Steel Rebar Storage Yard Gantry Crane | 35 /10 Ton Gantry Crane

35 Ton/10 Ton gantry crane for steel rebar storage. Dual hooks outdoor cranes, safe lifting make rebar handling efficient in outdoor storage yards.

Category: 35 Ton Gantry Crane

Your Trusted Gantry Crane Manufacturer & Supplier

35 Ton Gantry Crane for Sale,

35 Ton/10 Ton Gantry Crans Solution,

Tailored Steel Rebar Storage Yard Gantry Crane & Outdoor Gantry Crane

Storing and handling steel rebars in outdoor yards can be more complicated than it looks. Long, heavy bundles need to be moved frequently, often in tight spaces. Manual handling is risky, slow, and can easily damage the steel. Add in unpredictable weather and the constant need to load trucks, and you have a real challenge on your hands.

This is why storage yards need lifting solutions that are both reliable and efficient. A crane that can safely handle heavy loads, reach the full height of the stacks, and move smoothly along the yard runway makes a huge difference. It's not just about lifting steel; it's about keeping operations flowing without accidents or downtime.

For yards that handle large volumes of rebar, a 35 Ton/10 Ton double girder gantry crane offers a practical solution. With a main hook capable of lifting 35 tons and an auxiliary hook for 10-ton loads, this crane lets operators manage heavy and lighter bundles at the same time. It's ideal for outdoor steel storage yards where speed, safety, and versatility matter most.

Key points to consider:

- Heavy, long rebars require stable and precise lifting.

- Manual handling increases risk and slows down operations.

- Dual hook cranes allow simultaneous handling of different load sizes.

- Double girder design provides strength, reduces sway, and increases lifespan.

- Suitable for outdoor storage yards with large volumes of steel.

Key Features of the 35 Ton/10 Ton Yard Gantry Crane

When it comes to handling steel rebars in a storage yard, not all cranes are built the same. The 35 Ton/10 Ton double girder gantry crane is designed specifically for the heavy, repetitive work you face every day. Let's break down what makes this crane practical and reliable.

Double Girder Design

A double girder setup isn't just for show—it really makes a difference when lifting long, heavy steel bundles. The two girders provide extra stability, reducing bending and sway, which keeps loads under control even at maximum capacity.

- Supports heavy-duty operations with minimal deflection.

- Improves overall structural strength and longevity of the crane.

- Ideal for outdoor steel storage yards where large bundles are frequently moved.

Dual Hook System

One of the biggest advantages of this crane is its dual hook design. You get a 35-ton main hook for the heaviest bundles and a 10-ton auxiliary hook for smaller or lighter loads. This flexibility means operators can handle two different lifting tasks without switching equipment.

- 35 Ton Main Hook: Moves large rebar bundles, steel rods, or other heavy products safely.

- 10 Ton Auxiliary Hook: Handles lighter or smaller loads at the same time, improving yard efficiency.

- Reduces downtime by allowing simultaneous lifting of multiple load sizes.

Outdoor Operation Suitability

Steel storage yards are exposed to sun, rain, wind, and even dust. This crane is built to withstand outdoor conditions, ensuring reliable performance throughout the year.

- Weather-resistant components keep the crane functional in harsh environments.

- Corrosion-resistant coatings on steel structures extend service life.

- Designed for consistent performance in high-volume storage yards.

Enhanced Safety Features

Safety is never optional when moving tons of steel overhead. This crane comes with built-in systems to protect both operators and materials.

- Anti-collision devices prevent accidental impacts with other cranes or structures.

- Limit switches stop the crane before the hook exceeds safe travel limits.

- Overload protection ensures the crane never lifts more than its rated capacity.

- Makes daily operations safer and reduces the risk of costly accidents.

Applications in Steel Storage Yards

A crane is only as useful as the tasks it can handle every day. In a busy steel storage yard, a 35 Ton/10 Ton double girder gantry crane proves its worth by making heavy lifting safer, faster, and more organized.

Handling Long Rebar Bundles

Moving long, heavy rebars is no small task. Trying to do it manually or with smaller equipment can be slow and risky. With this crane, loading and unloading bundles onto trucks becomes much more efficient.

- Speeds up the transfer of large rebar bundles.

- Reduces physical strain and accident risk for workers.

- Maintains better control over long, flexible steel products during lifting.

Storage Yard Organization

A cluttered yard can cause delays and even damage materials. The crane's reach and precision make stacking and unstacking steel bundles straightforward, helping you keep the yard organized.

- Allows safe and efficient placement of steel stacks.

- Maximizes use of available yard space.

- Makes it easier to access specific bundles without moving multiple loads.

Versatility

While it's designed for rebars, this crane isn't limited to just one type of steel product. Its dual hook system and strong double girder design allow it to handle a variety of materials.

- Can lift billets, rods, steel plates, and other heavy items.

- Adapts to different lifting tasks without additional equipment.

- Makes the crane a flexible, long-term investment for yard operations.

Advantages for Rebar Handling with 35 Ton/10 Ton Gantry Cranes

Moving steel rebars efficiently and safely is critical in a busy storage yard. A 35 Ton/10 Ton double girder gantry crane offers features that streamline operations, improve safety, and provide long-term durability.

Increased Efficiency

Time is money in a busy yard. The crane's dual hook system allows you to lift multiple loads simultaneously, reducing waiting times and improving overall productivity.

- Handles multiple loads at the same time without swapping equipment.

- Reduces downtime during loading and unloading tasks.

- Helps operators complete more lifts in less time while maintaining control and precision.

Improved Safety

Handling long and heavy rebars can be tricky. The crane's stable design and precise controls minimize the risk of accidents, protecting both workers and materials.

- Provides stable lifting even with long, flexible rebar bundles.

- Reduces the chance of load swinging or tipping.

- Built-in safety systems like limit switches and overload protection safeguard personnel and materials.

Durability

Outdoor yards expose equipment to sun, rain, dust, and continuous use. The crane's double girder construction and weather-resistant components ensure long-lasting performance.

- Double girder design increases structural strength and lifespan.

- Corrosion-resistant coatings protect the steel structure from harsh conditions.

- Handles continuous operation in high-volume yards without excessive wear.

Operational Flexibility

No two storage yards are alike. This crane can be customized for various spans, lifting heights, and yard layouts, making it adaptable to a wide range of operational needs.

- Can accommodate different crane runway lengths.

- Lifting height can be adjusted based on rebar stack sizes.

- Suitable for a variety of steel products beyond rebars, increasing versatility.

Main Dimensions of Steel Rebar Bundles for Tailored Gantry Cranes

When planning a 35 Ton/10 Ton yard gantry crane for steel rebar handling, knowing the exact dimensions and weight of your bundles is crucial. The crane must safely lift, move, and stack them without overloading or instability.

Bundle Length

Rebar bundles can vary widely in length depending on the project and storage yard. Typical lengths are:

- Standard lengths: 6 m, 9 m, 12 m

- Custom lengths may reach up to 18 m for long reinforcement bars

Practical Note: The crane span and trolley travel must accommodate the longest bundle to avoid collisions or swinging.

Bundle Width and Height (Cross-Section)

Bundles are usually stacked with a certain number of rebars tied together. Knowing width and height helps plan lifting stability and hook design:

- Width: 0.15–0.5 m depending on bar diameter and quantity per bundle

- Height: 0.15–0.5 m depending on stacking pattern

Practical Note: Wider bundles may require specialized spreader bars or clamps to ensure balanced lifting.

Bundle Weight

Weight is a critical factor for selecting main and auxiliary hooks and calculating safety margins:

- Small bundles: 0.5–5 tons

- Standard large bundles: 5–20 tons

- Extra-large bundles for industrial yards: up to 30–35 tons

Practical Note: Always plan a 10–20% safety margin above maximum bundle weight to avoid overloading the crane.

Bundle Shape and Tie Method

- Most rebar bundles are rectangular or square in cross-section.

- Tied with wire, plastic straps, or bands; some may include lifting hooks or looped bands.

Practical Note: The crane's hook or lifting attachment should match the bundle tie method to prevent slipping or damage.

Stack Considerations

- Single-layer vs. multi-layer stacks affect lifting height requirements.

- Stacking orientation may require crane adjustments for trolley travel or hook clearance.

Practical Note: Measure the maximum stacked height to set the crane's lifting height and ensure safe operation.

Quick Reference Table for Tailored Gantry Crane Design

| Parameter | Typical Range | Practical Note |

|---|---|---|

| Length | 6–18 m | Determine crane span and travel path |

| Width | 0.15–0.5 m | Check hook or clamp compatibility |

| Height | 0.15–0.5 m | Ensure balanced lifting |

| Weight | 0.5–35 tons | Plan main/aux hook selection and safety margin |

| Shape | Rectangular/Square | Consider custom clamps or spreader bars |

| Tie Method | Wire/Plastic/Band | Ensure lifting device compatibility |

| Stack Height | 1–3 layers | Define crane lifting height and hook clearance |

Practical Buying Considerations for Steel Rebar Handling

Purchasing a 35 Ton/10 Ton yard gantry crane is a major investment. Choosing the right crane ensures safe, efficient, and reliable handling of steel rebar bundles for years to come.

Verify Maximum Load Requirements and Safety Margins

Rebar bundles can vary in weight depending on size, grade, or packing density. Always plan for the heaviest possible load plus a safety margin.

- Calculate the maximum weight of a single bundle and add 10–20% safety margin.

- Consider scenarios where both main and auxiliary hooks might lift simultaneously.

- Ensure the crane's rated capacity can safely handle peak loads to avoid accidents or downtime.

Assess Yard Dimensions for Optimal Crane Span and Lifting Height

The crane must fit the yard layout while reaching over high stacks and wide trucks.

- Measure total runway length and yard width to select the proper crane span.

- Determine tallest bundle stacks to define required lifting height.

- Check for obstacles such as buildings, poles, or nearby cranes that could interfere with operations.

Determine Frequency of Use to Choose Appropriate Lifting Speeds and Hoist Types

Frequency of lifting affects hoist type, speed, and travel mechanism.

- Select a hoist rated for your expected workload and duty cycle.

- Consider adjustable lifting speeds for different bundle sizes or weights.

- Evaluate trolley and crane travel speeds to ensure smooth, safe, and efficient movement of long bundles.

Confirm Power Supply and Electrical Compatibility

Matching the crane's electrical requirements to your yard avoids operational issues and equipment damage.

- Verify voltage, frequency, and phase compatibility with your power source.

- Plan ahead for possible yard expansions or higher electrical loads in the future.

- Decide on control type: cabin, remote, or pendant, based on operator convenience and yard layout.

Consider Supplier Support, After-Sales Service, and Warranty Coverage

A crane is a long-term investment. Reliable supplier support ensures minimal downtime and access to spare parts and expertise.

- Check warranty length and coverage, especially for high-use components.

- Ensure local or regional service support for fast response times.

- Ask about preventive maintenance programs to extend crane life and maintain safe rebar handling.

Request a Quote: Steel Rebar Handling Gantry Crane

If you're looking to improve efficiency and safety in your steel rebar storage yard, a 35 Ton/10 Ton double girder yard gantry crane could be the perfect solution. To help us provide a customized quotation, please share the following information:

Yard and Operation Details

- Yard dimensions (length, width, and height of storage stacks)

- Typical bundle sizes (length, width, height)

- Maximum bundle weight ,

- Daily or weekly lifting frequency

Crane Requirements

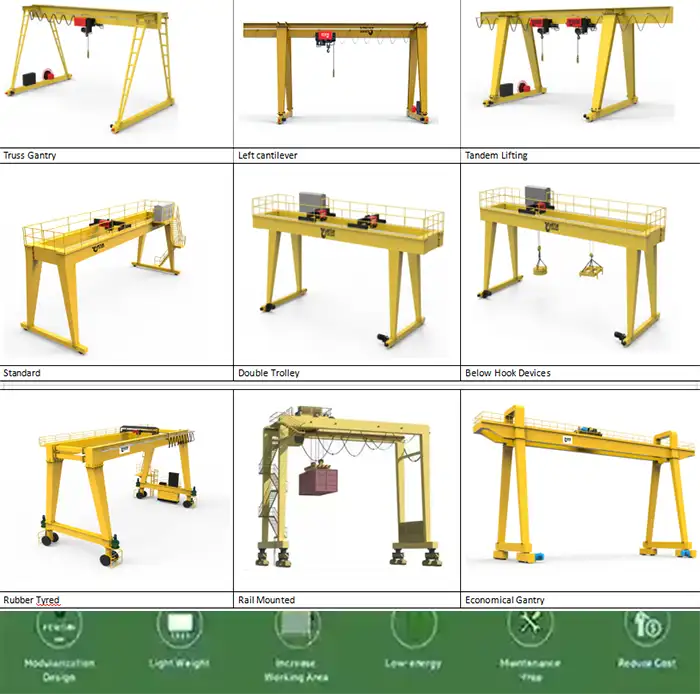

- Crane Types : Gantry Crane, left cantilever, right cantilever,

- Required main hook capacity (e.g., 35 Ton)

- Required auxiliary hook capacity (e.g., 10 Ton)

- Span and lifting height preferences

- Crane travelling length:

- Preferred control type (cabin, remote, pendant)

- Outdoor or indoor operation

Additional Information

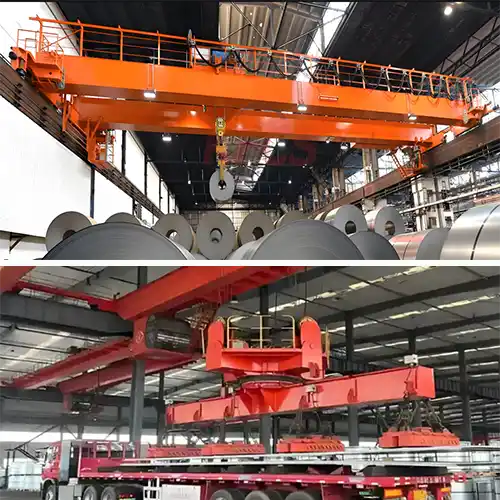

- Any special handling needs (below hook devices, mangetic spreader bars, clamps or other )

- Power supply details (voltage, phase, frequency)

- Deadline for installation or delivery

Tailored 35 ton gantry cranes are provided based on your lifting requirements and application conditions. Types of gantry cranes for sale from 3 ton to 550 ton.Contact us to get your tailored design.

For steel rebar storage yards, a 35 Ton/10 Ton double girder yard gantry crane with main and auxiliary hooks is a highly practical solution. It's not just about lifting heavy loads; it's about making daily operations smoother, safer, and more organized.

These cranes allow operators to handle large and small bundles at the same time, improving productivity and reducing the risk of accidents. Their sturdy double girder design ensures stability and long-term durability, even under harsh outdoor conditions.

Investing in the right crane doesn't just meet today's lifting needs—it sets up your yard for efficient, reliable, and well-managed material handling in the future.

- Handles heavy and long steel products safely and efficiently.

- Improves overall yard workflow and reduces downtime.

- Provides a durable, long-lasting solution for high-volume steel handling.

Send Us An Inquiry to Get Tailored Gantry Cranes Now

If you're ready to improve your steel rebar handling operations, contact a trusted crane manufacturer or supplier today. A customized 35 Ton/10 Ton yard gantry crane can be designed to fit your yard layout, lifting requirements, and operational needs.

- Request a personalized quotation tailored to your steel storage yard.

- Discuss options for spans, lifting heights, and dual hook configurations.

- Ensure professional support for installation, maintenance, and long-term service.

With the right crane, moving steel rebars becomes safer, faster, and more efficient—making your storage yard operations smoother from day one.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch