Overhead, Gantry & Jib Cranes Lead Time- Buying from China Guide

Learn key lead times for buying overhead, gantry, jib cranes and electric hoists from China, plus shipping and delivery tips to keep your project on schedule.

Category: Featured

Your Trusted Overhead Crane Manufacturer & Supplier

Buy Overhead Cranes from China, Lead Time Your Need Know

Overhead, Gantry, Jib Cranes & Electric Hoist Lead Times & Shipping Guide

Introduction: Why Lead Times and Shipping Matter for Crane Buyers

When buying ovehread cranes from China, one of the first questions on every buyer's mind is usually, "How long will it take to get my crane?" Lead time—the total time from order confirmation to delivery—is more than just a number. It directly affects your project schedule, installation planning, and operational readiness. Missed deadlines can create ripple effects, delaying production lines or construction projects, and sometimes even increasing costs.

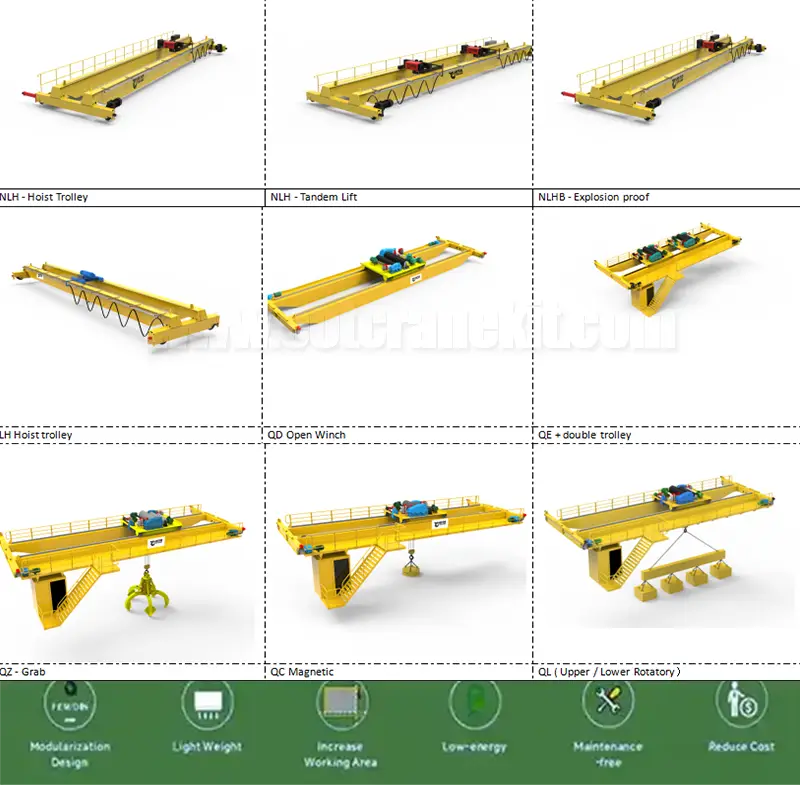

China is a leading manufacturer for industrial lifting equipment, offering a wide range of products to suit different industries. The main types of cranes you'll encounter include:

- Overhead Cranes: Single or double girder designs, used for material handling in factories and workshops.

- Gantry Cranes: Both indoor and outdoor models, ideal for heavy lifting over large spans.

- Jib Cranes: Compact, localized lifting solutions for workstations or small workshops.

- Electric Hoists: Wire rope or chain hoists, used standalone or mounted on crane structures.

Each type has its own production process, technical complexity, and shipping considerations. Understanding these factors ahead of time helps you plan installation schedules, align budgets, and avoid the stress of last-minute delays.

Your Trusted Overhead Crane Manufacturer & Supplier

Buy Overhead Material Handling Cranes from China

Lead Time Overview for Different Crane Types

Lead time in crane procurement refers to the period from placing an order with a manufacturer to receiving the equipment ready for use. It includes design finalization, material sourcing, production, quality testing, and shipping preparation.

Typical Production Timelines in China

China manufacturers are highly efficient, but production time varies depending on the crane type and level of customization:

- Overhead Cranes: Standard models typically take 20–40 days, while non-standard or heavy-duty models may require 45–60 days or more.

- Gantry Cranes: Standard indoor models usually need 25–50 days, whereas large or specialized outdoor gantry cranes may take 60–120 days.

- Jib Cranes: Production is fast due to simpler designs. Standard wall-mounted or floor-mounted units usually ship within 7–15 days, while customized versions may take 15–30 days.

- Electric Hoists: Standard models can be ready in 5–15 days, but high-end, explosion-proof, or long-chain hoists may need 20–60 days, depending on component availability.

Standard vs. Customized Models

Standard Models

- Designed according to established specifications.

- Production is mostly streamlined with existing parts in stock.

- Delivery is faster and cost predictable.

Customized Models

- Include features like special spans, lifting heights, corrosion-resistant coatings, or explosion-proof configurations.

- Require extra engineering, material preparation, and testing.

- Production and delivery timelines are longer, and costs can increase.

Overhead Bridge Cranes (EOT Cranes) Lead Times

When buying an overhead bridge crane in China, understanding the production cycle is essential for planning. Typical lead times range from 20 to 60 days, but the exact timeline depends on several key factors.

double girder overhead crane for sale in China

Underhung bridge crane for sale in China

Key Factors Affecting Production Time

1. Technical Complexity & Specifications

- Standard cranes: Mature models without special requirements are quicker to produce, usually 20–40 days.

- Customized cranes: Non-standard designs—like special spans, high lifting heights, explosion-proof, or anti-corrosion features—require extra engineering and testing, extending the cycle to 45–60 days or more.

2. Capacity & Span

- Small and medium cranes (≤50 tons): Production is faster and more straightforward.

- Large capacity (>50 tons) or long spans (>30m): These require reinforced structures, heavier components, and additional quality checks, which naturally lengthens production time.

3. Manufacturer Capacity & Scheduling

- Large manufacturers: Stable output, but full order books may delay delivery.

- SMEs: More flexible schedules, but supply chain or technical limitations can affect timelines.

4. Procurement Method

- Complete crane purchase: Typically a fixed cycle.

- Component purchase (crane body, hoist, control system separately): Coordinating multiple suppliers may extend total lead time.

5. Supply Chain & Raw Materials

- Availability of steel, motors, and electrical systems directly impacts production. Delays in any critical component can affect the overall schedule.

6. Quality Inspection & Testing

- Load tests, electrical system commissioning, and compliance with standards (e.g., GB/T 14405) are mandatory steps that add to the timeline but ensure safety and reliability.

Reference Production Times

| Type | Typical Capacity | Standard Cycle | Customized Cycle |

|---|---|---|---|

| Single girder | 1–20 tons | 15–30 days | 30–50 days |

| Double girder | 5–500 tons | 30–45 days | 45–70 days |

| Metallurgical / Special cranes | ≥50 tons | 50–80 days | 80–120 days |

Notes:

- Transport and installation are not included (typically 3–10 days).

- Contract terms, unforeseen events, or global supply chain disruptions can further extend the timeline.

Recommendations for Buyers

- Start procurement early: Begin 2–3 months ahead for standard cranes, longer for customized projects.

- Provide detailed specifications: Include lifting capacity, span, lifting height, and duty class to avoid delays.

- Choose reliable manufacturers: Prefer ISO-certified, licensed, and experienced suppliers to ensure timely production and smooth delivery.

Gantry Crane Lead Time

Buying a gantry crane in China? Lead times can vary widely depending on the type, size, and level of customization. Typical production cycles range from 30 days for small standard cranes to over a year for large, specialized projects. Understanding what affects these timelines helps buyers plan budgets and schedules effectively.

Key Factors Affecting Gantry Crane Production

1. Type & Structural Complexity

- Small/medium frame or truss gantry cranes (≤50 tons): Simple designs, typical lead 30–50 days.

- Box-type medium/large cranes (>50 tons): Require heavier structures, longer cycles 40–70 days.

- Rail-mounted container cranes: Highly standardized but complex, 5–9 months.

- Rubber-tyre container cranes: Large, project-based, 6–12 months.

- Special-purpose cranes (shipbuilding, power plants): Can exceed 8 months, depending on project needs.

2. Span & Leg Design

- Large spans (>30 m) require extra steel, precise welding, and reinforcement, adding time.

- Leg types (L/C/U) affect fabrication and assembly complexity.

3. Duty Level & Environment

- High duty class cranes (A6–A8), corrosion protection, coastal wind resistance, or explosion-proof features all extend production cycles.

4. Travel Mechanism & Rails

- Rubber-tyre cranes involve complex steering and driving systems, increasing production time.

- Rail readiness at the site affects installation scheduling.

5. Manufacturer Selection

- Large manufacturers: Stable capacity and mature technology, but full order books may delay delivery.

- SMEs: Flexible schedules, but supply chain or technical limitations could be a risk.

Reference Production Times

| Type | Typical Use | Standard Cycle | Custom/Large Cycle |

|---|---|---|---|

| Small/medium frame/truss | Warehouses, small yards | 30–50 days | 50–80 days |

| Large box-type double girder | Steel mills, logistics parks | 45–70 days | 70–120 days |

| Rail-mounted container | Railway/river terminals | 5–9 months | 9–14 months |

| Rubber-tyre container | Container yards, ports | 6–12 months | 12+ months |

| Special-purpose | Shipbuilding, hydro | 8+ months | Project-dependent |

Notes:

- These cycles include manufacturing and factory assembly.

- Transport, installation, and commissioning require 1–4 weeks each, depending on distance and site readiness.

- Inspection and certification add 2–4 weeks.

Full Project Timeline (Contract → Ready to Use)

- Technical clarification & contract: 1–4 weeks

- Design & engineering: 2–4 weeks

- Material & component procurement: 2–4 weeks

- Manufacturing & assembly: See table above

- Transport: 1–4 weeks

- Installation & commissioning: 1–3 weeks

- Inspection & certification: 2–4 weeks

Practical Recommendations for Buyers

- Plan early: Start 4–6 months ahead for standard cranes and 1 year+ for large or customized cranes.

- Provide detailed specifications: Include lifting capacity, span, height, duty class, environment conditions.

- Choose turnkey-capable suppliers: Look for ISO-certified manufacturers that can handle design, fabrication, transport, installation, and commissioning.

- Consider long-term factors: Coastal or industrial environments may require extra protection, which affects lead times.

Jib Crane Lead Time

When it comes to jib or slewing cranes, China manufacturers offer relatively fast production cycles, but lead times still depend heavily on customization, lifting capacity, and the crane type. Typical cycles range from 7 days for standard models to up to 60 days for heavy-duty or complex cranes.

Practical Reference Table for Electric Jib Cranes,

- Wall-mounted jib cranes – Fixed to a wall; ideal for smaller workstations.

- Floor-mounted jib cranes – Supported by a column; versatile for medium to heavy loads.

- Port jib cranes – Rotating arm for extended coverage in tight or specialized areas.

Each type can be produced as standard stock models or customized solutions, and that choice significantly affects delivery time.

| Crane Type | Typical Use | Standard Production Cycle | Customized / Heavy-Duty Cycle | Notes / Critical Factors |

|---|---|---|---|---|

| Floor-Mounted Jib Crane | Workshops, factories, assembly lines | 7–15 days | 15–30 days | Standard capacities 125 kg–5 t, arm 3–6 m; foundation required; fast assembly if site ready |

| Wall-Mounted Jib Crane | Small workstations, limited floor space | 7–15 days | 15–30 days | Standard lifting 125 kg–3 t; mounting wall must be strong; corrosion-proof or explosion-proof options increase time |

| Wall-Traveling Jib Crane | Multiple workstations along a wall | 10–20 days | 20–40 days | Moves on wall-mounted rail; design complexity affects lead time; integration with hoist control system may extend production |

| Portable / Mobile Jib Crane | Flexible workshops, temporary lifting | 5–10 days | 10–15 days | Lightweight, mobile base; standard capacities 125 kg–2 t; quick assembly; custom hoist or longer arm may increase time |

| Hoist Availability | All types | Domestic: fast | Imported: 4–8 weeks | Confirm hoist type and brand in advance for scheduling |

| Installation Readiness | All types | Fast if site prepared | Delays if prep incomplete | Foundation, wall strength, and rail installation readiness are key for quick deployment |

Practical Notes for Buyers:

- Standard electric jib cranes: delivered in 1–2 weeks; ready to use in 2–3 weeks.

- Customized or heavy-duty models: delivery 15–40 days, depending on arm length, lifting capacity, coatings, or integration with rails.

- Always provide detailed site layout, power supply, and foundation/wall info to avoid delays.

Critical Factors Affecting Jib Crnae Lead Time

Several elements can influence how quickly a jib crane can be delivered and installed:

- Hoist availability: Domestic hoists are usually faster to get. Imported brands can take 4–8 weeks.

- Steel preparation & welding: Custom dimensions or heavier structures require more fabrication time.

- Surface treatment: Galvanizing or special coatings can add a few extra days.

- Installation readiness: Foundations prepared by the buyer allow faster on-site installation.

Recommendations for Buyers

To keep lead times short and avoid delays:

- Choose standard models whenever possible.

- Confirm the hoist brand and type in advance.

- Provide a detailed workstation layout and power supply information.

- Factor in installation time, usually 1–2 weeks for standard cranes.

Production Cycles

Standard Models (7–15 days)

- Lifting capacities: 125 kg–5 t

- Arm lengths: 3–6 m, standard column heights

- Quick assembly and testing due to minimal customization

Non-standard / Customized Models (15–30 days)

- Longer arms, higher lifting capacities, low headroom designs

- Special coatings: corrosion-proof, galvanizing, or explosion-proof

- Full production process: design → cutting → welding → machining → assembly → testing

Heavy-Duty / Complex Jib Cranes (30–60 days)

- Lifting capacities over 10 t, arm lengths above 8 m

- May include rigid rail integration, automated systems, or specialized hoists

Electric Hoist Lead Time

Electric hoists are generally quicker to produce than full cranes, but lead times can vary widely depending on type, specification, and origin. Understanding these timelines helps you plan installation and project schedules more accurately.

Key Considerations:

- Wire Rope vs. Chain Hoists: Wire rope hoists are usually for heavier capacities, chain hoists for lighter loads. Production time can vary accordingly.

- Standard vs. High-End / Explosion-Proof Models: Standard domestic hoists are fastest; imported or explosion-proof models take longer due to sourcing and assembly complexity.

- Supplier & Component Influence: Lead times are affected by motor availability, gears, chains, electrical components, and whether parts are domestic or imported.

Reference Production Times for Electric Hoists

| Type & Grade | Example Brands | Standard Cycle | Custom / Special Cycle | Main Delay Factors |

|---|---|---|---|---|

| Domestic standard wire rope | Yuantai Crane, Dongqi | 7–15 days | 15–30 days | Peak season, special motors/wires |

| Domestic high-end / metallurgical | Yuantai Crane, Dongqi | 15–30 days | 30–60 days | Special gear, imported parts |

| Domestic chain hoist | Yuantai Crane, Dongqi | 5–10 days | 10–20 days | Special chains, long lift |

| Foreign brands, local assembly | Demag, Kone | 4–8 weeks | 8–16 weeks | Imported core parts, order queue |

| Fully imported | ABUS, STAHL, Yale | 8–16 weeks+ | 16+ weeks | Production schedule, logistics, customs |

Practical Tips for Buyers:

- Prioritize standard domestic models for the fastest delivery.

- Clarify whether the timeline refers to factory production or delivery to site.

- Pre-select key components like motors and chains to avoid supply delays.

- Synchronize crane and hoist procurement to prevent project delays.

Factors Affecting Lead Times

Several practical factors influence how long it takes to get your crane or hoist from order to delivery. Understanding these can help buyers plan better and avoid costly delays.

1. Design Complexity & Customization

- Standard models are faster to produce because the design is proven and parts are readily available.

- Custom requirements—like unusual spans, heavy lifting capacities, corrosion-resistant coatings, or explosion-proof features—add extra time for design, fabrication, and testing.

2. Component Availability & Supplier Reliability

- Key parts such as motors, gearboxes, chains, and electrical systems can affect timelines.

- Domestic suppliers are usually faster, but imported components may take weeks due to manufacturing, shipping, and customs clearance.

3. Manufacturing Capacity & Production Schedules

- Large manufacturers have higher output but often a longer queue, especially in peak season.

- Smaller manufacturers or specialized workshops may be flexible, but limited capacity or technical challenges can extend lead times.

4. Quality Inspection, Testing & Certification

- All cranes undergo load testing, electrical checks, and compliance verification (e.g., GB/T 14405, ISO, CE).

- More stringent inspection standards, especially for high-capacity or hazardous-environment cranes, naturally add extra days or weeks.

Practical Tip for Buyers:

- Provide clear, detailed specifications upfront.

- Check component availability and potential bottlenecks.

- Factor in time for testing, inspection, and certification when planning project schedules.

Sea Freight from China (Qingdao Port)

Estimated port-to-port transit times

| Region | Example Ports | Direct / Fast | Common Transshipment | Notes |

|---|---|---|---|---|

| East & SE Asia | Busan, Tokyo, Singapore, Klang | 3–7 days | Similar | Short distance, frequent sailings |

| Oceania | Sydney, Melbourne, Auckland | 15–22 days | 18–25 days | Peak season may delay |

| Middle East | Dubai, Dammam, Colombo | 18–25 days | 20–28 days | Suez Canal route |

| South Asia | Mumbai, Karachi | 20–28 days | 22–30 days | Limited direct vessels |

| Mediterranean | Barcelona, Genoa, Piraeus | 28–35 days | 30–40 days | Suez Canal or NW Europe transshipment |

| NW Europe | Rotterdam, Hamburg | 32–40 days | 35–45 days | Weather may affect winter shipments |

| North America (West) | LA, Long Beach, Vancouver | 14–18 days | 16–22 days | Congestion may add delays |

| North America (East) | NY, Savannah, Houston | 25–35 days | 28–40 days | Via Panama Canal or rail |

| South America (W) | Valparaiso, Callao | 30–38 days | 35–45 days | Few direct routes |

| South America (E) | Santos, Buenos Aires | 40–50 days | 45–55+ days | Usually via Europe or Africa |

| Africa (W) | Durban, Lagos, Mombasa | 25–45 days | 30–50 days | Europe/Middle East transshipment common |

Notes:

- Times are port-to-port, add 2–3 weeks for customs, inland transport, and handling.

- Direct shipping is faster; transshipment adds 5–7 days per stop.

- Seasonal congestion (Aug–Jan) may add 1–2 weeks.

- Global events (Suez, Panama, storms) can cause additional delays.

Recommendation:

- Treat these times as baseline and add 10–20% buffer.

- Coordinate closely with freight forwarders and choose reliable shipping services.

Shipping & Delivery from China

Shipping and delivery are just as important as production when it comes to crane procurement. Understanding the process helps avoid surprises and keeps projects on schedule.

Sea Freight from China (Qingdao Port), Estimated port-to-port transit times,

| Region | Example Ports | Direct / Fast | Common Transshipment | Notes |

|---|---|---|---|---|

| East & SE Asia | Busan, Tokyo, Singapore, Klang | 3–7 days | Similar | Short distance, frequent sailings |

| Oceania | Sydney, Melbourne, Auckland | 15–22 days | 18–25 days | Peak season may delay |

| Middle East | Dubai, Dammam, Colombo | 18–25 days | 20–28 days | Suez Canal route |

| South Asia | Mumbai, Karachi | 20–28 days | 22–30 days | Limited direct vessels |

| Mediterranean | Barcelona, Genoa, Piraeus | 28–35 days | 30–40 days | Suez Canal or NW Europe transshipment |

| NW Europe | Rotterdam, Hamburg | 32–40 days | 35–45 days | Weather may affect winter shipments |

| North America (West) | LA, Long Beach, Vancouver | 14–18 days | 16–22 days | Congestion may add delays |

| North America (East) | NY, Savannah, Houston | 25–35 days | 28–40 days | Via Panama Canal or rail |

| South America (W) | Valparaiso, Callao | 30–38 days | 35–45 days | Few direct routes |

| South America (E) | Santos, Buenos Aires | 40–50 days | 45–55+ days | Usually via Europe or Africa |

| Africa (W) | Durban, Lagos, Mombasa | 25–45 days | 30–50 days | Europe/Middle East transshipment common |

Notes:

- Times are port-to-port, add 2–3 weeks for customs, inland transport, and handling.

- Direct shipping is faster; transshipment adds 5–7 days per stop.

- Seasonal congestion (Aug–Jan) may add 1–2 weeks.

- Global events (Suez, Panama, storms) can cause additional delays.

Recommendation:

- Treat these times as baseline and add 10–20% buffer.

- Coordinate closely with freight forwarders and choose reliable shipping services.

1. Domestic vs. International Delivery Timelines

- Domestic (within China): Usually 3–10 days via truck or rail, depending on distance and road conditions. Fastest for standard cranes and hoists.

- International (sea freight): Typical transit times range from 15–45 days for standard ports. Air freight is faster but much more expensive and usually reserved for small components or urgent deliveries.

2. Major Shipping Routes & Estimated Sea Freight Times

- China → USA: 25–35 days via West Coast ports, 30–45 days via East Coast.

- China → Europe: 30–40 days depending on port and transshipment.

- China → Middle East / Gulf: 20–30 days.

- China → Southeast Asia: 7–20 days depending on port proximity and shipping line.

3. Customs Clearance, Logistics & Handling

- Cranes are considered heavy machinery and may require import licenses or inspection certificates in some countries.

- Ensure documents like the packing list, commercial invoice, certificate of origin, and inspection report are complete to avoid delays.

- Local port handling, offloading, and inland transport can add 3–10 days depending on infrastructure and accessibility.

4. Project Location Impact

- Remote or inland sites may require additional trucking or rail, adding days to total delivery time.

- Urban areas with congested ports may see minor delays.

- Coordination with local riggers or crane installation teams is key to ensure timely commissioning.

5. Practical Advice for Buyers – Planning

- Start shipping planning as soon as production begins.

6. Practical Advice for Buyers – Port Facilities

- Confirm port facilities and local transport availability.

7. Practical Advice for Buyers – Customs & Inspection

- Factor in customs inspection and paperwork processing when calculating total project timelines.

8. Practical Advice for Buyers – Urgent Projects

- For urgent projects, consider combined strategies like partial air shipment for critical components.

9. Additional Notes – Delivery Transparency

Clear communication with suppliers ensures smoother coordination during shipping and unloading stages.

10. Additional Notes – Handling at Destination

Local handling conditions such as crane availability, site accessibility, or port congestion can influence the final delivery timeline.

11. Additional Notes – Coordination & Scheduling

Aligning logistics schedules with installation teams ensures that cranes can be commissioned without unnecessary delays.

Planning Tips for Buyers

Successfully buying cranes from China isn't just about picking the right model—it's about timing. Aligning lead times with your project schedule ensures smooth delivery and installation.

1. Align Lead Times with Project Schedules

- Start by mapping out your project milestones: foundation readiness, installation date, and commissioning.

- Work backward from your installation date to determine the latest possible order date. This helps avoid rushing or unexpected downtime.

2. Early Inquiries and Clear Specification Submission

- Contact suppliers as early as possible. Even if you don't have every detail finalized, initial discussions help manufacturers allocate production slots.

- Provide detailed specs upfront: lifting capacity, span, lifting height, duty class, hoist type, and any environmental requirements. Clear information reduces production errors and speeds up approval.

3. Buffer Time for Unexpected Delays

- Add at least 2–4 weeks for potential delays caused by supply chain issues, shipping congestion, or customs clearance.

- Weather, port congestion, or last-minute specification changes can push timelines, so plan conservatively.

4. Choosing Reliable Suppliers

- Work with ISO-certified or CE-certified manufacturers with a proven track record in crane delivery.

- Check references and past projects, especially for similar crane types or custom requirements.

- Reliable suppliers often have better production scheduling, component sourcing, and after-sales support, reducing surprises along the way.

5. Practical Advice – Communication

- Maintain regular communication with your supplier during production.

6. Practical Advice – Shipping Schedule Confirmation

- Confirm shipping schedules and installation support early.

7. Practical Advice – Documentation & Agreements

- Document agreements on delivery, installation, and post-delivery support to avoid misunderstandings.

8. Additional Note – Project Timeline Alignment

Ensuring procurement and construction timelines match avoids costly idle time or rushed installation.

9. Additional Note – Specification Accuracy

Providing complete and accurate technical data shortens approval cycles and helps prevent redesign delays.

10. Additional Note – Supplier Coordination

Close coordination ensures progress visibility throughout production, packaging, and dispatch.

11. Additional Note – Risk Reduction Planning

Adding reasonable buffers to your schedule minimizes the impact of unforeseen transport or documentation delays.

Conclusion & Summary

When buying cranes from China, timing is just as important as price. Lead times vary widely depending on crane type, customization, and shipping methods. Understanding these timelines helps you plan projects more effectively and avoid costly delays.

Overall Summary of Lead Times:

- Bridge cranes (EOT cranes): 20–60 days depending on specifications and complexity.

- Gantry cranes: 30–90+ days, with larger, custom, or heavy-duty models taking longer.

- Jib cranes: 7–30 days, with standard floor or wall-mounted models being the fastest.

- Electric hoists: 3–5 days for domestic standard units, up to 16+ weeks for imported or custom designs.

- Sea freight from Qingdao: 3 days to nearby Asian ports, 55+ days to South America east coast; remember to add handling and customs time.

Key Takeaways for Buyers:

- The closer your order is to standard catalog specifications, the faster the delivery.

- Custom features, heavy-duty applications, and imported components can significantly extend production and shipping timelines.

- Early planning, clear specifications, and choosing reliable suppliers are essential for keeping projects on track.

By factoring in production cycles, shipping, and installation time, buyers can better align procurement with project schedules, ensuring smoother execution and fewer surprises. Planning ahead isn't just smart—it's necessary.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch