Smart Selection Guide: Choosing the Right Overhead Crane Busbar

Smart Selection Guide: How to Choose the Right Power Line or Busbar for Your Overhead Crane System

Introduction

Overhead cranes need a reliable power supply to work smoothly. The power system usually includes cables, busbars, or conductor rails that deliver electricity to the crane motors and controls. Choosing the right power line or busbar is key to keeping the crane running safely and efficiently.

Using the wrong type or size can cause problems. It may lead to overheating, frequent breakdowns, or even electrical accidents. On the other hand, a good choice improves performance and reduces maintenance needs.

Here's why selecting the correct power line or busbar matters:

- Safety: Proper sizing prevents overheating and electrical fires. It also ensures stable power without voltage drops that can damage equipment.

- Efficiency: The right system delivers power with minimal losses, saving energy and reducing operating costs.

- Maintenance: A well-chosen power line reduces wear and tear. It lowers downtime and maintenance expenses over time.

In short, the power supply is the lifeline of your overhead crane. Taking the time to choose the correct power line or busbar pays off in smoother, safer crane operation and lower costs.

Overhead Crane Power Requirements

To select the right power line or busbar, you first need to understand how much power your crane actually uses. Overhead cranes have several electrical parts that draw power, and knowing these helps you calculate the total load correctly.

Overview of Crane Electrical Components and Power Consumption

An overhead crane mainly relies on:

- Motors: These drive the crane's movements—lifting, lowering, traveling, and trolley movement. Motors consume the largest share of power.

- Hoists: The hoisting motor lifts the load and needs strong, steady power to handle heavy weights.

- Control Systems: These include the electrical controls, brakes, and safety devices. Though they use less power, they require stable voltage to function properly.

Each component's power use varies depending on the crane's size, capacity, and speed.

Role of Motors, Hoists, and Control Systems

- Motors: They start and stop frequently, sometimes under heavy load. This causes current spikes, so the power supply must handle these peaks without overheating or voltage drops.

- Hoists: The hoisting motor often has the highest power demand. It can draw several times its rated current when lifting heavy loads quickly.

- Control Systems: These need clean, reliable power for smooth operation. Voltage fluctuations can cause errors or damage sensitive parts.

How Crane Operation Conditions Affect Power Demand

Not all cranes work the same way. The power demand changes with:

- Working Frequency: Cranes used constantly or for heavy lifting need more robust power systems. For example, a steel mill crane running all day draws more power than a warehouse crane used occasionally.

- Load Weight: Heavier loads increase motor current and heat generation, requiring a larger conductor size or busbar capacity.

- Duty Cycle: How often the crane operates and how long it runs affect average power needs. Intermittent use means lower average current, while continuous use needs steady, high capacity.

- Environmental Conditions: High temperatures or dusty, corrosive environments can reduce the power line's capacity, requiring derating or special insulation.

In short, understanding the crane's power components and how they operate helps you pick a power line or busbar that can safely and efficiently meet those demands. This avoids surprises like overheating, unexpected shutdowns, or costly repairs later.

4 types of overhead crane power line and busbar for your selection

Key Factors in Power Line / Busbar Selection

Choosing the right power line or busbar isn't just about picking the biggest one. Several important factors come into play to make sure the system works safely and reliably.

Rated Current Capacity and Load Calculation

The power line or busbar must carry all the current your crane needs. This means you have to:

- Calculate the total current based on motor power and operating conditions.

- Include a safety margin to handle start-up surges and unexpected loads.

- Choose a conductor size that can handle this current continuously without overheating.

If the conductor is too small, it can cause voltage drops and heat build-up, leading to failures.

Impact of Crane Operating Conditions and Duty Cycles

How the crane is used affects the choice:

- Cranes running all day under heavy loads need power lines with higher capacity.

- For cranes used occasionally or with light loads, a smaller capacity might work fine.

- Duty cycle (the percentage of time the crane is running) helps determine the average load on the power line.

Taking these factors into account avoids oversizing or undersizing the system.

Environmental Factors

The environment around the crane can affect power line performance:

- Temperature: Higher ambient temperatures reduce the current-carrying capacity of conductors, so you may need to choose a larger size or special materials.

- Dust and moisture: These can cause insulation damage or corrosion, requiring sealed or coated busbars.

- Corrosive atmospheres: Chemical plants or coastal areas need corrosion-resistant materials.

Always check environmental conditions before finalizing the choice.

Mechanical Installation Constraints

Physical space and installation needs also matter:

- How much room is available for running the power line or installing the busbar?

- Is it easy to access for maintenance and inspection?

- What is the length of the crane runway? Longer runs may require larger conductors to reduce voltage drop.

- Are there any obstacles or safety clearances to consider?

Considering these practical points helps avoid installation headaches and future maintenance problems.

In summary, selecting a power line or busbar is a balance. You need the right current capacity, consider how the crane is used, adapt to the environment, and fit the mechanical space. This careful approach keeps the crane safe, efficient, and trouble-free.

Calculating Electrical Load

Before choosing your power line or busbar, you need to figure out how much electrical load the crane system will draw. This step is critical for a safe and efficient setup.

Determining Total Power (kW) of the Crane System

Start by adding up the total power (in kilowatts) of all electrical equipment on the crane, mainly:

- Motors for lifting, traveling, and trolley movement

- Control system components

This total power, called PG, represents the full load your power supply must handle.

Applying Operating Condition Factors (fR) for Accurate Load Estimation

Not all cranes run at full power all the time. Operating conditions affect actual power use. So, multiply PG by an application factor fR to adjust for real working conditions:

- High-frequency, heavy-duty cranes (like steel mill or port cranes): fR = 0.75 to 0.80

- Normal cranes (such as warehouse or bridge cranes): fR = 0.65 to 0.75

- Intermittent-use cranes (maintenance or assembly line cranes): fR = 0.45 to 0.65

This factor accounts for the impact of load shocks, work frequency, and real usage patterns.

Using Simultaneous Operation Factor (Diversity Factor, fa) for Multiple Cranes

When several cranes share the same power line, they rarely run at full load all at once. Use the simultaneous operation factor fa to adjust the total power:

- Heavy machines and goliath cranes: fa = 0.8 to 0.85

- Container handling and port cranes: fa = 0.7 to 0.8

- Overhead cranes and electric hoists: fa = 0.6 to 0.7

- Warehouse cranes: fa = 0.5

Calculate total load for multiple cranes with:

PGK = fa × ∑PG

where ∑PG is the sum of each crane's adjusted power.

Example Calculation of Total Nominal Current

Suppose you have two overhead cranes:

- Crane A total power: 50 kW

- Crane B total power: 40 kW

Both are normal working conditions, so use fR = 0.7:

- Crane A adjusted power: 50 × 0.7 = 35 kW

- Crane B adjusted power: 40 × 0.7 = 28 kW

The cranes share the same power line. Use fa = 0.65 (typical for overhead cranes):

PGK = 0.65 × (35 + 28) = 0.65 × 63 = 40.95 kW

Convert to nominal current (I) based on system voltage (e.g., 400 V, three-phase):

I = PGK / (√3 × Voltage × Power Factor)

Assuming power factor is 0.85:

I = 40,950 W / (1.732 × 400 V × 0.85) ≈ 70 A

This 70 A is the nominal current your power line or busbar must support continuously.

Calculating electrical load like this ensures you pick the right conductor size and system. It avoids undersized power lines that cause voltage drops or overheating—and prevents overspending on oversized systems.

Selecting Conductor Size and Type

After you know how much current your crane system will draw, the next step is picking the right conductor size and type. This ensures your power supply runs smoothly and safely.

Matching Conductor Cross-Sectional Area with Calculated Load

The conductor's cross-sectional area determines how much current it can safely carry without overheating. When selecting:

- Use the calculated nominal current as the baseline.

- Refer to standard tables or manufacturer specs that list current capacities for different conductor sizes.

- Always add a safety margin—typically 20–30% above your expected current—to handle sudden load spikes or future expansions.

Too small a conductor risks overheating and fire hazards. Too large wastes money and space.

Material Considerations: Copper vs. Aluminum

Choosing between copper and aluminum conductors depends on several factors:

Copper:

- Higher conductivity, so smaller cross-section needed for the same current.

- Better mechanical strength and durability.

- More expensive upfront but often lower losses over time.

Aluminum:

- Lighter and cheaper than copper.

- Requires larger cross-section to carry the same current.

- More prone to oxidation; needs proper installation and maintenance.

- Good for longer runs where weight is a concern.

The choice often balances cost, weight, and maintenance considerations.

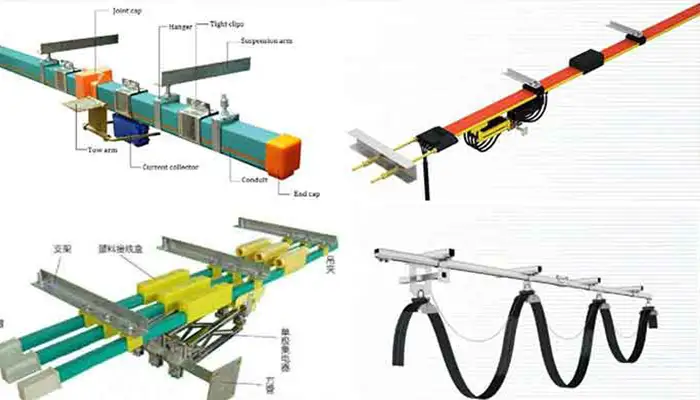

Choosing Between Different Busbar Systems

There are several busbar types to supply overhead cranes, each with pros and cons:

Rigid Busbars:

- Solid, usually copper or aluminum bars inside insulated housings.

- Durable and low resistance.

- Great for fixed installations with moderate to high current.

Flexible Busbars:

- Made from stacked thin strips or braided wires to allow bending.

- Useful where some flexibility or vibration absorption is needed.

- Slightly higher resistance than rigid busbars.

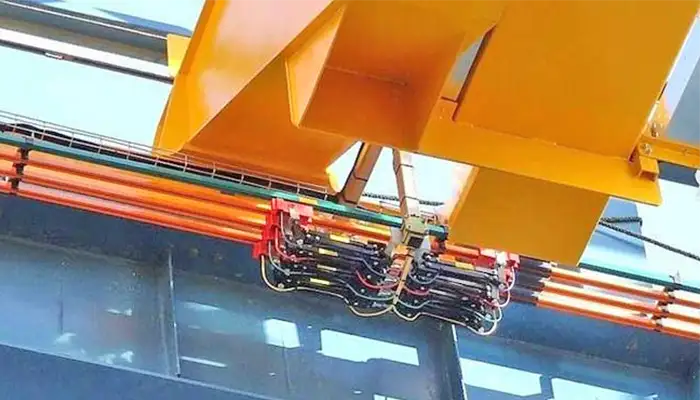

Conductor Rails (Sliding Rails):

- Typically insulated copper bars inside a track with sliding contacts.

- Allow for long travel distances and easy maintenance.

- Widely used in overhead crane power supplies.

Choosing the right system depends on crane type, travel distance, mechanical constraints, and budget.

Impact of Voltage Drop and Safety Margins

Voltage drop along the conductor line causes power loss and can reduce crane motor efficiency. To control this:

- Calculate expected voltage drop using length, conductor size, and load current.

- Keep voltage drop within allowable limits, often less than 5%.

- If voltage drop is too high, increase conductor size or use higher-quality materials.

Safety margins are critical. They help your system handle unexpected overloads, temperature rises, and aging effects without failure.The right conductor size and type match your load needs, material budget, and installation conditions. Careful selection avoids costly downtime, safety issues, and poor crane performance.

Environmental and Installation Considerations

Selecting the right power line or busbar isn't just about electrical specs. The environment and installation setup play a big role in ensuring safety and reliability.

Temperature Derating and Its Effect on Current Capacity

Ambient temperature affects how much current a conductor can carry safely:

- Most current ratings assume a standard temperature around 30–40°C.

- If the temperature is higher, the conductor heats up more easily, reducing its current capacity.

- To compensate, apply a temperature derating factor—a percentage reduction in allowable current.

- For example, at 50°C ambient, you might reduce current capacity by 10–20%.

- Always check manufacturer specs for exact derating values.

Failing to derate can cause overheating, insulation damage, or even fire hazards.

Protection Requirements (IP Ratings, Explosion-Proof Options)

Depending on the installation environment, your power supply system may need specific protections:

IP Ratings: Define how well the system is protected against dust and water ingress.

- For dusty or wet environments, use busbars or rails with at least IP54 or higher.

- For outdoor or washdown areas, look for IP65+ protection.

Explosion-Proof Options:

- In hazardous zones with flammable gases, dust, or vapors (like chemical plants or coal mines), use certified explosion-proof busbars and components.

- These are designed to prevent sparks or overheating that could ignite the atmosphere.

Selecting the correct protection class avoids equipment damage and ensures personnel safety.

Installation Methods and Maintenance Accessibility

How and where you install the power line matters:

Installation Space:

- Limited space might require compact or flexible busbar solutions.

- Check clearances for safe operation and maintenance.

Accessibility:

- Power lines should be easy to inspect and repair.

- Designs that allow quick access to components reduce downtime during maintenance.

Mechanical Support:

- Ensure proper mounting brackets, hangers, or enclosures to prevent sagging or vibration damage.

- Align the busbar carefully with the crane runway for smooth trolley travel.

Good installation planning reduces future headaches and extends equipment life.Environmental conditions and installation setup directly impact conductor performance and safety. Always factor in temperature derating, protection level, and easy maintenance access to keep your crane power system reliable and safe.

Standards and Compliance

Ensuring your overhead crane power supply meets all relevant standards and regulations is crucial for safety, performance, and legal reasons. Here's what you need to know:

Key Standards to Follow

- IEC (International Electrotechnical Commission):

Sets global benchmarks for electrical safety, conductor specs, insulation, and environmental factors for cranes. - NEC (National Electrical Code, USA):

Governs safe electrical installations in the U.S., including specific rules for overhead cranes. - ISO (International Organization for Standardization):

Focuses on quality management systems and safety standards in crane manufacturing and installation.

Important Certifications and Quality Marks

Look for products with these marks to ensure quality and compliance:

- CE Mark: Compliance with EU safety and environmental laws.

- UL Certification: Indicates products meet North American safety standards.

- CCC (China Compulsory Certificate): Required for electrical products in China.

- ISO 9001: Demonstrates adherence to international quality management processes.

Why Following Local Regulations and Manufacturer Guidelines Matters

- Local Regulations:

Regulations can vary widely. Always verify the electrical codes and safety laws in your country or region before installation. - Manufacturer Recommendations:

Stick to installation and maintenance instructions provided by manufacturers. This ensures proper operation, protects warranties, and prevents safety risks.

Practical Tips and Best Practices

When selecting and installing power lines or busbars for overhead cranes, a few practical tips can save time, money, and headaches down the road. Here are some best practices to keep in mind:

Plan for Future Expansion

- Expect growth: Your crane system might need to handle heavier loads or more cranes in the future.

- Oversize wisely: Choose conductors and busbars with some extra capacity to avoid costly upgrades later.

- Flexible design: Select systems that allow easy extension or modification without major downtime.

Check Compatibility with Existing Infrastructure

- Match equipment specs: Ensure new power lines or busbars fit the voltage, current, and mechanical setup of your current cranes.

- Consider control systems: Confirm compatibility with existing crane control panels and safety devices.

- Assess physical constraints: Review the available space, track length, and mounting points before finalizing selection.

Seek Professional Consultation and Proper Installation

- Get expert advice: Electrical engineers or crane specialists can help calculate loads, select materials, and design safe layouts.

- Follow standards: Proper installation is critical to meet regulations and avoid hazards.

- Use qualified installers: Experienced technicians will reduce installation errors and ensure long-term reliability.

Routine Inspection and Maintenance

- Regular checks: Inspect busbars and power lines for wear, corrosion, loose connections, or insulation damage.

- Cleanliness matters: Keep busbar tracks and conductor rails free of dust, debris, and moisture.

- Monitor performance: Watch for unusual voltage drops, overheating, or intermittent power that could signal problems.

- Scheduled maintenance: Follow manufacturer recommendations for lubrication, tightening, and replacement of worn parts.

Planning ahead, ensuring system compatibility, involving professionals, and committing to routine upkeep are the keys to a reliable and safe overhead crane power supply. This approach minimizes downtime and keeps your operation running smoothly.

Conclusion

Choosing the right power line or busbar for your overhead crane is a crucial decision. Let's recap the key points to keep in mind:

Key Takeaways

- Understand your crane's power needs: Calculate total load carefully, considering motors, control systems, and operating conditions.

- Consider environmental and installation factors: Temperature, dust, moisture, and space constraints all affect your choice.

- Select the correct conductor size and type: Match cross-sectional area to load, choose suitable materials, and consider voltage drop.

- Follow standards and regulations: Compliance ensures safety and avoids costly fines or shutdowns.

- Plan for the future: Build in flexibility and extra capacity to handle growth or changes.

- Maintain regularly: Routine checks and maintenance keep your system running smoothly.

Benefits of Proper Selection

- Improved safety: Correct components reduce risks of electrical faults or fires.

- Enhanced reliability: Properly sized and installed power lines minimize downtime and failures.

- Cost efficiency: Avoid overpaying for oversized systems or facing expensive retrofits later.

Take a methodical, informed approach when selecting your crane's power supply. Consult experts, use reliable data, and think long-term. This approach protects your investment and keeps your crane operating safely and efficiently for years to come.