LHB Double Girder Explosion-Proof Crane with BCD Exproof Hoist

Safe & reliable explosion-proof cranes 5 to 40 tons, equipped with BCD hoist for hazardous industrial lifting environments.Get your explosion proof crane!

Category: Explosion Proof Cranes

Your Trusted Explosion Proof Overhead Crane Manufacturer & Supplier

LHB Double Girder Explosion-Proof Cranes 5 Ton 40 Ton with BCD Explosion-Proof Hoist Trolley

LHB double girder explosion-proof overhead cranes are engineered for lifting operations in hazardous environments where flammable gases, vapors, or combustible dust are present. These cranes combine a robust double girder structure with a BCD-type explosion-proof hoist trolley, delivering safe and efficient material handling in Zone 1 and Zone 2 hazardous areas.

With rated capacities ranging from 5 tons to 40 tons and spans between 7.5 meters and 31.5 meters, these cranes offer dependable performance across industries such as oil refining, chemical production, gas processing, and dust-prone manufacturing facilities.

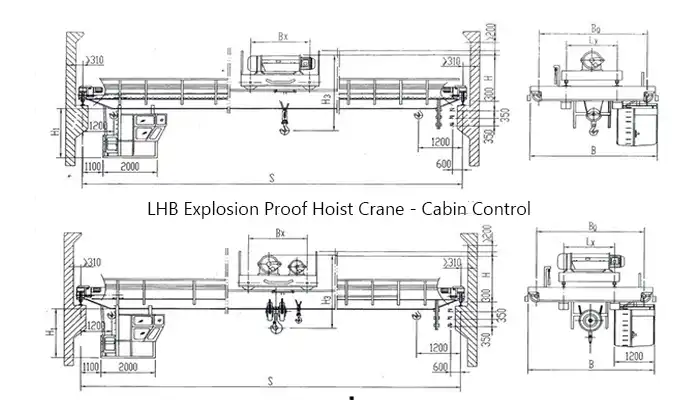

LHB Explosion Proof Electric Hoist Cranes

Drawing of LHB Explosion Proof Electric Hoist Cranes

Key Features

- Explosion-proof rating compliant with ExdIIBT4 or ExdIICT4 standards

- Lifting capacity: 5t to 40t

- Span range: 7.5m to 31.5m

- Working class: A3 / A4 (optional A5)

- Power supply: 3-phase, 380V, 50Hz (customizable upon request)

- Operation: Ground pendant control, remote control, or cabin control

- Travel and hoisting mechanisms feature single-speed or dual-speed configurations

- Flameproof electrical components for safe operation in explosive atmospheres

Technical Parameters Overview

| Item | Specification Range |

|---|---|

| Rated Capacity | 5t – 40 Ton |

| Lifting Height | 6m – 30m (customizable) |

| Hoisting Speed | 0.35/3.5 m/min, 0.7/7 m/min, etc. |

| Trolley Travel Speed | Up to 20 m/min |

| Crane Travel Speed | Up to 20 m/min |

| Working Duty | A3 / A4 |

| Power Supply | 3P, 380V, 50Hz (other voltages on request) |

| Control Method | Pendant, remote, or cabin operation |

| Explosion Protection | ExdIIBT4 or ExdIICT4 |

Explosion-Proof Design of Economical Explosion Proof Hoist Crane Double Girder

Safety in hazardous environments starts with the right design. Every part of the crane is built to reduce the risk of sparks and keep operations safe.

- Flameproof Electrical Components

All motors, control panels, junction boxes, and wiring are sealed in explosion-proof housings.

These enclosures are built to contain any sparks or arcs, so they won't ignite gases or vapors around them. - Non-Sparking Materials Where It Matters

Parts like wheels, cable rollers, and bumpers are made of copper or other non-sparking materials.

This helps prevent ignition from friction or impact during movement. - Stainless Steel Wire Ropes for Higher Gas Groups

For areas with IIC-class gas hazards, the crane can be equipped with stainless steel wire ropes.

These are more resistant to wear and won't create sparks, even under stress. - Built to Chinese Explosion-Proof Standards

The whole system is designed according to GB3836.1 and GB3836.2.

These standards are widely accepted for explosion protection in industrial applications.

This design ensures the crane performs safely and reliably—even in risky working environments with gas, dust, or chemical exposure.

Detailed Parameters of LHB Explosion Proof Electric Hoist Cranes

| Lifting Capacity | t | 20/5 | ||||||||

| Span | m | 7.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 |

| Lifting Height | 9 12 | |||||||||

| Working system | A3 | |||||||||

| Explosion-proof grade | ExdⅡBT4;ExdⅡCT4 | |||||||||

| Operaional method | Ground controlling | |||||||||

| Main hook speed | m/min | 3.5(0.35/3.5) | ||||||||

| Aux hook speed | 8(0.8/8) | |||||||||

| Crab travelling speed | 20 | |||||||||

| Crane travelling speed | 20 | |||||||||

| Electric hoist | HB | |||||||||

| Max wheel load | KN | 60.8 | 62 | 67 | 70 | 75 | 79 | 83 | 87 | 92 |

| Total power | KW | 26.5 | 26.7 | |||||||

| Crane weight | kg | 6695~23720 | ||||||||

| Power supply | 3ph AC 380v 50hz | |||||||||

| Lifting Capacity | t | 32/5 | |||||||

| Span | m | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 | 28.5 | 31.5 |

| Lifting Height | 9 12 | ||||||||

| Working system | A3 | ||||||||

| Explosion-proof grade | ExdⅡBT4;ExdⅡCT4 | ||||||||

| Operaional method | Ground controlling | ||||||||

| Main hook speed | m/min | 3(0.3/3) | |||||||

| Aux hook speed | 8(0.8/8) | ||||||||

| Crab travelling speed | 20 | ||||||||

| Crane travelling speed | 20 | ||||||||

| Electric hoist | HB | ||||||||

| Max wheel load | KN | 91 | 98 | 103 | 107 | 112 | 116 | 120 | 125 |

| Total power | KW | 36.4 | 38 | ||||||

| Crane weight | kg | 9987~28047 | |||||||

| Power supply | 3ph AC 380v 50hz | ||||||||

Custom Design Options of LHB Double Girder Explosion Proof Overhead Crane

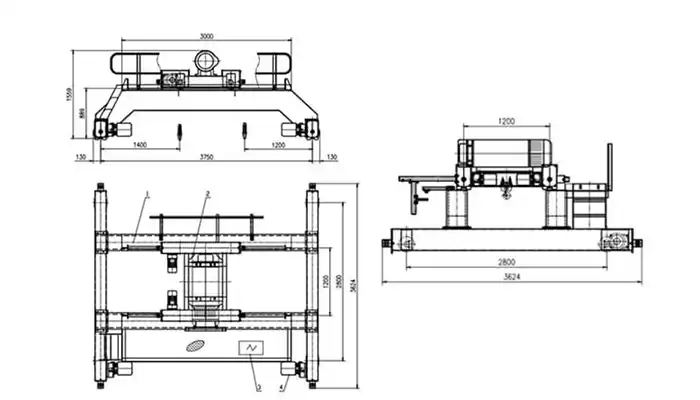

BCD Explosion-Proof Hoist Trolley

The hoist trolley is the heart of the lifting system. For explosive environments, every detail matters. That's why this trolley is designed with both safety and performance in mind.

BCD Explosion-Proof Hoist Trolley

- Equipped with flameproof motors and enclosures

- Constructed using anti-sparking materials for enhanced safety

- Available in single-speed or double-speed hoisting options

- Designed for smooth travel and reliable lifting performance

- Flameproof Motors and Enclosures

The hoist uses explosion-proof motors that are sealed to prevent sparks.

All electrical parts are housed in flameproof enclosures to avoid any fire risk.

These motors are built to last and stay cool even during long use. - Safe, Anti-Sparking Materials

The trolley frame and moving parts are made of non-sparking materials, like copper alloys or stainless steel.

This reduces the chance of friction sparks while the trolley moves or lifts.

Great for areas with gas, vapor, or dust hazards. - Flexible Speed Options

You can choose between single-speed or double-speed hoisting.

Single-speed is simple and reliable.

Double-speed gives you more control—slow for precise lifting, fast for daily tasks. - Stable Movement and Performance

The trolley is engineered to travel smoothly along the crane girders.

Even under load, it stays stable and easy to control.

It's tested for consistent lifting without sudden jerks or delays.

This explosion-proof trolley is not one-size-fits-all. It can be adjusted to suit your specific lifting height, speed, and usage needs

Double Girder Explosion Proof Overhead Crane with Main and Auxiliary Hoists

For jobs that require more than just simple lifting, a dual-hoist setup can make a real difference. This configuration adds flexibility and control to your crane system.

- Dual hoist configuration available for enhanced functionality

- Main hoist handles heavy loads; auxiliary hoist supports precision tasks or lighter lifting

- Independent controls enable flexible and efficient operation

- Ideal for processes requiring multi-stage or delicate lifting operations

- Dual Hoist Setup

The crane can be fitted with both a main hoist and an auxiliary hoist.

This setup is useful when lifting operations involve more than one task.

It helps you switch between heavy and light loads easily. - Different Roles, Same Crane

The main hoist is built for handling the heavier loads.

The auxiliary hoist is used for lighter tasks or when precision is needed.

It's a good fit for positioning components, feeding materials, or slow lifts. - Independent Operation

Each hoist works with its own control system.

This means you can operate them one at a time or in combination.

It adds flexibility and saves time during complex operations. - For Complex or Delicate Lifting

This dual-hoist setup is ideal for industries that require multi-step lifting.

It's especially helpful in tasks like loading sensitive equipment or placing parts in exact locations.

Whether your job involves heavy-duty lifting or more careful handling, this combination hoist setup helps you do both—without changing equipment.

Dual Explosion Proof Wire Rope Hoist Trolley Configuration for the Explosion Proof Overhead Cranes

When lifting gets more complex, having two trolleys on one bridge can really help. This setup gives more control and options in tight or demanding workspaces.

- Two independent hoist trolleys mounted on the same bridge

- Enables simultaneous or separate operation for handling wide or multiple loads

- Suitable for facilities requiring parallel or complex lifting tasks

- Supports a combination of different hoist types and speeds if required

- Two Trolleys, One Crane

The crane can be equipped with two separate hoist trolleys, each running independently on the same bridge beam.

This allows you to lift from two different points at the same time—or operate one while the other stands by. - More Flexible Lifting

You can use the trolleys together or separately, depending on the task.

For example, lift a long, wide load using both hoists, or run two jobs in the same bay without moving the crane again. - Perfect for Complex Operations

This setup is great for workshops or plants where parallel handling is common—like in equipment assembly, mold flipping, or pipe installation.

It saves time and reduces the need for extra lifting gear or repositioning. - Custom Combinations Possible

Each trolley can have different lifting capacities, speeds, or hoist types, if needed.

One can be optimized for heavy, single-speed lifting, while the other handles lighter or more delicate jobs with dual-speed or frequency conversion.

If your operations require precision, space efficiency, or multi-point lifting, the dual trolley configuration is a smart and reliable choice.

Application Areas

Explosion-proof overhead cranes are not for general use. They're built for tough, risky environments where safety is everything. These cranes are often used in areas where flammable gases, vapors, or dust are present in the air.

Here are some of the common places where they're put to work:

- Oil and Gas Refineries

For moving equipment or materials near flammable liquids and gases. - Petrochemical Processing Plants

Used in production zones where chemical reactions generate hazardous atmospheres. - Chemical Storage and Handling Facilities

Ideal for safely lifting drums, tanks, and materials in chemical warehouses. - Paint and Coating Manufacturing

Helps transport solvents and coating products without the risk of ignition. - Gas Cylinder Workshops

For handling filled or empty gas cylinders under strict safety requirements. - Cement and Flour Mills

In dry and dusty areas where airborne particles could ignite. - Hazardous Material Warehouses

Supports daily lifting tasks while keeping explosion risks under control.

If your facility handles flammable or dusty materials, these cranes are built to make lifting safer and more reliable.

Project Highlight: Customized LHB Explosion-Proof Cranes Supplied to Yemen

We successfully supplied four sets of LHB series double girder explosion-proof hoist cranes to a customer in Yemen, operating in a hazardous industrial environment with flammable gases present.

5 ton explosion proof crane with economical BCD explosion proof wire rope hoist

Drawing of 5 ton overhead bridge crane with BCD explosion proof electric hoist

Supplied Equipment:

- 2 units of 5-ton LHB explosion-proof cranes with 3.75m span

- 2 units of 5-ton LHB explosion-proof cranes with 5.75m span

All cranes were equipped with traditional wire rope hoist trolleys and built to meet Exd II BT4 / CT4 explosion-proof standards. The compact spans were specifically engineered to fit within the customer's restricted workspace while ensuring safe and effective load handling.

Designed for challenging working conditions, these cranes now contribute to safe, stable, and efficient operations at the client's facility in Yemen.

Looking for a tailored explosion-proof lifting solution? We're ready to design and deliver to your exact site requirements.

Customization and Quotation

Every working site is different. That's why our explosion-proof cranes can be tailored to fit your exact needs. Whether you need a simple setup or a complex double trolley system, we work closely with you to design a solution that's safe, efficient, and reliable.

To help us prepare a detailed and accurate quote, please share the following information:

- Lifting capacity and lifting height

Tell us how much weight you need to lift and how high it needs to go. - Span and runway length

Provide the distance the crane needs to cover on your runway beams. - Site classification

Let us know if your environment is Zone 1 or Zone 2, and the specific gas group involved (for example, Group IIB or IIC). - Hoist configuration

Specify if you want a single hoist, dual hoist, or double trolley setup, depending on your lifting tasks. - Control and power supply preferences

Tell us how you want to operate the crane — ground pendant, remote control, or cabin control — and your local power supply details.

Once we have this info, our technical team will design a crane solution customized for your site. The design will meet strict explosion-proof safety standards and be optimized to boost your productivity. We'll provide a clear, transparent quotation so you know exactly what you're getting.

Feel free to reach out with any questions — we're here to help make your crane purchase smooth and tailored to your needs. Click to learn more types of explosion proof single girder overhead crane and explosion proof double girder overhead crane, or contact us by leaving a message down below.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch