Why No Building Doesn’t Mean a Gantry Crane: Buyer Guide

Learn why outdoor crane choice isn’t only about buildings. Compare gantry, bridge, and semi-gantry cranes to optimize load, span, cost, and workflow.

Category: Featured

Your Trusted Overhead Crane Manufacturer & Supplier

Why No Building Does Not Automatically Mean a Gantry Crane

Key Insights for Outdoor Crane Buyers

Most Important Takeaway (Lead)

Choosing the right outdoor crane is not determined solely by the absence of a factory building. A gantry crane is just one of several options, and factors like lifting capacity, span, workflow integration, installation cost, and long-term maintenance often matter more.

Key Takeaways (Bullets)

- No building does not automatically require a gantry crane; standalone runway supports can enable top-running bridge cranes outdoors.

- Load capacity, span, and lifting height often dictate the crane type more than building presence.

- Workflow and material handling needs influence crane selection significantly.

- Gantry cranes may increase transportation and foundation costs for heavy loads or long spans.

- Semi-gantry cranes or outdoor bridge cranes can offer better efficiency and future scalability.

- Proper evaluation avoids overspending or operational inefficiencies in outdoor lifting projects.

Introduction

Many industrial buyers automatically assume that if there is no factory building, a gantry crane is the only way to lift and move heavy materials outdoors. It makes sense at first glance—after all, gantry cranes are the ones you often see in open steel yards or construction sites.

But in reality, choosing a crane based only on the presence or absence of a building can lead to problems. You might end up with higher transportation costs, complex foundation requirements, or a crane that doesn’t fit your workflow. Some buyers even face delays because the crane they ordered cannot handle the span or weight required efficiently.

This guide is meant to help you think beyond assumptions. It focuses on practical considerations for outdoor crane selection, including load capacity, span, installation, and integration with your material handling system. By the end, you’ll understand that the right crane depends on your actual site and workflow needs, not just whether there’s a roof over it.

Common Misconceptions About Outdoor Cranes

Clarifying frequent misunderstandings about gantry cranes and outdoor bridge cranes for buyers.

Gantry Crane = Only Outdoor Option

It's easy to think that if you're working outdoors, a gantry crane is the default choice. They are mobile, visible, and familiar, covering an open yard without needing a building. However, not every open site needs a gantry crane. For heavy loads or longer spans, a gantry crane can be less efficient and more expensive to operate than other types. Mobility comes at a price—the legs, wheels, and foundations for a heavy gantry crane can add significant cost and installation time.

- Gantry cranes are usually best for medium loads and moderate spans.

- Heavy-duty lifting over long distances is often better handled by a bridge crane on a steel runway.

- Mobility may be useful for temporary setups, but for a permanent or semi-permanent production system, a gantry can be more of a maintenance burden.

No Building = No Other Options

Another common mistake is assuming that without a factory building, you have no choice but a gantry crane. Modern solutions include:

Top-Running Outdoor Bridge Cranes with freestanding Runway:

- Installed on standalone steel runway supports.

- Handle heavier loads and longer spans than typical gantry cranes.

- Ideal for outdoor steel yards, precast concrete yards, or open production areas where workflow efficiency is important.

Semi-Gantry Cranes:

- One side of the crane is supported by a leg, the other by an existing structure or partial building.

- Useful when partial structures exist or when full mobility is not required.

- Can reduce foundation and transportation costs compared to a full gantry.

Outdoor Crane Options Without a Building

Choosing an outdoor crane when there is no building doesn’t mean you have to stick to one type. There are several practical options, each with its own advantages and limitations. Understanding these can save you time, money, and headaches during installation and operation.

| Crane Type | Description | Pros | Cons |

|---|---|---|---|

| Full Gantry Cranes | Mobile cranes with legs running on rails. Can cover open yards without building support. | - Mobile across the site - Flexible for temporary layouts - Handles moderate loads | - High transport and installation cost - Complex for heavy or long-span loads - Less efficient for permanent setups |

| Top-Running Outdoor Bridge Cranes | Cranes running on elevated beams (standalone runway). No legs on the ground. | - Supports heavier loads - Efficient for long spans - Integrates with production workflows | - Requires runway construction - Longer installation and planning - Upfront structure cost |

| Semi-Gantry Cranes | Hybrid design: one side on a leg, other attached to partial building or structure. | - Covers partial areas without full legs - Lower foundation and transport cost - Practical for partial structures | - Limited mobility vs full gantry - Less span and layout flexibility |

Practical Note: The absence of a building doesn't automatically mean a gantry crane is best. For heavy loads, long spans, or production integration, a bridge crane or semi-gantry crane may be more practical and cost-efficient.

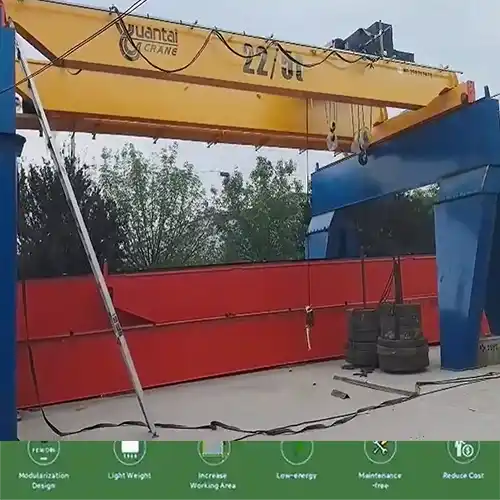

Full Gantry Cranes

Full gantry cranes are mobile cranes with legs running on rails. They cover open yards without building support and are often used in construction sites, steel yards, and temporary setups.

Pros:

- Mobility across the site for temporary or changing layouts.

- Flexible installation for sites without fixed structures.

- Handles moderate loads safely for most outdoor material handling tasks.

Cons:

- High transport and installation cost.

- Complex setup for heavy or long-span loads; requires strong foundations.

- Less efficient for permanent production yards.

Top-Running Outdoor Bridge Cranes

Top-running bridge cranes run on elevated beams (standalone runway) with no legs on the ground. They are ideal for heavier loads and longer spans in industrial yards.

Pros:

- Supports heavier loads than most gantry cranes.

- Efficient for long spans and large yard coverage.

- Integrates with production workflows, moving materials over obstacles.

Cons:

- Requires standalone runway construction and upfront planning.

- Installation can take longer than a simple gantry, though often more cost-effective for heavy lifting.

Semi-Gantry Cranes

Semi-gantry cranes are hybrids: one side on a leg, the other attached to an existing structure. They are practical when partial support structures exist but full gantry mobility is unnecessary.

Pros:

- Covers partial areas without full gantry legs on both sides.

- Lower foundation and transport costs than full gantry cranes.

- Suitable for yards with partial buildings or steel supports.

Cons:

- Limited mobility compared to full gantry cranes.

- Span and layout flexibility are reduced versus a full gantry setup.

Practical Note: Absence of a building doesn't automatically mean a gantry crane is best. For heavy loads, long spans, or integrated production workflows, a bridge crane or semi-gantry crane is often more practical and cost-efficient.

Key Factors Beyond "No Building"

Several critical considerations determine the best crane type for outdoor sites, beyond simply whether a building exists.

Load Capacity

- Heavy loads often favor top-running bridge cranes, which distribute weight across a steel runway rather than relying on legs.

- Ensure the crane's rated load includes a safety margin (typically 20–30%) for dynamic effects or unexpected lifting conditions.

- Consider frequency of lifting: repeated heavy lifts require more robust crane structures and hoists.

Span and Lifting Height

- Long spans and high lifts generally favor bridge cranes because gantry legs become expensive and harder to stabilize over wide distances.

- For shorter spans or low lifts, a gantry crane or semi-gantry may be sufficient.

- Always verify that the crane type can reach every point in your yard without limiting workflow.

Workflow Integration

- Consider how the crane will move materials between storage, production, and loading areas.

- Top-running bridge cranes can follow a straight-line path over obstacles, keeping operations smooth.

- Gantry cranes may require frequent repositioning if multiple areas need coverage, slowing workflow.

Cost Analysis

- Compare transportation costs: large gantry cranes are expensive to move and install.

- Factor in installation complexity, including foundations and steel supports.

- Consider maintenance costs, especially if the crane is exposed to harsh outdoor conditions.

- A bridge crane with a steel runway may have higher initial costs but lower long-term operational expenses.

Future Scalability

- Consider whether your facility may expand production or require heavier lifts in the future.

- Bridge cranes and semi-gantry cranes often allow for future upgrades, such as increasing hoist capacity or extending spans.

- Gantry cranes designed for temporary needs can be harder to scale.

Environmental Considerations

- Wind loads can affect gantry stability, especially for high or long-span cranes.

- Rain, snow, and humidity require corrosion-resistant coatings and hoists rated for outdoor use.

- Soil conditions for foundations are critical—soft or uneven ground may make gantry legs unstable, favoring elevated runways instead.

Practical Insight: A crane that works on paper may fail in practice if these factors are ignored. Load, span, workflow, cost, future needs, and environmental conditions all need to be analyzed before deciding on gantry, bridge, or semi-gantry cranes.

Practical Examples

Seeing how different cranes perform in real-world scenarios can help determine which solution fits your outdoor site.

Case 1: Steel Yard with Top-Running Outdoor Bridge Crane

A steel processing yard needed to move heavy slabs up to 25 tons across an open area with no building overhead. Instead of choosing a gantry crane, the buyer installed a top-running bridge crane on a standalone steel runway.

- The elevated runway supported heavy loads safely without requiring massive gantry legs.

- Long spans were easily covered, allowing the crane to access all storage and loading points efficiently.

- Minimal movement of the crane was required, reducing operational complexity and saving time during material handling.

Case 2: Construction Site with Mobile Gantry Cranes

On a construction site, the team used mobile gantry cranes to lift materials between different points. While this allowed flexibility, there were notable drawbacks.

- High transport and installation costs for moving large gantry legs between work zones.

- Limited lifting height and span compared to a bridge crane, making some lifts cumbersome.

- Frequent repositioning slowed down workflow and required additional labor.

Case 3: Semi-Gantry Crane for Partial Building Coverage

A production yard had a partial steel structure covering one side of the area. The buyer installed a semi-gantry crane—one side supported by the building, the other on a leg.

- Balanced foundation and installation costs, as fewer ground supports were needed.

- Improved stability for heavier loads compared to a fully mobile gantry.

- Workflow integration was smoother because the crane could cover the necessary areas without constant repositioning.

Decision-Making Checklist for Buyers

Selecting the right outdoor crane involves more than choosing between a gantry or bridge crane. Ask these key questions to make an informed, practical decision.

1. Existing Structure or Runway Possibility

Question: Do you have any existing structures, or can a steel runway be built?

Why it matters: The type of crane depends heavily on what supports are available.

- Semi-gantry cranes work well if there's partial building coverage.

- Bridge cranes require standalone steel runways if no building exists.

- Full gantry cranes can operate independently but may need strong foundations and extra space.

2. Maximum Load and Span Requirements

Question: How heavy are the loads, and how far must the crane span?

Why it matters: Heavy or wide-span lifts influence crane type, design, and foundation needs.

- Bridge cranes handle heavier loads and longer spans better than gantry cranes.

- Include a 20–30% safety margin above the heaviest expected load.

- Check if lifting height meets all operational points without interference.

3. Workflow Integration

Question: How will the crane fit into your production or material handling system?

Why it matters: A crane that doesn't align with your workflow can slow operations.

- Determine whether the crane needs to cover multiple areas or a straight path.

- Consider repositioning needs; frequent movement can reduce efficiency.

- Ensure crane placement avoids bottlenecks or obstructions.

4. Budget and Total Costs

Question: What's your budget for purchase, installation, and ongoing maintenance?

Why it matters: Upfront cost isn't the only factor; long-term costs matter too.

- Full gantry cranes may have higher transport and installation costs.

- Bridge cranes require steel runway investment but often save on maintenance and operational efficiency.

- Factor in outdoor durability: coatings, hoist protection, and corrosion prevention.

5. Future Expansion Needs

Question: Will your facility need to expand or lift heavier loads in the future?

Why it matters: Planning ahead prevents expensive replacements.

- Bridge and semi-gantry cranes often allow future upgrades for higher capacity or longer spans.

- Gantry cranes may require full replacement if future lifting requirements exceed initial design.

6. Environmental and Safety Factors

Question: Have you considered wind, rain, soil conditions, and safety regulations?

Why it matters: Outdoor cranes face conditions that affect stability and longevity.

- High winds can destabilize tall gantry cranes.

- Wet, humid, or corrosive environments require outdoor-rated hoists and coatings.

- Soft or uneven soil may favor elevated runways over freestanding gantry legs.

Quick Practical Tip:

Before buying, map your site layout, list lifting points, and check all environmental factors. The crane you choose should match load, workflow, and long-term plans—not just the absence of a building.

Frequently Asked Questions (FAQ)

Answers to common questions about outdoor bridge cranes and standalone runway systems.

Q1: Does the absence of a building automatically mean I must use a gantry crane?

A: No. While gantry cranes are common in open yards, the absence of a building doesn't automatically require one. Top-running bridge cranes or semi-gantry cranes can also operate outdoors efficiently when supported by standalone steel runways or partial structures. The right choice depends on load, span, workflow, and site layout, not just the presence of a building.

Q2: What are the alternative crane types suitable for outdoor lifting without a factory?

A: There are several practical options:

- Top-running bridge cranes: Ideal for heavier loads and longer spans; they run on steel runway beams.

- Semi-gantry cranes: One side supported by a structure, the other by a leg; balances stability and cost.

- Full gantry cranes: Mobile and flexible for temporary or moderate load applications, but may have higher transport and installation costs.

Each option has trade-offs in terms of mobility, cost, and installation, so site-specific evaluation is essential.

Q3: How do lifting capacity, span, and workflow affect outdoor crane selection?

A: These are critical factors:

- Lifting capacity: Heavy loads often favor bridge or semi-gantry cranes for stability.

- Span and height: Long spans or high lifts can make gantry cranes less practical.

- Workflow integration: A crane must match material flow patterns. Poor alignment can create bottlenecks or slow operations.

Selecting a crane without considering these factors can lead to inefficient material handling and higher operational costs.

Q4: What are the cost, installation, and maintenance considerations for outdoor cranes?

A: When evaluating cranes:

- Cost: Include purchase price, transport, and steel runway or foundation construction.

- Installation: Gantry cranes may require heavy foundations; bridge cranes need runway beams.

- Maintenance: Outdoor cranes face wind, rain, and corrosion, requiring protective coatings and durable hoists.

A crane with higher upfront costs may save money in the long run if it reduces labor, downtime, and repositioning needs.

Q5: How can I plan for future expansion or heavier lifting requirements?

A: Consider scalability from the start:

- Bridge and semi-gantry cranes often allow upgrades to hoist capacity or extended spans.

- Gantry cranes may need full replacement if lifting requirements increase.

- Evaluate the site layout, foundation, and available space to accommodate future expansion without costly modifications.

Planning ahead ensures your crane continues to meet operational needs as your business grows.

Conclusion

Just because there’s no factory building doesn’t automatically mean a gantry crane is the best choice. Many buyers make this assumption and later face higher costs, installation challenges, or operational inefficiencies.

The smarter approach is to evaluate your actual site and operational needs first:

- Load capacity: How heavy are the materials, and what safety margin is needed?

- Span and lifting height: Will the crane cover all required areas efficiently?

- Workflow integration: How will it fit into your material handling system?

- Cost: Consider transport, installation, and long-term maintenance.

- Future scalability: Will the crane support potential expansions or heavier loads?

Selecting the right crane—whether it’s a full gantry, top-running bridge, or semi-gantry—ensures long-term efficiency, safety, and cost savings.

Finally, don’t rely solely on assumptions or off-the-shelf solutions. Professional consultation with experienced crane suppliers can help you design and install the optimal outdoor lifting system tailored to your site, workflow, and future needs.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch