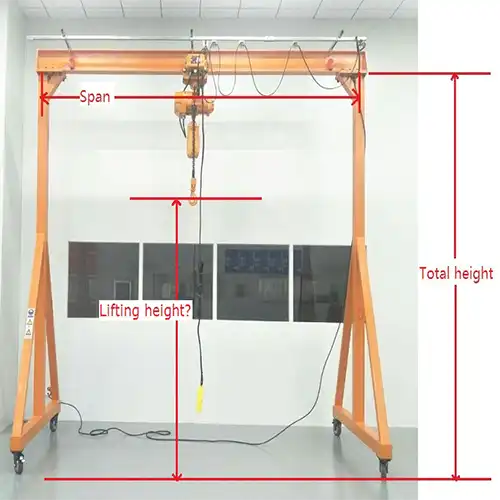

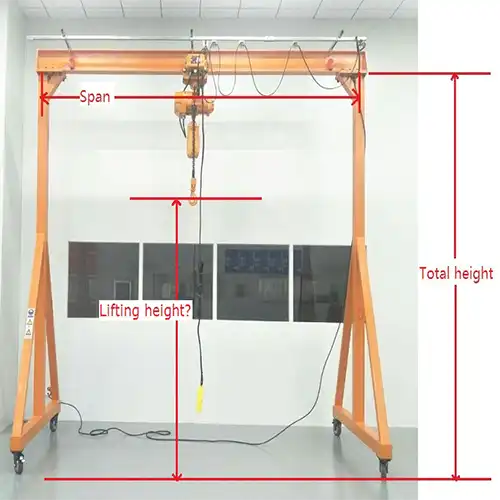

Span and Lifting Height

Span is the width the crane covers, while lifting height is how high it can lift a load.

- Longer spans require longer beams, which increases material costs.

- Higher lifting heights need taller frames and longer lifting chains or wire ropes.

- These dimensions impact both the cost of steel and the stability design of the crane.

Customization Options

Tailoring a crane to your specific worksite needs often adds to the cost.

- Low ceiling workshops may require shorter or adjustable-height designs.

- Outdoor use may need corrosion-resistant finishes or weatherproof covers.

- Uneven floors might require larger wheels or custom casters.

- Manual cranes are cheaper than motorized versions with powered travel or lifting.

Power Supply Requirements

Some cranes are manually operated, but many use electric hoists or motorized travel systems.

- Voltage options range from 220V to 480V, depending on your local power supply.

- Motorized travel or lifting functions cost more than manual operation.

- Remote controls and variable frequency drives can also add to the overall price.

Roller Travelling (Trackless) Feature

Many small A-frame gantry cranes use roller travelling systems instead of tracks.

- This makes them easier to move between work areas without needing rails.

- Installation is simple and fast—no concrete foundations required.

- High-quality wheels and brakes are needed for stability, especially on larger models.

Price Fluctuations to Keep in Mind

Market Prices Change Frequently

- Steel prices, shipping costs, and currency exchange rates all impact crane pricing.

- Even a small change in raw material costs can affect the final quotation.

- Always ask for a current price if your last quote is more than a few weeks old.

Get a Detailed Quote

To get the best value and the right fit for your needs:

- Provide clear details on your lifting tasks and work environment.

- Mention any special requirements like low headroom, floor type, or outdoor use.

- This helps the supplier recommend the most cost-effective solution without overbuilding.

This practical overview helps you understand how mobile gantry crane prices are determined, so you can budget wisely and choose the right model for your operation.

Why Mobile Gantry Cranes Are Perfect for Your Business

Mobile gantry cranes offer a reliable and versatile lifting solution for many industries. They are especially useful for small to medium-sized operations that need flexibility without permanent installation.

Portability

You can move a mobile gantry crane wherever it's needed, without relying on a fixed setup.

- Easily transported between workstations, indoors or outdoors

- No need for fixed tracks or concrete foundations

- Quick to relocate when work shifts or layouts change

Flexibility

These cranes can be adapted to different jobs or environments.

- Adjustable span and height options for a variety of lifting tasks

- Works in warehouses, workshops, repair yards, and construction sites

- A single crane can be used across multiple applications

Cost-Effectiveness

Mobile gantry cranes provide strong lifting power at a lower investment.

- Lower cost than installing a fixed overhead crane system

- No expenses for rail tracks or major civil work

- Suitable for small businesses with limited lifting needs but high mobility requirements

How to Choose the Right Mobile Gantry Crane

Choosing the right mobile gantry crane depends on your specific lifting job, workspace, and budget. Understanding what you need will help you avoid overpaying or under-equipping your team.

Evaluate Your Lifting Needs

Start by looking at what you plan to lift and where.

- Identify the maximum weight you need to lift regularly

- Measure your available floor space and ceiling height

- Determine how often you'll need to move the crane

Consider Your Budget

Mobile gantry cranes offer options for nearly every budget.

- Smaller cranes (under 2 tons) are affordable and suitable for light-duty tasks

- Larger cranes (up to 10 tons) cost more but handle heavier workloads

- Focus your budget on the specs that matter most: capacity, durability, and mobility

Customization Options

Some projects require more than standard specifications. Customization can help the crane fit your space and tasks more precisely.

- Height-adjustable designs for low headroom areas

- Corrosion-resistant materials for outdoor or wet environments

- Heavy-duty wheels for rough or uneven flooring

Always discuss your detailed needs with your supplier. This helps ensure you get a crane that fits your operation without paying for unnecessary features.

Conclusion

Mobile gantry cranes are a smart and practical solution for many businesses. Whether you're lifting small tools or heavy equipment, these cranes offer flexibility and reliability without the high cost of permanent installations.

Mobile gantry cranes combine performance and mobility in one package.

- Suitable for a wide range of lifting needs, from 0.25 ton to 10 tons

- Easy to move, adjust, and operate

- Saves time, labor, and setup costs in the long run

With different sizes, capacities, and customization options, there's a model to suit nearly every workspace and budget.

Ready to find the right mobile gantry crane for your business?

- Reach out for a personalized consultation

- Share your lifting needs, workspace layout, and any special requests

- Receive a clear, accurate quote with no guesswork

Get started today and improve your lifting efficiency with a reliable, portable gantry crane built to fit your operation.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch