Overhead Cranes for Construction Materials Handling 5 T, 10 T, 20 T +

Overhead cranes & construction material handling guide for handling construction materials using types of overhead cranes, from concrete to steel and more.

Category: Construction

Your Trusted Overhead Crane Manufacturer & Supplier

Overhead Cranes for Construction Materials Handling 5 Ton, 10 Ton, 20 Ton +

Overhead cranes & construction material handling guide for handling construction materials using types of overhead cranes, from concrete to steel and more.

Building Foundations: Overhead Crane Usage in Construction Material Handling

In the realm of construction, efficiency is key, and that begins with material handling. It's the foundational pillar upon which successful projects are built. In this guide, we delve into a crucial aspect of this process: the specialized role of overhead cranes in construction material handling. As we explore various construction materials and their unique handling requirements, we'll discover how advanced crane solutions for construction industry provide the precision, safety, and efficiency that construction projects demand.

Types of overhead cranes used in different construction material handling

Overhead cranes used for construction material handling in various construction sites can vary based on the type of material, the construction site's specific requirements, and the scale of the project. Here are some common types of overhead cranes used in different construction sites for handling construction materials:

The main types of overhead cranes used for different construction materials handling at various construction sites:

Bridge Cranes (Overhead Bridge Cranes):

Construction Site: Building construction, industrial construction, infrastructure projects.

Materials Handling: Steel beams, concrete components, roofing materials, HVAC units, precast elements.

Description: Bridge cranes are versatile and can be configured with single or double girders. They are often used for lifting and positioning heavy materials in large construction sites.

Typical Configuration: Single or double girder bridge crane with a hoist.

Typical Capacity: Varies based on the project, typically ranging from 1 ton to 20+ tons.

Customized Features: Various hoist options, remote controls, and safety features can be customized to suit specific project requirements.

Construction Site: Ports, shipyards, bridge construction, outdoor construction sites.

Materials Handling: Construction materials, bags, pipes, and stone, sands, etc.

Description: Portable gantry cranes can be used on light loads handling

Typical Configuration Portable: gantry cranes with adjustable height and width, mounted on wheels or tracks.

Typical Capacity: Ranges from 1 ton to over 10 tons, depending on the size and configuration.

Customized Features: Adjustable height and span, different wheel options for varied terrains, and specialized attachments.

Construction Site: Ports, shipyards, bridge construction, outdoor construction sites.

Materials Handling: Large structural components, equipment, containers, heavy machinery.

Description: Gantry Goliath cranes have legs that move on wheels or tracks, providing mobility and the ability to handle heavy loads in open spaces.

Typical Configuration: Goliath Gantry cranes can be customized single girder , double girder and semi gantry crane design.

Typical Capacity: Ranges from 1 ton to over 100 tons, depending on the size and configuration.

Customized Features: Adjustable height and span, different wheel options for varied terrains, and specialized attachments.

Jib Cranes (Wall-Mounted or Freestanding):

Construction Site: Small workshops, masonry yards, renovation projects.

Materials Handling: Bricks, blocks, tools, small equipment, building materials.

Description: Jib cranes have a vertical mast and a horizontal boom. They are ideal for localized lifting and materials handling in smaller construction settings.

Typical Configuration: Wall-mounted or freestanding jib crane with a hoist.

Typical Capacity: Typically up to 5 tons, though smaller jib cranes can have lower capacities.

Customized Features: Different boom lengths and rotations, motorized or manual operation.

Vacuum Lifting Cranes:

Construction Site: Glass installation, glazing, curtain wall construction.

Materials Handling: Glass panels, windows, fragile materials.

Description: Vacuum lifting cranes use suction cups to lift and move delicate materials without causing damage.

Typical Configuration: Bridge or gantry crane equipped with vacuum lifting attachments.

Typical Capacity: Varies based on the crane's specifications and the size of the vacuum cups, typically ranging from hundreds of pounds to several tons.

Customized Features: Adjustable suction cups, specialized glass-handling attachments.

Specialized Material Handling Cranes:

Construction Site: Specialized projects with unique material handling needs.

Materials Handling: Specialized materials or equipment unique to the project.

Description: Custom-designed cranes may be used for specific construction projects with unique requirements, such as nuclear facility construction or other specialized industries.

Typical Configuration: Tailored to project-specific needs, ranging from light to heavy lifting capacities.

Typical Capacity: Designed to meet the specific lifting requirements of the project.

Customized Features: Uniquely designed for the specialized tasks and materials of the project.

These overhead cranes are essential tools in construction material handling, and their configurations and capacities can be customized to meet the specific needs of construction projects across various industries and settings.

Operation of overhead cranes for different construction material handling

Overhead cranes play a crucial role in handling various types of construction materials mentioned earlier. The choice of the appropriate type of overhead crane depends on the specific material, its weight, size, and the requirements of the construction project. Here are typical types of overhead cranes used for handling different construction materials:

What are the typical overhead cranes, typical configuration, capacity, applications of the overhead crane used for the above mentioned each and every types of construction material handling ?

Concrete is a versatile and widely used construction material composed of cement, water, and aggregates (such as sand, gravel, or crushed stone). It is used for foundations, walls, floors, and many other structural components.

Typical Overhead Crane: Bridge Crane

Typical Configuration: Single or double girder bridge crane with a hoist.

Capacity: Varies based on the weight of the materials but typically ranges from 1 to 20+ tons.

Functions & Applications: Bridge cranes are often used to handle concrete components like precast concrete panels, beams, and blocks. They provide precise positioning and efficient material handling within construction sites.

Brick:

Bricks are made from fired clay and are used for building walls, facades, and decorative elements.

Typical Overhead Crane: Jib Crane

Typical Configuration: Wall-mounted or freestanding jib crane with a hoist.

Capacity: Typically up to 5 tons.

Functions & Applications: Jib cranes are suitable for moving pallets of bricks, blocks, or masonry units within brickyards, construction sites, and masonry workshops.

Masonry Units:

Masonry units include concrete blocks, clay blocks, and other units made of materials like concrete, clay, or stone. They are used for load-bearing walls and partitions.

Typical Overhead Crane: Bridge Crane

Typical Configuration: Single or double girder bridge crane with a hoist.

Capacity: Varies depending on the size and weight of masonry units, typically ranging from 1 to 10 tons.

Functions & Applications: Bridge cranes are used to lift and position masonry units for wall construction within construction sites.

Steel is used for structural framing, reinforcing concrete, and creating various building components like beams, columns, and roofing systems.

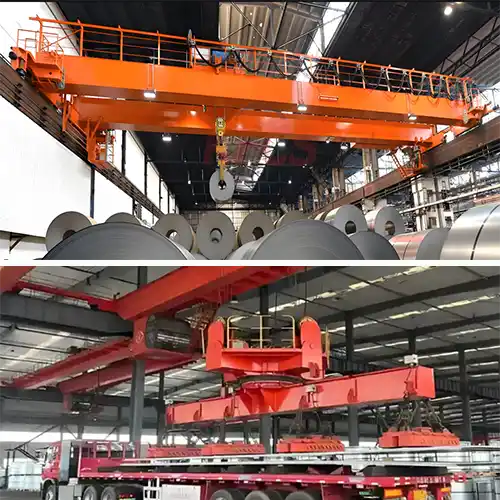

Typical Overhead Crane: Overhead Bridge Crane

Typical Configuration: Single or double girder bridge crane with a hoist or magnetic lifter for steel plates.

Capacity: Ranges from 1 ton to over 100 tons.

Functions & Applications: Overhead bridge cranes are essential for handling steel beams, columns, pipes, and other structural steel components during building construction and steel fabrication.

Wood is commonly used in construction for framing, flooring, roofing, and siding. Different types of wood, such as softwood and hardwood, are used depending on the application.

Typical Overhead Crane: Jib Crane or Bridge Crane

Typical Configuration: Wall-mounted or freestanding jib crane for workshop applications. Single or double girder bridge crane with a hoist for larger wood handling.

Capacity: Varies based on the size and weight of wood materials, typically ranging from 1 to 10 tons.

Functions & Applications: Overhead cranes assist in moving wooden beams, boards, and trusses within sawmills, woodworking shops, and during construction framing and carpentry stages.

Glass is used for windows, doors, curtain walls, and decorative features. It can be clear, tinted, or patterned for different architectural effects.

Typical Overhead Crane: Bridge Crane with a Vacuum Lifting Attachment

Typical Configuration: Single or double girder bridge crane with a vacuum lifter.

Capacity: Varies based on the size and weight of glass panels, typically ranging from a few hundred pounds to several tons.

Functions & Applications: Overhead cranes with vacuum lifters are used to safely lift and position large glass panels, windows, and sheets during glazing and curtain wall installation.

Plastic and Composite Materials:

These materials are used for various purposes, such as plumbing pipes, electrical insulation, and exterior cladding.

Typical Overhead Crane: Jib Crane or Bridge Crane

Typical Configuration: Wall-mounted jib crane for handling smaller materials or single or double girder bridge crane with a hoist for larger materials.

Capacity: Varies depending on the material and application, ranging from 0.5 to 10 tons.

Functions & Applications: Overhead cranes assist in moving plastic and composite materials within manufacturing facilities and construction sites for applications such as plumbing, insulation, and cladding.

Asphalt:

Asphalt is primarily used for road and pavement construction, as well as roofing materials.

Typical Overhead Crane: Bridge Crane or Gantry Crane

Typical Configuration: Single or double girder bridge crane or gantry crane with a hoist.

Capacity: Typically 1 to 10 tons.

Functions & Applications: Overhead cranes are used for transporting rolls of roofing material, shingles, and asphalt sheets for roofing and pavement projects.

Roofing Materials:

Roofing materials include asphalt shingles, metal roofing, clay or concrete tiles, and various flat roofing systems like EPDM and TPO.

Typical Overhead Crane: Bridge Crane or Gantry Crane

Typical Configuration: Single or double girder bridge crane or gantry crane with a hoist.

Capacity: Typically 1 to 10 tons.

Functions & Applications: Overhead cranes assist in the movement and placement of roofing materials during roof installation and repair projects.

Insulation Materials:

Insulation materials like fiberglass, foam boards, and cellulose are used to regulate temperature and sound within buildings.

Typical Overhead Crane: Jib Crane or Bridge Crane

Typical Configuration: Wall-mounted jib crane for handling smaller materials or single or double girder bridge crane with a hoist for larger materials.

Capacity: Varies depending on the material and application, ranging from 0.5 to 10 tons.

Functions & Applications: Overhead cranes assist in moving insulation materials within manufacturing facilities and during construction and insulation installation projects.

Cementitious Materials:

Besides concrete, construction uses other cementitious materials like mortar and grout for bonding and finishing applications.

Typical Overhead Crane: Bridge Crane or Gantry Crane

Typical Configuration: Single or double girder bridge crane or gantry crane with a hoist.

Capacity: Ranges from 1 to 20+ tons.

Functions & Applications: Overhead cranes are used for transporting and mixing cementitious materials, as well as placing them in construction forms and molds.

Aggregates:

Aggregates are used in concrete and asphalt production, as well as for drainage and landscaping purposes. They include sand, gravel, crushed stone, and more.

Typical Overhead Crane: Bridge Crane, Gantry Crane, or Mobile Crane

Typical Configuration: Single or double girder bridge crane, gantry crane, or mobile crane with a grab bucket or clamshell bucket attachment.

Capacity: Ranges from 1 ton to over 100 tons, depending on the type and

volume of aggregates.

Functions & Applications: Overhead cranes are used for the efficient handling and stockpiling of aggregates at construction sites, quarries, and concrete batching plants.

Plaster and Drywall:

These materials are used for interior wall finishes and partitions. Drywall, in particular, is a popular choice for its ease of installation.

Typical Overhead Crane: Jib Crane or Bridge Crane

Typical Configuration: Wall-mounted jib crane for handling smaller materials or single or double girder bridge crane with a hoist for larger materials.

Capacity: Varies based on the size and weight of materials, typically ranging from 0.5 to 10 tons.

Functions & Applications: Overhead cranes assist in moving plaster and drywall sheets within construction sites and during interior finishing work.

Natural stone like granite, marble, limestone, and slate is used for decorative and structural purposes, including countertops, facades, and flooring.

Typical Overhead Crane: Bridge Crane or Gantry Crane

Typical Configuration: Single or double girder bridge crane or gantry crane with a hoist.

Capacity: Ranges from 1 ton to 20+ tons, depending on the size and weight of stone slabs.

Functions & Applications: Overhead cranes are used for lifting and positioning stone slabs during installation in construction and architectural projects.

Various metals, such as aluminum, copper, and stainless steel, are used for architectural elements, roofing, and decorative features.

Typical Overhead Crane: Bridge Crane or Gantry Crane

Typical Configuration: Single or double girder bridge crane or gantry crane with a hoist.

Capacity: Ranges from 1 ton to 20+ tons, depending on the type and size of metal materials.

Functions & Applications: Overhead cranes assist in moving metal sheets, coils, and structural components in metal fabrication shops and construction sites.

Waterproofing and Sealants:

These materials help protect buildings from moisture intrusion and include products like membranes, sealants, and coatings.

Typical Overhead Crane: Jib Crane or Bridge Crane

Typical Configuration: Wall-mounted jib crane for handling smaller materials or single or double girder bridge crane with a hoist for larger materials.

Capacity: Varies based on the size and weight of materials, typically ranging from 0.5 to 10 tons.

Functions & Applications: Overhead cranes assist in moving and positioning waterproofing and sealing materials for construction and building maintenance projects.

Paints and coatings are applied for protection, decoration, and maintenance of surfaces.

Typical Overhead Crane: Jib Crane or Bridge Crane

Typical Configuration: Wall-mounted jib crane for handling smaller materials or single or double girder bridge crane with a hoist for larger materials.

Capacity: Varies based on the size and weight of materials, typically ranging from 0.5 to 10 tons.

Functions & Applications: Overhead cranes assist in moving and positioning paints, coatings, and related materials for construction and maintenance projects.

These materials are used to bond various components together, such as tiles, panels, and insulation.

Typical Overhead Crane: Jib Crane or Bridge Crane

Typical Configuration: Wall-mounted jib crane for handling smaller materials or single or double girder bridge crane with a hoist for larger materials.

Capacity: Varies based on the size and weight of materials, typically ranging from 0.5 to 10 tons.

Functions & Applications: Overhead cranes assist in moving and positioning adhesives, fasteners, and related materials for construction and assembly processes.

Ceramic and Porcelain Tiles:

These are used for flooring, walls, and decorative purposes, offering durability and aesthetic appeal.

Typical Overhead Crane: Jib Crane or Bridge Crane

Typical Configuration: Wall-mounted jib crane for handling smaller materials or single or double girder bridge crane with a hoist for larger materials.

Capacity: Varies based on the size and weight of tiles, typically ranging from 0.5 to 10 tons.

Functions & Applications: Overhead cranes assist in moving pallets of ceramic and porcelain tiles within manufacturing facilities and during installation in construction and interior design projects.

Reinforcement Materials:

Materials like rebar (steel reinforcing bars) and mesh are used to reinforce concrete and provide structural strength.

Typical Overhead Crane: Jib Crane or Bridge Crane

Typical Configuration: Wall-mounted jib crane for handling smaller materials or single or double girder bridge crane with a hoist for larger materials.

Capacity: Varies based on the size and weight of materials, typically ranging from 0.5 to 10 tons.

Functions & Applications: Overhead cranes assist in moving and positioning reinforcement materials for concrete structures in construction sites and concrete production facilities.

These overhead cranes play a crucial role in efficiently and safely handling a wide range of construction materials, contributing to the success of construction projects across various industries.

Construction materials handling overhead crane adopted at different construction site

Construction material handling is required in various construction sites and scenarios where different types of materials need to be transported, lifted, and positioned. Here are some of the common construction sites and settings where material handling plays a crucial role:

Building Construction Sites:

Residential: Handling materials for houses, apartments, and other residential buildings.

Commercial: Managing materials for office buildings, retail stores, and shopping centers.

Industrial: Transporting materials for factories, warehouses, and manufacturing facilities.

Institutional: Handling materials for schools, hospitals, and government buildings.

Building Construction Sites

Residential Building Construction:

Residential: Handling materials for houses, apartments, and other residential buildings.

Typical Overhead Crane: Bridge Crane

Description: Bridge cranes, often with single or double girders, are commonly used in residential construction. They provide precise positioning and efficient material handling, making them suitable for tasks like lifting lumber, roofing materials, precast elements, and other materials used in houses and apartments.

Typical Crane Capacity: Varies based on project needs.

Typical Application: Lifting and positioning materials in residential construction.

Customized Features: Various hoist options, remote controls, and safety features can be customized to suit specific project requirements.

Commercial Building Construction:

Commercial: Managing materials for office buildings, retail stores, and shopping centers.

Typical Overhead Crane: Bridge Crane, Gantry Crane

Description: Both bridge and gantry cranes are used in commercial construction. Bridge cranes are employed for lifting and positioning materials such as steel beams, glass, HVAC units, and construction components in office buildings, retail stores, and shopping centers.

Typical Crane Capacity: Varies based on project needs.

Typical Application: Handling materials in commercial construction.

Customized Features: Adjustable height and span, different wheel options for varied terrains, and specialized attachments.

Industrial Building Construction:

Industrial: Transporting materials for factories, warehouses, and manufacturing facilities.

Typical Overhead Crane: Bridge Crane, Gantry Crane

Description: Industrial construction projects, including factories, warehouses, and manufacturing facilities, often utilize bridge and gantry cranes for handling heavy machinery, structural components, and various materials within the industrial setting. These cranes ensure efficient material placement.

Typical Crane Capacity: Varies based on project needs.

Typical Application: Handling materials in industrial construction.

Customized Features: Various hoist options, adjustable height and span, and safety features tailored to industrial requirements.

Institutional Building Construction:

Institutional: Handling materials for schools, hospitals, and government buildings.

Typical Overhead Crane: Bridge Crane

Description: Bridge cranes are commonly employed in institutional construction projects for tasks such as lifting and placing materials like concrete panels, equipment, and other components used in schools, hospitals, government buildings, and similar structures.

Typical Crane Capacity: Varies based on project needs.

Typical Application: Material handling in institutional construction.

Customized Features: Various hoist options, remote controls, and safety features tailored to institutional requirements.

These overhead crane types play essential roles in construction material handling in various building construction sectors, ensuring efficient and safe operations. Customization options allow them to meet specific project demands.

Infrastructure Construction Sites:

Roads and Highways: Transporting aggregates, asphalt, and concrete for road construction.

Bridges: Lifting and placing structural elements like beams and girders.

Tunnels: Managing materials for tunnel construction and reinforcement.

Infrastructure Construction Sites

Roads and Highways:

Roads and Highways: Transporting aggregates, asphalt, and concrete for road construction.

Typical Overhead Crane: Gantry Crane

Description: Gantry cranes are commonly used in road and highway construction for efficient transportation of aggregates, asphalt, and concrete. They facilitate precise material placement, contributing to the construction process.

Typical Crane Capacity: Varies based on the scale of the road project.

Typical Application: Handling materials in road and highway construction.

Customized Features: Adjustable height and span to accommodate different road sizes and terrains.

Bridges:

Bridges: Lifting and placing structural elements like beams and girders.

Typical Overhead Crane: Bridge Crane

Description: Bridge cranes are essential for bridge construction. They excel in lifting and positioning heavy structural elements such as beams and girders with precision, ensuring the integrity of the bridge's construction.

Typical Crane Capacity: Varies based on the size and design of the bridge.

Typical Application: Handling structural elements in bridge construction.

Customized Features: Various hoist options, remote controls, and safety features tailored to bridge construction requirements.

Tunnels:

Tunnels: Managing materials for tunnel construction and reinforcement.

Typical Overhead Crane: Gantry Crane

Description: Gantry cranes play a crucial role in tunnel construction by efficiently managing materials needed for tunnel excavation and reinforcement. They contribute to the safe and precise handling of segments and equipment.

Typical Crane Capacity: Varies based on tunnel dimensions and material weight.

Typical Application: Handling materials in tunnel construction and reinforcement.

Customized Features: Adjustable height and span, different wheel options for various tunnel conditions, and specialized attachments.

These overhead cranes are indispensable in infrastructure construction, ensuring that materials are handled efficiently and accurately in road and highway projects, bridge construction, and tunnel construction and reinforcement. Customized features cater to the specific needs of each type of infrastructure project.

Utility and Pipeline Projects:

Water and Sewer Systems: Handling pipes, concrete segments, and materials for water and sewer infrastructure.

Gas and Oil Pipelines: Transporting large pipes, valves, and equipment for pipeline construction.

Utility and Pipeline Projects

Water and Sewer Systems:

Water and Sewer Systems: Handling pipes, concrete segments, and materials for water and sewer infrastructure.

Typical Overhead Crane: Jib Crane, Bridge Crane

Description: Jib cranes and bridge cranes are commonly used in water and sewer infrastructure projects. Jib cranes efficiently handle pipes, concrete segments, and materials during the construction of water and sewer systems, ensuring precise placement.

Typical Crane Capacity: Varies based on the size and weight of pipes and segments.

Typical Application: Lifting and positioning materials in water and sewer infrastructure construction.

Customized Features: Different boom lengths and rotations for flexibility in confined spaces, motorized or manual operation options.

Gas and Oil Pipelines:

Gas and Oil Pipelines: Transporting large pipes, valves, and equipment for pipeline construction.

Typical Overhead Crane: Gantry Crane, Bridge Crane

Description: Gantry and bridge cranes are vital in the construction of gas and oil pipelines. They efficiently transport large pipes, valves, and equipment, contributing to the assembly and installation of the pipeline infrastructure.

Typical Crane Capacity: Varies based on the size and weight of pipeline components.

Typical Application: Handling materials in gas and oil pipeline construction.

Customized Features: Adjustable height and span, specialized lifting attachments, and safety features tailored to pipeline construction requirements.

These overhead cranes are crucial in utility and pipeline projects, ensuring the efficient and accurate handling of materials and components in water and sewer system construction and gas and oil pipeline projects. Customization options make them suitable for various construction challenges and site conditions.

Energy and Power Projects:

Power Plants: Managing heavy equipment, structural components, and machinery.

Renewable Energy: Handling components for wind turbines, solar panels, and hydropower installations.

Substations: Transporting transformers, switchgear, and electrical components.

Power Plants:

Power Plants: Managing heavy equipment, structural components, and machinery.

Typical Overhead Crane: Bridge Crane, Gantry Crane

Description: Bridge and gantry cranes are commonly used in power plant construction. They efficiently manage heavy equipment, structural components, and machinery, ensuring their precise placement within the power plant facility.

Typical Crane Capacity: Varies based on the size and weight of equipment.

Typical Application: Handling materials and equipment in power plant construction.

Customized Features: Various hoist options, adjustable height and span, and safety features tailored to power plant construction requirements.

Renewable Energy:

Renewable Energy: Handling components for wind turbines, solar panels, and hydropower installations.

Typical Overhead Crane: Gantry Crane, Telescopic Boom Crane

Description: Gantry and telescopic boom cranes play essential roles in renewable energy projects. They efficiently handle components such as wind turbine parts, solar panels, and equipment for hydropower installations, contributing to the assembly and installation of renewable energy infrastructure.

Typical Crane Capacity: Varies based on the size and weight of renewable energy components.

Typical Application: Handling materials and components in renewable energy projects.

Customized Features: Adjustable height and span, specialized lifting attachments, and mobility options for various renewable energy installations.

Substations:

Substations: Transporting transformers, switchgear, and electrical components.

Typical Overhead Crane: Bridge Crane

Description: Bridge cranes are commonly used in substation construction. They efficiently transport transformers, switchgear, and electrical components, ensuring their accurate placement within the substation infrastructure.

Typical Crane Capacity: Varies based on the size and weight of electrical components.

Typical Application: Handling materials and equipment in substation construction.

Customized Features: Various hoist options, remote controls, and safety features tailored to substation construction requirements.

These overhead cranes are essential in energy and power projects, ensuring efficient and precise handling of materials, equipment, and components in power plant construction, renewable energy projects, and substation construction. Customization options make them adaptable to the specific needs of each type of project.

Mining and Quarry Sites:

Extraction: Moving and stockpiling raw materials like ores, coal, and aggregates.

Processing: Handling materials within processing plants and facilities.

Extraction:

Extraction: Moving and stockpiling raw materials like ores, coal, and aggregates.

Typical Overhead Crane: Gantry Crane, Crawler Crane

Description: Gantry and crawler cranes are frequently used in mining and quarry operations. They efficiently handle the movement and stockpiling of raw materials such as ores, coal, and aggregates. These cranes are crucial for the extraction process.

Typical Crane Capacity: Varies based on the size and weight of the materials and the mining operation's scale.

Typical Application: Material handling in mining and quarry extraction.

Customized Features: Adjustable height and span, different wheel options for various terrains, and specialized lifting attachments for handling raw materials.

Processing:

Processing: Handling materials within processing plants and facilities.

Typical Overhead Crane: Bridge Crane, Gantry Crane

Description: Bridge and gantry cranes are integral to the processing phase in mining and quarry sites. They efficiently handle materials within processing plants and facilities, contributing to the sorting, crushing, and preparation of materials for further use.

Typical Crane Capacity: Varies based on the size and weight of the processed materials.

Typical Application: Material handling within processing plants and facilities.

Customized Features: Various hoist options, adjustable height and span, and safety features tailored to processing plant requirements.

These overhead cranes are vital in mining and quarry sites, ensuring the efficient and precise handling of raw materials during the extraction process and materials within processing plants. Customization options make them adaptable to the specific requirements of each mining and quarry operation.

Commercial and Residential Renovations:

Demolition: Removing and disposing of existing materials.

Renovation: Transporting new materials and equipment for remodeling projects.

Demolition:

Demolition: Removing and disposing of existing materials.

Typical Overhead Crane: Crawler Crane, Telescopic Boom Crane

Description: Crawler and telescopic boom cranes are often utilized in demolition projects during the removal and disposal of existing materials. They efficiently handle heavy materials and equipment to facilitate the demolition process.

Typical Crane Capacity: Varies based on the size and weight of materials and the scale of the demolition project.

Typical Application: Material removal and disposal in demolition.

Customized Features: Various boom configurations and lengths, specialized attachments for demolition tasks.

Renovation:

Renovation: Transporting new materials and equipment for remodeling projects.

Typical Overhead Crane: Bridge Crane, Jib Crane

Description: Bridge and jib cranes are valuable in renovation projects for transporting new materials and equipment to support remodeling efforts. They ensure efficient and precise handling of construction materials within renovation sites.

Typical Crane Capacity: Varies based on the materials and equipment being transported.

Typical Application: Handling new materials and equipment in renovation projects.

Customized Features: Various hoist options, different boom lengths, and rotations for flexible material handling.

These overhead cranes are essential in commercial and residential renovation projects, contributing to the safe and efficient removal of existing materials during demolition and the precise handling of new materials and equipment for remodeling efforts. Customization options make them adaptable to the specific needs of each renovation project.

Agricultural Construction:

Farm Buildings: Managing materials for barns, storage facilities, and agricultural structures.

Irrigation: Handling pipes, pumps, and irrigation equipment.

Farm Buildings:

Farm Buildings: Managing materials for barns, storage facilities, and agricultural structures.

Typical Overhead Crane: Bridge Crane, Gantry Crane

Description: Bridge and gantry cranes are commonly used in agricultural construction to efficiently manage materials for the construction of barns, storage facilities, and various agricultural structures. They ensure precise material placement.

Typical Crane Capacity: Varies based on the size and weight of materials and the scale of the agricultural construction project.

Typical Application: Handling materials in the construction of farm buildings and agricultural structures.

Customized Features: Adjustable height and span, specialized lifting attachments for farm equipment.

Irrigation:

Irrigation: Handling pipes, pumps, and irrigation equipment.

Typical Overhead Crane: Jib Crane, Bridge Crane

Description: Jib and bridge cranes play essential roles in irrigation projects by efficiently handling pipes, pumps, and irrigation equipment. They contribute to the precise placement and installation of irrigation systems.

Typical Crane Capacity: Varies based on the size and weight of irrigation components.

Typical Application: Material handling in the installation of irrigation systems.

Customized Features: Different boom lengths and rotations for flexibility in irrigation projects, various hoist options.

These overhead cranes are crucial in agricultural construction, ensuring the efficient and accurate handling of materials for the construction of farm buildings, storage facilities, and irrigation systems. Customization options make them adaptable to the specific requirements of each agricultural construction project.

Marine Construction:

Ports and Harbors: Lifting and positioning materials for dock construction.

Coastal Structures: Managing materials for seawalls, breakwaters, and offshore platforms.

Marine Construction

Ports and Harbors:

Ports and Harbors: Lifting and positioning materials for dock construction.

Typical Overhead Crane: Gantry Crane, Tower Crane

Description: Gantry and tower cranes are commonly employed in marine construction projects for lifting and positioning materials during dock construction. They facilitate the precise placement of heavy components.

Typical Crane Capacity: Varies based on the size and weight of materials and the scale of the dock construction project.

Typical Application: Handling materials in the construction of ports, harbors, and docks.

Customized Features: Adjustable height and span, specialized lifting attachments for marine components, different wheel options for various terrains.

Coastal Structures:

Coastal Structures: Managing materials for seawalls, breakwaters, and offshore platforms.

Typical Overhead Crane: Gantry Crane, Crawler Crane

Description: Gantry and crawler cranes are essential in coastal construction projects for efficiently managing materials used in seawalls, breakwaters, and offshore platforms. They ensure the precise placement of materials even in challenging coastal environments.

Typical Crane Capacity: Varies based on the size and weight of coastal construction materials.

Typical Application: Handling materials in the construction of coastal structures.

Customized Features: Different wheel options for various coastal terrains, specialized attachments for coastal materials.

These overhead cranes are vital in marine construction, ensuring the efficient and accurate handling of materials for the construction of ports, harbors, docks, seawalls, breakwaters, and offshore platforms. Customization options make them adaptable to the specific needs and conditions of each marine construction project.

Environmental Remediation:

Cleanup Sites: Transporting and disposing of hazardous materials.

Land Reclamation: Moving earth and materials for land restoration.

Cleanup Sites:

Cleanup Sites: Transporting and disposing of hazardous materials.

Typical Overhead Crane: Bridge Crane, Vacuum Lifting Crane

Description: Bridge cranes and vacuum lifting cranes are often used in environmental cleanup projects for transporting and disposing of hazardous materials safely. They ensure the precise and secure handling of dangerous substances.

Typical Crane Capacity: Varies based on the size and weight of hazardous materials.

Typical Application: Material transport and disposal in environmental cleanup projects.

Customized Features: Specialized attachments for hazardous materials, vacuum lifting technology for secure material handling.

Land Reclamation:

Land Reclamation: Moving earth and materials for land restoration.

Typical Overhead Crane: Gantry Crane, Telescopic Boom Crane

Description: Gantry and telescopic boom cranes play crucial roles in land reclamation projects by efficiently moving earth and materials to restore land to its natural state. They contribute to the precise placement of materials during the restoration process.

Typical Crane Capacity: Varies based on the scale of the land reclamation project.

Typical Application: Material handling in land reclamation and restoration.

Customized Features: Adjustable height and span, specialized lifting attachments for reclamation materials.

These overhead cranes are essential in environmental remediation, ensuring the safe and efficient transport and disposal of hazardous materials in cleanup sites and the precise handling of materials during land reclamation and restoration projects. Customization options make them adaptable to the specific requirements of each environmental remediation project.

Commercial and Residential Landscaping:

Hardscaping: Handling materials for patios, walkways, and retaining walls.

Softscaping: Transporting soil, mulch, and plants for landscaping projects.

Hardscaping:

Hardscaping: Handling materials for patios, walkways, and retaining walls.

Typical Overhead Crane: Jib Crane, Bridge Crane

Description: Jib and bridge cranes are often used in hardscaping projects to efficiently handle materials such as stone pavers, bricks, and concrete blocks for constructing patios, walkways, and retaining walls. They ensure precise material placement.

Typical Crane Capacity: Varies based on the size and weight of hardscaping materials.

Typical Application: Material handling in hardscaping projects.

Customized Features: Different boom lengths and rotations for flexible material handling, various hoist options.

Softscaping:

Softscaping: Transporting soil, mulch, and plants for landscaping projects.

Typical Overhead Crane: Bridge Crane, Vacuum Lifting Crane

Description: Bridge cranes and vacuum lifting cranes are commonly used in softscaping projects to handle materials like soil, mulch, and plants for landscaping. They ensure efficient and gentle material handling, especially when working with delicate plants.

Typical Crane Capacity: Varies based on the size and weight of softscaping materials.

Typical Application: Material transport and placement in softscaping projects.

Customized Features: Vacuum lifting technology for secure material handling, adjustable hoist options.

Specialized Construction:

Historical Restoration: Managing materials for restoring historic buildings and structures.

Entertainment and Events: Handling materials for stage and event construction.

Historical Restoration:

Historical Restoration: Managing materials for restoring historic buildings and structures.

Typical Overhead Crane: Bridge Crane, Gantry Crane

Description: Bridge and gantry cranes are often employed in historical restoration projects to efficiently manage materials used in the restoration of historic buildings and structures. They ensure precise and sensitive material handling.

Typical Crane Capacity: Varies based on the size and weight of historical restoration materials.

Typical Application: Material handling in historical restoration projects.

Customized Features: Various hoist options, adjustable height and span, and safety features tailored to historical restoration requirements.

Entertainment and Events:

Entertainment and Events: Handling materials for stage and event construction.

Typical Overhead Crane: Telescopic Boom Crane, Articulating Boom Crane

Description: Telescopic and articulating boom cranes play essential roles in entertainment and event construction projects, efficiently handling materials for stage and event setups. They contribute to the precise and flexible placement of stage equipment and structures.

Typical Crane Capacity: Varies based on the size and weight of stage equipment and event materials.

Typical Application: Material handling in stage and event construction.

Customized Features: Various boom configurations and lengths for flexibility, mobility options for different event venues.

Interior Construction:

Office Fit-Outs: Transporting materials for interior office renovations.

Retail Spaces: Managing materials for store remodeling and build-outs.

Interior Construction

Office Fit-Outs:

Office Fit-Outs: Transporting materials for interior office renovations.

Typical Overhead Crane: Jib Crane, Bridge Crane

Description: Jib and bridge cranes are valuable in office fit-out projects for efficiently transporting materials used in interior office renovations, such as partitions, furniture, and fixtures.

Typical Crane Capacity: Varies based on the size and weight of office fit-out materials.

Typical Application: Material handling in interior office renovation projects.

Customized Features: Different boom lengths and rotations for flexibility, various hoist options.

Retail Spaces:

Retail Spaces: Managing materials for store remodeling and build-outs.

Typical Overhead Crane: Bridge Crane, Gantry Crane

Description: Bridge and gantry cranes are commonly used in retail space construction to efficiently handle materials for store remodeling and build-outs, including shelving, displays, and fixtures.

Typical Crane Capacity: Varies based on the size and weight of retail construction materials.

Typical Application: Material handling in retail space remodeling and build-out projects.

Customized Features: Adjustable height and span, specialized lifting attachments for retail materials.

These are just some of the many construction sites and contexts where material handling equipment, including cranes and other lifting devices, is essential for the efficient and safe movement of construction materials and equipment. Proper material handling contributes to project productivity, safety, and overall success.

Overhead Crane used in different construction material handling production facility

Concrete Production Plant:

Features: Concrete batching plants feature mixing equipment, aggregate storage bins, cement silos, and control systems.

Production Procedure: Aggregates, cement, water, and additives are precisely mixed to create concrete. The mixed concrete is then transported to construction sites or precast facilities for casting into various forms.

Typical Overhead Crane: Bridge Crane, Gantry Crane

Description: Bridge and gantry cranes are used for handling raw materials like aggregates, cement, and additives. They facilitate the movement of materials within the batching and mixing areas.

Customized Crane Features for the Facility: Customized features may include specialized lifting attachments for molds, high-temperature-resistant components, and precise control systems for accurate material placement.

Brick Manufacturing Facility:

Features: Brickworks consist of kilns, molding machines, and drying facilities.

Production Procedure: Clay or other raw materials are molded into brick shapes, dried, and fired in kilns at high temperatures to harden and create bricks.

Typical Overhead Crane: Gantry Crane, Jib Crane

Description: Gantry cranes are employed for moving raw materials like clay or shale to molding machines. Jib cranes may be used for precise handling during brick stacking and storage.

Customized Crane Features for the Facility: Customized features may include specialized attachments for handling bricks during the firing process, heat-resistant components, and precise load control.

Masonry Unit Manufacturing:

Features: Similar to brick manufacturing facilities, masonry unit plants include molding equipment and curing areas.

Production Procedure: Raw materials are molded into blocks, pavers, or other masonry units and then cured to achieve the desired strength.

Typical Overhead Crane: Gantry Crane, Jib Crane

Description: Gantry and jib cranes assist in material handling, curing, and stacking of masonry units.

Customized Crane Features for the Facility: Customized features may include attachments for handling curing racks or stacking units with precision.

Steel Mill:

Features: Steel mills include blast furnaces, rolling mills, and processing equipment.

Production Procedure: Iron ore and other raw materials are smelted in blast furnaces to produce molten iron. The molten iron is then processed and rolled into various steel products.

Typical Overhead Crane: Overhead Crane with Magnet or Grapple Attachment

Description: Overhead cranes equipped with magnets or grapples are used to handle raw materials like scrap metal and transport steel coils and plates within the mill.

Customized Crane Features for the Facility: Customized features may include specialized magnet or grapple attachments for efficient material handling within the steel mill.

Sawmill (Wood Processing Facility):

Features: Sawmills are equipped with sawing machines, kilns for drying wood, and processing equipment.

Production Procedure: Logs are cut into lumber using sawing machines, and the lumber is dried in kilns to achieve the desired moisture content.

Typical Overhead Crane: Bridge Crane, Jib Crane

Description: Bridge cranes are used for transporting logs and lumber within the sawmill. Jib cranes may be employed for precise positioning during processing.

Customized Crane Features for the Facility: Customized features may include specialized attachments for log or lumber handling and precise load control.

Glass Manufacturing Plant:

Features: Glass manufacturing plants include glass melting furnaces, forming machines, and annealing lehrs.

Production Procedure: Raw materials like silica, soda ash, and limestone are melted to form glass, which is then shaped and gradually cooled to anneal it.

Typical Overhead Crane: Glass Handling Crane, Vacuum Lifting Crane

Description: Specialized cranes designed for glass handling, often equipped with vacuum lifting technology, are used for moving glass sheets and products safely.

Customized Crane Features for the Facility: Customized features may include specialized vacuum lifting attachments, precise control systems, and glass-friendly materials to prevent scratching or damage.

Plastic and Composite Material Factory:

Features: Plastic and composite material factories have extrusion lines, molding machines, and processing equipment.

Production Procedure: Raw materials like plastic pellets or composite resins are melted and shaped into various products using extrusion or molding processes.

Typical Overhead Crane: Bridge Crane, Gantry Crane

Description: Bridge and gantry cranes are used for handling raw materials, molds, and finished composite products.

Customized Crane Features for the Facility: Customized features may include specialized attachments for mold handling, precise positioning, and load control.

Asphalt Mixing Plant:

Features: Asphalt mixing plants have storage silos, heating systems, and mixing equipment.

Production Procedure: Aggregates and

bitumen are heated and mixed to produce asphalt, which is stored for transportation to construction sites.

Typical Overhead Crane: Gantry Crane, Bridge Crane

Description: Gantry and bridge cranes are used for material handling within the plant, including the loading of aggregates and bitumen into mixing equipment.

Customized Crane Features for the Facility: Customized features may include precise control systems for accurate material measurement and mixing.

Roofing Materials Manufacturing:

Features: Roofing materials factories produce shingles, membranes, and other roofing products.

Production Procedure: Raw materials like asphalt, fiberglass, and granules are combined to create roofing materials, which are then cut and packaged.

Typical Overhead Crane: Bridge Crane, Gantry Crane

Description: Bridge and gantry cranes are used for material handling, including moving rolls of materials and facilitating the packaging process.

Customized Crane Features for the Facility: Customized features may include specialized lifting attachments for rolls and precise positioning.

Insulation Materials Manufacturing:

Features: Insulation materials facilities produce products like fiberglass insulation and foam boards.

Production Procedure: Raw materials like fiberglass or foam materials are processed, cut, and packaged into insulation products.

Typical Overhead Crane: Bridge Crane, Gantry Crane

Description: Bridge and gantry cranes are used for material handling, including moving rolls or sheets of insulation materials.

Customized Crane Features for the Facility: Customized features may include specialized lifting attachments for rolls or sheets and precise control systems.

Cementitious Materials Manufacturing:

Features: Cementitious materials plants produce products like cement, mortar, and grout.

Production Procedure: Raw materials like limestone, clay, and additives are processed and ground to produce cementitious products.

Typical Overhead Crane: Bridge Crane, Gantry Crane

Description: Bridge and gantry cranes are used for material handling within the plant, including transporting raw materials and finished products.

Customized Crane Features for the Facility: Customized features may include specialized attachments for handling bulk materials and precise control systems.

Aggregates Processing Plant:

Features: Aggregates processing plants crush, screen, and wash raw materials like stone and gravel to produce aggregates.

Production Procedure: Raw materials are processed to create aggregates of various sizes for construction use.

Typical Overhead Crane: Gantry Crane, Bridge Crane

Description: Gantry and bridge cranes are used for material handling, including loading and unloading trucks with aggregates.

Customized Crane Features for the Facility: Customized features may include high-capacity lifting equipment for heavy aggregates and precise load control.

Plaster and Drywall Manufacturing:

Features: Plaster and drywall factories produce gypsum-based products.

Production Procedure: Raw materials like gypsum are processed and formed into plaster and drywall products.

Typical Overhead Crane: Bridge Crane, Gantry Crane

Description: Bridge and gantry cranes are used for material handling, including transporting raw materials and finished products.

Customized Crane Features for the Facility: Customized features may include specialized attachments for handling gypsum boards and precise positioning.

Stone Processing Plant:

Features: Stone processing plants cut, polish, and shape natural stone materials like granite and marble.

Production Procedure: Blocks of stone are processed into slabs, tiles, and decorative stone products.

Typical Overhead Crane: Gantry Crane, Bridge Crane

Description: Gantry and bridge cranes are used for material handling, including moving stone blocks, slabs, and finished products.

Customized Crane Features for the Facility: Customized features may include specialized attachments for handling stone slabs and precise load control.

Metals Fabrication Plant:

Features: Metals fabrication plants include equipment for cutting, welding, and shaping metal materials.

Production Procedure: Raw metal materials are processed into various metal products, including structural components.

Typical Overhead Crane: Overhead Crane with Magnet or Grapple Attachment

Description: Overhead cranes equipped with magnets or grapples are used for material handling, including moving metal sheets, beams, and parts.

Customized Crane Features for the Facility: Customized features may include specialized attachments for lifting metal sheets and precise load control.

Ceramic and Porcelain Tile Manufacturing:

Features: Tile manufacturing facilities produce ceramic and porcelain tiles.

Production Procedure: Raw materials like clay, feldspar, and additives are processed, shaped, fired, and glazed to create tiles.

Typical Overhead Crane: Bridge Crane, Gantry Crane

Description: Bridge and gantry cranes are used for material handling, including moving raw materials and finished tile products.

Customized Crane Features for the Facility: Customized features may include specialized attachments for handling fragile tiles and precise positioning.

Reinforcement Materials Manufacturing:

Features: Reinforcement materials plants produce products like rebar and wire mesh.

Production Procedure: Raw materials like steel rods and wires are processed and shaped into reinforcement products.

Typical Overhead Crane: Gantry Crane, Bridge Crane

Description: Gantry and bridge cranes are used for material handling, including transporting steel rods and finished reinforcement products.

Customized Crane Features for the Facility: Customized features may include specialized attachments for handling long steel rods and precise load control.

Waterproofing and Sealants Manufacturing:

Features: Waterproofing and sealants factories produce products for building

protection.

Production Procedure: Raw materials are processed and mixed to create waterproofing and sealing products.

Typical Overhead Crane: Bridge Crane, Gantry Crane

Description: Bridge and gantry cranes are used for material handling, including moving raw materials and packaging finished products.

Customized Crane Features for the Facility: Customized features may include specialized lifting attachments for drums or containers and precise load control.

Paints and Coatings Manufacturing:

Features: Paints and coatings factories produce a wide range of protective and decorative coatings.

Production Procedure: Raw materials like pigments, solvents, and binders are mixed and processed to create paints and coatings.

Typical Overhead Crane: Bridge Crane, Gantry Crane

Description: Bridge and gantry cranes are used for material handling, including moving raw materials, mixing components, and packaging finished products.

Customized Crane Features for the Facility: Customized features may include specialized attachments for handling containers and precise load control.

Adhesives and Fasteners Manufacturing:

Features: Adhesives and fasteners factories produce products like adhesives, screws, and nails.

Production Procedure: Raw materials are processed and mixed to create adhesives and fastening products.

Typical Overhead Crane: Bridge Crane, Gantry Crane

Description: Bridge and gantry cranes are used for material handling, including moving raw materials, mixing components, and packaging finished products.

Customized Crane Features for the Facility: Customized features may include specialized lifting attachments for containers or drums and precise load control.

These overhead cranes play a crucial role in material handling and production processes across various construction material manufacturing facilities, ensuring efficiency, safety, and precision in handling raw materials and finished products. The specific crane types and features can vary depending on the facility's needs and the characteristics of the materials being produced.

Conclusion: Elevating Construction Material Handling to Specialized Heights

As we wrap up this guide, it's evident that specialized overhead crane designs have transformed material handling in construction. They've elevated efficiency, safety, and precision to new heights. We encourage construction professionals to explore the specialist capabilities of crane manufacturers to solve their material handling concerns. In doing so, they can achieve excellence in construction material handling and set their projects on the path to success.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch