5 Ton Mobile Gantry Cranes, Types & Uses of Mobile Gantry Cranes

5 ton mobile gantry cranes for sale. Types of mobile gantry cranes 5 ton for various applications. Get your custom 5 ton gantry crane for your needs.

Category: 5 Ton Gantry Crane

Your Trusted 5 Ton Gantry Crane Manufacturer & Supplier

5 Ton Mobile Gantry Cranes, Types & Uses of Mobile Gantry Cranes

5 ton mobile gantry cranes for sale. Types of mobile gantry cranes 5 ton for various applications. Get your custom 5 ton gantry crane for your needs.5 Ton Mobile Gantry Cranes are portable lifting devices engineered to handle loads of up to 5 tons with ease and precision. Their design revolves around mobility, allowing for swift relocation within a workspace or between different job sites.The versatility and utility of 5 Ton Mobile Gantry Cranes extend across various industries and applications, offering a multitude of advantages:

- Portability: Unlike traditional fixed cranes, mobile gantry cranes can be easily transported and deployed in different locations as needed. This mobility allows for flexible handling of lifting tasks across diverse job sites or work areas.

- Space Efficiency: With their compact design and minimal footprint, mobile gantry cranes excel in environments where space is limited. Whether operating in crowded manufacturing facilities or confined construction sites, these cranes optimize available space without compromising on performance.

- Quick Setup: The modular design and simple assembly process of mobile gantry cranes enable rapid deployment and setup, minimizing downtime and maximizing productivity. This quick setup capability ensures efficient utilization of resources and seamless integration into existing workflows.

- CostEffectiveness: Mobile gantry cranes offer a costeffective alternative to permanent overhead cranes, especially for small to mediumsized businesses with budget constraints. With lower initial investment costs and reduced installation expenses, these cranes deliver significant cost savings without compromising on lifting capacity or performance.

- Versatility: From lifting heavy machinery on manufacturing shop floors to loading and unloading cargo in warehouses, mobile gantry cranes adapt to a wide range of applications with ease. Their versatility makes them indispensable tools across industries such as manufacturing, construction, warehousing, maintenance, and more.

Hot Sale Steel Made 5 Ton Mobile Gantry Cranes

When it comes to lifting heavy loads with precision and efficiency, 5 Ton Mobile Gantry Cranes offer unparalleled versatility and functionality. In this section, we'll delve into the two primary types of these cranes: Fixed Height and Adjustable Height, each designed to cater to specific lifting requirements and operational needs.

Adjustable Height 5 Ton Mobile Gantry Cranes:

Adjustable Height 5 Ton Mobile Gantry Cranes are engineered to provide flexibility and adaptability in lifting operations. The key feature of these cranes is the ability to adjust the height of the lifting beam or gantry frame according to the specific requirements of the task at hand. This adjustability allows users to accommodate varying load sizes, work environments, and clearance constraints with ease.

Key Features:

Height Adjustment Mechanism: These cranes are equipped with a mechanism that enables vertical adjustment of the lifting beam or gantry frame. This mechanism may include telescopic legs, adjustable leg inserts, or hydraulic cylinders, depending on the design of the crane.

Versatile Lifting Capabilities: By allowing height adjustments, these cranes can handle a wide range of load sizes and shapes, from smaller components to larger machinery, without compromising on stability or safety.

Adaptability to Different Environments: The ability to adjust the height of the crane makes it suitable for use in various work environments, including warehouses, manufacturing facilities, construction sites, and maintenance workshops.

Enhanced Flexibility: Adjustable Height Gantry Cranes offer enhanced flexibility in load positioning and handling, allowing users to optimize lifting operations and maximize productivity.

Safety Features: These cranes are equipped with safety features such as locking mechanisms and overload protection systems to ensure safe and secure lifting operations at all times.

Applications:

Manufacturing: Handling and positioning components of different sizes on assembly lines.

Warehousing: Loading and unloading goods of varying dimensions in distribution centers.

Maintenance: Assisting in equipment installation, repair, and maintenance tasks in industrial settings.

Fixed Height 5 Ton Mobile Gantry Cranes:

Fixed Height 5 Ton Mobile Gantry Cranes are designed for applications where a consistent lifting height is required. Unlike their adjustable height counterparts, these cranes feature a fixed lifting beam or gantry frame height, providing stability and reliability in lifting operations.

Key Features:

Stable and Rigid Structure: Fixed Height Cranes are built with a fixedheight gantry frame or lifting beam, ensuring stability and rigidity during lifting tasks. This fixed configuration enhances loadbearing capacity and minimizes sway or deflection during operation.

Simplified Design: With a fixed height structure, these cranes offer a simpler design and construction, reducing maintenance requirements and operational complexities.

CostEffectiveness: Fixed Height Cranes are typically more costeffective than adjustable height models, making them an economical choice for applications where height adjustability is not a primary concern.

Easy Setup and Operation: These cranes are straightforward to set up and operate, requiring minimal adjustment or configuration before use.

Durability: Constructed from highquality materials such as steel, Fixed Height Cranes are built to withstand the rigors of daily operation in demanding industrial environments.

Applications:

Construction: Lifting and positioning materials, equipment, and prefabricated structures at construction sites.

Outdoor Work: Handling loads in outdoor environments where overhead clearance is consistent and predictable.

HeavyDuty Lifting: Performing heavyduty lifting tasks in manufacturing, mining, and shipbuilding industries.

In the subsequent sections of this guide, we will delve deeper into the operational considerations, maintenance practices, and purchasing factors associated with both Adjustable Height and Fixed Height 5 Ton Mobile Gantry Cranes, providing you with valuable insights to choose the right crane for your specific requirements.

Aluminum 5 Ton Mobile Gantry Cranes: Fixed and Adjustable Heights

Aluminum 5 Ton Mobile Gantry Cranes offer a lightweight yet robust lifting solution ideal for a variety of applications. In this section, we'll delve into the two main configurations of Aluminum 5 Ton Mobile Gantry Cranes: those with Fixed Height and Span, and those with Adjustable Height and Span. Each configuration brings its own set of advantages and applications, providing versatility and efficiency in lifting operations.

Aluminum 5 Ton Mobile Gantry Crane with Fixed Height and Span:

Aluminum Fixed Height and Span Cranes are engineered for applications where consistent lifting height and span are required. These cranes offer the lightweight properties of aluminum combined with a fixed configuration, ensuring stability and reliability in lifting tasks.

Key Features:

Lightweight Construction: Aluminum construction provides the crane with a lightweight yet durable frame, facilitating easy maneuverability and transportation.

Fixed Height and Span: These cranes feature a fixedheight gantry frame and span, providing stability and consistency in lifting operations. This fixed configuration enhances loadbearing capacity and minimizes deflection during operation.

Corrosion Resistance: Aluminum construction offers excellent corrosion resistance, making these cranes suitable for both indoor and outdoor applications, including marine environments.

Simplified Design: With a fixed configuration, these cranes offer a simplified design and construction, reducing maintenance requirements and operational complexities.

Easy Assembly: Aluminum Fixed Height and Span Cranes are designed for easy assembly and setup, allowing for quick deployment in various work environments.

Applications:

Warehousing: Loading and unloading cargo, pallets, and containers in distribution centers and storage facilities.

Maintenance: Assisting in equipment maintenance, repair, and installation tasks in industrial settings.

Outdoor Work: Handling loads in outdoor environments where corrosion resistance and lightweight properties are essential.

Aluminum 5 Ton Mobile Gantry Crane with Adjustable Height and Span:

Aluminum Adjustable Height and Span Cranes offer versatility and adaptability in lifting operations, allowing users to customize the crane's height and span according to specific requirements. These cranes combine the lightweight properties of aluminum with adjustable features for enhanced flexibility.

Key Features:

Adjustable Height and Span: These cranes feature mechanisms for adjusting the height and span of the gantry frame, providing versatility in lifting operations. Users can tailor the crane's configuration to accommodate varying load sizes and work environments.

Lightweight and Portable: Aluminum construction ensures the crane remains lightweight and portable, facilitating easy relocation and setup in different locations.

Versatile Lifting Capabilities: The adjustable height and span features enable the crane to handle a wide range of load sizes and shapes, making it suitable for diverse applications across industries.

Easy Adjustment: Userfriendly adjustment mechanisms allow for quick and effortless changes to the crane's height and span, minimizing downtime and maximizing productivity.

Enhanced Maneuverability: The lightweight nature of aluminum construction, combined with adjustable features, enhances the crane's maneuverability, making it suitable for use in confined spaces or challenging work environments.

Applications:

Manufacturing: Handling and positioning components of different sizes on assembly lines.

Construction: Lifting materials, prefabricated structures, and machinery at construction sites.

Event Setup: Rigging and lifting equipment for event setups and exhibitions.

Whether you require the stability of a fixed configuration or the flexibility of adjustable features, Aluminum 5 Ton Mobile Gantry Cranes provide reliable lifting solutions for a wide range of applications. Consider the specific requirements of your lifting tasks and work environment to determine the ideal configuration for your needs.

Rubber Tired 5 Ton Mobile Gantry Crane

Rubber tired Mobile Gantry Cranes offer a unique combination of mobility, versatility, and lifting capacity, making them indispensable in various industrial settings. In this section, we'll explore the features, advantages, and applications of these specialized cranes designed to operate on rubber tires.

Rubber Tired Mobile Gantry Crane Features:

Rubber Tires: The hallmark feature of these cranes is their rubber tires, which enable smooth movement and navigation across different surfaces, including concrete floors, asphalt, and gravel.

SelfPropelled: Rubbertired cranes are often equipped with selfpropulsion mechanisms, such as electric or diesel engines, allowing them to move independently without the need for external towing or assistance.

Adjustable Height: Many rubbertired gantry cranes feature adjustable height capabilities, enabling users to customize the crane's lifting height to suit specific applications and clearance requirements.

Compact Design: These cranes are designed with a compact footprint, making them suitable for operation in confined spaces where traditional fixed or overhead cranes may not be practical.

Load Capacity: Despite their compact size, rubbertired gantry cranes boast impressive load capacities, typically ranging from 1 ton to 20 tons or more, depending on the model and configuration.

Advantages of RubberTired Mobile Gantry Cranes:

Mobility: The primary advantage of rubbertired cranes is their mobility. Unlike fixed or overhead cranes, which are confined to a specific location, rubbertired cranes can be easily moved and deployed to different areas within a facility or between job sites.

Versatility: Rubbertired gantry cranes excel in a wide range of applications, including manufacturing, construction, warehousing, and maintenance. Their ability to operate on various surfaces makes them suitable for both indoor and outdoor use.

Quick Setup: These cranes are designed for rapid deployment, with minimal assembly and setup required. This quick setup capability ensures minimal downtime and maximum productivity.

CostEffectiveness: Rubbertired gantry cranes offer a costeffective lifting solution compared to permanent overhead cranes or heavy machinery. Their versatility and mobility make them an economical choice for businesses with evolving lifting needs.

Safety: Safety features such as overload protection systems, emergency stop buttons, and antisway mechanisms ensure safe operation of rubbertired gantry cranes, protecting both personnel and equipment.

Applications of RubberTired Mobile Gantry Cranes:

Manufacturing: Handling raw materials, components, and finished products on assembly lines.

Construction: Lifting and positioning materials, equipment, and structures at construction sites.

Warehousing: Loading and unloading cargo, containers, and pallets in distribution centers and storage yards.

Maintenance: Assisting in equipment installation, repair, and maintenance tasks in industrial facilities.

Event Setup: Rigging and lifting equipment for event setups, exhibitions, and entertainment venues.

Rubbertired Mobile Gantry Cranes are versatile lifting solutions that offer mobility, efficiency, and reliability in various industrial applications. Whether you need to maneuver heavy loads in tight spaces or transport materials across different surfaces, these cranes provide the flexibility and performance required to streamline your operations effectively.

Uses and Applications of 5 Ton Mobile Gantry Cranes

From bustling manufacturing floors to dynamic construction sites and beyond, 5 Ton Mobile Gantry Cranes serve as indispensable lifting solutions across a multitude of industries. Let's explore how these versatile cranes are utilized in various applications:

Industrial Manufacturing:

In industrial manufacturing, efficiency and precision are paramount. 5 Ton Mobile Gantry Cranes play a crucial role in streamlining production processes by effortlessly handling heavy components, machinery, and materials on assembly lines. Whether it's positioning equipment for assembly, transporting materials between workstations, or loading finished products onto trucks for shipment, these cranes ensure seamless operations and optimized productivity.

In the industrial manufacturing sector, 5 ton mobile gantry cranes are typically used to handle heavy components, machinery, and materials on assembly lines. The key reasons for selecting a 5 ton mobile gantry crane in this sector include:

- Lifting Capacity: Many manufacturing processes involve the movement of heavy equipment, parts, and subassemblies. The 5 ton lifting capacity of these cranes allows for the safe and efficient handling of these substantial loads.

- Versatility: The mobility and adjustable dimensions of 5 ton mobile gantry cranes enable them to navigate tight spaces, access different workstations, and position loads with precision on the assembly line.

- Productivity: By streamlining the movement of materials and components, these cranes help to optimize production workflows, reduce downtime, and improve overall manufacturing efficiency.

- Safety: The controlled and stable lifting provided by the 5 ton mobile gantry cranes helps to mitigate the risks associated with manual material handling, enhancing workplace safety.

Construction Sites:

Construction sites are bustling hubs of activity where materials need to be lifted, positioned, and transported with precision and efficiency. 5 Ton Mobile Gantry Cranes provide the necessary lifting power and mobility to tackle a wide range of construction tasks, from lifting steel beams and precast concrete panels to hoisting equipment and machinery into place. Their ability to operate on uneven terrain and navigate tight spaces makes them indispensable assets on construction projects of all sizes.

On construction sites, 5 ton mobile gantry cranes are commonly used to handle a variety of heavy materials and equipment, such as:

Steel beams and structural components

Precast concrete panels and building materials

Heavy machinery, such as generators, compressors, and lifting equipment

The key advantages of using a 5 ton mobile gantry crane in construction include:

Ability to navigate uneven terrain and access hardtoreach areas

Flexibility to move and position materials and equipment as needed

Increased safety by reducing manual handling of heavy loads

Improved site organization and workflow efficiency

Warehouses and Logistics:

In warehouses and distribution centers, the efficient movement of goods is essential to maintaining smooth operations. 5 Ton Mobile Gantry Cranes excel in loading and unloading cargo, pallets, and containers, maximizing space utilization and minimizing handling times. Whether it's stacking pallets in storage racks or loading trucks for shipment, these cranes offer the flexibility and maneuverability needed to keep logistics operations running smoothly.

In warehouses and logistics operations, 5 ton mobile gantry cranes are essential for handling a range of cargo, including:

Palletized goods and bulk materials

Shipping containers and oversized packages

Heavy machinery and equipment

The 5 ton capacity allows these cranes to efficiently load, unload, and transport a wide variety of items, while their mobility enables them to navigate tight aisles and maneuver around obstacles. This helps to optimize space utilization, streamline workflows, and minimize handling times in warehouse and logistics environments.

Maintenance and Repair Work:

In industrial facilities and maintenance workshops, equipment downtime can have costly repercussions. 5 Ton Mobile Gantry Cranes play a vital role in facilitating maintenance and repair work by providing reliable lifting capabilities for servicing machinery, replacing components, and conducting inspections. Their portability and ease of setup make them ideal for use in environments where space is limited or where temporary lifting solutions are required.

In industrial facilities and maintenance workshops, 5 ton mobile gantry cranes are valuable for a variety of maintenance and repair tasks, such as:

Servicing and overhauling machinery, equipment, and heavy components

Lifting and positioning parts and assemblies for inspection and troubleshooting

Facilitating the replacement of worn or damaged components

The key benefits of using a 5 ton mobile gantry crane in maintenance and repair work include:

Ability to safely handle heavy, bulky, or awkwardly shaped equipment

Portability and ease of setup, allowing the crane to be deployed as needed

Improved efficiency and reduced downtime during maintenance activities

Enhanced safety by eliminating the need for manual lifting of heavy items

Shipbuilding and Maritime Industries:

The shipbuilding and maritime industries demand heavyduty lifting solutions capable of handling large and cumbersome loads with precision. 5 Ton Mobile Gantry Cranes are indispensable tools in shipyards, where they are used to lift and position ship components, engines, and other equipment during construction and repair operations. Their robust construction and ability to operate in harsh marine environments make them wellsuited for the rigors of shipbuilding activities.

In the shipbuilding and maritime industries, 5 ton mobile gantry cranes are extensively used to handle the large and heavy components associated with these sectors, such as:

Ship engines, propellers, and other machinery

Steel hull sections and superstructure elements

Specialized equipment and tools for shipyard operations

The robust construction and heavyduty lifting capacity of 5 ton mobile gantry cranes make them wellsuited for the demanding conditions of shipyards and maritime environments. Their ability to navigate tight spaces and maneuver around ships under construction or repair is particularly valuable in these settings.

Event Setup and Rigging:

5 Ton Mobile Gantry Cranes are invaluable in these settings, providing the lifting power and versatility needed to hoist lighting rigs, audio equipment, and stage props into place safely and efficiently. Their ability to operate in indoor and outdoor environments makes them ideal for event setups in a variety of venues.

For event setup and rigging, 5 ton mobile gantry cranes are utilized to handle a variety of equipment and structures, including:

Lighting rigs, sound systems, and stage components

Audiovisual equipment and display elements

Truss systems and other event infrastructure

The key advantages of using a 5 ton mobile gantry crane in event setups include:

Ability to safely lift and position heavy or bulky equipment

Flexibility in maneuvering the crane to access different areas of the event space

Efficient setup and teardown of event infrastructure

Improved safety by reducing manual handling of heavy items

Overall, the 5 ton lifting capacity, mobility, and versatility of these cranes make them a valuable asset across a wide range of industrial and commercial applications, enabling efficient material handling, streamlined workflows, and enhanced safety.

In conclusion, 5 Ton Mobile Gantry Cranes are versatile lifting solutions that find application across a wide range of industries and settings. Whether it's lifting heavy machinery in manufacturing plants, hoisting materials on construction sites, or facilitating logistics operations in warehouses, these cranes provide the power, mobility, and reliability needed to tackle the toughest lifting tasks with ease.

Factors to Consider When Selecting for Specialized Uses

Selecting the appropriate 5 Ton Mobile Gantry Crane for specialized applications requires careful consideration of various factors to ensure optimal performance, safety, and efficiency. Here are the key factors to keep in mind:

Weight Capacity and Load Requirements:

Determine the maximum weight capacity needed to lift and maneuver loads in your specific application.

Consider the types of loads you will be handling, including their weight distribution and dimensions.

Ensure that the crane's weight capacity aligns with your current and future lifting requirements to avoid overloading and safety hazards.

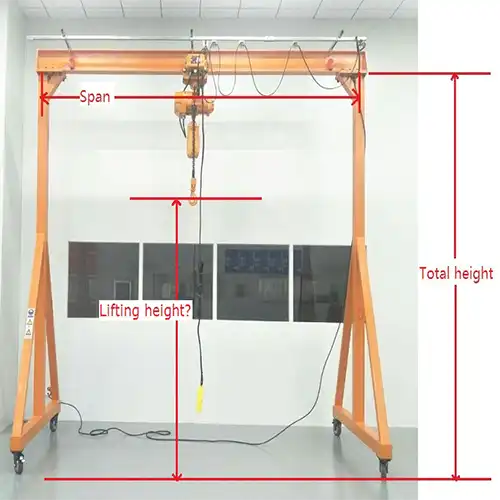

Height and Span Requirements:

Assess the vertical and horizontal clearance available in your workspace to determine the required height and span of the crane.

Consider the height of the loads you need to lift and the distance they need to be moved.

Choose a crane with adjustable height and span features if you anticipate varying clearance requirements or if flexibility is needed for different tasks.

Mobility and Portability:

Evaluate the mobility requirements of your application, including the need to move the crane between different locations or work areas.

Consider the terrain and surface conditions over which the crane will operate, such as smooth floors, rough terrain, or outdoor environments.

Choose a crane with robust, maneuverable wheels or tracks suitable for the intended operating environment to ensure smooth mobility and easy transportation.

Environmental Considerations:

Assess the operating environment for potential hazards such as dust, moisture, chemicals, or extreme temperatures.

Choose a crane with suitable corrosionresistant materials and protective coatings if it will be exposed to harsh environmental conditions.

Consider environmental regulations and compliance requirements that may impact the selection and operation of the crane in your specific industry or location.

Safety Features:

Prioritize safety features such as overload protection systems, emergency stop buttons, and antisway mechanisms to ensure safe lifting operations.

Evaluate the crane's stability, structural integrity, and safety certifications to mitigate risks of accidents or equipment failures.

Train operators and personnel on proper usage, maintenance, and safety procedures to minimize the risk of injuries or incidents during crane operations.

Budget Constraints:

Determine your budget allocation for purchasing, operating, and maintaining the crane over its lifecycle.

Compare the upfront costs, ongoing maintenance expenses, and potential return on investment of different crane options.

Balance cost considerations with the required features, performance, and safety standards to choose the most costeffective solution that meets your specialized needs.

By carefully evaluating these factors, you can select the right 5 Ton Mobile Gantry Crane tailored to your specialized application, ensuring optimal performance, safety, and efficiency in lifting operations.

5 Ton Mobile Gantry Crane Buying Guide

When procuring a 5 ton mobile aluminum gantry crane, the first step is to thoroughly research reputable suppliers and manufacturers in the market. This comprehensive research will help you identify the most suitable partner who can provide a crane that meets your specific requirements, delivers reliable performance, and ensures compliance with relevant safety standards.

Researching Suppliers and Manufacturers:

Start by researching reputable suppliers and manufacturers:

Utilize online search engines, industry directories, and trade publications to identify leading suppliers and manufacturers of 5 ton mobile gantry cranes.

Look for companies that specialize in material handling equipment or industrial cranes, as they are more likely to have a robust product portfolio and expertise in this segment.

Attend industry trade shows or events to network with potential suppliers and gain firsthand insights into their capabilities and product offerings.

Reach out to your professional network, including industry associations or peers, to get recommendations for reliable suppliers in the market.

After identifying a list of potential suppliers, it is essential to explore their product offerings, capabilities, and customer reviews to assess their suitability further.

Explore their product offerings, capabilities, and customer reviews:

Review the supplier's website and marketing materials to understand their product range, technical specifications, and customization options for 5 ton mobile gantry cranes.

Assess their manufacturing capabilities, such as inhouse design, fabrication, and quality control processes.

Examine their customer testimonials, case studies, or references to gauge their track record of delivering reliable and highperforming equipment.

Look for certifications or industry recognitions that demonstrate the supplier's commitment to quality, safety, and customer satisfaction.

Additionally, when evaluating potential suppliers, it is crucial to consider factors such as experience, expertise, certifications, and adherence to safety standards.

Consider factors such as experience, expertise, certifications, and adherence to safety standards:

Evaluate the supplier's years of experience in the material handling equipment industry, as well as their specific expertise in designing and manufacturing gantry cranes.

Verify if the supplier has obtained relevant certifications, such as ISO 9001 for quality management or OSHA/ASME standards for crane safety, to ensure their products meet industry benchmarks.

Assess the supplier's approach to safety, including their compliance with regulations, training programs for operators, and the availability of safety features on their gantry cranes.

Inquire about the supplier's technical support, maintenance services, and warranty coverage to ensure reliable longterm performance of the gantry crane.

By thoroughly researching and evaluating potential suppliers and manufacturers, you can identify a reputable partner who can provide a 5 ton mobile aluminum gantry crane that meets your specific requirements, delivers reliable performance, and ensures compliance with relevant safety standards.

Requesting and Evaluating Quotations:

When procuring a 5 ton mobile aluminum gantry crane, it's essential to engage with multiple reputable suppliers to ensure you obtain the most suitable and costeffective solution. The first step is to reach out to these suppliers and request quotations for the crane models that meet your specific requirements.

Reach out to multiple suppliers to request quotations:

Compile a list of the reputable suppliers and manufacturers you identified during your initial research.

Prepare a detailed request for quotation (RFQ) that outlines your specific requirements, such as the load capacity, span, height, mobility needs, and any customization requirements.

Provide clear instructions on the information you expect to receive in the quotation, including technical specifications, pricing, delivery timelines, and warranty details.

Request that suppliers provide detailed product datasheets, drawings, or technical information to support their quotations.

Ensure that the RFQ is sent to multiple suppliers to facilitate a competitive bidding process and allow for a comprehensive comparison.

Review the quotations carefully:

Thoroughly examine each supplier's quotation to ensure that it addresses all the requirements specified in your RFQ.

Verify that the technical specifications of the proposed 5 ton mobile gantry crane, such as load capacity, span, and height, meet your operational needs.

Check for the inclusion of key features, such as adjustable height, specialized attachments, or integrated safety systems.

Assess the pricing structure, including the base cost of the crane, any optional accessories or customizations, freight/shipping charges, and applicable taxes or fees.

Evaluate the delivery timelines and lead times provided by each supplier, as this can be a crucial factor in your decisionmaking process.

Compare the quotations based on various factors:

Compare the overall pricing of the 5 ton mobile gantry cranes from different suppliers, taking into account the total cost of ownership, including any maintenance or service agreements.

Assess the warranty coverage offered by each supplier, including the duration and scope of the warranty, to ensure longterm reliability and protection.

Consider the supplier's reputation, customer references, and track record of delivering highquality equipment and reliable aftersales support.

Evaluate any additional services or valueadded offerings, such as operator training, installation support, or ongoing maintenance and repair services.

Determine the supplier that can provide the best overall value, balancing factors like price, quality, features, and customer service.

By carefully requesting and evaluating quotations from multiple suppliers, you can make an informed decision that aligns with your operational requirements and budget for the 5 ton mobile aluminum gantry crane.

Assessing Warranty and Support Options:

When procuring a 5 ton mobile aluminum gantry crane, it is crucial to carefully assess the warranty coverage and aftersales support services offered by the potential suppliers. This evaluation will ensure that you select a partner who can provide comprehensive support and address any issues that may arise during the crane's lifecycle.

Inquire about the warranty coverage offered by each supplier:

Ask the suppliers to provide detailed information on the warranty coverage they offer for the 5 ton mobile gantry crane, including the duration of the warranty.

Understand the scope of the warranty, such as whether it covers the entire crane system or specific components like the frame, motors, wheels, or lifting mechanisms.

Ensure that the warranty includes both parts and labor, so any necessary repairs or replacements are covered by the supplier.

Inquire about any prorated or limited warranty clauses, as they may impact the level of coverage over the crane's lifetime.

After understanding the warranty coverage provided by each supplier, it is important to evaluate their aftersales support services to ensure reliable longterm performance of the gantry crane.

Evaluate the supplier's aftersales support services:

Assess the supplier's technical assistance capabilities, including the availability of dedicated support staff, remote troubleshooting options, and response times for addressing technical queries or issues.

Understand the supplier's maintenance and repair services, such as the availability of scheduled preventive maintenance programs, onsite repair services, or the option to send the crane back to the supplier for servicing.

Determine if the supplier offers operator training programs or resources to ensure your personnel are equipped to safely and effectively operate the gantry crane.

Inquire about the availability of spare parts, their lead times, and the supplier's ability to provide timely delivery to minimize downtime.

Finally, it is important to choose a supplier that provides comprehensive warranty coverage and reliable aftersales support to ensure the longterm performance and reliability of the 5 ton mobile aluminum gantry crane.

Choose a supplier that provides comprehensive warranty and reliable support:

Compare the warranty coverage and aftersales support services offered by the different suppliers to identify the one that provides the most comprehensive and reliable package.

Prioritize suppliers that offer extended warranty periods, cover a broader scope of components, and have a track record of prompt and effective technical support.

Evaluate the supplier's reputation, customer reviews, and industry standing to ensure they have the capability and commitment to stand behind their products and provide reliable aftersales services.

Consider the overall value proposition, balancing the warranty coverage, support services, and the total cost of ownership for the 5 ton mobile aluminum gantry crane.

By thoroughly assessing the warranty and support options offered by different suppliers, you can make an informed decision that ensures the longterm reliability and performance of your 5 ton mobile gantry crane investment.

Considering Customization Options:

When procuring a 5 ton mobile aluminum gantry crane, it is essential to consider customization options that can tailor the equipment to your specific requirements. By engaging with potential suppliers and collaborating closely with them, you can ensure the crane meets your operational needs and integrates seamlessly into your work environment.

Discuss customization options with potential suppliers:

Engage with reputable suppliers of gantry cranes and discuss your specific requirements in detail.

Share your intended use cases, operating environment, and any unique challenges you need to address.

Ask the suppliers about the range of customization options they can provide to meet your needs.

Inquire about the lead time, costs, and technical feasibility of different customization features.

Request samples or demonstration units, if possible, to evaluate the customized crane's performance.

After discussing the customization options with the suppliers, you can then consider the specific areas where you may want to tailor the 5 ton mobile aluminum gantry crane to your needs.

Consider customization options:

Adjustable height and span: Discuss the ability to adjust the crane's height and span to accommodate different load sizes, ceiling heights, or storage configurations.

Specialized lifting attachments: Explore the availability of specialized attachments, such as hooks, clamps, or spreader beams, to handle specific load types or shapes.

Integration with existing infrastructure: Understand the options for integrating the gantry crane with your facility's layout, floor plans, or existing material handling systems.

Safety features: Inquire about customization options that enhance the crane's safety, such as emergency stop mechanisms, overload protection, or collision avoidance systems.

Mobility and maneuverability: Consider customizations that improve the crane's mobility, such as specialized wheels, swivel casters, or motorized drives, to navigate your work environment efficiently.

Finally, it is essential to work closely with the supplier to ensure the customized crane meets your operational requirements and complies with relevant safety standards.

Work closely with the supplier:

Collaborate with the supplier to ensure the customized crane meets your operational requirements and complies with relevant safety standards and regulations.

Provide detailed specifications, including load capacities, lift heights, span dimensions, and any unique operational needs.

Review the supplier's design proposals, engineering drawings, and test reports to verify the crane's suitability for your application.

Discuss the installation, commissioning, and training requirements to ensure a smooth integration of the customized crane into your facility.

Establish a clear communication channel and followup mechanisms to address any issues or modifications during the customization and implementation process.

By considering these customization options and working closely with the supplier, you can tailor the 5 ton mobile aluminum gantry crane to your specific requirements, ensuring optimal performance, safety, and integration within your operational environment.

Operations

Operating a 5 Ton Mobile Gantry Crane requires careful attention to safety protocols, proper procedures, and efficient load handling techniques. Here's a comprehensive guide to mastering crane operations:

PreOperation Inspection and Safety Checks:

Conduct a thorough preoperation inspection of the crane, checking for any signs of damage, wear, or malfunction.

Inspect critical components such as the steel beams, Aframe legs, casters, hoist, and controls for signs of corrosion, cracks, or loose fittings.

Verify that all safety features, including overload protection systems, emergency stop buttons, and limit switches, are functioning correctly.

Ensure that the crane is positioned on stable ground and that there are no obstructions or hazards in the operating area.

Understanding Controls and Operation Procedures:

Familiarize yourself with the crane's controls and operation procedures before attempting to operate the crane.

Understand how to use the control panel, pendant station, or remote control to maneuver the crane, raise and lower the load, and adjust the trolley position.

Follow the manufacturer's guidelines and recommended procedures for starting up, shutting down, and operating the crane safely and efficiently.

Train operators thoroughly on proper crane operation techniques and emergency procedures to ensure safe and effective performance.

Load Handling Techniques:

Assess the weight, size, and center of gravity of the load before attempting to lift it with the crane.

Use appropriate lifting attachments, such as slings, hooks, or spreader bars, to secure the load safely to the hoist.

Position the crane directly over the load, ensuring proper alignment and balance to prevent swinging or shifting during lifting.

Lift the load smoothly and steadily, avoiding sudden movements or jerks that could destabilize the crane or the load.

Communicate with spotters or ground personnel to ensure safe clearance and maneuvering of the load within the operating area.

Safety Protocols During Operation:

Maintain a safe distance from the crane and the load while it is in operation, and never stand underneath a suspended load.

Observe load weight limits and never exceed the crane's rated capacity to prevent overloading and potential accidents.

Keep bystanders and unauthorized personnel clear of the operating area to minimize the risk of injury or accidents.

Continuously monitor the crane and the load during lifting operations, and be prepared to take corrective action in case of any anomalies or safety hazards.

Adhere to all applicable safety regulations, industry standards, and company policies governing crane operations to ensure a safe working environment for everyone involved.

Maintenance

Keeping Your Crane in Prime Condition: Essential Maintenance Practices for a 5 Ton Mobile Gantry Crane

Regular maintenance is crucial for ensuring the safe and efficient operation of a 5 Ton Mobile Gantry Crane. Here's a comprehensive guide to maintaining your crane in optimal condition:

Regular Inspection and Lubrication:

Perform routine inspections of the crane's components, including steel beams, Aframe legs, casters, hoist, and controls, to identify any signs of wear, damage, or corrosion.

Check for loose fittings, cracks, or deformation in critical components, and tighten or replace them as necessary to maintain structural integrity.

Lubricate moving parts and components regularly to reduce friction and wear, ensuring smooth operation and prolonging the lifespan of the crane.

Use appropriate lubricants recommended by the manufacturer, and follow their guidelines for lubrication intervals and procedures.

Component Replacement and Repair:

Monitor the condition of components such as bearings, gears, cables, and electrical connections, and replace or repair them promptly if signs of wear or malfunction are detected.

Keep spare parts on hand for quick replacement of worn or damaged components, minimizing downtime and ensuring continuous operation of the crane.

Work with qualified technicians or authorized service providers to perform component replacements and repairs according to manufacturer specifications and safety guidelines.

Document all maintenance activities, including component replacements and repairs, to track the crane's maintenance history and identify any recurring issues or trends.

Cleaning and Rust Prevention:

Regularly clean the crane's components and surfaces to remove dirt, debris, and contaminants that can accelerate corrosion and wear.

Use mild detergent solutions and nonabrasive cleaning tools to avoid damaging the crane's finish or protective coatings.

Inspect the crane for signs of rust or corrosion, especially in areas exposed to moisture or harsh environmental conditions.

Apply corrosionresistant coatings or protective treatments to vulnerable components to prevent rust formation and prolong their service life.

Training Maintenance Personnel:

Provide comprehensive training to maintenance personnel on proper maintenance procedures, including inspection, lubrication, component replacement, and repair.

Ensure maintenance personnel are familiar with the crane's operation and safety features to perform maintenance tasks safely and effectively.

Offer ongoing training and professional development opportunities to keep maintenance personnel updated on the latest maintenance techniques, technologies, and best practices.

Encourage open communication and collaboration between maintenance personnel and crane operators to identify and address maintenance issues promptly.

By following these maintenance practices and investing in regular inspections, lubrication, component replacement, and repair, you can ensure that your 5 Ton Mobile Gantry Crane remains in optimal condition, providing reliable and efficient lifting operations for years to come.

Storage and Space Considerations

Maximizing Efficiency: Storage and Space Considerations for Your 5 Ton Mobile Gantry Crane

Efficient storage of your 5 Ton Mobile Gantry Crane is essential for ensuring its longevity and maintaining optimal performance. Here's a comprehensive guide to help you navigate storage and space considerations:

Indoor vs. Outdoor Storage:

Evaluate your available space and determine whether indoor or outdoor storage is more suitable for your crane.

Indoor storage offers protection from the elements and may be preferable for cranes used in environments with temperature fluctuations or high humidity.

Outdoor storage may be necessary if indoor space is limited or if the crane is frequently used outdoors. However, outdoor storage exposes the crane to weather conditions and requires additional protection measures.

Shelter Requirements:

If storing the crane outdoors, consider investing in a dedicated shelter or canopy to provide protection from rain, snow, and direct sunlight.

Ensure that the shelter is tall enough to accommodate the crane's height and offers adequate clearance for safe maneuverability.

Use weatherresistant materials for the shelter construction to withstand exposure to the elements and prevent corrosion or damage to the crane.

Space Optimization Techniques:

Maximize available space by organizing storage areas efficiently and utilizing vertical storage solutions such as racks or shelves.

Implement a systematic storage layout that allows easy access to the crane and minimizes the risk of obstruction or clutter.

Store accessories, spare parts, and maintenance tools in designated storage areas near the crane for convenient access during maintenance and repair tasks.

Longterm Storage Precautions:

Before storing the crane for an extended period, conduct a thorough inspection to ensure it is in good condition and free of any damage or defects.

Lubricate moving parts and components to prevent corrosion and ensure smooth operation when the crane is put back into service.

Consider implementing a regular maintenance schedule for stored cranes to prevent deterioration and prolong their lifespan.

Use protective covers or tarps to shield the crane from dust, debris, and moisture during longterm storage periods.

By carefully considering indoor vs. outdoor storage options, shelter requirements, space optimization techniques, and longterm storage precautions, you can ensure that your 5 Ton Mobile Gantry Crane is stored safely and efficiently, ready for use whenever needed.

Safety Practices and Regulations

Prioritizing Safety: Essential Practices and Regulations for 5 Ton Mobile Gantry Crane Operations

Ensuring the safety of personnel and equipment is paramount when operating a 5 Ton Mobile Gantry Crane. Here are essential practices and regulations to uphold safety standards:

OSHA Guidelines and Compliance:

Familiarize yourself with Occupational Safety and Health Administration (OSHA) guidelines and regulations pertaining to crane operations, including 29 CFR 1910.179 for overhead and gantry cranes.

Ensure compliance with OSHA standards regarding crane design, inspection, operation, and maintenance to mitigate safety risks and prevent accidents.

Regularly review and update safety protocols and procedures to align with OSHA guidelines and industry best practices.

Training and Certification Requirements:

Provide comprehensive training for crane operators, riggers, and maintenance personnel to ensure they understand safe operating procedures and equipment maintenance practices.

Ensure that crane operators receive proper certification and licensing in accordance with OSHA and industry requirements.

Conduct regular refresher training sessions to reinforce safety protocols and update personnel on changes in regulations or technology.

Risk Assessment and Mitigation Strategies:

Conduct a thorough risk assessment of crane operations, identifying potential hazards, such as overloading, improper rigging, or inadequate clearances.

Implement mitigation strategies to minimize risks, such as establishing safe work zones, using proper lifting techniques, and implementing emergency stop procedures.

Provide personal protective equipment (PPE) such as hard hats, safety glasses, and gloves to personnel working in the vicinity of the crane to mitigate the risk of injury.

Emergency Procedures:

Develop and communicate clear emergency procedures for crane operations, including protocols for responding to accidents, equipment malfunctions, or natural disasters.

Ensure that personnel are trained in emergency response procedures and know how to evacuate the area safely in the event of an emergency.

Keep emergency contact information readily available and establish communication protocols for coordinating response efforts with emergency services and onsite personnel.

By adhering to OSHA guidelines, providing comprehensive training, conducting risk assessments, and establishing clear emergency procedures, you can create a safe working environment for 5 Ton Mobile Gantry Crane operations, minimizing the risk of accidents and ensuring the wellbeing of personnel and equipment.

Case Studies and Success Stories

Inspiring Success: Case Studies and Lessons from 5 Ton Mobile Gantry Crane Applications

Realworld applications and success stories provide valuable insights into the effectiveness and benefits of using 5 Ton Mobile Gantry Cranes. Here are some compelling examples and lessons learned:

Applications and Success Stories:

- Manufacturing Efficiency Boost: In a large automotive manufacturing plant, the implementation of multiple 5 Ton Mobile Gantry Cranes revolutionized the production process. By efficiently lifting and maneuvering heavy components along the assembly line, the cranes significantly reduced production time and improved workflow efficiency, leading to increased output and cost savings.

- Construction Site Productivity: On a busy construction site, a 5 Ton Mobile Gantry Crane played a pivotal role in lifting and positioning steel beams and prefabricated structures. Its versatility and mobility allowed for easy maneuverability in tight spaces, enabling swift and precise construction operations. The crane's reliability and efficiency contributed to the timely completion of the project, resulting in satisfied clients and contractors.

- Warehousing Optimization: In a bustling warehouse and logistics facility, the integration of 5 Ton Mobile Gantry Cranes streamlined material handling processes. By efficiently loading and unloading cargo, pallets, and containers, the cranes enhanced warehouse productivity and throughput, leading to improved inventory management and customer satisfaction.

Lessons Learned and Best Practices:

- Proper Training and Education: One common theme across successful deployments of 5 Ton Mobile Gantry Cranes is the emphasis on thorough training and education for operators and maintenance personnel. Investing in comprehensive training programs ensures safe and efficient crane operation, minimizes the risk of accidents, and maximizes productivity.

- Regular Maintenance and Inspection: Another critical factor contributing to the success of 5 Ton Mobile Gantry Crane applications is the implementation of regular maintenance and inspection protocols. By conducting routine inspections, lubrication, and component replacements, organizations can prolong the lifespan of the crane, prevent downtime, and optimize performance.

- Flexibility and Adaptability: Successful case studies highlight the importance of choosing versatile and adaptable crane solutions that can meet the diverse needs of different industries and applications. 5 Ton Mobile Gantry Cranes with adjustable height, span, and mobility features offer the flexibility to handle various loads and work environments effectively.

By studying realworld applications and success stories, businesses can gain valuable insights into the potential benefits and best practices associated with deploying 5 Ton Mobile Gantry Cranes. Incorporating these lessons learned can help organizations maximize the value and impact of their crane investments, driving operational efficiency, and achieving success in their respective industries.

Conclusion: Custom Mobile Gantry Cranes for Your Needs

In industrial operations, mastering the art of 5 Ton Mobile Gantry Cranes is essential for achieving efficiency, productivity, and safety. Throughout this guide, we've explored the multifaceted aspects of these versatile lifting solutions, from their fundamental components to their realworld applications and success stories. Here's a recap of key takeaways:

- Versatility and Mobility: 5 Ton Mobile Gantry Cranes offer unparalleled versatility and mobility, allowing them to adapt to various environments and applications, from manufacturing floors to construction sites and warehouses.

- Efficiency and Productivity: By streamlining material handling processes, optimizing workflow efficiency, and enhancing productivity, these cranes play a pivotal role in driving operational excellence and achieving business objectives.

- Safety and Compliance: Prioritizing safety and compliance with regulatory standards, such as those outlined by OSHA, is paramount when operating 5 Ton Mobile Gantry Cranes. Thorough training, regular maintenance, and adherence to best practices are essential for ensuring a safe working environment.

- Cost Analysis and ROI: When considering the investment in a 5 Ton Mobile Gantry Crane, conducting a comprehensive cost analysis and evaluating the potential return on investment is crucial. By weighing initial costs against longterm benefits and operational efficiencies, businesses can make informed decisions that align with their financial goals.

- Continuous Improvement: Learning from realworld applications, success stories, and lessons learned from industry peers is essential for continuous improvement and optimization of crane operations. Embracing best practices, investing in training and education, and staying abreast of technological advancements are key to mastering the art of crane management.

If you have any need, please feel free to contact us to get your custom 5 ton mobile gantry crane design!

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch