Your Trusted Overhead Ceiling Crane Manufacturer & Supplier

Ceiling Crane, Ceiling Mounted Crane & Ceiling Crane System

Ceiling crane for sale 500kg -10 ton. All types of ceiling mounted crane designs, ceiling mounted bridge crane, workstation crane,monorail cranes for you.

A ceiling crane is a general term that encompasses any type of crane system that is mounted or attached to the ceiling or overhead structure of a building or workspace. These cranes are used for material handling and lifting tasks and offer various configurations and capabilities to suit different applications.

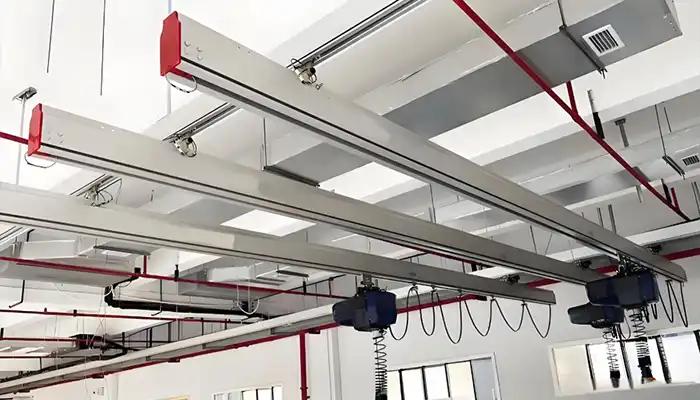

A ceiling-mounted crane specifically refers to a crane system that is attached to the ceiling or overhead structure without the need for support columns on the floor. It operates on a track or rail system mounted on the ceiling, allowing the hoist and trolley to move along a specified path. This type of crane is commonly used in industrial settings, manufacturing facilities, and warehouses where floor space needs to be kept clear for other operations.

Ceiling-Mounted Bridge Crane:

This type of crane consists of a bridge or horizontal beam that spans the width of the working area, supported by end trucks that run along tracks attached to the ceiling. Bridge cranes are available in both single and double girder configurations, offering different load capacities and spans.

Ceiling-mounted bridge cranes, especially those with double girder configurations, are capable of handling heavy loads and can cover large work areas. They are commonly used in heavy manufacturing, construction, and other industries that require substantial lifting capacities.

Features:

- High load capacity and long spans available in double girder configuration.

- Smooth and precise movement along the bridge.

- Can cover a large area, providing flexibility in material handling.

Advantages:

- Efficient use of floor space as no support columns are required.

- Suitable for heavy-duty lifting applications.

- Ideal for moving loads across a wide workspace.

Limitations:

- May require significant initial investment for installation.

- Limited mobility within the fixed path of the bridge.

Main typs of ceiling mounted overhead crane system

A ceiling crane system refers to the complete setup of a ceiling-mounted crane, including the supporting structure, track or rail system, hoist, trolley, and any additional components required for safe and efficient material handling. The following are the main types of ceiling mounted crane systems are presented for your reference. If you have any need, please feel free to contact us to get your ceiling mounted cranes

Single Girder Ceiling Mounted Bridge Crane:

- This type of ceiling-mounted bridge crane features a single horizontal beam (girder) that spans the width of the workspace.

- It is designed for lighter to moderate lifting tasks and is often used in manufacturing, workshops, and warehouses.

- Single girder cranes are cost-effective and versatile solutions for various material handling needs.

Double Girder Ceiling Mounted Bridge Cranes:

- Double girder ceiling-mounted bridge cranes have two horizontal beams (girders) that provide increased load capacity and stability.

- They are suitable for handling heavier loads and are commonly found in heavy manufacturing, steel mills, and other industrial settings requiring high lifting capacity.

European Style Ceiling Mounted Bridge Cranes:

- European style ceiling-mounted bridge cranes are known for their advanced design, precision, and reliability.

- They often feature modular components and advanced safety features, complying with European crane standards and regulations.

- These cranes are used in a wide range of industries and are recognized for their high-quality engineering.

Chinese Style Ceiling Mounted Bridge Cranes:

- Chinese style ceiling-mounted bridge cranes are typically manufactured in China and designed to meet various industrial needs.

- They can vary in design and quality, and their features may differ based on the manufacturer.

- These cranes are often cost-effective options for industries looking for budget-friendly material handling solutions.

The choice between single and double girder cranes depends on the lifting capacity required for a specific application. European style and Chinese style ceiling-mounted bridge cranes may differ in terms of design, engineering standards, and quality, so it's essential to consider factors such as load capacity, safety requirements, and budget when selecting the appropriate crane type for a particular project. Consulting with crane experts or suppliers can help determine the best fit for your specific needs.

Ceiling-Mounted Monorail Crane:

Monorail cranes use a single track or rail mounted on the ceiling to support the hoist and trolley assembly. They are best suited for linear material movement along a fixed path and are commonly used in assembly lines and other repetitive production processes.

For applications that involve repetitive linear material movement along a fixed path, such as assembly lines or paint booths, monorail cranes are a practical choice. They offer smooth and efficient material transport along a single track, reducing the need for manual handling and increasing productivity.

Ceiling-Mounted Monorail Crane:

Features:

- Single track allows for linear movement along a fixed path.

- Can be installed in various configurations, including single or multiple tracks.

Advantages:

- Maximizes floor space utilization.

- Ideal for repetitive material movement in a straight line.

- Can be integrated into existing production processes.

Limitations:

- Limited coverage area compared to bridge cranes.

- Not suitable for moving loads over larger distances.

Straight Monorail Ceiling Mounted Crane and Curved Monorail Ceiling Mounted Crane are specific types of ceiling-mounted cranes that are characterized by the shape of the monorail track they use for material handling. Here's a brief explanation of each:

Straight Monorail Ceiling Mounted Crane:

- A Straight Monorail Ceiling Mounted Crane utilizes a straight, linear monorail track that is attached to the ceiling structure.

- This type of crane is designed for linear material handling tasks, where loads need to move in a straight line within a specific work area.

- Straight monorail cranes are commonly used for applications such as assembly lines, production processes, and moving materials from one point to another in a straight path.

Curved Monorail Ceiling Mounted Crane:

- A Curved Monorail Ceiling Mounted Crane is equipped with a monorail track that has curved sections.

- These cranes are designed for applications where loads need to be moved along a curved or circular path within a workspace.

- Curved monorail cranes are particularly useful for material handling tasks that involve maneuvering loads around obstacles or following specific production line layouts.

The choice between a straight monorail crane and a curved monorail crane depends on the specific layout and material handling needs of the workspace. Straight monorail cranes are suitable for linear tasks, while curved monorail cranes provide the flexibility to navigate around obstacles or follow curved production processes. Both types of cranes are commonly used in manufacturing and assembly applications to improve efficiency and streamline material handling operations.

Ceiling-mounted Workstation Crane

A ceiling-mounted workstation crane, often referred to as a workstation bridge crane or monorail crane, is a type of material handling equipment designed to facilitate the movement of loads within a specific work area or workstation. Unlike larger overhead cranes that span a wide area, workstation cranes are intended for localized lifting and transport tasks. They are typically mounted on the ceiling or overhead structure of a building and consist of a single bridge or monorail track.

Rigid workstation ceiling mounted crane and Flexible workstation ceiling mounted crane. These terms describe the flexibility and adaptability of these cranes for different material handling needs. Let's explore these, as well as other types of ceiling-mounted workstation cranes:

Rigid Workstation Ceiling Mounted Crane:

- A Rigid Workstation Ceiling Mounted Crane is designed for fixed or repetitive material handling tasks within a defined workspace.

- It offers precise load positioning and stability, making it suitable for applications where loads need to be moved with accuracy and minimal sway.

- These cranes are often used in manufacturing, assembly lines, and other environments with predictable material handling requirements.

Flexible Workstation Ceiling Mounted Crane:

- A Flexible Workstation Ceiling Mounted Crane is designed to provide versatility and adaptability in material handling.

- It allows for easy repositioning of the hoist and load within the workspace, making it suitable for applications with changing or varied handling needs.

- Flexible workstation cranes are commonly used in maintenance areas, job shops, and facilities with evolving production setups.

Light Duty Workstation Ceiling Mounted Crane and Heavy Duty Workstation Ceiling Mounted Crane are two distinct types of ceiling-mounted workstation cranes designed to handle varying load capacities and material handling requirements. Here's an overview of each type:

Light Duty Workstation Ceiling Mounted Crane( single girder ) :

- Light-duty workstation ceiling mounted cranes are designed for handling smaller loads and are suitable for applications where precision and flexibility are key.

- They are commonly used in settings where materials are moved frequently, but the loads are relatively light.

- Light-duty cranes are ideal for tasks such as assembly work, machine loading, and moving lightweight materials within a workspace.

- They offer easy maneuverability, precise load positioning, and reduced operator fatigue.

Heavy Duty Workstation Ceiling Mounted Crane ( double girder ) :

- Heavy-duty workstation ceiling mounted cranes are engineered to handle larger and heavier loads, making them suitable for industrial applications with demanding material handling requirements.

- They are commonly used in environments where loads can range from moderate to very heavy.

- Heavy-duty cranes are often employed in manufacturing facilities, warehouses, and workshops for tasks like moving heavy machinery components, loading/unloading materials, and handling bulk items.

- These cranes provide the strength and stability needed to safely lift and transport heavy objects within a workspace.

Here are some key features and characteristics of ceiling-mounted workstation cranes:

- 1. Single Bridge or Monorail: Workstation cranes typically have a single horizontal bridge or monorail track that runs parallel to the work area. This track allows for the movement of the hoist and load along a fixed path.

- 2. Precise Positioning: These cranes are designed for precision and control, making them ideal for tasks that require accurate load placement.

- 3. Light to Moderate Capacity: Workstation cranes are suitable for lifting and moving loads ranging from a few hundred pounds to a few tons, depending on the specific model and configuration.

- 4. Variety of Hoist Options: They can be equipped with various types of hoists, including manual, electric, or pneumatic hoists, depending on the lifting requirements and operator preferences.

- 5. Easy Installation: Workstation cranes are often easier to install than larger overhead cranes, making them a cost-effective solution for localized material handling needs.

- 6. Modular Design: Many workstation crane systems have a modular design, allowing for easy expansion or reconfiguration to adapt to changing workflow requirements.

- 7. Enhanced Ergonomics: These cranes are designed to improve worker ergonomics and reduce the risk of injuries associated with manual lifting and handling.

Workstation cranes are commonly used in manufacturing, assembly lines, maintenance and repair areas, and other workstations where precise and efficient load movement is required within a limited space. They are an excellent solution for enhancing productivity and workplace safety in these environments.

The choice between a light-duty and heavy-duty workstation ceiling-mounted crane depends on the specific load capacities and material handling needs of the workspace. Selecting the appropriate crane type ensures efficient and safe material handling operations, reduces the risk of accidents, and maximizes productivity in the given environment.

All in all, , the choice of ceiling-mounted crane system depends on the specific lifting requirements, available space, and budget considerations of the application. Each type of ceiling-mounted crane offers unique features, advantages, and limitations, making them suitable for different material handling scenarios.

Your Trusted Overhead Ceiling Crane Manufacturer & Supplier