Who Buys Crane Kits in Bekasi? Fabricators, EPCs & OEMs

Introduction: Bekasi’s Industrial Landscape

Bekasi, just east of Jakarta, has grown into one of Indonesia’s most active industrial regions. From steel workshops to machinery factories, the city hosts a variety of operations that rely heavily on material handling equipment.

For suppliers of overhead cranes and crane kits, Bekasi is not just a market—it’s a hub of informed and practical buyers. These buyers are hands-on and often have specific requirements for their lifting equipment. Understanding these requirements is essential for suppliers who want to provide the right solutions.

Why this matters:

- Buyers in Bekasi often prefer crane kits over fully assembled cranes due to cost and flexibility.

- Knowing who purchases these kits helps suppliers align production, logistics, and support.

- Identifying buyer types—fabricators, EPCs, or OEMs—clarifies market strategy and communication.

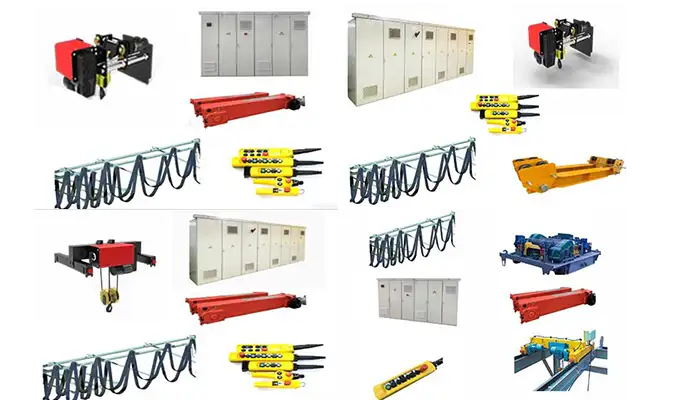

Crane Kits

A crane kit is a set of crane components delivered without the main girders. Typically, it includes hoists, trolleys, end trucks, wheels, electrical controls, panels, and supporting hardware. These kits are designed for local assembly, allowing buyers to fabricate or adapt the main steel structure according to their workshop or project requirements.

Advantages of Crane Kits – Cost Efficiency

- Reduces shipping costs compared to delivering fully assembled cranes.

- Buyers can fabricate steel structures locally, saving on imported materials.

- Eliminates unnecessary expenses for parts that can be produced in-house.

Advantages of Crane Kits – Flexibility in Fabrication

- Allows buyers to adjust spans, lifting heights, and load capacities.

- Supports future expansions or layout changes in the workshop.

- Enables modifications without compromising standardized crane components.

Advantages of Crane Kits – Simplified Logistics and Installation

- Smaller, modular parts are easier to transport and handle on-site.

- Reduces dependency on heavy-lift equipment during delivery.

- On-site assembly can be scheduled around production, minimizing downtime.

Crane kits offer practical, cost-effective, and flexible solutions for buyers in Bekasi. Suppliers who understand these advantages can better cater to local needs, improve lead times, and provide tailored support.

Buyer Profiles in Bekasi

Bekasi's industrial ecosystem includes a variety of buyers for crane kits. The main groups are fabricators, EPC companies, and OEMs. Each has different motivations, technical requirements, and purchasing patterns. Understanding these profiles helps suppliers target their solutions more effectively.

Fabricators

Who they are:

Fabricators are local workshops or factories capable of producing steel structures and assembling machinery. In Bekasi, many fabricators focus on steel processing, machinery manufacturing, and small-to-medium industrial projects.

Why they buy crane kits:

- Local steel fabrication: Fabricators can produce the main girders or supporting structures themselves, reducing costs and shipping requirements.

- Customization: Kits allow them to adjust spans, lifting capacities, and designs according to client-specific needs.

- Cost savings: By handling steel fabrication locally, they minimize expenses on logistics, import taxes, and pre-assembled crane transport.

Typical industries served:

- Steel mills and workshops

- Machinery manufacturing

- Automotive parts factories

EPC (Engineering, Procurement, Construction) Companies

Who they are:

EPC companies manage complete industrial projects, including design, procurement, and on-site construction. In Bekasi and surrounding regions, EPCs often oversee new factories, warehouses, and production facilities.

Motivations for buying crane kits:

- Project integration: Kits are easier to incorporate into larger construction or renovation projects.

- Reduced lead times: Pre-packaged components allow for faster on-site assembly compared to fully built cranes.

- Scalability: EPCs can deploy multiple cranes across different project sites with consistent components.

Where crane kits are preferred:

- New industrial plants requiring multiple overhead cranes

- Expansion projects in workshops or steel plants

- Temporary or modular setups where flexibility is needed

OEMs (Original Equipment Manufacturers)

Who they are:

OEMs produce industrial machinery or equipment and may include overhead cranes as part of their solutions for clients. They often supply standardized systems to factories and production lines.

Why they choose crane kits:

- Standardized components: Ensures consistent quality across multiple machines or facilities.

- Faster order fulfillment: Kits allow OEMs to respond quickly to client requests without waiting for full crane fabrication.

- Simplified maintenance: Using standard parts simplifies spare part supply and long-term servicing.

Industries most served:

- Heavy machinery manufacturers

- Automotive assembly lines

- Metalworking and fabrication plants

Fabricators, EPCs, and OEMs in Bekasi each have unique reasons to buy crane kits. Suppliers who understand their specific needs—from local steel fabrication to large-scale project integration—can tailor products and services to win this market.

Comparing Buyer Needs and Priorities

While fabricators, EPCs, and OEMs all purchase crane kits in Bekasi, their priorities and purchasing patterns differ significantly. Understanding these differences helps suppliers tailor their offers, support, and delivery schedules.

Key differences between buyer types:

| Buyer Type | Key Motivations | Typical Purchase Volume | Technical Requirements |

|---|---|---|---|

| Fabricators | Customization, cost efficiency | Medium to large | Ability to fabricate steel locally |

| EPCs | Project integration, speed | Large | Standardized, ready-to-assemble components |

| OEMs | Consistency, aftermarket support | Medium | Compliance with quality standards and certifications |

Practical insights:

- Fabricators: Value flexibility. They often buy medium-to-large volumes, but their main focus is on kits that can be adapted to specific client projects. They prefer suppliers who can provide modular components suitable for local fabrication.

- EPCs: Prioritize speed and integration. They typically handle large projects, requiring multiple cranes or kits for different sites. Kits must be standardized to ensure fast assembly and consistent performance.

- OEMs: Focus on consistency and long-term service. They usually purchase medium volumes, but the quality of components and compliance with industry standards are critical. They also look for kits that simplify maintenance and spare part management.

Each buyer type in Bekasi has distinct priorities, which influence the type of crane kit they purchase, the volume, and the technical specifications they require. Suppliers who clearly understand these differences can better align their product offerings, improve customer satisfaction, and reduce delivery or installation issues.

Market Trends and Insights

Bekasi's industrial sector continues to expand, and with it, the demand for overhead cranes and crane kits is steadily growing. Suppliers looking to enter or expand in this market need to understand the trends shaping buyer behavior.

Growth of Crane Kit Demand

- More factories in Bekasi are choosing crane kits over fully assembled cranes due to cost savings and flexibility.

- Local workshops and fabricators prefer kits because they can adapt the steel structures to fit their specific layouts and production needs.

- Industries such as steel processing, automotive parts, and machinery manufacturing are driving consistent demand for modular crane solutions.

Influence of Local Fabrication Capacity

- Bekasi has a strong network of skilled fabricators and steel workshops, which makes crane kits particularly attractive.

- Buyers who can produce or modify the main girders locally value kits with standardized components, allowing them to maintain quality while keeping costs under control.

- Suppliers offering detailed technical guidance and modular components have an advantage because they support local assembly without requiring specialized fabrication tools.

Role of Cost-Conscious and Practical Buyers

- Buyers in Bekasi are highly practical and cost-conscious, often comparing the total project cost rather than just the unit price of a crane.

- They prefer suppliers who can provide flexible solutions, reliable delivery, and easy-to-install kits.

- This focus on practicality encourages suppliers to offer pre-tested components, clear documentation, and optional customization, ensuring the crane kits meet local industrial needs.

The Bekasi market favors suppliers who understand local fabrication capabilities, focus on cost-effective solutions, and provide flexible crane kits that align with practical industrial requirements. Meeting these needs is key to building long-term partnerships in the region.

Supplier Recommendations

Suppliers aiming to succeed in Bekasi's crane kit market need a clear strategy that addresses the specific needs of fabricators, EPCs, and OEMs. A one-size-fits-all approach rarely works in this region.

Targeting Each Buyer Type Effectively

- Offer modular crane kits that allow local steel structure fabrication.

- Provide technical guidance for customization of spans, lifting capacities, and trolley configurations.

- Highlight cost advantages of kits compared to fully assembled cranes.

- Focus on standardized components that are easy to integrate into large projects.

- Ensure fast delivery and clear assembly instructions to meet tight project timelines.

- Provide scalable solutions for multiple project sites.

- Emphasize quality standards and certifications, such as CE or ISO, to meet client expectations.

- Offer kits that simplify maintenance and spare parts management.

- Ensure consistency across batches for multiple production lines or facilities.

Highlight Certification, Customization, and Local Support

- Certification: Providing CE, ISO, or other recognized certifications builds trust and assures buyers of compliance with safety and quality standards.

- Customization Options: Allow buyers to adjust crane spans, lifting capacities, or hoist types to suit specific workshop layouts.

- Local Support: Offering on-site assembly guidance, technical training, or local after-sales support strengthens relationships with practical, cost-conscious buyers in Bekasi.

Examples of Successful Partnerships

- Local steel workshops in Bekasi have successfully assembled 20–32 ton overhead cranes using crane kits from Chinese suppliers, reducing lead time by several weeks.

- EPC firms deploying multiple crane kits in new industrial plants have reported faster project completion due to modular components and standardized assembly instructions.

- OEMs supplying automotive and metalworking equipment have benefited from consistent crane quality and simplified spare part management, improving client satisfaction.

Suppliers who understand each buyer type's priorities, provide certified and customizable solutions, and support local assembly and maintenance can capture a strong position in Bekasi's crane kit market. Tailoring the approach for fabricators, EPCs, and OEMs is key to long-term success.

Supplier Recommendations

For suppliers looking to succeed in Bekasi's crane kit market, understanding the priorities of different buyer types is essential. Fabricators, EPCs, and OEMs all have distinct needs, and offering a one-size-fits-all solution is rarely effective. A tailored approach improves customer satisfaction, reduces lead times, and builds long-term partnerships.

Targeting Each Buyer Type Effectively

- Provide modular crane kits that allow local fabrication of steel structures.

- Support customization of crane spans, lifting capacities, and hoist configurations.

- Highlight cost savings from local assembly compared to fully assembled cranes.

- Offer standardized components suitable for fast integration into larger industrial projects.

- Ensure quick delivery and clear assembly instructions to meet project deadlines.

- Supply scalable solutions for multiple sites or project phases.

- Focus on consistency and compliance, with CE, ISO, or other recognized certifications.

- Provide kits that simplify maintenance and spare part management.

- Maintain uniform quality across batches to support multiple client facilities.

Emphasizing Certification, Customization, and Local Support

- Certification: CE, ISO, or third-party inspection assures buyers of safety and quality compliance.

- Customization Options: Adapt crane dimensions, hoist types, and controls to local workshop or plant layouts.

- Local Support: On-site guidance, technical training, and after-sales service build trust with practical, cost-conscious buyers.

Examples of Successful Partnerships in Bekasi

- Local steel workshops assembled 20–32 ton overhead cranes using crane kits from Chinese suppliers, reducing lead time by weeks.

- EPC companies deploying multiple crane kits in new industrial plants achieved faster project completion due to modular components and clear assembly instructions.

- OEMs supplying automotive and metalworking equipment improved client satisfaction through consistent crane quality and simplified spare parts management.

Suppliers who understand the needs of each buyer type, provide certified and customizable kits, and offer practical local support are best positioned to succeed in Bekasi. Tailored solutions for fabricators, EPCs, and OEMs ensure efficiency, reliability, and long-term partnerships.

Conclusion

Bekasi has become a thriving hub for industrial activity, and with it, the demand for crane kits continues to grow. Buyers in this market are not a single group but a mix of fabricators, EPC companies, and OEMs, each with distinct priorities and purchasing patterns. Fabricators value flexibility and cost efficiency, EPCs focus on project integration and speed, while OEMs prioritize consistency and long-term maintenance support.

For suppliers looking to succeed in Bekasi, the key takeaway is clear: understand your buyer profiles and their specific needs. This means knowing what type of crane kit suits each buyer, the scale of their projects, and the level of customization or support they require. By aligning products and services with these practical requirements, suppliers can build strong partnerships, improve customer satisfaction, and secure a competitive position in the local crane kit market.

Success in Bekasi’s crane kit market is about matching solutions to buyers’ real-world needs, offering certified, customizable, and locally supported crane kits that work in practice, not just on paper.