30 Ton Overhead Crane for Sale – Workshop & Industrial Use Peru

30 ton European double girder overhead crane for salePeru. Reliable, heavy-duty, and low headroom crane options for workshop and industrial buyers.

| Crane Type | Europeans tyle overhead crane |

| Crane Capacity | 30 ton |

| Lifting Height | 12 meters |

| Crane Span | 12 meters |

Category: 30 Ton Overhead Crane

Your Trusted 30 Ton Overhead Crane Manufacturer & Supplier

30 Ton Overhead Crane for Sale, Tailored Eot Crane Soluation for Peru

30 Ton Overhead Crane for Sale – Workshop & Industrial Use Peru

In early 2025, we received an inquiry from a customer in Peru for a 30 ton overhead crane. The customer was looking for a reliable solution that could handle heavy lifting in a workshop environment. This request immediately highlighted the growing interest in workshop overhead cranes 30 ton across South America.

Many industrial facilities in the region are upgrading their material handling equipment. There is a clear demand not just for standard cranes but for solutions that combine high capacity with flexibility, such as low headroom cranes 30 ton and heavy-duty industrial cranes 30 ton. Buyers are looking for cranes that can work efficiently in tight spaces while maintaining durability and safety under frequent use.

The purpose of this case study is to show how a fully customized European type 30-ton overhead crane can meet these practical needs. By focusing on quality components, proper working class, and tailored design, the crane provides an ideal solution for both industrial operations and workshop applications.

Key points about the project and market needs:

- High lifting capacity: 30 tons, suitable for heavy-duty operations.

- Workshop suitability: Designed to fit compact workspaces without sacrificing performance.

- Low headroom options: Ideal for facilities where ceiling height is limited.

- Industrial reliability: Built to handle frequent operation with minimal maintenance.

- European components: Motors, VFDs, and electrical systems from trusted brands ensure consistent performance.

This project demonstrates how understanding local market demands and providing a tailored, reliable solution helps industrial buyers make informed decisions when selecting 30 ton overhead cranes.

Customer Inquiry Background

Before contacting us, the customer had already received several offers from other suppliers. Their main interest was in a 30 ton overhead crane that could operate reliably in a workshop and industrial setting. The two main options presented to them were:

- Standard double girder crane (M3 working class): A conventional solution, suitable for moderate lifting tasks but limited in long-term heavy-duty performance.

- European type double girder crane with Chinese components: Offered improved features, but the customer wanted clarity on whether Chinese components could match the reliability and durability of European brands.

The customer's main concern was understanding the differences in performance, reliability, and working class between these options. They wanted a crane that could handle frequent use, fit within their workshop, and maintain consistent operation under heavy loads.

To address this, we prepared a detailed proposal featuring our NLH European type double girder crane with fully European components. This solution was tailored for the South American market and included:

- Case references from similar projects in Peru and other countries in South America.

- Detailed comparison of working class (M5 vs M3), lifting capacity, and component quality.

- Explanation of long-term benefits, such as reduced maintenance, stable operation, and higher safety standards.

By providing this practical and detailed comparison, we helped the customer make an informed decision, showing how a properly specified workshop overhead crane 30 ton, low headroom crane 30 ton, or heavy-duty industrial crane 30 ton can meet both immediate and long-term operational needs.

30 Ton Overhead Crane Specifications

The 30 ton overhead crane for this project was designed to meet heavy-duty industrial and workshop requirements. Every aspect of the crane, from lifting capacity to control system, was specified to ensure reliable, long-term operation in South American facilities.

General Details

The crane's basic specifications provide a clear picture of its capabilities:

Lifting capacity: 30 Ton – suitable for heavy materials and frequent lifting tasks.

Span: 12.333 m – fits medium to large workshop layouts.

Lifting height: 12.5 m – sufficient for multi-level storage and industrial operations.

Working class: M5 – ideal for heavy-duty workshop and industrial applications, providing long-term reliability under frequent use.

Core Components

Every key component was carefully selected to ensure stable performance and low maintenance:

Hoist trolley lifting motor: SEW brand – strong and reliable for heavy lifting.

Hoist trolley traversing gear motors: SEW brand – smooth operation across the bridge.

Crane long traveling gear motors: SEW brand – durable for repeated full-span travel.

Electrical components: Schneider brand – ensures safety, consistency, and long service life.

VFD: ABB brand – precise speed control for lifting and traveling operations.

Power & Control

The crane's power and control system provides flexibility and safety for operators:

Power supply: 380V, 60Hz, 3-phase – compatible with industrial facilities in South America.

Control method: Pendant control and wireless remote control – allows operators to work safely from the ground and easily maneuver heavy loads.

Features Relevant for Buyers

This 30-ton solution was designed with practical workshop and industrial needs in mind:

Workshop overhead crane 30 ton: Compact design suitable for limited workshop spaces.

Low headroom crane 30 ton: Can be configured for facilities with restricted ceiling heights.

Heavy-duty crane 30 ton: Engineered for continuous industrial operations without compromising reliability.

Industrial overhead crane 30 ton reliability: European components (SEW, Schneider, ABB) ensure consistent performance and lower maintenance costs.

Advantages of European Type Overhead Crane (30 Ton)

Choosing a European type overhead crane 30 ton brings several clear benefits, especially for industrial and workshop applications where reliability and efficiency are critical. Compared to standard cranes with Chinese components or lower working classes, European cranes deliver consistent performance under demanding conditions.

Key Advantages

- Higher working class (M5): The M5 rating provides stronger mechanical durability and better handling of frequent heavy-duty lifting compared to M3 cranes. This makes it ideal for heavy-duty industrial crane 30 ton operations.

- Superior reliability: European components, including SEW motors, Schneider electrical systems, and ABB VFDs, ensure smooth and predictable performance. This reliability reduces downtime and keeps workshop operations running efficiently.

- Longer lifespan and lower maintenance: High-quality materials and precise engineering extend the crane's service life. Fewer unexpected repairs mean lower total cost of ownership, making it a practical investment for any facility needing a workshop overhead crane 30 ton.

- Stable operation in low headroom setups: The design allows safe, precise lifting even in tight spaces. This makes it suitable as a low headroom crane 30 ton, where ceiling constraints might otherwise limit lifting capacity or efficiency.

Customer Decision & Order Placement

After reviewing the proposal, the customer carefully considered the advantages of a European type 30 ton overhead crane compared to other options. To help them make an informed decision, we shared references from previous projects in Peru and across South America, demonstrating real-world performance of similar cranes.

The customer was particularly impressed by:

- Detailed comparison of cranes: Clear side-by-side information on working class, component quality, and operational reliability.

- Successful project references: Examples of similar installations in workshops and industrial facilities that confirmed the crane's performance and durability.

As a result of this practical and transparent approach, the customer quickly placed the order and made the advance payment, confident that the proposed crane would meet their workshop and industrial lifting needs.

This decision highlights how providing reliable references, clear comparisons, and detailed specifications can help buyers feel confident when investing in a workshop overhead crane 30 ton, low headroom crane 30 ton, or heavy-duty industrial crane 30 ton.

Production Status of 30 Ton Overhead Crane

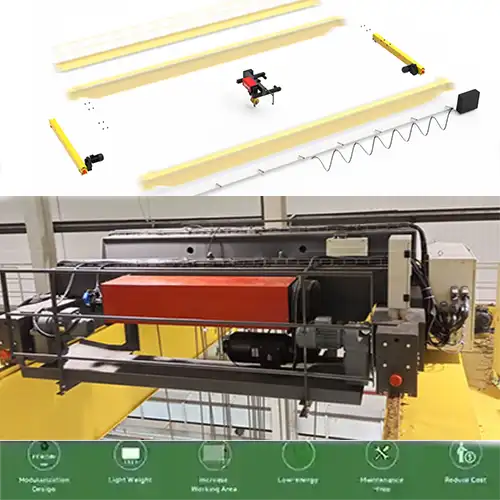

The production of the 30 ton European type overhead crane is progressing steadily, with key components nearing completion. Our team ensures that each part is manufactured according to high-quality standards to guarantee reliability for workshop, low headroom, and heavy-duty industrial operations.

Current Production Highlights

- Main girders and end carriages: Fully completed and inspected for quality and alignment.

- Wire rope hoist trolley: Scheduled to be finished within one week, with precise attention to assembly and testing.

- Ready for delivery: Once the hoist trolley is completed, the crane will be prepared for immediate shipment to the customer in Peru.

- Visual documentation: Progress photos of the main girders, end carriages, and hoist trolley are recorded to provide transparency and assurance to the customer.

This production stage demonstrates our commitment to delivering industrial overhead cranes 30 ton that meet strict quality standards while staying on schedule, ensuring a smooth installation and operation process for the customer.

Key Takeaways for 30 Ton Overhead Crane Buyers

Selecting the right 30 ton overhead crane requires more than just comparing prices. Buyers need to carefully evaluate technical specifications, operational requirements, and component quality to ensure long-term reliability.

Important Considerations

Understand working class and crane type: The working class (M5 in this case) determines how well the crane can handle heavy-duty or frequent operations. Knowing the difference between M3 and M5 can prevent unexpected downtime.

Match crane type to operational needs: Different facilities require different solutions:

- Workshop overhead cranes 30 ton for compact spaces.

- Low headroom cranes 30 ton for facilities with limited ceiling height.

- Heavy-duty cranes 30 ton for continuous industrial operations.

- Industrial overhead cranes 30 ton for large-scale production environments.

European components for reliable performance: SEW motors, Schneider electrical systems, and ABB VFDs provide smooth operation, lower maintenance, and longer service life.

Use local project references: Seeing similar cranes successfully installed in Peru and South America helps buyers trust the supplier and make faster, more confident decisions.

Conclusion

This case study demonstrates how a 30 ton European double girder overhead crane can meet the diverse needs of industrial and workshop operations in South America. By combining high lifting capacity with a robust M5 working class, this crane provides reliable performance for workshop overhead cranes 30 ton, low headroom cranes 30 ton, and heavy-duty industrial cranes 30 ton.

Key factors that made this solution successful for the customer include:

- Reliability: European components (SEW, Schneider, ABB) ensure consistent operation and reduced maintenance.

- Flexibility: Designed to suit various facility layouts, including low headroom and compact workshop environments.

- Quality: Precision engineering and high-grade materials extend the crane's service life, making it a practical investment.

For buyers looking to purchase a 30 ton industrial overhead crane, this case highlights the importance of choosing a supplier that provides detailed specifications, proven local references, and fully customized solutions tailored to operational needs.

Frequently Asked Questions (FAQ) – 30 Ton Overhead Crane in Peru

Answers to common questions from Peruvian buyers considering a 30 ton European double girder overhead crane for workshops or industrial facilities.

Is a 30 ton overhead crane suitable for workshops or industrial facilities in Peru?

Many Peruvian buyers wonder if a crane can handle heavy lifting while fitting the space available in their facilities. The European double girder design works well in both compact workshops and larger industrial plants. With an M5 working class, it's built for frequent, heavy lifts common in steel processing, manufacturing, and logistics operations in Peru.

How reliable are the crane components for operations in Peru?

Peruvian buyers often ask about durability under local working conditions. Using European components—SEW motors, Schneider electrical systems, and ABB VFDs—ensures smooth operation, minimal downtime, and a long service life even in demanding environments like heavy-duty workshops or industrial plants.

Can this crane be adapted for low headroom spaces common in Peru's older factories?

Yes. Many facilities in Peru, especially older workshops or retrofitted plants, have limited ceiling heights. This crane can be configured as a low headroom crane 30 ton, allowing full lifting capacity without compromising safety or workflow.

What control options are available for operators in Peru?

Operators can use pendant control or wireless remote control, which is particularly useful for larger workshops or facilities where line-of-sight operation is needed. Peruvian buyers appreciate these options for safe and precise handling of heavy loads.

How does installation and delivery work in Peru?

A common concern is timely delivery and setup. Our European-type cranes are shipped ready for assembly. We provide progress photos, detailed instructions, and references from previous projects in Lima, Arequipa, and other regions, ensuring confidence in local installation.

Why choose European components over local or Chinese alternatives in Peru?

Buyers often compare options for cost versus reliability. European components offer longer lifespan, less frequent maintenance, and better performance in high-duty workshops or industrial environments, which is important for Peruvian operations handling steel, heavy machinery, or other large loads.

What about maintenance and operational costs in Peru?

Peruvian buyers want practical solutions with minimal downtime. Using SEW motors and ABB VFDs reduces unexpected repairs, while routine inspections keep the crane performing reliably. This helps manage operational costs effectively, especially in busy industrial workshops.

Can one crane handle both workshop and industrial applications in Peru?

Yes. This 30 ton European double girder overhead crane is versatile. It can serve as a workshop crane 30 ton in compact facilities while also supporting heavy-duty industrial operations in factories, steel plants, or construction material yards across Peru.

Are there local references or projects in Peru to verify performance?

Many Peruvian buyers want proof before placing an order. We provide references from similar installations in Lima, Arequipa, and other industrial hubs, showing the crane's performance in real South American conditions.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch