Pillar Jib Crane Price Guide: Key Specs Every Buyer Should Offer

Introduction-Pillar Jib Crane Key Parameters Every Buyer Should Provide

When you’re looking to buy a pillar jib crane, it’s not just about asking for a price and waiting for a number. A jib crane, whether you call it a floor jib crane, a pillar jib crane, or even a freestanding jib crane, needs to be designed around your actual lifting work. That means the supplier must know certain details in advance before they can prepare a quotation that makes sense.

Think about it this way: if you don’t confirm the lifting height, capacity, or rotation range, the crane may not fit your workshop, or worse, it may not handle the loads you expect. That’s why sharing the right information up front saves both time and money. It also ensures that when the quotation arrives, it comes with a technical drawing you can actually use for planning your site or foundation.

Providing these parameters is not just a formality. It directly affects:

- The design of the jib arm and its rotation (270° or 360°).

- The foundation requirements for a floor-mounted system.

- The type of hoist fitted to the crane and how it operates.

- The safety and efficiency of your daily lifting work.

In short, giving full details helps you get the right crane at the right cost without unpleasant surprises later.

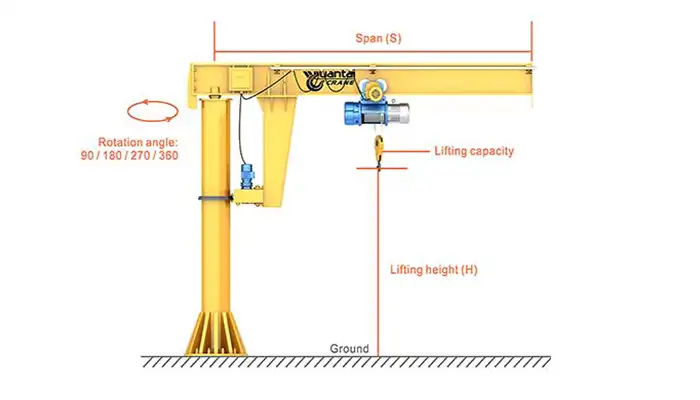

main specifcaiton of pillar jib crane that needed to get price including, capacity, span, lifting height and rotating angle, control, etc.

Key Parameters Buyers Should Confirm

Before you request a quotation for a pillar jib crane, it’s normal to have a lot of questions. Buyers often wonder which type of crane is best for their workshop or whether a crane will fit their space and lifting needs. To make it easier, here are some of the common questions we get and what you should know.

1. Pillar Jib Crane Type

Buyer Questions:

- “Which type of jib crane is best for my workshop?”

- “Do you have a floor jib crane or freestanding jib crane?”

- “Can I get a pillar jib crane with 270° or 360° rotation?”

A BZ type pillar jib crane is floor-mounted and widely used in workshops, warehouses, and assembly lines. It is stable, easy to install, and well suited for short-distance, frequent lifting work.

Confirming the crane type helps the supplier recommend the right model for your space, lifting requirements, and rotation needs. It also ensures that the technical drawings and quotation you receive are accurate and tailored to your workshop. This step avoids problems later, like having a crane that doesn’t fit or isn’t strong enough for your loads.

2. Lifting Capacity

Before choosing a jib crane, many buyers ask about how much weight the crane can safely handle. It’s important to match the crane to your heaviest load, and to think about future lifting needs as well.

Buyer Questions:

- “What size jib crane do I need for a 3-ton load?”

- “Can a freestanding jib crane handle 5 tons?”

- “Do you have light-duty and heavy-duty options?”

The standard lifting capacity for a pillar jib crane ranges from 1 ton to 16 ton. Selecting the right capacity ensures the crane can safely lift your loads without strain. It also prevents unnecessary overdesign, which can increase costs and take up more space than needed.

Providing clear lifting capacity information allows the supplier to choose the correct hoist, motor, and structural design, so your crane is safe, reliable, and built for your daily lifting work. Check Jib Cranes Price range of different Capacity from 1 Ton to 16 Ton.

3. Lifting Height

Many buyers are concerned about whether a jib crane will fit their workshop vertically and if it can reach the heights they need. Knowing the correct lifting height upfront helps avoid installation issues or operational limits later.

Buyer Questions:

- “What ceiling height is needed for a 6 m lifting height?”

- “Can this jib crane work if the workshop height is limited?”

The standard lifting height for a pillar jib crane is 3 m to 6 m. If your lifting needs exceed 6 m, it’s important to confirm both:

- Underground lifting height – the depth of the foundation pit if required.

- Above-ground lifting height – the hook travel above the floor level.

Providing accurate lifting height information ensures the crane operates safely without hitting ceilings, lights, or other equipment. It also helps the supplier design the correct jib arm length, hoist, and support structure for your workshop.

4. Arm Length (Jib Length / Span)

Buyers often want to know how far a jib crane can reach and whether it will cover their work area efficiently. The correct arm length ensures smooth material handling and prevents unnecessary movement or repositioning.

Buyer Questions:

- “What arm length is suitable for my workspace?”

- “Can I get a custom 8 m span pillar jib crane?”

- “How far can a freestanding jib crane reach?”

The arm length, or jib span, is usually customized according to your workshop and lifting needs. A longer arm increases the working radius but may require a stronger base or additional support. A shorter arm saves space and makes installation easier, but reduces coverage.

Providing your preferred arm length allows the supplier to design a crane that fits your workspace, operates efficiently, and matches the lifting tasks you perform daily.

5. Rotation Range

Many buyers wonder how much a jib crane can rotate and whether it will fit safely in their workspace. The rotation angle determines how easily you can move loads without repositioning the crane or the material.

Buyer Questions:

- “Which is better: 270° or 360° rotation jib crane?”

- “Can a floor jib crane rotate fully without hitting walls?”

For pillar jib cranes, you can usually choose between 270° or 360° rotation. The right choice depends on the available space in your workshop and the workflow for your lifting tasks. Confirming the rotation angle helps the supplier design the crane so it operates safely, reaches all necessary areas, and avoids collisions with walls or other equipment.

6. Power Supply

Buyers often want to know if a jib crane will work with their existing electrical setup. Using the wrong power supply can cause operational issues or even damage the crane.

Buyer Questions:

- “Is the crane compatible with 220V single-phase?”

- “Can you provide a jib crane with custom voltage?”

The standard pillar jib crane uses 380V, 50Hz, 3-phase power. However, your workshop may have a different voltage or phase. Confirming your local power supply allows the supplier to provide the correct motor and electrical components. This ensures smooth operation, safety, and avoids extra costs for modifications later.

7. Control Method

Buyers often ask about how they can operate the crane safely and conveniently. The control method affects how easily the crane can be used and how much the operator needs to move around the workshop.

Buyer Questions:

- “Can I operate the jib crane from a distance?”

- “Is it possible to have both pendant and remote control?”

Most pillar jib cranes offer pendant control, which is simple and cost-efficient, or remote control, which allows the operator to stay clear of the load for safer operation. Some setups can include both options for added flexibility.

Choosing the right control method ensures smooth operation, improves efficiency, and reduces the risk of accidents in daily lifting tasks.

8. Working Conditions & Load Type

Buyers often ask about whether a jib crane can handle their specific materials and work environment. Knowing this helps ensure the crane lasts longer and operates safely every day.

Buyer Questions:

- “Which jib crane is suitable for repetitive lifting of steel plates?”

- “Can a pillar jib crane work outdoors?”

- “Do you have cranes for short-distance frequent lifting?”

It’s important to specify:

- Type of material – steel parts, machinery, raw materials, or other items.

- Environment – indoor or outdoor use.

- Duty cycle – light, medium, or heavy daily operation.

Providing this information allows the supplier to design the crane with the right hoist, motor, and protective features. This ensures smooth operation, reduces wear and tear, and matches your daily workflow.

9. Delivery Terms

Many buyers want to know how the crane will be delivered and how much shipping will cost, especially for international orders. Clear delivery information helps avoid misunderstandings and unexpected charges.

Buyer Questions:

- “How long to ship a freestanding jib crane?”

- “What’s the CFR price to [port name]?”

If you need a quotation under CFR terms, be sure to provide the destination port name. This allows the supplier to calculate shipping costs accurately and plan the delivery schedule. Providing complete delivery details ensures the crane reaches you on time and within budget.

Why These Parameters Matter for Buyers

Before requesting a quotation, it’s important to provide all the key details about your jib crane needs. Many buyers don’t realize how much time and cost can be saved by sharing accurate information upfront.

Confirming these parameters helps:

- Match the crane to your lifting needs and workshop space – Ensures the crane fits your area, handles your heaviest loads, and rotates or reaches where it’s needed.

- Prevent hidden costs or misquotation – Suppliers can provide accurate pricing and avoid later adjustments for under- or over-specified cranes.

- Speed up delivery with correct technical drawings – Accurate information allows the supplier to prepare drawings and plan production efficiently, reducing lead time.

By providing these details clearly, you make sure the crane you receive is safe, functional, and ready for your daily operations.

Buyer’s Quick Checklist

When preparing to request a quotation for a pillar jib crane, having a clear checklist makes the process faster and avoids missing important details. Make sure you have the following information ready:

- Jib crane type – BZ pillar jib crane, floor-mounted, or freestanding.

- Lifting capacity – 1–16 ton, based on your heaviest load.

- Lifting height – 3–6 m, or confirm both above-ground and underground height if over 6 m.

- Arm length (jib span) – as required for your workspace.

- Rotation range – 270° or 360° depending on your workshop layout.

- Power supply – voltage, frequency, and phase of your local supply.

- Control method – pendant, remote, or both.

- Working material & conditions – type of load, indoor/outdoor, and duty cycle.

- Delivery terms – FOB or CFR, plus destination port if applicable.

Having this checklist ready ensures the supplier can provide an accurate quotation, technical drawing, and delivery plan without back-and-forth clarification.

Conclusion

A pillar jib crane with a 270° or 360° rotating arm is a solid and reliable choice for short-distance, frequent lifting tasks in workshops, warehouses, or assembly lines.

By providing all the key parameters—such as crane type, lifting capacity, lifting height, arm length, rotation, power supply, control method, working conditions, and delivery details—you make it possible for the supplier to prepare a tailored quotation and accurate technical drawing.

This ensures the crane fits your space, meets your lifting needs, and operates safely from day one.Send your inquiry today to check the latest pillar jib crane, floor jib crane, or freestanding jib crane prices and get a design recommendation for your workshop.