Guide to Procuring Overhead Cranes & Electric Hoists at Canton Fair

How to buy electric overhead cranes & electric hoists in China with the most competitive price? Go to Canton Fair. Factory Sale, Good Price,Custom Design.

| Overhead Crane | 0.5 ton to 320 ton |

| Gantry Crane | 1 ton to 550 ton |

| Jib Crane | 500kg to 16 ton |

| Electric Hoist | 1 ton to 80 Ton |

| Builtup hoist | 3 ton to 550 ton |

Category: Featured

Your Trusted Overhead Cranes and Electric Hoists Manufacturer & Supplier in China

Guide to Procuring Overhead Cranes & Electric Hoists at Canton Fair

Buy Bridge Crane from China at Canton Fair, Factory Sale, Good Price, Custom Design 1 Ton to 550 Ton

How to buy electric overhead cranes & electric hoists in China with the most competitive price? Go to Canton Fair. Factory Sale, Good Price,Custom Design.

Comprehensive Guide to Procuring Overhead Cranes and Electric Hoists at the Canton Fair

The Canton Fair stands tall as China's foremost trade event, drawing business enthusiasts from across the globe. It's a grand spectacle where opportunities abound, connections flourish, and deals materialize. In this guide, we'll unveil the intricacies of the Canton Fair, highlighting its significance, and provide indispensable tips for navigating the realm of overhead crane and electric hoist procurement in China.

The Canton Fair, also known as the China Import and Export Fair, epitomizes China's prowess in international trade. Held biannually in Guangzhou, it serves as a beacon for manufacturers, suppliers, and buyers seeking lucrative business ventures. With its vast exhibition space and diverse array of products, the fair is a melting pot of innovation, commerce, and cultural exchange.

Success at the Canton Fair isn't a stroke of luck but a result of meticulous planning and preparation. Buyers must arm themselves with knowledge, set clear objectives, and devise effective strategies to navigate the bustling fairgrounds. From researching potential suppliers to fine-tuning negotiation skills, thorough preparation lays the groundwork for fruitful outcomes.

In the realm of heavy machinery, overhead cranes and electric hoists stand out as indispensable assets for various industries. Whether in manufacturing, construction, or logistics, these equipment play a pivotal role in enhancing efficiency and productivity. Thus, buyers attending the Canton Fair with a focus on procuring such machinery must approach their mission with clarity and determination.

Preparing for the Canton Fair

As the anticipation builds for the upcoming Canton Fair, it's essential to lay down a solid foundation for success. Preparation is the key to unlocking the full potential of this premier trade event. Let's delve into the crucial steps involved in gearing up for your Canton Fair journey.

Researching Overhead Crane Manufacturers and Suppliers: Identifying Potential Partners

Before diving into the bustling fairgrounds of the Canton Fair, it's imperative to conduct thorough research on overhead crane manufacturers and suppliers. Take advantage of online resources, industry directories, and trade publications to compile a list of potential partners. Pay attention to factors such as reputation, product range, and customer reviews to narrow down your options and identify reliable suppliers who align with your business needs.

Researching overhead crane manufacturers and suppliers is a crucial step in preparing for the Canton Fair. Here's how to effectively identify potential partners:

- Utilize Online Resources: Begin your research by leveraging online platforms such as business directories, industry forums, and supplier databases. These resources provide valuable insights into the reputation, capabilities, and offerings of various overhead crane manufacturers and suppliers.

- Explore Industry Directories: Consult industry-specific directories and listings to identify reputable suppliers in the overhead crane sector. These directories often categorize suppliers based on product types, certifications, and geographical locations, making it easier to find relevant partners.

- Read Trade Publications: Stay informed about the latest trends, innovations, and market dynamics by reading trade publications and industry magazines. These publications often feature articles, reviews, and advertisements from leading overhead crane manufacturers, offering valuable insights into their products and services.

- Consider Reputation and Reviews: Pay attention to the reputation and track record of potential suppliers. Look for testimonials, case studies, and customer reviews to gauge the quality of their products, reliability of their services, and satisfaction levels among previous clients.

- Evaluate Product Range and Expertise: Assess the product range and technical expertise of each supplier to ensure they can meet your specific requirements. Consider factors such as crane types, lifting capacities, customization options, and compatibility with your industry and applications.

- Seek Recommendations and Referrals: Reach out to industry colleagues, trade associations, and professional networks for recommendations and referrals. Word-of-mouth referrals from trusted sources can provide valuable insights and help you identify reliable suppliers with proven track records.

- Verify Certifications and Compliance: Verify that potential suppliers adhere to relevant industry standards, certifications, and regulatory requirements. Look for certifications such as ISO 9001 for quality management and ISO 14001 for environmental management, as well as compliance with safety regulations and standards.

By conducting thorough research and due diligence, you can identify potential partners who meet your criteria for reliability, quality, and compatibility. This groundwork lays the foundation for successful collaboration and procurement at the Canton Fair.

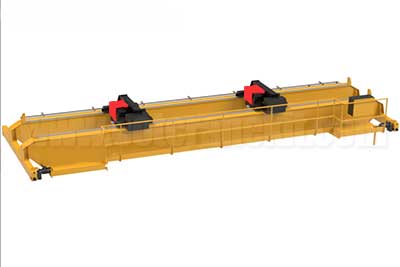

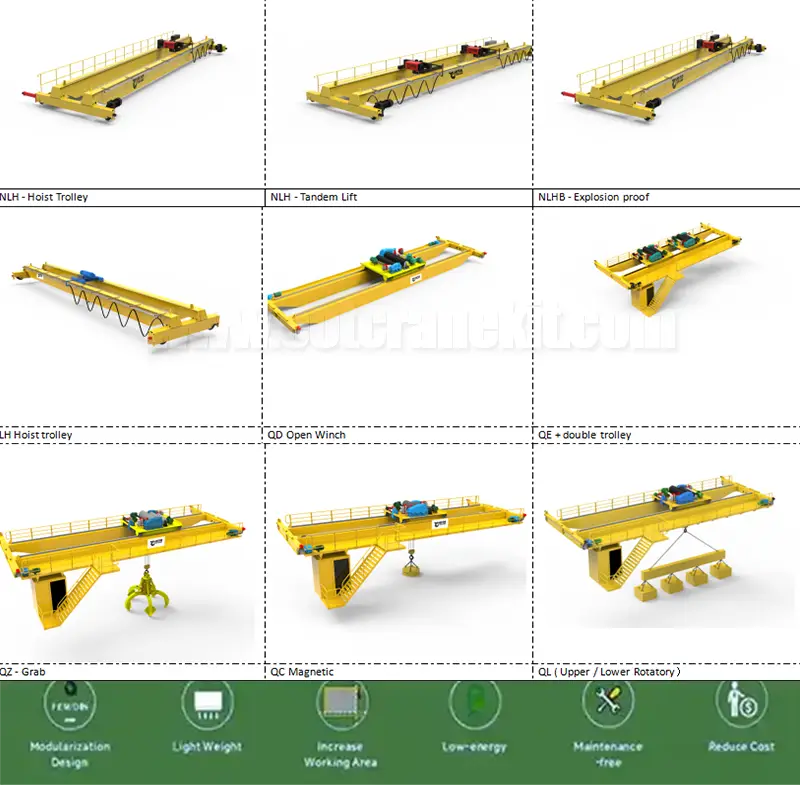

European Style Electric Overhead Crane with Advanced Crane Design with Smart Features

Double girder overhead crane with rotary trolley for sale

Double girder gantry cranes with smart electric hoists including main hoist and auxialiry

Intelligent Eot Crane and Smart Hoist Parts and Components

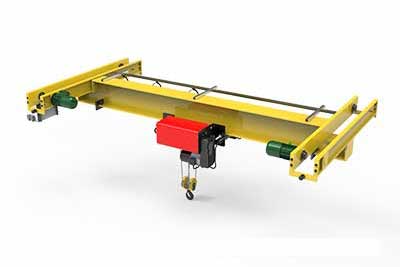

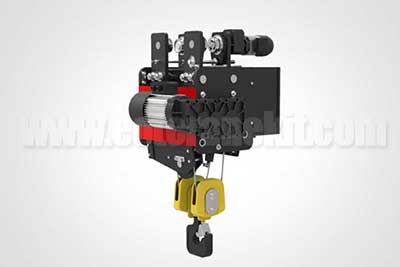

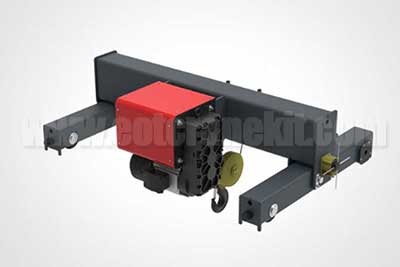

NR mode standard headroom electric hoist

Lifting capacity: 3 ton ~20 ton

Lifting height: 6m~30m

Work level: M3~M5

Application: For Single Girder Cranes

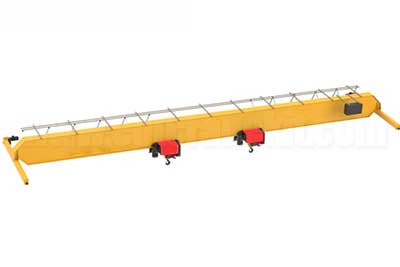

NR mode low headroom electric hoist

Lifting capacity: 3 ton ~20 ton

Lifting height: 6m~30m

Work level: M3~M5

Application: For Single Girder Cranes

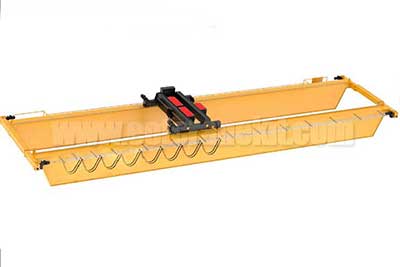

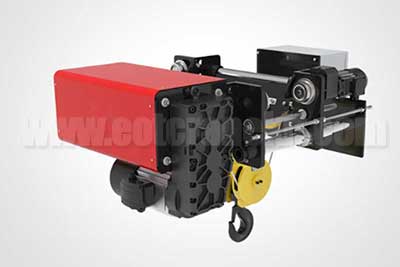

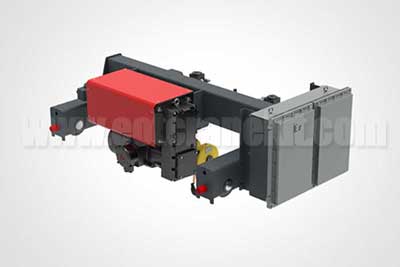

NRT crab electric hois ton

Lifting capacity: 3 ton ~80 ton

Lifting height: 6m~30m

Work level: M3~M5

Application: For Double Girder Cranes

Explosion Proof Electric Wire Rope Hoists

Lifting capacity: 3 ton ~20 ton

Lifting height: 6m~30m

Work level: M3~M5

Application: For Single Girder Cranes

BNR low headroom explosion-proof electric hoist

Lifting capacity: 3 ton ~20 ton

Lifting height: 6m~30m

Work level: M3~M5

Application: For Single Girder Cranes

BNRT crab model explosion-proof electric hoist

Lifting capacity: 3 ton ~30 ton

Lifting height: 6m~30m

Work level: M3~M5

Application: For Double Girder Cranes

Confirm Your Hoist and Specifications Specifications and Requirements

After confirming your required crane type, and then the main overhead crane specifications needs to be confirmed. Navigating the technical intricacies of overhead cranes and electric hoists requires a solid understanding of product specifications and requirements. Familiarize yourself with industry standards, performance metrics, and regulatory compliance to ensure that you make informed decisions during supplier interactions. Clarify your specific requirements, such as crane types, lifting capacity, span length, and safety features, to effectively communicate your needs to potential suppliers.

The technical aspects of overhead cranes and electric hoists is essential for making informed decisions and effectively communicating your requirements to potential suppliers. Here's how to navigate the technical details:

- Familiarize Yourself with Industry Standards: Gain a basic understanding of industry standards and regulations governing overhead cranes and electric hoists. Standards such as ANSI, CMAA, and OSHA outline safety requirements, design criteria, and performance specifications that manufacturers must adhere to.

- Learn Performance Metrics: Understand key performance metrics and specifications relevant to overhead cranes and electric hoists, such as lifting capacity, span length, lifting height, and speed. These metrics determine the suitability of a crane or hoist for specific applications and operational requirements.

- Consider Application-Specific Requirements: Clarify your specific application requirements and operational needs to identify the most suitable crane or hoist configuration. Consider factors such as load characteristics, duty cycle, frequency of use, environmental conditions, and space constraints when determining the optimal solution.

- Evaluate Safety Features: Prioritize safety by understanding the various safety features and mechanisms incorporated into overhead cranes and electric hoists. Look for features such as overload protection, emergency stop buttons, limit switches, anti-collision devices, and redundant safety systems to minimize the risk of accidents and ensure compliance with safety regulations.

- Assess Customization Options: Determine whether customization options are necessary to meet your unique requirements. Discuss customization possibilities with potential suppliers, such as tailored crane configurations, specialized lifting attachments, or integration with existing equipment and systems.

- Seek Expert Advice: Consult with technical experts, engineers, or crane specialists to gain deeper insights into technical specifications and requirements. Engage in discussions with suppliers to clarify any technical uncertainties and ensure alignment between your needs and their product offerings.

- Prioritize Regulatory Compliance: Verify that potential suppliers comply with relevant regulatory requirements and standards applicable to overhead cranes and electric hoists. Ensure that products meet or exceed safety, quality, and performance standards mandated by regulatory bodies and industry associations.

By navigating the technical details of overhead cranes and electric hoists, you can make informed decisions, mitigate risks, and ensure that your procurement process is aligned with your operational needs and regulatory obligations. This proactive approach lays the groundwork for successful collaboration with suppliers and facilitates the acquisition of reliable and compliant equipment at the Canton Fair.

Setting Budgets and Negotiation Strategies: Ensuring Cost-Effective Solutions

In the realm of procurement, cost-effectiveness is paramount. Set clear budgets and negotiation strategies to secure the best deals on overhead cranes and electric hoists. Determine your price range based on market research, competitive analysis, and budget constraints. Equip yourself with effective negotiation tactics, such as leveraging volume discounts, exploring payment terms, and seeking value-added services, to drive favorable outcomes during supplier negotiations.

When it comes to purchasing overhead cranes and electric hoists, achieving cost-effectiveness is crucial. Here's how to set budgets and employ negotiation strategies to ensure you secure the best deals:

Determine Your Price Range: Begin by conducting thorough market research and competitive analysis to understand prevailing price ranges for overhead cranes and electric hoists. Consider factors such as equipment specifications, brand reputation, and additional services offered by suppliers. Based on your findings and budget constraints, establish a clear price range within which you are comfortable negotiating.

Equip Yourself with Negotiation Tactics:

Develop effective negotiation tactics to maximize your bargaining power and drive favorable outcomes. Leverage strategies such as:

- Volume Discounts: Negotiate volume discounts with suppliers based on the quantity of equipment you intend to purchase. Bulk purchases often qualify for discounted pricing, allowing you to save costs per unit.

- Payment Terms: Explore flexible payment terms, such as extended payment periods or milestone-based payments, to improve cash flow and minimize upfront expenses. Negotiate favorable terms that align with your financial capabilities and procurement timelines.

- Value-Added Services: Seek value-added services or incentives from suppliers, such as free installation, maintenance packages, or training programs for your staff. These additional benefits enhance the overall value proposition and contribute to cost savings over the equipment's lifecycle.

Prioritize Total Cost of Ownership: Look beyond upfront purchase costs and consider the total cost of ownership (TCO) when evaluating offers from suppliers. Assess factors such as maintenance requirements, spare parts availability, energy efficiency, and operational downtime to determine the long-term economic viability of each proposal. Choose suppliers that offer competitive TCO and provide comprehensive support throughout the equipment's lifespan.

Maintain Flexibility and Openness: Remain flexible during negotiations and be open to exploring alternative solutions or concessions that may benefit both parties. Foster a collaborative atmosphere with suppliers and seek mutually beneficial agreements that address your needs while respecting their business interests.

Document Agreements and Commitments: Once negotiations are finalized, ensure that all agreements, pricing terms, and commitments are documented in writing. Clarify any ambiguities or discrepancies to avoid misunderstandings and establish a clear framework for the procurement process.

By setting clear budgets and employing effective negotiation strategies, you can maximize cost-effectiveness and secure favorable deals on overhead cranes and electric hoists at the Canton Fair. This proactive approach enables you to optimize your procurement outcomes and achieve significant savings while meeting your operational requirements.

Arranging Travel and Accommodations: Facilitating a Seamless Experience

With your procurement objectives in place, it's time to take care of logistics and ensure a seamless experience at the Canton Fair. Arrange travel and accommodations well in advance to avoid last-minute hassles. Book flights or train tickets to Guangzhou, the host city of the fair, and secure accommodations near the fairgrounds for convenience. Consider factors such as proximity, amenities, and transportation options when selecting your lodging to ensure a comfortable and hassle-free stay during the event.

Arranging travel and accommodations is a crucial aspect of preparing for the Canton Fair, ensuring a smooth and hassle-free experience. Here's how to facilitate a seamless journey:

- Plan Ahead: Start by outlining your travel itinerary and accommodation requirements well in advance of the fair dates. This allows you to secure the best deals on transportation and lodging options.

- Book Flights or Train Tickets: Depending on your location and preferences, decide whether to fly or take a train to Guangzhou, the host city of the Canton Fair. Book your tickets early to secure favorable rates and convenient travel times. Guangzhou Baiyun International Airport serves as the main gateway, offering direct flights from major cities worldwide. Alternatively, high-speed trains connect Guangzhou to various destinations within China, providing a convenient and efficient travel option.

- Choose Accommodations Near the Fairgrounds: Select accommodations that are in close proximity to the fairgrounds to minimize commuting time and maximize convenience. Consider factors such as distance, amenities, and transportation options when choosing your lodging. Many hotels offer special packages and discounts for Canton Fair attendees, so be sure to inquire about any available promotions when making your reservation.

- Consider Transportation Options: Familiarize yourself with transportation options available in Guangzhou, including public transit, taxis, and ridesharing services. The city boasts an extensive public transportation network, making it easy to navigate to and from the fairgrounds. Plan your transportation logistics in advance to ensure smooth travel during your stay.

- Prioritize Comfort and Convenience: Opt for accommodations that offer the amenities and facilities you need for a comfortable stay. Whether you prefer a luxury hotel, serviced apartment, or budget-friendly guesthouse, prioritize factors such as Wi-Fi access, in-room amenities, and proximity to dining and shopping options.

By arranging travel and accommodations in advance, you can streamline your experience at the Canton Fair and focus on achieving your procurement objectives. With convenient transportation and comfortable lodging secured, you'll be well-prepared to make the most of your time at the fairgrounds and maximize your business opportunities.

Navigating the Canton Fair

As you step foot into the bustling halls of the Canton Fair, navigating through the myriad of offerings can seem like a daunting task. Fear not, for we're here to guide you through the maze of opportunities with precision and finesse. Let's explore the essential steps to help you make the most of your time at the fairgrounds.

Identifying Relevant Phases and Exhibitor Locations: Planning Efficient Routes

With the Canton Fair spanning multiple phases and sprawling across vast exhibition spaces, efficient route planning is crucial. Identify the phases and exhibitor locations relevant to your procurement objectives to streamline your journey through the fairgrounds. Leverage floor plans, maps, and exhibitor directories to chart out strategic routes and optimize your time spent exploring potential suppliers and products.

Identifying relevant phases and exhibitor locations is key to navigating the expansive Canton Fair efficiently. Here's how to plan efficient routes:

- Understand the Phases: The Canton Fair is divided into multiple phases, each focusing on different product categories. Determine which phases align with your procurement objectives to prioritize your visit accordingly. Whether you're interested in machinery, electronics, or consumer goods, familiarize yourself with the schedule to plan your attendance strategically.

- Study Floor Plans and Maps: Obtain floor plans and maps of the fairgrounds to get a clear overview of the exhibition layout. Highlight the areas and halls where exhibitors relevant to your business sector are located. This will help you navigate the sprawling venue more efficiently and avoid wasting time wandering aimlessly.

- Utilize Exhibitor Directories: Take advantage of exhibitor directories provided by the Canton Fair to identify suppliers and manufacturers of interest. Narrow down your list based on product categories, company profiles, and booth numbers. Prioritize visiting exhibitors that match your sourcing needs to maximize the value of your time at the fair.

- Plan Strategic Routes: Once you've identified the phases and exhibitor locations you want to visit, plan your routes strategically. Group together exhibitors in close proximity to minimize walking distance between booths. Consider factors such as booth popularity, product relevance, and scheduled meetings when charting out your itinerary.

- Allow Flexibility: While it's essential to have a plan in place, remain flexible and open to unexpected opportunities. Leave room in your schedule for impromptu meetings, last-minute discoveries, and spontaneous networking opportunities. Be prepared to adapt your route based on real-time feedback and changing priorities during your visit.

By planning efficient routes and prioritizing relevant exhibitors, you can make the most of your time at the Canton Fair and ensure a productive sourcing experience. With careful preparation and strategic navigation, you'll maximize your opportunities for successful business partnerships and product acquisitions.

Exploring Product Displays and Demonstrations: Hands-On Evaluation

The Canton Fair is a treasure trove of innovation, with exhibitors showcasing their latest products and technologies. Take advantage of product displays and demonstrations to gain firsthand insights into the functionality, quality, and features of overhead cranes and electric hoists. Engage with exhibitors, ask questions, and request live demonstrations to assess the suitability of products for your specific requirements.

Exploring product displays and demonstrations at the Canton Fair offers a valuable opportunity for hands-on evaluation. Here's how to make the most of this experience:

- Dive into Innovation: Immerse yourself in the diverse array of products and technologies showcased by exhibitors. Explore the latest advancements in overhead cranes and electric hoists, keeping an eye out for innovative features and designs that could meet your business needs.

- Engage with Exhibitors: Approach exhibitors with curiosity and enthusiasm, expressing genuine interest in their products. Strike up conversations to learn more about their offerings, manufacturing processes, and unique selling points. Engaging with exhibitors not only provides valuable information but also helps build rapport and establish connections.

- Ask Questions: Don't hesitate to ask questions and seek clarification on any aspects of the products being showcased. Inquire about technical specifications, performance capabilities, and customization options to ensure a thorough understanding of the offerings. Exhibitors are typically eager to share insights and address inquiries from potential buyers.

- Request Live Demonstrations: Take advantage of the opportunity to witness live demonstrations of overhead cranes and electric hoists in action. Observing the functionality and performance of the products firsthand allows you to assess their suitability for your specific applications. Pay attention to factors such as speed, precision, and safety features during the demonstrations.

- Evaluate Quality and Suitability: As you explore product displays and demonstrations, focus on evaluating the quality and suitability of the offerings for your business requirements. Assess factors such as durability, reliability, and compatibility with your operational needs. Take notes and compare different products to make informed decisions.

By actively engaging with exhibitors, asking questions, and requesting live demonstrations, you can gain valuable insights and make informed decisions when evaluating overhead cranes and electric hoists at the Canton Fair. This hands-on approach allows you to assess the functionality, quality, and suitability of products, ultimately guiding your purchasing decisions effectively.

All types of ovehread cranes, gantry cranes, jib cranes for indoor workshops, warehouses, workstations , factories or other workplaces and worksites, custom electric eot cranes for sale 1 ton to 550 tons

Networking with Manufacturers and Suppliers: Building Valuable Connections

Networking lies at the heart of the Canton Fair experience, offering unparalleled opportunities to forge valuable connections with manufacturers and suppliers. Strike up conversations, exchange business cards, and build relationships with potential partners in the industry. Cultivate a spirit of collaboration and mutual respect, laying the groundwork for future business endeavors and partnerships.

Networking with manufacturers and suppliers at the Canton Fair is essential for building valuable connections and fostering mutually beneficial relationships. Here's how to make the most of your networking efforts:

- Initiate Conversations: Approach manufacturers and suppliers with a friendly and approachable demeanor. Start conversations by introducing yourself and expressing genuine interest in their products or services. Be proactive in seeking out opportunities to engage with industry professionals.

- Exchange Contact Information: Exchange business cards or contact details with manufacturers and suppliers you meet at the fair. This allows you to stay in touch and follow up after the event. Remember to collect information not only from exhibitors but also from fellow attendees who may offer valuable insights or collaboration opportunities.

- Attend Networking Events: Take advantage of networking events and social gatherings organized during the Canton Fair. These events provide excellent opportunities to meet industry peers, exchange ideas, and establish connections in a more relaxed setting. Keep an eye out for networking receptions, cocktail parties, and industry forums where you can expand your professional network.

- Cultivate Relationships: Focus on building genuine relationships based on trust, respect, and mutual benefit. Take the time to listen to manufacturers and suppliers, understand their needs and challenges, and offer support or solutions where possible. Demonstrating genuine interest and empathy can lay the foundation for long-term partnerships.

- Follow Up Promptly: After the fair, follow up with the contacts you've made to nurture relationships and explore potential collaborations. Send personalized follow-up emails or messages to express gratitude for the interaction and reiterate your interest in further discussion or collaboration. Prompt follow-up demonstrates professionalism and reinforces your commitment to building meaningful connections.

By actively networking with manufacturers and suppliers at the Canton Fair, you can expand your professional network, gain valuable industry insights, and lay the groundwork for future business opportunities. Approach networking with an open mind and a spirit of collaboration, and you'll unlock a wealth of opportunities for growth and success in your business endeavors.

Attending Seminars and Workshops on Crane Technology: Staying Informed and Educated

Stay ahead of the curve by attending seminars and workshops on crane technology offered during the Canton Fair. These sessions provide invaluable insights into the latest trends, innovations, and advancements in the field. Take notes, participate in discussions, and interact with industry experts to deepen your understanding of crane technology and stay informed about industry developments.

Attending seminars and workshops on crane technology at the Canton Fair is a strategic move to stay informed and educated about the latest advancements in the field. Here's why it's essential and how you can make the most of these sessions:

- Gain Insights: Seminars and workshops offer a platform for industry experts to share valuable insights, trends, and best practices related to crane technology. By attending these sessions, you can gain a deeper understanding of emerging technologies, market dynamics, and regulatory updates affecting the industry.

- Stay Updated: Crane technology is constantly evolving, with new innovations and solutions emerging regularly. Attending seminars allows you to stay abreast of the latest developments and trends shaping the industry landscape. Whether it's advancements in automation, safety enhancements, or sustainability initiatives, staying updated ensures you remain competitive and informed in your procurement decisions.

- Expand Knowledge: Seminars and workshops provide opportunities to expand your knowledge base and deepen your understanding of specific aspects of crane technology. Whether you're interested in crane design, operation, maintenance, or safety protocols, these sessions offer valuable insights and practical tips from industry professionals and subject matter experts.

- Network with Peers: In addition to learning from experts, seminars and workshops offer networking opportunities with peers and fellow professionals in the crane industry. Engage in discussions, share experiences, and exchange ideas with like-minded individuals who share your passion for crane technology. Networking with peers can lead to valuable connections, collaborations, and knowledge-sharing opportunities that enhance your professional growth and development.

- Ask Questions: Don't hesitate to actively participate in seminars by asking questions and seeking clarification on topics of interest. Engage with presenters and panelists to deepen your understanding, address specific challenges or concerns, and gain practical insights that you can apply to your business operations.

By attending seminars and workshops on crane technology at the Canton Fair, you can stay informed, expand your knowledge, and network with industry peers, ultimately empowering you to make more informed procurement decisions and stay ahead of the curve in the ever-evolving crane industry.

Evaluating Overhead Crane Suppliers

In the quest to procure the ideal overhead crane for your business needs, thorough evaluation of potential suppliers is paramount. Let's delve into the critical aspects to consider when assessing overhead crane suppliers at the Canton Fair.

Assessing Quality Control Measures and Certifications: Ensuring Reliability and Compliance

Quality control lies at the core of any reputable overhead crane supplier. Assess the supplier's adherence to stringent quality control measures and certifications to ensure product reliability and compliance with industry standards. Look for certifications such as ISO 9001 for quality management systems and CE certification for product compliance with European safety standards. A robust quality assurance framework underscores the supplier's commitment to delivering high-quality, dependable products.

When evaluating overhead crane suppliers at the Canton Fair, it's essential to prioritize quality control measures and certifications to ensure reliability and compliance. Here's why assessing these aspects is crucial and how you can go about it effectively:

- Reliability Assurance: Quality control measures and certifications serve as indicators of a supplier's commitment to reliability and excellence. By assessing a supplier's adherence to stringent quality standards, you can have confidence in the reliability and durability of their overhead cranes. Look for suppliers who have established robust quality management systems and demonstrate a track record of delivering reliable products that meet or exceed customer expectations.

- Compliance with Standards: Compliance with industry standards and regulations is non-negotiable when it comes to overhead crane procurement. Verify that the supplier's products are certified to meet relevant safety and performance standards, such as CE certification for European markets or ANSI/ASME standards for North America. Compliance ensures that the overhead cranes are designed, manufactured, and tested according to established guidelines, minimizing risks and ensuring safe operation in your facility.

- Certification Credentials: Certifications such as ISO 9001 accreditation for quality management systems provide further validation of a supplier's commitment to quality and customer satisfaction. ISO 9001 certification demonstrates that the supplier has implemented rigorous quality control processes and continuous improvement initiatives to enhance product quality and meet customer requirements consistently. Additionally, certifications specific to the crane industry, such as FEM (European Federation of Materials Handling) standards, validate the supplier's expertise and adherence to industry best practices.

- Inspection and Testing Protocols: Inquire about the supplier's inspection and testing protocols to ensure that each overhead crane undergoes thorough scrutiny before delivery. A reputable supplier will conduct comprehensive quality inspections, including material inspections, dimensional checks, and functional testing, to verify product integrity and performance. Request documentation of testing results and quality certificates to validate compliance with specifications and standards.

- Track Record and References: Research the supplier's reputation and track record in the industry by seeking references and customer testimonials. A supplier with a proven history of delivering high-quality overhead cranes and excellent customer service is more likely to meet your expectations and deliver a satisfactory procurement experience. Reach out to past customers to inquire about their experiences with the supplier, including product performance, reliability, and after-sales support.

By prioritizing the assessment of quality control measures and certifications when evaluating overhead crane suppliers at the Canton Fair, you can mitigate risks, ensure product reliability, and make informed procurement decisions that align with your business objectives and requirements.

Reviewing Technical Capabilities and Engineering Expertise: Evaluating Competence

An overhead crane is a complex piece of machinery that demands technical prowess and engineering expertise. Review the supplier's technical capabilities, including design proficiency, manufacturing processes, and engineering prowess. Evaluate their track record in delivering custom solutions and handling complex projects. A supplier with proven technical competence demonstrates the ability to meet your specific requirements and deliver innovative solutions tailored to your needs.

When assessing overhead crane suppliers at the Canton Fair, it's crucial to thoroughly review their technical capabilities and engineering expertise to ensure they can meet your business needs effectively. Here's why evaluating competence in these areas is essential and how you can do it:

- Design Proficiency: Start by examining the supplier's design capabilities and expertise in developing overhead crane solutions. Look for evidence of innovative design approaches, such as advanced CAD/CAM software utilization and engineering analysis tools. A supplier with strong design proficiency can tailor crane designs to your unique specifications, optimizing performance, safety, and efficiency.

- Manufacturing Processes: Assess the supplier's manufacturing processes and facilities to gauge their capacity and efficiency. Look for modern manufacturing technologies, state-of-the-art equipment, and adherence to industry best practices. A well-equipped manufacturing facility with stringent quality control measures ensures consistency, precision, and reliability in the production of overhead cranes. Inquire about production lead times and capacity to ensure timely delivery of your orders.

- Engineering Prowess: Evaluate the supplier's engineering capabilities and technical expertise in crane design, structural analysis, and mechanical systems. A competent supplier will have a team of skilled engineers and technicians capable of solving complex engineering challenges and optimizing crane performance. Look for evidence of past engineering achievements, such as successful project implementations and innovative solutions to technical problems.

- Custom Solutions: Consider the supplier's track record in delivering custom solutions and handling specialized projects. A supplier experienced in providing tailored crane solutions for unique applications demonstrates flexibility and adaptability to meet diverse customer requirements. Review case studies or examples of customized crane designs and installations to assess the supplier's ability to address specific challenges and deliver value-added solutions.

- Project Management Skills: Assess the supplier's project management capabilities, including planning, coordination, and execution. Effective project management ensures seamless communication, timely delivery, and successful implementation of overhead crane projects. Inquire about the supplier's project management processes, including milestone tracking, risk management, and customer collaboration, to ensure a smooth procurement experience from start to finish.

By thoroughly reviewing the supplier's technical capabilities and engineering expertise, you can confidently select a partner who can deliver high-quality overhead crane solutions tailored to your requirements. Prioritize suppliers with a proven track record of technical competence, innovation, and project success to ensure a successful procurement outcome.

Inquiring About Customization Options and After-Sales Support: Meeting Specific Requirements

Every business has unique requirements when it comes to overhead cranes. Inquire about the supplier's customization options and flexibility in tailoring solutions to meet your specific needs. Assess their capacity to accommodate special requests, such as custom configurations, load capacities, and operational features. Additionally, consider the supplier's after-sales support services, including installation, training, maintenance, and technical support. A reliable supplier offers comprehensive after-sales support to ensure seamless integration and optimal performance of your overhead crane.

When evaluating overhead crane suppliers at the Canton Fair, it's essential to inquire about their customization options and after-sales support services to ensure they can meet your specific requirements effectively. Here's why it's crucial and how you can assess these aspects:

- Customization Options: Start by discussing your unique requirements with the supplier and assessing their ability to customize overhead crane solutions accordingly. Inquire about their range of customization options, including custom configurations, load capacities, span lengths, and operational features. A supplier with flexible customization capabilities can tailor crane designs to fit your facility layout, operational needs, and industry-specific requirements.

- Flexibility and Adaptability: Evaluate the supplier's flexibility and willingness to accommodate special requests and unique specifications. Consider their track record in delivering customized solutions for diverse applications and industries. Look for evidence of past custom projects or case studies demonstrating their ability to meet challenging customer requirements and deliver tailored crane solutions effectively.

- After-Sales Support Services: In addition to customization options, consider the supplier's after-sales support services, which are critical for the long-term performance and reliability of your overhead crane. Inquire about their installation services, including site assessment, assembly, and commissioning, to ensure seamless integration into your facility. Ask about training programs for operators and maintenance personnel to ensure safe and efficient crane operation.

- Maintenance and Technical Support: Assess the supplier's provision of maintenance services, spare parts availability, and technical support to address any issues or concerns that may arise after installation. A reliable supplier offers prompt and responsive technical assistance, troubleshooting expertise, and on-site support to minimize downtime and maximize crane uptime. Inquire about their warranty policies, service contracts, and response times for maintenance and repair requests to ensure comprehensive after-sales support.

- Customer Satisfaction and References: Seek feedback from existing customers or request references from the supplier to validate their after-sales support capabilities and customer satisfaction levels. Contact references to inquire about their experience with the supplier's after-sales services, including responsiveness, reliability, and overall satisfaction. Positive references and testimonials from satisfied customers are indicative of a supplier's commitment to providing excellent after-sales support and customer service.

By thoroughly assessing the supplier's customization options and after-sales support services, you can ensure that they can meet your specific requirements and provide comprehensive support throughout the lifecycle of your overhead crane. Prioritize suppliers with a proven track record of flexibility, responsiveness, and customer satisfaction to secure a reliable partner for your crane procurement needs.

Negotiating Pricing, Discounts, and Terms: Securing Favorable Agreements

Negotiation is an integral part of the procurement process, allowing you to secure favorable terms and agreements with overhead crane suppliers. Enter negotiations armed with market research, competitive pricing benchmarks, and a clear understanding of your budget constraints. Seek opportunities for price discounts, volume incentives, and favorable payment terms to maximize cost savings. Maintain open communication and transparency throughout the negotiation process to foster a collaborative relationship with the supplier. Ultimately, aim to strike a win-win agreement that delivers value for both parties involved.

Negotiating pricing, discounts, and terms with overhead crane suppliers at the Canton Fair is a crucial step in securing favorable agreements that align with your budget and requirements. Here's how you can navigate the negotiation process effectively to achieve mutually beneficial outcomes:

- Market Research and Competitive Analysis: Before entering negotiations, conduct thorough market research to gather pricing data and competitive benchmarks for overhead cranes. Compare quotes from multiple suppliers and assess their pricing strategies, discounts, and terms. Armed with this information, you'll be better equipped to negotiate from a position of knowledge and leverage.

- Clear Budget Constraints: Establish clear budget constraints and cost targets for your overhead crane procurement. Determine the maximum amount you're willing to spend and identify areas where cost savings can be achieved without compromising quality or performance. Communicate your budget constraints to the supplier upfront to set realistic expectations and guide the negotiation process.

- Seek Opportunities for Discounts and Incentives: During negotiations, explore opportunities for price discounts, volume incentives, and special promotions offered by the supplier. Leverage your purchasing power and willingness to commit to larger orders to negotiate favorable pricing terms. Be prepared to negotiate on various aspects of the deal, including unit pricing, bulk discounts, delivery schedules, and payment terms.

- Flexible Payment Terms: Negotiate flexible payment terms that align with your cash flow requirements and financial preferences. Request extended payment terms, milestone payments, or installment plans to spread out the cost of the overhead crane procurement over time. Balance your need for favorable payment terms with the supplier's financial considerations to reach a mutually acceptable agreement.

- Open Communication and Transparency: Maintain open communication and transparency throughout the negotiation process to build trust and rapport with the supplier. Clearly communicate your priorities, concerns, and expectations regarding pricing, discounts, and terms. Listen actively to the supplier's feedback and be receptive to compromise where feasible. By fostering a collaborative and transparent negotiation environment, you can work together to find mutually beneficial solutions.

- Win-Win Agreements: Aim to negotiate win-win agreements that deliver value for both parties involved. Focus on creating long-term partnerships based on trust, mutual respect, and shared goals. Strive to achieve a balance between price concessions and value-added benefits to ensure that both you and the supplier benefit from the final agreement. By prioritizing fairness and cooperation, you can lay the foundation for a successful and sustainable business relationship.

In summary, negotiating pricing, discounts, and terms with overhead crane suppliers requires careful preparation, clear communication, and a collaborative approach. By leveraging market insights, setting realistic budget constraints, and seeking opportunities for value-added benefits, you can secure favorable agreements that meet your procurement objectives while strengthening your partnership with the supplier.

Visiting Manufacturing Facilities

Embarking on visits to manufacturing facilities provides invaluable insights into the capabilities, practices, and ethos of potential overhead crane suppliers. Let's delve into the essential steps to make the most of these immersive experiences.

Arranging Factory Visits with Selected Suppliers: Deepening Understanding

Coordinate with selected overhead crane suppliers to arrange factory visits, providing firsthand exposure to their manufacturing operations. Schedule these visits in advance to ensure optimal planning and coordination. Engage with suppliers to gain insights into their production processes, capabilities, and facilities. By witnessing operations firsthand, you'll gain a deeper understanding of the supplier's capabilities and commitment to quality.

Arranging factory visits with selected overhead crane suppliers is a strategic step towards gaining deeper insights into their manufacturing operations and capabilities. Here's how you can maximize the value of these visits to deepen your understanding:

- Preparation and Coordination: Reach out to the selected suppliers well in advance to schedule factory visits during your trip to the Canton Fair. Coordinate logistics such as transportation, timing, and itinerary to ensure a seamless experience. Clarify expectations and objectives for the visit with the suppliers to ensure that your time at the factory is well spent.

- Hands-On Experience: During the factory visit, immerse yourself in the production environment and observe the manufacturing processes firsthand. Take the opportunity to tour the facilities, from raw material storage to assembly lines and quality control areas. Engage with the production team and technical experts to gain insights into their workflow, equipment, and quality assurance measures.

- Assessment of Capabilities: Evaluate the supplier's technical capabilities, infrastructure, and resources to assess their capacity to meet your specific requirements. Pay attention to factors such as production capacity, machinery, technology adoption, and adherence to industry standards. Assess the level of automation, efficiency, and quality control measures in place to ensure consistent product quality and reliability.

- Quality Control and Compliance: Inquire about the supplier's quality control processes, testing procedures, and adherence to regulatory standards. Review certifications, accreditations, and compliance with international quality management systems such as ISO 900 Verify the supplier's commitment to product excellence, safety standards, and environmental sustainability practices.

- Interactive Learning: Engage in interactive discussions with the supplier's management, engineers, and production staff to gain insights into their expertise and commitment to customer satisfaction. Ask questions, seek clarification on technical aspects, and discuss customization options to tailor solutions to your specific needs. Use this opportunity to build rapport with the supplier and establish a foundation for future collaboration.

- Documentation and Follow-Up: Take notes, capture photographs, and gather relevant documentation during the factory visit for reference and documentation purposes. Follow up with the supplier after the visit to address any additional questions, requests for clarification, or further discussions on customization options. Document key takeaways and observations to inform your decision-making process during supplier evaluation and selection.

By arranging factory visits with selected suppliers, you can gain invaluable insights into their manufacturing capabilities, quality control processes, and commitment to customer satisfaction. These visits provide a unique opportunity to deepen your understanding of the supplier's operations and build trust and confidence in their ability to meet your overhead crane procurement needs.

Observing Production Processes and Quality Assurance: Ensuring Excellence

During factory visits, pay close attention to the production processes and quality assurance measures employed by the supplier. Observe manufacturing techniques, equipment utilization, and quality control protocols in action. Assess the supplier's adherence to industry best practices and standards, ensuring that their production processes uphold the highest levels of quality and reliability. Quality assurance is paramount in guaranteeing the excellence of the overhead cranes produced.

When observing production processes and quality assurance during factory visits, it's essential to focus on key aspects to ensure excellence in the overhead cranes produced. Here's how you can make the most of your observations:

- Manufacturing Techniques: Observe the manufacturing techniques employed by the supplier, including material handling, machining, welding, assembly, and finishing processes. Pay attention to efficiency, precision, and consistency in manufacturing operations. Evaluate the use of advanced technologies, automation, and modern equipment to enhance productivity and quality.

- Equipment Utilization: Assess the utilization of machinery, tools, and equipment in the production process. Look for investments in state-of-the-art equipment, such as CNC machines, robotic arms, and precision measurement tools, to optimize manufacturing efficiency and accuracy. Evaluate the condition and maintenance of equipment to ensure uninterrupted production and product consistency.

- Quality Control Protocols: Evaluate the supplier's quality control protocols and procedures implemented throughout the production cycle. Look for systematic inspection checkpoints, testing methodologies, and documentation processes to ensure compliance with quality standards and specifications. Assess the rigor of quality checks, sampling methods, and defect detection mechanisms to identify and rectify issues promptly.

- Adherence to Standards: Verify the supplier's adherence to industry standards, regulatory requirements, and customer specifications. Look for certifications such as ISO 9001 for quality management systems and product certifications for compliance with safety standards. Ensure that the supplier follows established protocols for product design, material selection, manufacturing processes, and testing to deliver products that meet or exceed expectations.

- Continuous Improvement: Inquire about the supplier's commitment to continuous improvement and quality enhancement initiatives. Look for evidence of feedback mechanisms, process optimization efforts, and corrective actions taken to address quality issues and drive continuous improvement. Evaluate the supplier's willingness to incorporate customer feedback and implement best practices to enhance product quality and customer satisfaction.

- Employee Training and Engagement: Assess the competence and engagement of the workforce involved in production and quality assurance. Look for evidence of employee training programs, skill development initiatives, and empowerment strategies to ensure a culture of quality consciousness and accountability. Engage with production staff and quality control personnel to understand their roles, responsibilities, and commitment to product excellence.

By closely observing production processes and quality assurance measures during factory visits, you can gain valuable insights into the supplier's commitment to excellence and quality. Use these observations to assess the supplier's capabilities, reliability, and suitability as a partner for procuring overhead cranes that meet your specific requirements and quality standards.

Interacting with Workforce and Technical Teams: Building Relationships

Engage with the workforce and technical teams responsible for manufacturing overhead cranes. Interact with engineers, technicians, and production staff to gain insights into their expertise, dedication, and commitment to excellence. Foster relationships with key personnel, establishing rapport and trust with the individuals responsible for delivering your overhead crane solutions. Building strong relationships paves the way for seamless collaboration and communication throughout the procurement process.

When interacting with the workforce and technical teams during factory visits, take proactive steps to build meaningful relationships and gain valuable insights into the manufacturing process of overhead cranes. Here's how you can effectively engage with engineers, technicians, and production staff:

- Engage in Open Dialogue: Initiate conversations with engineers, technicians, and production staff to understand their roles, experiences, and contributions to the manufacturing process. Ask questions about their areas of expertise, challenges faced, and innovative solutions implemented. Show genuine interest in their work and accomplishments to foster open dialogue and collaboration.

- Seek Technical Insights: Tap into the knowledge and expertise of technical teams to gain insights into the design, engineering, and manufacturing aspects of overhead cranes. Discuss technical specifications, design considerations, and customization options to align the product with your specific requirements. Leverage their expertise to address technical queries, explore innovative solutions, and optimize crane performance.

- Observe Work Practices: Take the opportunity to observe work practices and operational procedures followed by the workforce on the factory floor. Pay attention to safety protocols, ergonomic practices, and efficiency measures implemented to enhance productivity and minimize risks. Engage with production staff to understand their adherence to quality standards, adherence to schedules, and commitment to continuous improvement.

- Acknowledge Contributions: Recognize the efforts and contributions of the workforce in delivering high-quality overhead cranes. Express appreciation for their dedication, craftsmanship, and attention to detail in manufacturing products that meet or exceed customer expectations. Acknowledge individual achievements and team accomplishments to motivate and inspire the workforce to maintain excellence.

- Build Rapport and Trust: Establish rapport and trust with key personnel by demonstrating respect, integrity, and professionalism in your interactions. Listen attentively to their perspectives, concerns, and suggestions, acknowledging their expertise and insights. Show empathy and understanding towards their challenges and constraints, fostering a collaborative and supportive environment conducive to productive partnerships.

- Follow-Up and Stay Connected: Maintain communication and follow-up with key personnel after the factory visit to nurture relationships and keep the lines of communication open. Send thank-you notes, share feedback, and express interest in future collaborations to demonstrate your commitment to building long-term partnerships. Stay connected through email, phone calls, or periodic visits to sustain rapport and collaboration beyond the factory visit.

By actively engaging with the workforce and technical teams during factory visits, you can build meaningful relationships, gain valuable insights, and foster collaboration with the individuals responsible for manufacturing overhead cranes. Use these interactions to strengthen partnerships, enhance communication, and drive continuous improvement in product quality and performance.

Verifying Environmental Practices and Sustainability Initiatives: Emphasizing Responsibility

Environmental responsibility and sustainability are increasingly important considerations in supplier selection. Take this opportunity to verify the supplier's environmental practices and sustainability initiatives. Inquire about their efforts to minimize environmental impact, reduce energy consumption, and adopt eco-friendly manufacturing practices. Assess certifications, such as ISO 14001 for environmental management systems, to ensure alignment with your sustainability goals. By partnering with environmentally conscious suppliers, you demonstrate your commitment to responsible sourcing and environmental stewardship.

Verifying the environmental practices and sustainability initiatives of potential overhead crane suppliers is a crucial step in responsible procurement. Here's how you can emphasize environmental responsibility during factory visits:

- Inquire About Environmental Policies: Start by discussing the supplier's environmental policies and practices. Inquire about their commitment to sustainability, waste reduction, and pollution prevention. Ask specific questions about their efforts to conserve resources, minimize waste generation, and mitigate environmental impacts throughout the production process.

- Assess Environmental Certifications: Evaluate the supplier's adherence to environmental standards and certifications, such as ISO 14001 for environmental management systems. Verify the validity of certifications and assess the extent to which they reflect the supplier's dedication to environmental stewardship. Look for evidence of compliance with regulatory requirements and industry best practices in environmental management.

- Tour Eco-Friendly Facilities: During factory visits, observe firsthand the supplier's facilities and operations with a focus on environmental sustainability. Look for initiatives such as energy-efficient lighting, recycling programs, and waste management systems. Assess the use of renewable energy sources, water conservation measures, and green building practices to gauge the supplier's commitment to sustainability.

- Discuss Sustainable Materials and Processes: Engage in discussions about the use of sustainable materials and processes in overhead crane manufacturing. Inquire about efforts to source environmentally friendly materials, reduce emissions, and optimize resource utilization. Explore opportunities for eco-friendly design features, recyclable components, and energy-efficient technologies in crane production.

- Evaluate Supply Chain Practices: Consider the environmental impact of the supplier's supply chain practices, including transportation, raw material sourcing, and subcontracting. Assess their efforts to minimize carbon emissions, promote ethical sourcing, and support sustainable procurement practices throughout the supply chain. Seek transparency and accountability in supplier relationships to ensure alignment with your sustainability objectives.

- Encourage Continuous Improvement: Encourage suppliers to continually improve their environmental performance and sustainability initiatives. Collaborate on identifying opportunities for innovation, efficiency gains, and environmental impact reduction. Emphasize the importance of ongoing dialogue, collaboration, and shared responsibility in advancing environmental sustainability goals.

- Commit to Responsible Sourcing: By partnering with suppliers that prioritize environmental responsibility and sustainability, you demonstrate your commitment to responsible sourcing practices. Support suppliers that align with your values and sustainability objectives, contributing to positive environmental outcomes and fostering a culture of sustainability throughout your supply chain.

By emphasizing environmental responsibility and sustainability during factory visits, you can ensure that your overhead crane procurement aligns with your environmental values and contributes to sustainable business practices. Collaborate with suppliers that share your commitment to environmental stewardship, driving positive change and promoting a greener future for the industry.

Making Informed Purchasing Decisions

Now that you've thoroughly evaluated potential overhead crane suppliers and visited manufacturing facilities, it's time to make informed purchasing decisions. Let's explore the crucial steps involved in this process.

Reviewing Proposals, Contracts, and Warranty Policies: Ensuring Clarity and Protection

Carefully review the proposals, contracts, and warranty policies provided by shortlisted overhead crane suppliers in China . Pay close attention to terms and conditions, pricing details, delivery schedules, and warranty coverage. Seek clarity on all aspects of the agreement to avoid misunderstandings or disputes down the line. Ensure that warranty policies provide adequate protection and coverage for your investment, safeguarding against potential issues or defects.

When reviewing proposals, contracts, and warranty policies from overhead crane suppliers in China, thoroughness is key to ensuring clarity and protection for your procurement process. Here's a detailed approach to this essential step:

- Examine Terms and Conditions: Begin by carefully examining the terms and conditions outlined in the proposals and contracts. Pay close attention to details such as payment terms, delivery schedules, and liability clauses. Ensure that all terms are clearly defined and agreeable to both parties involved.

- Evaluate Pricing Details: Scrutinize the pricing details provided in the proposals and contracts. Verify that the pricing structure is transparent and comprehensive, including costs for equipment, shipping, and any additional services or fees. Compare pricing across different suppliers to ensure competitiveness and value for money.

- Clarify Delivery Schedules: Seek clarification on delivery schedules and lead times outlined in the proposals and contracts. Ensure that delivery timelines align with your project requirements and deadlines. Discuss contingencies for potential delays and establish clear communication channels for updates on delivery progress.

- Review Warranty Coverage: Thoroughly review the warranty policies offered by overhead crane suppliers. Assess the scope of warranty coverage, including parts replacement, repair services, and duration of coverage. Verify any limitations or exclusions that may apply and seek clarification on warranty claim procedures.

- Seek Legal Advice if Necessary: If you encounter complex contractual terms or legal language that requires further interpretation, consider seeking legal advice from a qualified professional familiar with international trade and contract law. Legal guidance can help ensure that you fully understand your rights and obligations under the proposed agreements.

- Negotiate Favorable Terms: Use the review process as an opportunity to negotiate favorable terms with overhead crane suppliers. Discuss areas where you seek modifications or improvements to better align with your needs and preferences. Aim for mutually beneficial outcomes that balance your requirements with the supplier's capabilities and interests.

- Document Agreements in Writing: Once all terms have been clarified and agreed upon, document the agreements in writing through formal contracts or purchase orders. Ensure that all parties involved sign and acknowledge the terms outlined in the contracts to formalize the procurement arrangements.

- Maintain Open Communication: Throughout the review and negotiation process, maintain open communication with overhead crane suppliers. Address any questions or concerns promptly and seek clarification on any ambiguous or unclear terms. Clear communication fosters transparency and trust, laying the foundation for a successful partnership.

By diligently reviewing proposals, contracts, and warranty policies, you can ensure clarity, protection, and peace of mind as you proceed with your overhead crane procurement from suppliers in China.

Conducting Due Diligence on Shortlisted Suppliers: Confirming Suitability

Before finalizing your decision, conduct thorough due diligence on shortlisted overhead crane suppliers. Verify their credentials, reputation, and track record in the industry. Research their financial stability, customer reviews, and any past performance indicators. Confirm that the supplier possesses the requisite expertise, resources, and capabilities to meet your requirements effectively. Due diligence is crucial in confirming the suitability and reliability of your chosen supplier.

When it comes to selecting the right overhead crane supplier for your business needs, conducting due diligence on shortlisted candidates is essential to confirm their suitability and reliability. Here's how you can conduct thorough due diligence:

- Verify Credentials and Reputation: Start by verifying the credentials and reputation of each shortlisted overhead crane supplier. Check for industry certifications, affiliations, and awards that demonstrate their commitment to quality and professionalism. Look for testimonials and references from past clients to gauge their reputation and track record.

- Assess Financial Stability: Assess the financial stability of each supplier to ensure they are capable of fulfilling their contractual obligations. Review financial statements, credit reports, and other relevant financial indicators to evaluate their liquidity, solvency, and overall financial health. A financially stable supplier is more likely to deliver consistent quality and service over the long term.

- Research Customer Reviews: Research customer reviews and feedback about each supplier to gain insights into their performance and reliability. Online platforms, industry forums, and social media channels can provide valuable feedback from previous customers regarding their experiences with the supplier's products and services. Pay attention to recurring themes and patterns in the reviews to identify strengths and potential areas for improvement.

- Evaluate Track Record and Experience: Evaluate each supplier's track record and experience in the industry. Consider factors such as the number of years in business, successful projects completed, and expertise in handling similar projects or clients. A supplier with a proven track record and relevant experience is better equipped to understand and meet your specific requirements effectively.

- Assess Resources and Capabilities: Assess the resources and capabilities of each supplier to ensure they have the necessary infrastructure, facilities, and personnel to support your project requirements. Evaluate their production capacity, technological capabilities, and access to raw materials to gauge their ability to fulfill large orders or customized solutions. A supplier with robust resources and capabilities can offer greater flexibility and reliability in meeting your needs.

- Request Site Visits or Audits: Consider requesting site visits or audits of the supplier's facilities to assess their operations firsthand. This allows you to observe their production processes, quality control measures, and overall working environment. Engage with key personnel, including management and technical staff, to gain deeper insights into their operations and capabilities.

- Seek Clarification on Key Issues: During the due diligence process, don't hesitate to seek clarification on any key issues or concerns that arise. Engage in open and transparent communication with the supplier to address any questions regarding their capabilities, processes, or policies. Clear communication fosters trust and transparency, helping to build a strong foundation for a successful partnership.

- Compare Options and Make Informed Decisions: After completing due diligence on all shortlisted suppliers, compare your findings and weigh the pros and cons of each option. Consider factors such as reputation, experience, capabilities, and overall fit with your requirements. Use this information to make an informed decision on the supplier that best aligns with your needs and priorities.

By conducting thorough due diligence on shortlisted overhead crane suppliers, you can confirm their suitability, reliability, and ability to meet your requirements effectively. This ensures a successful partnership and contributes to the overall success of your procurement process.

Seeking Client References and Testimonials: Validating Reputation

Request client references and testimonials from the overhead crane supplier to validate their reputation and performance. Reach out to past or existing clients to inquire about their experiences and satisfaction with the supplier's products and services. Listen to firsthand accounts and testimonials to gauge the supplier's reliability, responsiveness, and commitment to customer satisfaction. Client references offer valuable insights into the supplier's reputation and credibility.

Before finalizing your decision on an overhead crane supplier, it's essential to conduct thorough due diligence to confirm their suitability and reliability. Here's how you can dive deeper into this critical step:

- Verify Credentials and Reputation: Begin by verifying the credentials and reputation of the shortlisted suppliers. Look into their industry certifications, years of experience, and any awards or accolades they've received. Research their reputation within the industry and check for any past legal or ethical issues that may raise concerns.

- Assess Financial Stability: Assess the financial stability of the suppliers to ensure they have the resources to fulfill your orders and provide ongoing support. Review their financial statements, creditworthiness, and any indications of financial distress or instability. A financially stable supplier is more likely to deliver consistent quality and service over the long term.

- Review Customer Reviews and Feedback: Dive into customer reviews and feedback to gain insights into the supplier's performance and customer satisfaction levels. Explore online review platforms, industry forums, and social media channels to see what past customers have to say about their experiences with the supplier. Look for patterns in feedback and pay attention to how the supplier responds to customer concerns or complaints.

- Request Client References: Request client references from the overhead crane supplier to directly speak with past or existing clients. Reach out to these references to inquire about their experiences working with the supplier. Ask specific questions about product quality, delivery timelines, communication, and overall satisfaction to get a comprehensive understanding of the supplier's performance.

- Evaluate Testimonials and Case Studies: Review testimonials and case studies provided by the supplier to further validate their reputation and capabilities. Look for real-world examples of successful projects or satisfied clients that demonstrate the supplier's ability to deliver on their promises. Pay attention to details such as project scope, challenges overcome, and outcomes achieved.

- Consider Industry Reputation and Partnerships: Consider the supplier's standing within the industry and any partnerships or affiliations they have with reputable organizations or associations. Suppliers with strong industry connections and a positive reputation among peers are more likely to uphold high standards of quality and professionalism.

- Seek Transparency and Open Communication: During the due diligence process, prioritize suppliers who demonstrate transparency and open communication. Look for suppliers who are willing to provide detailed information, address your concerns openly, and collaborate closely to meet your requirements. Transparent communication fosters trust and ensures a positive working relationship moving forward.

By conducting comprehensive due diligence on shortlisted suppliers and seeking client references and testimonials, you can validate their reputation and performance, ultimately making an informed decision that aligns with your business needs and objectives.

Finalizing Orders and Payment Arrangements: Securing Commitments

Once satisfied with your due diligence and negotiations, finalize orders with the selected overhead crane supplier. Confirm product specifications, quantities, and delivery timelines to ensure alignment with your requirements. Establish clear payment arrangements, including payment terms, methods, and milestones. Secure written confirmation of the agreed-upon terms and commitments from the supplier to formalize the arrangement. By finalizing orders and payment arrangements, you solidify your partnership and move one step closer to acquiring your desired overhead crane solution.

After conducting thorough due diligence and negotiations, it's time to solidify your partnership with the selected overhead crane supplier by finalizing orders and payment arrangements. Here's how to ensure a smooth and secure process:

- Confirm Product Specifications and Quantities: Review and confirm all product specifications, including features, dimensions, and capacities, to ensure they meet your requirements. Double-check quantities to avoid any discrepancies or misunderstandings.

- Establish Delivery Timelines: Clarify delivery timelines with the supplier to ensure timely receipt of your overhead cranes. Agree on specific delivery dates or timelines for each order, taking into account factors such as manufacturing lead times and shipping logistics.

- Define Payment Terms and Methods: Establish clear payment terms and methods to facilitate smooth transactions. Discuss payment schedules, milestones, and any applicable discounts or incentives. Determine whether payments will be made upfront, in installments, or upon delivery, and choose the most suitable payment method for both parties.

- Secure Written Confirmation: Obtain written confirmation of the agreed-upon terms and commitments from the supplier. This may include a formal purchase order or contract outlining product specifications, pricing, delivery terms, and payment conditions. Ensure that both parties sign the document to formalize the arrangement and mitigate any potential disputes.

- Monitor Order Progress: Stay in regular communication with the supplier to monitor the progress of your orders. Keep track of key milestones, such as production start dates, shipping notifications, and delivery dates, to ensure everything stays on schedule. Address any delays or issues promptly to avoid disruptions to your operations.

- Prepare for Receipt and Inspection: Prepare your facility for the receipt and inspection of the overhead cranes upon delivery. Ensure that you have adequate space, equipment, and personnel to handle the installation and commissioning process. Conduct thorough inspections to verify that the delivered products meet your specifications and quality standards.

By finalizing orders and payment arrangements with the overhead crane supplier, you secure commitments and pave the way for a successful partnership. Clear communication, written agreements, and diligent monitoring ensure that both parties uphold their obligations, ultimately leading to the acquisition of your desired overhead crane solution.

Post-Fair Follow-Up and Logistics

As the Canton Fair draws to a close, it's time to shift focus towards post-fair activities and logistics. Let's delve into the essential steps to ensure a smooth transition from procurement to implementation.

Continuing Negotiations and Finalizing Deals: Cementing Partnerships

Following the fair, continue negotiations with overhead crane suppliers to finalize deals and cement partnerships. Address any outstanding issues or concerns and strive to reach mutually beneficial agreements. Ensure clarity on all aspects of the deal, including pricing, terms, and delivery schedules. By nurturing ongoing negotiations, you strengthen partnerships and lay the foundation for successful collaboration moving forward.

After the conclusion of the Canton Fair, the journey towards acquiring overhead cranes continues through ongoing negotiations and finalizing deals with suppliers. Here's how to effectively cement partnerships and secure favorable agreements:

- Address Outstanding Issues: Review any unresolved issues or concerns that arose during initial negotiations or discussions at the fair. Addressing these matters promptly demonstrates your commitment to finding mutually satisfactory solutions and paves the way for smoother deal finalization.

- Strive for Mutual Benefit: During negotiations, prioritize achieving outcomes that benefit both parties involved. Seek to find common ground and compromises that align with the interests and objectives of both your business and the overhead crane supplier. By fostering a spirit of collaboration and fairness, you lay the groundwork for a strong and enduring partnership.

- Ensure Clarity on Terms: Clarify all aspects of the deal to avoid misunderstandings or discrepancies. Discuss pricing, payment terms, delivery schedules, and any additional terms or conditions relevant to the agreement. Achieving clarity and consensus on these details is essential for establishing a solid foundation for the partnership.

- Maintain Open Communication: Maintain open lines of communication with the overhead crane suppliers throughout the negotiation process. Promptly address any questions, concerns, or requests for clarification to keep the dialogue transparent and constructive. Effective communication fosters trust and facilitates smoother negotiations.

- Commit to Timely Follow-Up: Commit to timely follow-up on any outstanding matters or requests for information. Respond promptly to communications from the supplier and provide the necessary feedback or input to keep negotiations moving forward. Proactive engagement demonstrates your dedication to reaching a swift and successful resolution.

- Formalize Agreements: Once negotiations are complete and terms are agreed upon, formalize the agreements in writing. Prepare contracts or purchase orders that clearly outline the terms and conditions of the deal, including pricing, quantities, delivery timelines, and any applicable warranties or guarantees. Both parties should review and sign the documents to formalize their commitment to the partnership.