What is Overhead Crane’s Lift Height, Headroom & C-dimension?

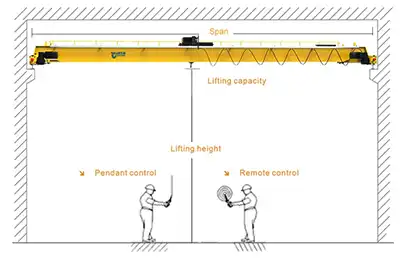

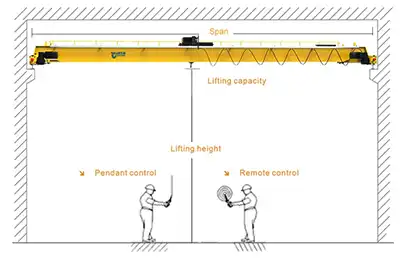

Lifting height is a vital specification or parameters that needs to be confirmed to construct an overhead crane project.

And one of the most common questions we get on the overhead crane designing is about the c-dimension. The c-dimension is actually just one of several requirements required to construct an overhead crane project. You must have a thorough understanding of lift height in order to fully understand the parameter of c -dimension. In the following, we'll go over the fundamentals of lift height, head room, and c-dimension, as well as how they're related, so you'll be fully informed what the lifting height is required when you are planing to buy an new overhead crane in the future.

Everything is interconnected when getting a quote,for an overhead crane, just like many specs. A seemingly simple specification can quickly turn into a panicked research project to try to figure out what it all means. As we discuss the relationship between c-dimension, headroom, and lift height, we will also discuss some other factors that influence lift height and how a bridge crane manufacturer or authorized dealer can optimize these dimensions to meet your lifting needs and at same time make the best use of your workshop or facility working space.

Hook Height or Lift Height

What is lift height, and how do I calculate it for my bridge crane?

When the crane hook is in its highest position, the hook height represents the required dimensions from the crane hook to the floor, another words, when the hook is in the upmost position, the distance from the hook to the floor is the required parameters of lifting height. This critical measurement determines how high the runway must be from the ground and is directly related to the building's or structure's clear interior height.

A overhead crane project's lift height is an important specification because it ensures that there is enough space to lift or hoist and reposition the load or object you are lifting. A entire crane project could be destroyed if this dimension is miscalculated.

Understanding what you are lifting, how it needs to be hoisted or moved, and whatever limitations or hinders you have is the first step to success so that the lift height may be maximized for the present and the future.

C-Dimension

What is the C-Dimension of your overhead crane?

The C-Dimension refers to the distance between the running surface of the hoist trolley wheels and the hook saddle.

How is c-dimension related to the lifting height of your overhead crane?

The C-Dimension specifies the maximum height to which the hook can be lifted. It is the point determined by measuring between the running surfaces of the hook saddle and the hoist trolley wheels. Due to the fact that each hoist's c-dimension is a set measurement, this dimension helps you determine which hoist to utilize. Now that we've brought hoists into the situation, let's talk about headroom.

Headroom

The space between the top of the lowest impediment and the top of the rail is the headroom available on an overhead crane.

How do c-dimension and lift height relate to headroom?

The distance between the top of the lowest impediment and the top of the rail is the amount of headroom that is accessible in a building. Unfortunately, the crane rail height is fixed in most existing structures. You will probably have greater control over the rail height established by the architects if a crane is being built into a new building. When determining the lift height for your crane, you must also take into account headroom, c-dimension, and rail height. Check types of low headroom cranes and hoists for low built workshops and facilities.

Factors to affect the lifting height of overhead cranes

Is there any other way to affect the lifting height of an bridge crane for a existing facility?

There are ways to optimize the crane's dimensions even though you don't have complete control over every parameter in an existing crane bay.

First, girder arrangements and connections between the main girder and the end carriages / end trucks.

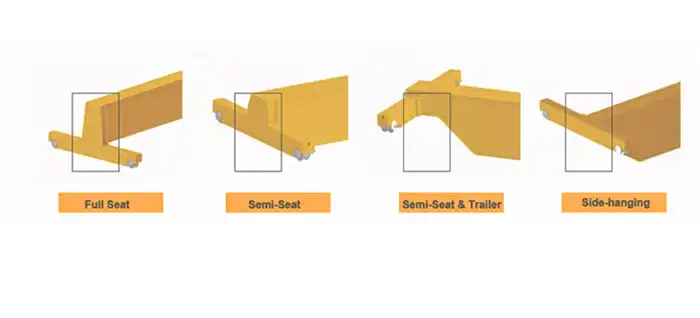

The maximum lift height might be impacted by how the girder is attached to the end truck. To maximize measurements for the design of your eot crane project, the main bridge girders of overhead cranes can be attached to end trucks or end carriages utilizing a variety of connections.

- By connecting a girder to the end truck via a side connection rather than a top connection, the crane dimensions can be optimized to fit within the available headroom.

- Girders can be designed to connect to end trucks and fit within a space in a variety of ways, and they can be built to optimize these measurements.

- To optimize lift height, girders can be built from short to tall and everything in between.

Full seat, top connection

Semi seat, half top connection

Side-hanging, side connection

The ultimate lift height is determined by the girder height, end truck dimensions, girder to end truck connection design, and hoist c-dimension.

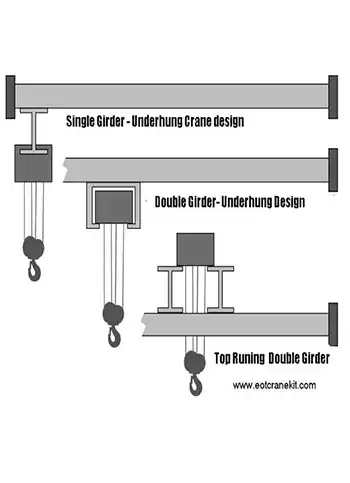

Secondly, your crane design : Single girder or double girder ?

A double girder crane may assist you optimize the lift height of your overhead crane project depending on your design because of the advantage of the space between the girders.

The three measurements can be maximized by selecting a single- or double-girder overhead crane. On single girder overhead cranes, the hoist is always suspended on the lower part of the main girder. Whereas on the double girder crane design, due to the space between the two girders, the overhead crane can lift objects up to a little bit higher, depending on how the trolley is built into the girder.

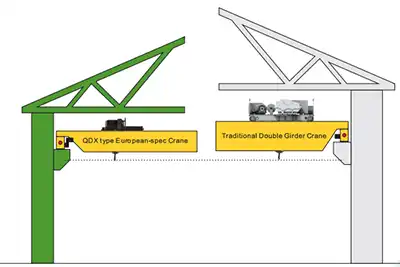

Third, right crane girder design & hoist combination

Thirdly, maximizing your lift height can be achieved by selecting the proper crane girder design and hoist combination. A double girder crane, as previously explained, can optimize lift height by allowing the hook to rise higher than the bottom of the girder while being contained between the two girders. The major consideration in this situation is choosing the location of the trolley or hoist on the girders that best suits the lifting operation.

double girder cranes with top running crab hoist trolley comparioson - low headroom vs traditional electric hoist trolley

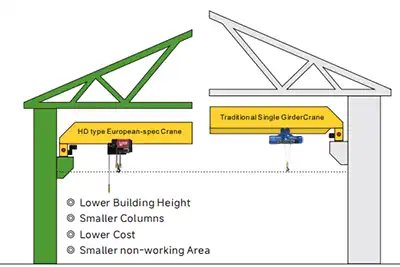

single girder cranes with under running electric hoist trolley comparison - low headroom hoist vs traditional suspension hoist and trolley

Double girder overhead crane with grab , the grab bucke will take your vertical space, which needs your workshop with enough headroom.

Generl use overhead crane for large headroom workshop , economical overhead hoist crane solution

Single girder overhead cranes have lifting hoists that run on the bottom flange of the bridge girder.

The electric travelling hoist of a single-girder crane can only move along the girder's bottom flange. Special low headroom hoists are designed by manufacturers to increase lift height on a single girder crane. These hoists' parts are constructed to maximize lift height. For example, a low headroom hoist's body will move parallel to the girder rather than above or below it.To reduce the quantity of equipment riding over the top of the girder, parts like control boxes are shifted. Since low headroom hoists are not placed exactly beneath the girder, you gain a little bit of height from the alternative mounting method, which also contributes to help optimize lift height.

Is reeving related to c-dimension and lift height?Reeving enables a hoist to raise more weight. With each distinct reeving setup, the C-dimension modifies.

Reeving is the final restriction we'll cover that has to do with c-dimension and lift height. Reeving can be defined as the process of wrapping a wire rope around the drums of sheaves. To increase the amount of weight the hoist can carry, different reeving 1/1, 2/1, 4/1, 4/2, etc. is done. The c-dimension varies depending on the reeving number because the ropes must be at the correct angle at the top of the lift height. Always keep in mind that as you progress through a project to reach a final print, your c-dimension will alter as reeving does.

How to determine the height of your lift ?

How high of a lift are you going to need to support production, taking into account that the overhead crane and hoist will need at least a few feet of space off the roof of your facility?

Crane drawing for your to confirm the lifting height of double girder overhead crane

Crane drawing for your to confirm the lifting height of single girder overhead crane

If a higher lift height is required, consider a top-running double girder overhead crane, in which the hoist travels along the top of two parallel bridges. In contrast to the under-running single girder overhead crane, which travels along the bottom of a single bridge. A higher mount point on the hoist allows for a higher lift height and more space below the hook.

Standard lifting height of overhead cranes

The lifting height of the main types of overhead cranes are presented for your reference:

- Top Running Single girder overhead crane lifting height : 6-30 m

- Underhung running single girder bridge crane lifting height: 6-30m

- Top Running Double girder overhead crane lifting height: 6-25 m

- Customized lifting height overhead cranes are available.

Contact us to get more information on the lifting height, headroom of overhead crane. If you have a low headroom workshop or facility, or need a special designed overhead cranes with super tall lifting height, please feel free to contact us. Customized overhead crane will processed for your application. Get free consultation today.