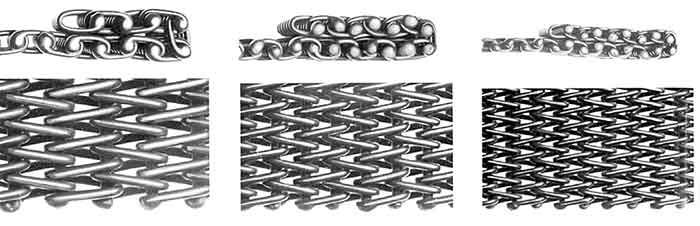

Wire Mesh, Chain Mesh Slings, Metal Wire Mesh Lifting Sling

Metal mesh slings are made of high-tensile carbon, alloy, or stainless steel wire mesh and are commonly used in metalworking and other industries where the loads are hot, abrasive, or have the potential to cut through softer synthetic slings. They're corrosion-resistant and built to last in demanding and harsh operational situations.

Metal mesh slings are flexible and have a large bearing surface that can be utilized to firmly hold an uneven load without stretching, and they can be employed in vertical, basket, or choker hitches. They're incredibly resistant to abrasion and cutting, but if there's even one broken wire in the sling, the whole thing has to be taken out of operation. Wire rope slings have a 5:1 Design Factor, which means the sling's breaking strength is five times more than the specified Working Load Limit. Despite the design aspect of metal mesh slings, the user should never exceed the stated Working Load Limit.

Applications and configurations

Metal mesh lifting slings are the most often used rigging slings in the metalworking industry. These slings are especially excellent for hoisting loads that are hot, abrasive, and/or tend to cut through softer synthetic slings due to the wire mesh's unique form and composition. Wire mesh slings can firmly grip and safely hoist irregular loads that other slings would struggle to raise due to their flexibility and vast bearing surface. Metal mesh slings are extremely adaptable, and they can be utilized in vertical, choker, and basket hitches.

Advantages of metal mesh slings

- Corrosion, abrasion, and cutting are all protected by the high-strength and robust design.

- Can be utilized in metalworking and other high-heat, high-demand situations.

- Similar to synthetic slings, it has a flexible design with a wide bearing surface that can firmly handle uneven loads.

Disadvantages of metal mesh slings

- If one wire appears to be broken, the entire sling must be taken out of operation.

- Metal mesh slings are susceptible to crushing.

Metal mesh slings are made of high-tensile carbon, stainless steel, or alloy wire mesh and are also known as wire mesh slings or chain mesh slings. Metal mesh lifting slings are particularly resistant to cutting and abrasion. Wire mesh lifting slings provide the largest standard bearing surface of any rigging sling used in material handling, providing top-of-the-line load securement and balancing. Metal mesh slings' high-strength and durability design makes them particularly corrosion resistant, making them ideal for demanding and severe operating settings.

If you can't find what you're searching for or aren't sure what you need, give our sales team a call or send an email to speak with a rigging product specialist.

Wire mesh sling inspection

- Metal mesh lifting slings should be inspected on a regular basis, and a record of all sling inspections should be kept. We provide a broad range of rigging inspection and repair services at Tri-State Rigging Equipment. OSHA 1910.184 and ASME B30.9 are the regulations that govern metal mesh sling inspection. When you receive a wire mesh lifting sling from the manufacturer, it is recommended that you perform an initial check. The goal of this preliminary inspection is to:

- Verify the capacity of the sling tag.

- Verify the sling's length.

- Confirm that the sling is constructed using the proper materials and in the proper arrangement.

- Confirm that the lifting sling complies with any additional lifting specifications or requirements you may have.

Every day before use, a certified and qualified individual should inspect metal mesh slings to ensure that they are in good working order and will lift their rated capacity. All fastenings and attachments on the wire mesh sling should be examined by the person performing the examination. The inspector is looking for visual signs of any faults, deformities, or general degradation that could compromise the sling's integrity.

You might wish to make these visual inspections more than once a day, depending on your application. If the metal mesh lifting sling is used frequently throughout the day, by various people, throughout multiple shifts, it is critical that it be inspected before each shift change and any change in lifting application.

- A thorough periodic inspection must be performed at least once a year by either a professional service provider or a Qualified Person, according to ASME requirements. Written records must also be preserved until the next scheduled inspection. The following are the rejection criteria for periodic metal mesh sling inspections:

- Missing or incorrectly labeled sling identification

- On the sling edge, a fractured brazed joint or a broken weld

- In any portion of the mesh, a single broken wire or evidence of a broken wire

- Abrasion causes a 25% reduction in wire diameter, while corrosion causes a 15% reduction.

- Mesh distortion that results in a loss of flexibility

- Due to distortion, the depth of the choker fitting slot has increased by 10%.

- Due to distortion, each end fitting's eye opening width decreases by 10%.

- The original cross-sectional area of any point around the hook opening of the end fitting is reduced by 15%.

- Visible twisting of either end of the fitting if it is out of plane

- End fitting with a crack

- If the spirals are locked or do not have free articulation, slings are not to be used.

- Fittings that have been pitted, rusted, cracked, bent, twisted, gouged, or shattered.

- Any and all issues, including obvious damage, that raise concerns about the sling's continued safety.

If your wire mesh sling meets any of the above rejection criteria, it must be removed from service and destroyed. Because you might be held liable for damage caused by anyone who find and use your discarded slings, properly eliminating rigging equipment is critical. As a result, slings that are declared unfit for service must be destroyed after they have been used and repaired. The following is the procedure for dismantling a wire mesh sling:

- Cut the sling into three or four halves.

- Dismantle or cut sling eyes

- Remove or separate any labels or tags that are attached.

The goal of daily and quarterly metal mesh sling inspections is to learn more about the frequency of use, severity of conditions, and kind of lifts, and to analyze how all of these aspects affect your metal mesh sling. The most crucial reason to inspect metal mesh slings on a daily and periodic basis is to keep you and your coworkers safe.