30 Ton Overhead Crane Kit: Good Price,Short Lead Time & Sound Support

30 ton bridge crane kits for global buyers, covering lead time, tariffs, local fabrication, installation, and after-sales support for reliable operations.

| Crane Type | Overhead Crane Kit |

| Crane span | As your request |

| Lifting Height | As your request |

| Crane power supply | Customized. |

Category: 30 Ton Overhead Crane

Your Trusted 30 Ton Overhead Crane Manufacturer & Supplier

30 Ton Overhead Crane Kits for Sale,

Econoical Overhead Bridge Crane Solutions

30 Ton Overhead Crane Kit without Main Girder, Good Price,Short Lead Time & Sound Support

When we talk about a 30 ton overhead crane, or 30 ton overhead crane kit or a 30 ton bridge crane kit, we are referring to a set of major crane components that a supplier provides, but without the main girders. In other words, the kit includes everything from the hoist, trolley, end trucks, and electrical systems to control panels—but the buyer is expected to handle or locally fabricate the main girders and the runway structure. This approach allows factories and workshops to adapt the crane to their specific facility dimensions while still relying on pre-engineered, tested components for the core lifting system.

Key points about 30 tonbridge crane kits:

- Supplied as modular components ready for local assembly.

- Main girders and runway beams are usually fabricated onsite or at a local steel workshop.

- Suitable for workshops that have the capability to fabricate large steel structures.

Global buyers in industries such as steel mills, heavy machinery manufacturing, and large-scale workshops often prefer overhead bridge crane kits because of their flexibility. A standard crane may not fit the exact dimensions or operational requirements of every facility. By opting for a kit, buyers can tailor the installation while still getting high-quality hoisting and control systems from a reliable supplier.

Industries that commonly use 30 ton overhead crane kits:

- Steel mills – for handling slabs, billets, and heavy coils.

- Machinery plants – lifting large molds, machinery parts, or castings.

- Heavy industrial workshops – moving heavy components in fabrication lines or assembly bays.

Evaluating lead time, tariffs, fabrication requirements, and after-sales support is essential before investing in overhead bridge crane kits. The delivery schedule can vary depending on supplier workload, component complexity, and shipping distance. Tariffs and import duties can significantly affect the final cost if the components are sourced internationally. Buyers must also assess whether their facility is equipped to fabricate the main girders correctly and safely. Finally, after-sales support, including spare parts availability, technical guidance, and maintenance services, ensures the crane continues to operate reliably for years.

Practical considerations for global buyers:

- Check if the supplier provides detailed assembly drawings and technical manuals.

- Confirm lead time for critical components and any factory testing (FAT) before shipment.

- Understand local import duties and potential customs delays for heavy components.

- Plan for on-site fabrication, welding, and alignment of main girders.

- Verify availability of spare parts and technical support after installation.

Choosing a 30 ton overhead crane kit is not just about price—it’s about ensuring your facility can safely and efficiently install, operate, and maintain a heavy-duty lifting solution. For global buyers, taking the time to evaluate all these factors upfront can save months of delays and unexpected costs.

Scope & Key Definitions

Understanding the scope and the terminology is the first step in making a confident decision about a 30 tonbridge crane kit or any overhead bridge crane kits. The difference between a bridge crane kit and a turnkey crane is especially important for buyers who want to balance cost, customization, and installation control.

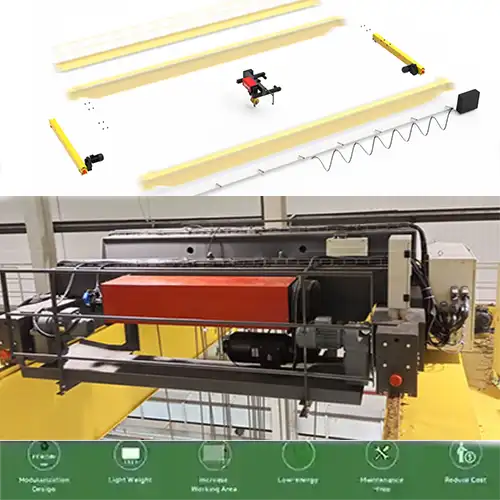

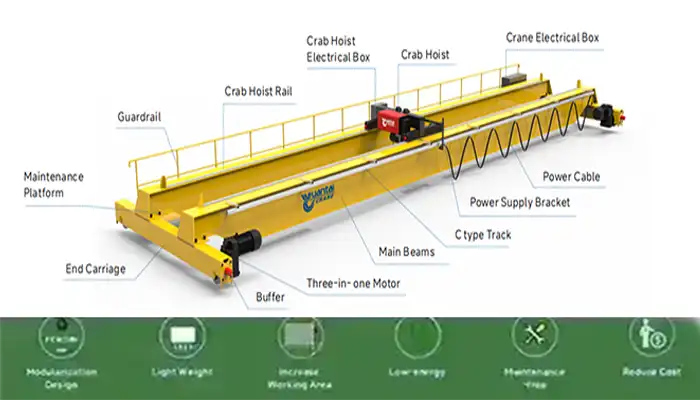

Main parts and compoennts of overhead crane system

30 ton overhead crane kit without main girder, covering electric hoist trokke, end carriages and , power supply, electrical cabinets , crane controller, and other safety devices, etc.

A bridge crane kit typically includes:

- Hoist and trolley system

- End trucks with wheels and motors

- Control panel and wiring system

- Safety components such as limit switches and overload protection

What it usually does not include:

- Main girders (to be fabricated locally)

- Runway beams and supporting steel structure

- On-site installation labor or commissioning (unless separately contracted)

In contrast, a turnkey crane is delivered fully assembled or pre-fabricated, with main girders included. The supplier handles fabrication, delivery, installation, and testing. While turnkey solutions reduce on-site work and complexity, they are usually more expensive and less flexible in terms of adapting to local facility constraints.

Key terms for 32 ton overhead crane kits:

- 30 tonbridge crane kit – a crane kit designed for lifting 30 tons, supplied without main girders.

- Overhead bridge crane kits – general term for modular bridge cranes supplied for local assembly.

- Duty class – defines how frequently and intensively the crane can operate (light, medium, or heavy duty).

- Span – the distance between runway rails that the crane must cover.

- Lift height – the maximum vertical distance the hook can travel.

Typical industrial applications for 32 ton cranes:

- Steel mills – moving heavy slabs, billets, and coils across production floors.

- Heavy machinery plants – handling large molds, castings, and assembled machine components.

- Large workshops – transferring heavy parts for fabrication or assembly operations.

By clarifying these definitions, buyers can accurately communicate their requirements to suppliers and compare overhead bridge crane kits effectively. It also ensures that local fabrication plans, such as main girder construction, runway alignment, and installation resources, match the kit’s specifications.

What is in the 30 Ton Overhead Bridge Crane Kits?

Frame (Bridge Structure)

Main Girder: (Part of the complete crane system, usually not included in standard crane kits)

The main girder is the strongest beam of the crane and carries the load. It supports the trolley and hook while resisting bending or twisting during lifting.

- Handles both the weight of the load and dynamic forces like swaying or sudden stops.

- For example, a 15 ton overhead crane in a steel mill must manage heavy slabs and impact forces safely.

- Why it's usually not in crane kits: Main girders are often made locally to match workshop span, building structure, and support conditions. Including it in the kit would increase shipping costs and reduce flexibility.

End girders connect the main girder to the runway rails and support the wheels and drive motors.

- Provide smooth and safe travel for the crane across the runway.

- Included in kits because they integrate directly with hoisting mechanisms.

- Help ensure proper alignment and stability during operation.

The cabin gives the operator a clear view of the work area while providing safety and comfort.

- Can be side-mounted or suspended depending on crane design.

- Reduces operator fatigue and improves precision handling.

- Included in crane kits when full operator control is needed, especially for larger cranes.

Travelling Mechanism (Bridge & Trolley Travel)

This mechanism allows the crane and trolley to move smoothly along the runway and main girder. Both complete systems (30 ton overhead cranes) and crane kits (32 ton bridge cranes) include these components, but understanding each part helps buyers plan installation and maintenance.

Wheels: Travel wheels sit on the end girders for bridge movement, and trolley wheels run along the main girder for hoist movement.

- Made of high‑strength alloy steel with precise machining to resist wear and vibration.

- Proper alignment prevents uneven wear and reduces maintenance needs.

- Critical for smooth travel and safety during heavy lifts.

Motor: Drive motors power both bridge and trolley travel.

- Convert electrical energy into motion with controlled speed and torque.

- Variable Frequency Drive (VFD) options allow smooth start/stop and precise positioning.

- Proper motor sizing ensures reliable operation under continuous or heavy-duty cycles.

Reducer (Gearbox): The reducer transmits motor power to the wheels at low speed with high torque.

- Multi-stage gears provide strength for moving heavy loads.

- Durable materials and good lubrication ensure long service life.

- Designed to handle frequent starts and stops in industrial settings.

Brake: Brakes stop the crane reliably and hold it in position.

- Essential for safety under load and inertia.

- In heavy-duty cranes or steel‑plant crane kits, brakes must withstand frequent operation and high temperatures.

- Well-maintained brakes prevent accidents and reduce wear on other components.

Coupling: Couplings connect the motor to the reducer or the reducer to the wheels.

- Absorb slight misalignments and reduce shocks from sudden starts/stops.

- Must be rated for the expected vibration and impact in your facility.

- Proper couplings protect motors, gearboxes, and wheels, extending component life.

Hoisting Mechanism (Hoists & Trolleys)

Whether your crane kit includes the hoist and trolley or you source them separately, understanding these components is essential for safe and efficient lifting.

Hoist Types:

- Wire Rope Electric Hoist: Common for capacities of 10 tons and above. Provides smooth operation, long travel distance, and high durability.

- Electric Chain Hoist: Compact design, suitable for lighter loads under 5 tons. Requires less space and is easier to install.

- Open Winch Trolley: Used mainly on double‑girder cranes. Trolley assembly sits between main girders and uses a drum and wire rope to lift loads.

- Sheaves: Guide the wire rope and can multiply lifting capacity via blocks. Fixed sheaves change rope direction; movable sheaves travel with the load to reduce required pull force. Proper groove design and alignment minimize rope wear.

- Hooks & Lifting Attachments: Hooks are made of high‑strength alloy steel and usually include safety latches. Double hooks distribute heavy loads more evenly, improving safety and stability—especially important in steel‑mill operations. Attachments such as grabs, clamps, or magnets may be used depending on the material being handled.

- Hoist Motor / Reducer / Brake: Hoist motor provides high torque at low speed, reducer transfers motion with high torque, and brake holds the load securely when lifting stops.

- Drum & Wire Rope: The rope drum collects and releases the wire rope to control lift and descent. Proper groove design, rope guides, and alignment prevent rope overlap, slippage, or fatigue. Wire rope selection must match lifting capacity, fatigue life, and environmental conditions.

Electrical & Control Systems

These systems power and control the crane's movements. Both complete 30 ton overhead crane systems and 32 ton bridge crane kits include electrical components.

- Busbar (Conductive Rail): Supplies power to the bridge and trolley travels via sliding collectors. Precise alignment and reliable contact are essential.

- Power Supply Cables: Connect motors and control devices, routed via cable carriers or festoon systems. Proper management reduces wear and extends service life.

- Control Methods: Cabin control for operator inside the crane, remote control for wireless operation, pendant wired control for simple lifts. Choose based on layout, lifting frequency, capacity, and operator training.

Rail System & Runway Structure

Note: In crane kits, rails and runway beams are usually not included; they are part of the complete crane system or fabricated locally.

- Rails: Support smooth movement of the bridge along the building structure. Must be strong, wear-resistant, and correctly aligned.

- Runway Beam: Carry the rails and full crane load. Can be I-beams, box girders, or fabricated beams anchored to columns or independent supports. Precise drawings, material specs, tolerances, and alignment procedures are essential for safe operation.

Safety & Protection Devices

Essential in industrial environments to protect personnel, equipment, and the facility.

- Emergency Power Off (EPO): Instantly disconnects power to prevent accidents.

- Warning Bell / Audible Alert: Alerts personnel before movement begins.

- Overload Limiter: Monitors the load; alarms at ~90 % and cuts power at ~105 %.

- Upper-Limit Switch: Stops the hoist at top travel limit.

- Travel Limit Switches: Stop bridge/trolley at end of travel and allow controlled reverse.

- Lighting: Provides adequate illumination for safe operation.

- Buffers: Installed at ends of travel paths to absorb impact energy.

Key Terminologies for Your Reference

| Term | Meaning |

|---|---|

| Main Girder | Primary load‑carrying beam spanning the crane width. |

| End Girder | Beam linking main girder to the runway wheels/drive units. |

| Bridge Travel | Movement of the crane structure along the runway rails. |

| Trolley Travel | Movement of the hoist equipment along the main girder. |

| Hoist | The lifting device (wire rope or chain) that raises/lowers the load. |

| Trolley | The mobile support that carries the hoist along the main girder. |

| Runway Beam | Structural beam(s) supporting rails for bridge travel. |

| Busbar | Conductive rail system supplying power to the moving crane. |

| Overload Limiter | Device monitoring load and preventing over‑capacity lifts. |

Buyer Needs Assessment for 32 Ton Overhead Crane Kits

Before investing in a 30 tonbridge crane kit, it's essential to carefully evaluate your facility's needs and capabilities. This step ensures that the crane operates safely, efficiently, and reliably once installed.

Technical Requirements

The first step is to define exactly what your operation needs from the crane:

- Maximum load – For a 32 ton overhead crane kit, confirm both the nominal lifting capacity and peak loads that may occur during unusual operations.

- Span – Measure the distance between runway rails accurately. The crane must travel smoothly across this span without interference.

- Lift height – Determine the vertical distance the hook needs to reach, factoring in any overhead obstructions.

- Duty cycle – Classify the expected frequency and intensity of use: light, medium, or heavy-duty.

- Operating frequency – How often the crane will lift, travel, or work per day can impact component selection, such as motors and brakes.

Local Fabrication Capability

A 30 tonbridge crane kit requires some level of local fabrication, especially for the main girders and runway:

- Assess whether your team or a local contractor can fabricate main girders to the required steel grade and tolerance.

- Ensure the ability to assemble end trucks, runway connections, and electrical systems according to supplier specifications.

- Check whether welding, coating, and alignment capabilities meet the manufacturer's standards.

Infrastructure Readiness

Even with the best crane kit, installation can fail if your facility isn't prepared:

- Runway beams – Must be straight, level, and designed for 32 t loads.

- Foundations – Columns and supports need to handle the crane's weight and dynamic forces.

- Installation equipment – Cranes, lifts, or jacks for raising and assembling the kit components.

- Commissioning teams – Skilled technicians to align, test, and calibrate the crane after assembly.

Volume and Batch Considerations

If you plan to purchase multiple overhead bridge crane kits:

- Ordering in batches may reduce cost per unit.

- Suppliers may offer faster delivery or technical support for large-volume orders.

- Check if your facility can handle multiple crane installations at once without interfering with ongoing operations.

Global Buyer Concerns

International buyers need to account for factors beyond just the crane itself:

- Shipping distances – Large components may require special transport or handling.

- Local regulations – Electrical, safety, and structural codes vary by country.

- Power supply compatibility – Confirm voltage, phase, and frequency match your facility's systems.

Lead Time Considerations for 32 Ton Overhead Crane Kits

Understanding lead time is one of the most important steps when planning for a 30 tonbridge crane kit. Delays at any stage—from production to installation—can affect your project timeline and operational efficiency.

Typical Production Lead Time

A 30 ton overhead crane kit involves multiple stages before it is ready for installation:

- Engineering & Drawings – Detailed designs and layouts are created, ensuring the kit fits your facility and meets duty requirements. Depending on complexity, this can take 2–4 weeks.

- Component Fabrication – Hoist, trolley, end trucks, control systems, and electrical components are manufactured and tested at the factory. For a 32 t capacity crane, fabrication may take 4–8 weeks.

- Factory Acceptance Testing (FAT) – Critical components are tested at the supplier's facility to ensure proper operation and safety. FAT usually adds 1–2 weeks.

- Shipping and Local Delivery – Depending on the distance and mode of transport, delivery can take 2–6 weeks for overseas buyers. Oversized components may require special handling.

- On-site Installation and Commissioning – After delivery, the crane is assembled, main girders installed, electrical systems connected, and the crane is tested on site. Installation may take 1–3 weeks depending on facility readiness and team experience.

Factors Influencing Lead Time

Several elements can affect the overall schedule for overhead bridge crane kits:

- Custom specifications – Any changes from standard designs, such as extra lift height or span modifications, may extend production.

- Component size/weight – Larger hoists, trolleys, or end trucks require longer manufacturing, special transport, and careful handling.

- Global shipping – Customs clearance, port congestion, and long-distance freight can introduce delays, especially for international buyers.

Strategies for Buyers

To manage lead time effectively, buyers can take practical steps:

- Staggered delivery – Receive critical components first, like hoists and trolleys, while main girders are fabricated locally.

- Local fabrication of main girders – Reduces shipping delays for oversized steel structures and allows adjustments to fit your facility.

- Buffer time planning – Always add 10–20% extra time to account for unforeseen delays in production, shipping, or installation.

Planning for lead time in detail ensures your 30 tonbridge crane kit is delivered, installed, and operational without unnecessary stress or cost overruns. Proper scheduling can also improve coordination between suppliers, local fabrication teams, and installation crews.

Tariffs, Duties, and Landed-Cost Implications for 32 Ton Overhead Crane Kits

For global buyers, understanding the full cost of a 30 ton overhead crane kit goes far beyond the supplier's quoted price. Import duties, tariffs, and other fees can significantly increase the total investment, so it's crucial to plan ahead.

How Tariffs Affect Pricing

Heavy equipment like overhead bridge crane kits is often classified under specific HS codes that attract high import duties. Depending on the country, duties can range from 5% to over 25% of the declared value. In addition, delays in customs clearance due to incomplete documentation can increase handling costs.

Key Cost Components

When calculating the landed cost of a 30 tonbridge crane kit, consider:

- Customs duties – Percentage of the value of imported goods, which varies by country and HS code.

- VAT/GST – Value-added tax applied on imported equipment.

- Brokerage fees – Charges by customs brokers who handle documentation and clearance.

- Handling costs – Additional fees for moving heavy components at ports, warehouses, or between transport modes.

Risks for Buyers

- High tariff exposure – Large or heavy components like main girders, end trucks, and hoists may attract higher tariffs than smaller parts.

- Documentation errors – Missing certificates or incorrect HS codes can delay clearance and increase demurrage costs.

- Unexpected charges – Some countries apply extra fees for oversized or high-weight shipments, which is common for 32 t crane components.

Strategies for Buyers

To reduce landed costs and avoid surprises:

- Source from countries with favorable trade agreements – Look for suppliers in regions that have lower tariffs or free trade agreements with your country.

- Local assembly – Import only critical components like hoists and trolleys while fabricating main girders locally to reduce import duties.

- Negotiate shipping terms – Using CIF, FOB, or DDP terms can help control shipping risk and clarify which party handles duties and customs clearance.

- Plan documentation carefully – Ensure all technical certificates, drawings, and invoices are accurate and ready before shipping.

Fabrication and Local Assembly Considerations for 32 Ton Overhead Crane Kits

A 30 tonbridge crane kit is designed for buyers who have the ability to handle local fabrication. Instead of receiving a fully assembled crane, you get the critical components while taking responsibility for the main girders and runway installation. This approach allows for flexibility, faster shipping, and often lower costs, but it requires careful planning and skilled labor.

Why Local Fabrication Works

- Buyers with local steel workshops or fabrication teams can tailor the crane to their exact facility dimensions.

- Oversized main girders can be produced on-site, avoiding shipping issues and customs complications.

- Local assembly gives more control over alignment, welding quality, and final adjustments.

Components Typically Included in Kits

A standard 30 ton overhead crane kit generally includes:

- Hoist and trolley – Rated for 32 t lifting, tested at the factory.

- End trucks – Wheels, motors, and drive systems for bridge movement.

- Control system and electrics – Push buttons, pendant control, or radio control with safety features.

- Safety components – Limit switches, overload protection devices, and wiring.

Quality Control and Inspection

- Drawings approval – Ensure that fabrication drawings match the supplier's design specifications.

- Welding standards – Use certified welders and follow recommended welding procedures for steel grades.

- Coating – Apply corrosion protection if required, particularly in humid or industrial environments.

- Factory tests – Hoists, trolleys, and control systems should undergo Factory Acceptance Testing (FAT) before shipment.

On-Site Fabrication and Installation Checkpoints

- Steel grade – Confirm the local steel used meets supplier specifications for strength and durability.

- Dimensional accuracy – Check girder straightness, flange and web alignment, and connection points.

- Crane alignment – Ensure end trucks are properly aligned on runway beams to prevent uneven wear or stress.

- Site welding – Follow proper welding procedures and inspect joints for quality and safety.

Trade-Offs: Kits vs Turnkey Solutions

- Cost and lead-time savings – Kits are usually cheaper and faster to ship because large girders don't cross borders.

- Flexibility – Local fabrication allows minor adjustments to suit facility constraints.

- Responsibility – Buyers must have skilled teams to fabricate, assemble, and align the crane correctly.

- Turnkey alternative – A turnkey crane reduces on-site work but comes at higher cost and shipping complexity.

Choosing a 30 tonbridge crane kit is ideal for buyers who want to balance quality, cost, and flexibility while maintaining control over the installation process. Proper planning and attention to quality during local fabrication ensure long-term reliability of the crane.

After-Sales Support and Spare Parts for 32 Ton Overhead Crane Kits

Buying a 30 ton overhead crane kit is only the first step. Long-term performance depends heavily on after-sales support and access to spare parts. Downtime for a heavy-duty crane can halt production and cost thousands, so planning for service and maintenance is critical.

Importance of After-Sales Support

- Even high-quality overhead bridge crane kits require ongoing attention to remain safe and efficient.

- Quick response times for repairs can prevent minor issues from turning into major production losses.

- Access to technical guidance, both remotely and onsite, is essential when handling complex systems like 32 t cranes.

Key Support Elements

- Warranty coverage – Ensure that the supplier offers clear terms covering mechanical, electrical, and control components.

- Spare parts availability – Hoists, trolleys, limit switches, drives, and control components should be available for years after installation.

- Technical assistance – Remote troubleshooting and optional onsite visits can help resolve issues faster and avoid prolonged downtime.

Maintaining a Spare Parts Inventory

Critical spares for overhead bridge crane kits include:

- Limit switches and sensors

- Wire rope or chain

- Gearbox, motors, and drives

- Electrical components and fuses

Maintaining a small inventory onsite ensures that minor failures can be addressed immediately, keeping production moving.

Life-Cycle Cost Perspective

- The total cost of a crane is not just the purchase price. Maintenance, parts replacement, and periodic inspections all contribute to long-term expenses.

- Proper upkeep reduces the likelihood of catastrophic failures and extends the service life of your 30 tonbridge crane kit.

- Planning for regular inspections, lubrication, and load testing protects both the crane and the people operating it.

Recommended Maintenance and Service Plans

- Establish a maintenance schedule based on the manufacturer's recommendations and duty cycle.

- Train local staff in basic inspections, daily checks, and reporting procedures.

- Consider a service contract with the supplier or a certified local partner for yearly inspections and preventive maintenance.

- Keep detailed records of repairs, parts replacements, and inspections to ensure compliance with safety standards.

Buyer Checklist for 30 tonBridge Crane Kits

A 30 tonbridge crane kit is a significant investment, and careful planning is key to a smooth procurement, installation, and operation. Using a structured checklist helps global buyers avoid costly mistakes and ensures the crane meets all technical and regulatory requirements.

Pre-Order Checklist

Before placing an order, confirm the following:

- Specifications – Maximum load (32 t), span, lift height, and duty cycle.

- Duty class – Light, medium, or heavy-duty operation based on daily usage.

- Layout drawings – Accurate facility dimensions and crane path clearances.

- Inspection certificates – Steel quality, hoist testing, and compliance documents.

Contract Checklist

Ensure your contract clearly defines:

- Scope of supply – Components included in the kit, excluding main girders if applicable.

- Lead time – Production, testing, and delivery schedules.

- Shipping schedule – Method, estimated transit time, and handling requirements.

- Testing requirements – Factory Acceptance Testing (FAT) and on-site testing.

- Payment terms – Clear milestones linked to production or delivery stages.

Import and Customs Checklist

For international purchases, verify:

- HS codes – Correct classification for customs clearance.

- Duties and taxes – Estimate import tariffs, VAT/GST, and handling fees.

- Regulatory compliance – Local safety, electrical, and structural standards.

On-Site Readiness

Prepare your facility for smooth assembly and commissioning:

- Runway beams – Properly aligned and capable of supporting the 32 t crane.

- Lifting equipment – Cranes, jacks, or forklifts for assembly.

- Installation team – Skilled personnel for assembly, welding, and alignment.

- Utilities – Electrical supply compatible with crane components.

- Commissioning plan – Testing schedule, adjustments, and operator training.

After-Sales Checklist

Plan for long-term support and maintenance:

- Warranty terms – Coverage for mechanical, electrical, and control components.

- Spare parts – Availability of critical items such as hoists, trolleys, ropes, and drives.

- Service contacts – Supplier support for remote troubleshooting or onsite visits.

- Training schedule – Operator and maintenance staff education for safe operation.

Specific Tips for Steel Mill Crane Applications & 32 Ton Overhead Crane Kit

1. Load Handling

- Always account for dynamic forces like impact and swaying, not just static weight.

- Include a safety margin of 20–30 % above the maximum expected load.

- Use appropriate lifting attachments (double hooks, grabs, or magnets) for uneven or heavy steel products.

2. Main Girder & Structural Considerations

- Main girders are usually fabricated locally, tailored to your workshop span and building supports.

- Check material grade, welding quality, and alignment to ensure smooth crane operation and long service life.

- End girders and other kit-included parts must integrate precisely with the locally fabricated main structure.

3. Hoist & Trolley Selection

- Wire rope electric hoists are recommended for heavy loads; they provide durability and long travel distances.

- Chain hoists are suitable only for lighter loads or secondary auxiliary lifting.

- Double-hook trolleys help distribute heavy loads evenly and increase safety in steel mill operations.

4. Safety Devices

- Include overload limiters, upper-limit switches, travel-limit switches, and buffers.

- Emergency power off (EPO) and warning alarms must be properly installed and tested.

- Safety devices protect both personnel and equipment in harsh, heavy-duty industrial environments.

5. Electrical & Control Systems

- Select the right control method: cabin, pendant, or remote control depending on operator experience and plant layout.

- Ensure busbars, cables, and control systems are compatible with local power supply and environmental conditions (dust, heat, moisture).

- Proper cable management and VFD options for motors improve precision, reduce wear, and extend service life.

6. Rail & Runway Alignment

- Rails and runway beams are not included in the crane kit, but correct fabrication and alignment are crucial.

- Ensure parallelism, levelness, and deflection limits to prevent uneven wear, vibration, or operational issues.

- Locally fabricated runway structures must comply with design tolerances and support dynamic loads safely.

7. Maintenance & Environment

- Schedule routine inspection of wheels, brakes, wire ropes, hoist drums, and electrical components.

- Plan for easy access to critical parts for lubrication, adjustments, or replacement to reduce downtime.

- Use protective covers and corrosion-resistant components in hot, dusty, or harsh steel mill conditions.

Summary & Recommendations

Selecting a 30 tonbridge crane kit involves more than just comparing prices. Buyers must evaluate multiple factors to ensure the crane will operate safely, efficiently, and reliably in their facility.

Key Considerations Recap

- Lead time – From engineering and component fabrication to shipping and on-site commissioning, delays can affect project timelines.

- Tariffs and landed cost – Import duties, taxes, and handling fees can significantly increase the overall investment.

- Fabrication capability – Local ability to fabricate main girders, align runways, and assemble components is essential.

- After-sales support – Access to spare parts, technical guidance, and maintenance services ensures long-term reliability.

Strategic Advice for Buyers

- Plan early – Start discussions with suppliers well before your desired installation date to avoid rushed decisions.

- Factor in buffer time – Allow extra time for production, shipping, customs clearance, and local assembly.

- Prioritize experienced suppliers – Choose vendors with proven global experience in overhead bridge crane kits to minimize risk.

Total Cost of Ownership

- Consider the long-term costs, not just the purchase price.

- Maintenance schedules, replacement parts, and potential downtime all impact the overall value of the crane.

- A well-planned investment in a 30 ton overhead crane kit can save money and avoid headaches over its operational lifetime.

Additional Resources & Next Steps

Once you’ve assessed specifications, lead time, fabrication, and after-sales support, it’s useful to explore additional resources to make informed decisions about a 30 tonbridge crane kit.

Suggested Further Reading

- Tariffs and import regulations – Understand customs duties, HS codes, and local compliance requirements for heavy lifting equipment.

- Local installation services – Research experienced contractors who can fabricate main girders, align runways, and commission the crane on-site.

- Supplier directories – Identify trusted suppliers with global experience in overhead bridge crane kits and verified quality standards.

Related Products

Latest project

Workshop Overhead Crane 5 Ton & 10 Ton Buying Guide

Practical guide for selecting, installing, and maintaining 5 ton to10 ton workshop overhead cranes for safe, efficient, and reliable material handling.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch