From Hook to Magnet: China’s Top 5 Heavy Lift Open Winch Cranes

Discover top 5 open winch double girder overhead crane designs in China, from hook models to magnetic lifting solutions. Affordable heavy lifting crane!

Category: Featured

Your Trusted Overhead Open Winch Crane Manufacturer & Supplier

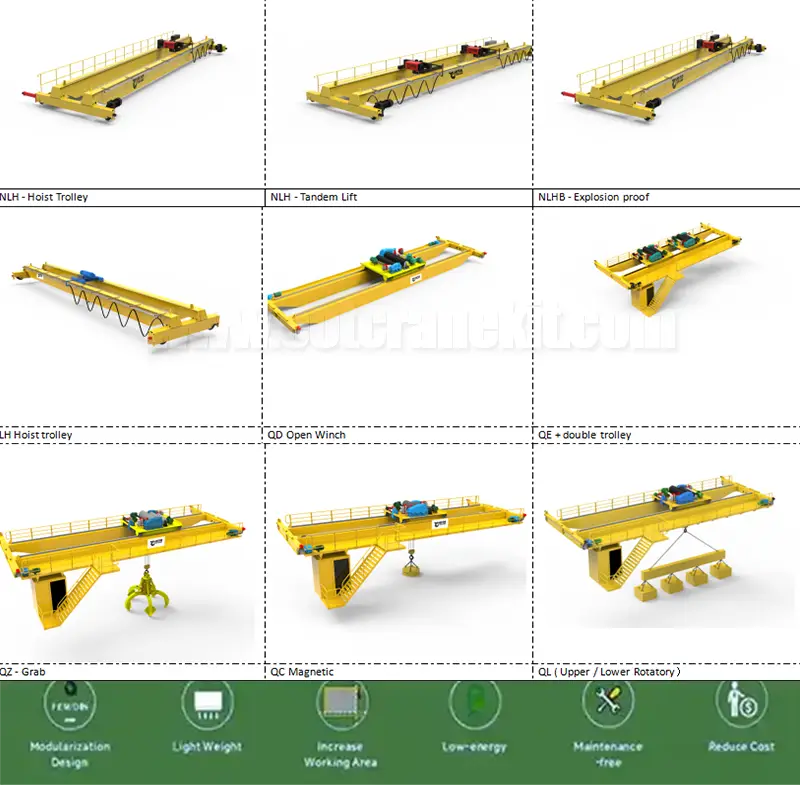

From Hooks to Magnets- Top 5 Designs for Heavy Lifting

Selecting the Best Open Winch Double Girder Overhead Crane in China

Choosing the right open winch double girder overhead crane is more than just picking a tonnage or span. In real-world industrial settings, the crane you select can affect safety, workflow efficiency, and even long-term operating costs. A crane that's perfectly suited to your material type, lifting height, or factory layout can make operations smoother, reduce downtime, and protect your workforce.

In China, open winch double girder cranes are widely used across industries because of their practical design and versatility. They're especially popular in factories, steel plants, ports, and logistics centers, where reliable lifting equipment is essential.

This guide is aimed at helping buyers understand the differences and relationships between the five main series of open winch cranes: QD, QE, QB, QC, and QL. By the end, you'll know which type fits your operational needs best, what makes each unique, and why the open winch design is so widely preferred in industrial environments.

While all five crane series share the open winch design in China , they serve distinct functions:

Key Advantages of Open Winch Design Across All Series:

- Easier inspection and maintenance due to exposed components

- Flexible attachment options: hooks, grabs, or electromagnetic lifters

- Adaptable to a wide range of spans, capacities, and lifting heights

- Reduced downtime and lower maintenance costs

This section sets the stage for a practical understanding of the cranes themselves. Later, we'll explore each series in depth, highlighting how they differ, where they excel, and why buyers often turn to China for cost-effective, high-quality solutions.

Why Choose an Open Winch Double Girder Crane from China

Selecting the right crane supplier is as important as selecting the crane itself. Chinese manufacturers have become a preferred choice for industrial buyers worldwide, offering a balance of quality, affordability, and practical design. Their open winch double girder cranes are designed to meet diverse industrial needs while keeping operational efficiency in mind.

Here are the main reasons why buyers turn to China for open winch cranes:

- Cost-Effective Solutions: Competitive pricing without compromising quality. Factories and warehouses can invest in reliable lifting equipment without stretching budgets.

- Customizable Designs: Ability to tailor capacity, span, lifting height, and attachments to match operational requirements. Whether you need a heavy-duty QD crane or a precise QE dual-trolley crane, customization ensures it fits your workflow perfectly.

- Proven Manufacturing Standards: Many Chinese manufacturers follow CE, ISO, and industry-specific standards, ensuring safety, durability, and long-term reliability.

- After-Sales Support: Suppliers often provide detailed installation guidance, ready supply of spare parts, and maintenance consultation, helping reduce downtime and keep operations running smoothly. Check more types of overhead cranes for sale in China.

Beyond cost and support, the open winch design itself adds practical value.

- Easy Inspection and Maintenance: Components are exposed, allowing quick checks on ropes, brakes, and gears without disassembling the crane.

- Supports Hooks, Grabs, and Electromagnetic Attachments: Flexibility to handle different materials efficiently, from steel coils to long pipes or scrap metal.

- Adaptable to Multiple Industrial Scenarios: Suitable for steel mills, ports, warehouses, logistics centers, and construction sites, the open winch design allows smooth operation across various applications.

Choosing an open winch double girder crane from China combines affordability, flexibility, and practical design features. It ensures your lifting operations are safe, efficient, and aligned with the specific requirements of your industry.

5 Top Open Winch Crane Series, Economical Solution In China

Choosing a crane isn't just about matching tonnage or span. Understanding the function, design purpose, and special features of each series helps buyers pick the right crane for their operations. This section breaks down the top 5 open winch crane series, showing how each serves unique roles while sharing the open winch design for flexibility and maintenance efficiency.

QD Series – Open Winch Crane with Hook for General Heavy-Duty Lifting

The QD series is the backbone of industrial lifting. Known for robustness and versatility, it is the go-to choice for general-purpose operations requiring high reliability and heavy-duty performance.

- Function: Handles heavy lifting efficiently in general industrial environments.

- Relation: Serves as the base design; other series are adaptations for specialized tasks.

Key Features:

- Capacity: 3–550 tons

- Span: 5–60 meters

- Box-shaped main girder with open winch trolley

Special Features:

- Durable steel structure for long-term reliability

- High-duty operation with adjustable lifting speeds

- Supports hooks, grabs, and optional electromagnetic attachments

- Easy inspection and maintenance thanks to open winch design

Applications:

- Steel mills

- Construction machinery

- Logistics centers

- Rail transit operations

Price Range for Reference Only: $15,600 – $720,000

QE Series – Dual Trolley Open Winch Crane for Long Loads

Designed for precision handling of long and heavy materials, the QE series uses dual trolleys for independent or synchronized operation.

- Function: Provides stable lifting for long or awkward loads, minimizing swing and improving placement accuracy.

- Relation: Builds on QD reliability but adds dual trolleys for enhanced handling of long items.

Key Features:

- Capacity: 5+5 – 200+200 tons

- Dual trolleys for independent or synchronized operation

Special Features:

- Smooth synchronization for dual-lift operations

- Can lift long molds, pipes, or steel beams safely

- Reduced stress on materials due to even load distribution

- Optional remote control for enhanced operator convenience

Applications:

- Steel pipes and molds

- Wind turbine tower sections

- Long wood or steel bars

Price Range for Reference Only: $24,200 – $425,000

QB Series – Explosion-Proof Open Winch CraneSafety

QB series cranes are built for hazardous environments where explosive gases, dust, or high-risk conditions are present.

- Function: Ensures safe lifting in industrial zones with potential fire or explosion hazards.

- Relation: Specialized derivative of QD for industrial safety.

Key Features:

- Capacity: 5–50 tons

- Explosion-proof design with open winch trolley

Special Features:

- Certified explosion-proof electrical components

- Safe operation in chemical, steel, and mining environments

- Durable design for industrial wear and tear

- Can integrate hooks, grabs, or auxiliary lifting devices

Applications:

- Chemical plants

- Steel mills

- Mining operations

- Port terminals with combustible materials

Price Range for Reference Only: $25,500 – $72,000

QC Series – Electromagnetic Open Winch Crane

QC series cranes use electromagnets to handle steel parts and billets efficiently. They are ideal for scrap handling and steel processing.

- Function: Lift and transport steel safely and quickly, using magnetic attachments rather than mechanical hooks.

- Relation: Functional adaptation of QD for steel handling with electromagnets.

Key Features:

- Capacity: 5–32 tons

- Electromagnetic lifting system

- Cab or pendant control

Special Features:

- Round, rectangular, or oval magnets for different steel shapes

- Emergency power-off battery system for safety

- Precise load handling with minimal swing

- Suitable for indoor warehouses, freight yards, or steel mills

Applications:

- Steel billets and plates

- Scrap handling

- Freight yards and warehouses

Price Range for Reference Only: 233,042 – 308,600 RMB

QL Series – Revolving Electromagnetic Precision -Open Winch Crane with Magnetic Spreader

The QL series combines electromagnetic lifting with a revolving mechanism, ideal for flexible steel handling in complex environments.

- Function: Rotate and position steel materials accurately while lifting them magnetically.

- Relation: Advanced derivative of QC, adding rotation capability for precision placement.

Key Features:

- Capacity: 10+10 – 200+200 tons

- Revolving electromagnet

- Cab or remote control

Special Features:

- Allows 360° rotation for narrow spaces or precise placement

- Can handle steel plates, bars, and coils simultaneously

- Reduces material handling time and improves efficiency

- Supports both single and dual-lift operations

Applications:

- Steel mills

- Shipyards

- Ports

- Storage yards and warehouses

Price Range for Reference Only: $96,000 – $166,700

How the Series Relate and Complement Each Other

When selecting a double girder open winch crane, tonnage and span are just the starting point. The real decision should be function-driven. Each series in the top 5 lineup serves a specific purpose, and understanding their relationships helps buyers make smarter choices.

Function-Based Decision:

- QD Series: Acts as the backbone for general heavy lifting across industrial applications. Reliable for high-duty operations.

- QE Series: Adds dual-trolley precision for long or unusually shaped materials. Ideal for steel beams, pipes, molds, or wind tower sections.

- QB Series: Specialized for hazardous or explosive environments, maintaining safety without sacrificing lifting efficiency.

- QC Series: Focused on steel handling with electromagnetic lifting, reducing manual work and increasing speed.

- QL Series: Advanced derivative of QC with revolving electromagnets for tight or complex layouts, providing precision placement.

Shared Advantages Across Series:

- Open winch trolley allows easy inspection and maintenance.

- Supports a wide range of attachments: hooks, grabs, and electromagnets.

- Flexible enough to adapt to different industries and operational workflows.

- Cab or remote control options for operator safety and convenience.

Buyers' Perspective:

- Start by understanding your operational needs: material type, load size, lifting frequency, and work environment.

- Match the series to the specific function rather than just lifting capacity.

- Consider complementary series if operations involve mixed material types or specialized handling, e.g., combining QD for general lifting with QC/QL for steel handling.

- Factor in maintenance ease, control options, and long-term adaptability when choosing a crane series.

Pricing Overview

Understanding the cost of an open winch double girder crane is crucial for budgeting and operational planning. Prices vary depending on capacity, span, attachments, and customization, but having a general reference helps buyers make informed decisions.

Summary Table of Top Series:

Before diving into specifics, here's a snapshot of the main crane series, their capacities, spans, lifting heights, and Price Range for Reference Onlys. This gives a clear picture of what to expect financially for different industrial needs.

| Series | Capacity | Typical Span | Lifting Height | Price Range for Reference Only (USD/RMB) |

|---|---|---|---|---|

| QD | 3–800 t | 5–60 m | 3–100 m | $15,600 – $720,000 |

| QE | 5+5–200+200 t | 10–50 m | 10–50 m | $24,200 – $425,000 |

| QB | 5–50 t | 10–31.5 m | 12–16 m | $25,500 – $72,000 |

| QC | 5–32 t | 10–31.5 m | 12–20 m | 233,000 – 308,600 RMB |

| QL | 10+10–200+200 t | 13–50 m | 12–25 m | Custom per order |

Factors Influencing Price:

Crane pricing isn't one-size-fits-all. Several technical and operational factors directly affect the cost:

- Capacity: Higher tonnage cranes require more robust girders, motors, and components, which increases cost.

- Span and Lifting Height: Longer spans and taller lifts mean more steel structure, stronger hoists, and higher material costs.

- Attachments: Adding hooks, grabs, or electromagnets increases complexity and overall price.

- Customization: Special duty classes, explosion-proof features, or anti-sway systems add to the expense.

- Control Method: Cabin, pendant, or remote/PLC-based automated controls affect both equipment and installation cost.

Practical Tips for Buyers

Choosing the right crane isn't just about price or capacity—it's about ensuring your equipment matches your operational needs. Thinking ahead saves downtime, reduces maintenance issues, and improves workflow efficiency.

Function First: Before selecting a series, carefully consider what the crane will actually handle and how often.

- Identify your material type: Are you lifting steel billets, long pipes, heavy machinery, or hazardous materials?

- Evaluate the environment: Will the crane operate indoors, outdoors, in a hazardous area, or in a confined space?

- Determine lifting frequency and precision: How often will the crane be in use, and how precise does placement need to be?

Manufacturer Considerations: Choosing a reliable manufacturer can impact long-term costs and support.

- Chinese open winch crane manufacturers: Often provide cost-effective options with high customization potential.

- Certifications: Look for CE, ISO, or industry-specific certifications to ensure quality and compliance.

- After-sales support: Check for installation guidance, spare parts availability, and maintenance services.

Series Selection Tips: Once you understand operational needs, select the series that aligns with your materials, workflow, and environment:

- QD Series: Heavy-duty, high-frequency lifting for a wide range of industries.

- QE Series: Dual-trolley design for precise handling of long and heavy loads.

- QC & QL Series: Specialized for steel handling, scrap materials, and applications requiring electromagnetic lifting or rotation.

Selecting the right double girder overhead crane goes beyond simply comparing tonnage or span. The key is understanding what you actually need the crane to do. Functionality—whether handling heavy loads, long materials, hazardous environments, or steel-specific applications—should guide your decision first.

Why Chinese Open Winch Double Girder Cranes are a Smart Choice:

Before making a purchase, consider these practical advantages:

- Flexible Solutions: Open winch design allows easy attachment of hooks, grabs, or electromagnets to match different lifting needs.

- Cost-Effective: Competitive pricing without compromising on quality or safety.

- Reliable Performance: Many Chinese manufacturers follow CE, ISO, and industry-specific standards, ensuring dependable operation.

Advice for Buyers:

- Consult manufacturers about your specific operational requirements—materials, workflow, and environment—so they can recommend the most suitable series (QD, QE, QB, QC, or QL).

- Consider customization options for lifting capacity, span, attachments, and control methods to optimize your workflow.

- Ensure after-sales support is available, including installation guidance, spare parts, and maintenance services.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch