Engine Room Overhead Crane, 2 to 50 Ton Overhead Cranes for Sale

Engine room overhead cranes 2 to 50 tons for sale.Check types, features & tips to select right crane for marine, power, petrochemical & industrial uses.

Category: Featured

Your Trusted Overhead Crane Manufacturer & Supplier

Engine Room Overhead Crane for Sale

2–50 Ton Overhead Crane Buyer's Guide for Industrial Enginer Rooms

Engine Room Overhead Crane for Sale | 2–50 Ton Overhead Crane Buyer’s Guide

Explore our practical guide for buying engine room overhead cranes from 2 to 50 tons. Learn about types, capacities, features, and tips to select the right crane for marine, power, petrochemical, and industrial applications.

Engine room overhead cranes are specialized lifting solutions designed for industrial spaces where heavy machinery needs to be moved safely and efficiently. These cranes are commonly installed in ship engine rooms, power plants, petrochemical facilities, and manufacturing plants. Unlike standard overhead cranes, engine room cranes are built to work in confined spaces with low ceilings, tight clearances, and challenging layouts.

For buyers, the main concern is safety and precision. Engine room equipment such as engines, turbines, generators, pumps, and compressors can weigh several tons. Moving them manually or with unsuitable lifting equipment isn’t just difficult—it can be dangerous. A properly selected engine room crane ensures that machinery can be lifted, positioned, and maintained without accidents or damage.

This guide is intended to provide practical advice for buyers. It will help you understand the different types of engine room overhead cranes, their capacities, design options, and how they fit into various industrial sectors. By the end, you should have a clear idea of how to select the right crane for your engine room, taking into account space, load, and operational needs.

Why Engine Room Overhead Cranes Matter

- Safety first: Reduce the risk of accidents when moving heavy machinery in confined spaces.

- Efficiency: Speed up installation, maintenance, and replacement of engines and equipment.

- Space optimization: Designed for low-ceiling or tight areas where standard cranes cannot operate.

- Precision handling: Smooth hoist and trolley movement allows accurate placement of equipment.

- Durability: Built to withstand vibration, heat, humidity, and sometimes corrosive environments.

Key Considerations for Buyers

- Load capacity: Know the weight of the heaviest equipment you plan to lift.

- Space constraints: Measure ceiling height, room width, and potential obstructions.

- Crane type: Single girder, double girder, underhung, gantry, or monorail, depending on your engine room layout.

- Operational needs: Electric or manual hoists, speed control, and safety features.

- Future requirements: Consider if machinery upgrades or expansions may require higher capacity cranes.

This guide will break down all these factors, making it easier for industrial buyers to make informed decisions without second-guessing or costly mistakes.

Common Types of Engine Room Overhead Cranes

Engine room overhead cranes come in several types, each suited to different loads, spaces, and machinery. Choosing the right type ensures safe, efficient, and precise handling of engines, turbines, and auxiliary equipment.

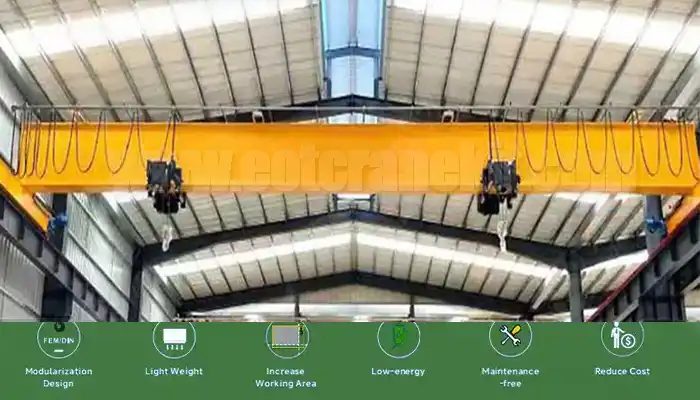

Single Girder Engine Room Overhead Crane

- Uses / Examples: Marine ship engine rooms, small turbine rooms

- Capacity: 1–20 tons

- Buyer Notes: Compact, fits low ceilings, easy to install and maintain; ideal for lighter engines and pumps.

Double Girder Engine Overhead Crane

- Uses / Examples: Power plants, steel mill engine rooms

- Capacity: 10–50 tons

- Buyer Notes: Handles heavier machinery with precise positioning; requires more overhead space but provides greater stability.

Gantry-Style Engine Room Crane

- Uses / Examples: Petrochemical pump rooms, refinery machinery

- Capacity: 2–30 tons

- Buyer Notes: Floor-supported, semi-portable; useful where overhead support is limited; needs rails on the floor.

- Uses / Examples: Ship workshops, small compressor rooms

- Capacity: 1–10 tons

- Buyer Notes: Fixed travel path, compact, cost-effective; ideal for light machinery and repetitive lifts.

Underhung / Underslung Crane for Limisted Space Engine Rooms

- Uses / Examples: Ports, floating platform machinery rooms

- Capacity: 1–20 tons

- Buyer Notes: Ceiling-mounted, saves floor space; often electric; ceiling must support crane load.

Practical Tip: Consider maximum load, room layout, ceiling height, and lifting frequency to select the most efficient and safe crane for your engine room.

| Type | Typical Use / Industry | Capacity | Notes |

|---|---|---|---|

| Single Girder Overhead Crane | Marine ship engine room Small turbine rooms | 1–20 tons | Compact, fits low ceilings Easy to maintain |

| Double Girder Overhead Crane | Power plants Steel mill engine rooms | 10–50 tons | Handles heavier machinery Precise positioning |

| Gantry-Style Engine Room Crane | Petrochemical pump rooms Refinery machinery | 2–30 tons | Semi-portable Floor-mounted rails Used where overhead support is limited |

| Monorail Hoist System | Ship workshops Small compressor rooms | 1–10 tons | Fixed path lifting Budget-friendly Ideal for small components |

| Underhung / Underslung Crane | Ports Floating platform machinery rooms | 1–20 tons | Suspended from ceiling rails Saves floor space Often electric |

Typical Designs and Configurations

Engine room overhead cranes can be customized in many ways, depending on the layout, load, and operating environment. The right design ensures safety, precision, and efficient workflow in confined spaces.

Top-Running vs. Underhung Bridges

Choosing the correct bridge type depends largely on the structural support available and the height of the engine room. Each option has distinct advantages for different situations:

- Top-running overhead crane with European style : The bridge moves on rails mounted on the walls. Ideal when the floor cannot carry the crane load.

- Underhung (underslung): Suspended from ceiling-mounted rails, saving floor space and maximizing clearance.

- Buyer insight: Ceiling height, structural strength, and floor load capacity are critical factors in deciding which bridge type to use.

Single vs. Double Trolley Systems

Trolley configuration affects how many items can be lifted at once and the coverage area within the engine room. Consider how often multiple lifts are needed:

- Single trolley: Moves one hoist along the bridge; suitable for lighter or occasional lifting.

- Double Trolley Overhead Cranes or Double Hoist Overhead Crane for Tandem Lift: Allows two hoists to operate simultaneously, covering a wider area or handling multiple items.

- Buyer insight: Double trolleys are valuable in engine rooms with frequent heavy lifting or complex maintenance operations.

Hoist Type

The hoist determines how the load is lifted and moved. Selecting the right hoist type improves efficiency and reduces operator fatigue:

- Manual hoist: Low-cost, simple, suitable for occasional light lifting.

- Semi-electric: Manual bridge movement combined with an electric hoist for better efficiency.

- Fully electric: Both bridge and hoist are powered electrically for smooth, precise, and fast operation.

- Buyer insight: Consider the lifting frequency, load weight, and ease of operation when choosing a hoist type.

Load Control Features

Modern engine room cranes are equipped with safety and control systems to protect both operators and equipment. These features ensure reliable operation in tight spaces:

- Overload protection to prevent accidents

- Emergency stop for immediate shutdown

- Anti-sway systems for smooth, safe handling

- Variable speed control for precise positioning

- Buyer insight: These controls are essential in confined engine rooms where precision and safety are crucial.

Environmental Adaptations

The operating environment significantly affects crane durability and maintenance requirements. Choosing the right adaptations prolongs service life:

- Heat-resistant for power plants or high-temperature areas

- Oil-resistant for petrochemical or pump rooms

- Corrosion-resistant coatings or materials for marine applications

- Buyer insight: Match the crane materials and protective finishes to the industrial environment to reduce downtime and maintenance costs.

Practical Tip: Always review engine room layout, load type, and environmental conditions before specifying crane designs and configurations. Proper choices minimize downtime, enhance safety, and simplify long-term maintenance.

Typical Lifting Capacities

Selecting the right lifting capacity is one of the most important steps when choosing an engine room overhead crane. The capacity must match the weight of your equipment while leaving room for safety and future needs.

- Light-duty: 1–10 tons

Small cranes suitable for light machinery.

Example: Small marine auxiliary engines, pumps, compressors. - Medium-duty: 10–30 tons

Ideal for moderate loads in engine rooms.

Example: Medium-size ship main engines, industrial generators, small turbines. - Heavy-duty: 30–50 tons or more

For large engines and heavy industrial machinery.

Example: Large marine engines, power plant turbines, steel mill pumps.

When planning crane capacity, always include a 20–30% safety margin above the maximum load. This accounts for unexpected weight variations, ensures safe operation, and reduces wear on the crane over time.

Engine Room Applications by Industry – Buyer-Focused Guide

Engine room overhead cranes are critical for lifting and maintaining heavy machinery across industrial sectors. Each industry has unique requirements in terms of equipment type, load, space, and environmental conditions. Below is a detailed guide with practical insights for buyers, highlighting typical crane types, capacities, special features, and reminders for sending inquiries.

Providing this information upfront ensures suppliers can recommend the most suitable crane, hoist type, protective features, and accurate pricing, saving time and improving safety and operational efficiency.

| Sector | Engine Room Examples | Typical Crane Type | Capacity |

|---|---|---|---|

| Maritime | Ship engine rooms Auxiliary pump rooms | Single / Double Girder | 5–30 tons |

| Power Generation | Thermal engine rooms Hydro & gas turbine rooms | Double Girder Gantry | 10–50 tons |

| Petrochemical / Oil & Gas | Pump rooms Compressor stations Refinery engine rooms | Gantry Underhung | 5–30 tons |

| Heavy Manufacturing | Steel mill machinery rooms Injection molding engine rooms | Double Girder Gantry | 10–50 tons |

| Mining / Minerals | Mill engine rooms Crusher drive units | Gantry Double Girder | 10–40 tons |

| Ports & Docks | Floating platform engine rooms Dock machinery rooms | Underhung Monorail | 5–20 tons |

| Water & Wastewater | Pump engine rooms | Single Girder Monorail | 2–10 tons |

Practical insight: Buyers should consider not just the load, but also the engine room layout, access points, and future maintenance needs.

Maritime Industry

Ship engine rooms and auxiliary pump rooms often have limited space and exposure to marine conditions. Choosing the right crane ensures efficient lifting and protects against corrosion.

- Engine Rooms: Ship engine rooms, auxiliary pump rooms

- Crane Types: Single Girder, Double Girder

- Capacity: 5–30 tons

Special Features:

- Corrosion-resistant coatings for saltwater environments

- Low headroom design for compact engine rooms

- Smooth trolley movement for precise engine alignment

Buyer Reminder: Share ceiling height, engine weights, and lifting frequency. This helps suppliers recommend a crane that fits your engine room and handles loads safely.

Power Generation

Engine rooms in power plants require lifting heavy turbines and generators, often in high-temperature environments. Cranes must be precise, durable, and capable of frequent operation.

- Engine Rooms: Thermal, hydro, gas turbine engine rooms

- Crane Types: Double Girder, Gantry

- Capacity: 10–50 tons

Special Features:

- High-capacity hoists for heavy turbines and generators

- Heat-resistant components for high-temperature areas

- Anti-sway and precise speed control for safe positioning

Buyer Reminder: Note how often heavy lifts occur and environmental conditions. This allows suppliers to suggest appropriate hoists and safety features.

Petrochemical & Oil & Gas

Pump rooms, compressor stations, and refinery engine rooms operate in potentially hazardous environments. Cranes must be designed for safety, chemical resistance, and precise handling.

- Engine Rooms: Pump rooms, compressor stations, refinery machinery rooms

- Crane Types: Gantry, Underhung

- Capacity: 5–30 tons

Special Features:

- Oil- and chemical-resistant components

- Explosion-proof or flameproof options for hazardous areas

- Anti-sway systems for safe handling of pumps and compressors

Buyer Reminder: Indicate if the area is classified as hazardous. Suppliers can then recommend cranes with certified safety features.

Heavy Manufacturing

Steel mills, injection molding plants, and other manufacturing engine rooms require cranes that handle frequent heavy lifting while maintaining precision and durability.

- Engine Rooms: Steel mill machinery rooms, injection molding engine rooms

- Crane Types: Double Girder, Gantry

- Capacity: 10–50 tons

Special Features:

- Heavy-duty frames for high-load cycles

- Vibration-resistant design for industrial machinery

- Optional dual-trolley system for multiple simultaneous lifts

Buyer Reminder: Provide lifting frequency, load types, and span requirements. Suppliers can then recommend the optimal bridge and hoist configuration.

Mining & Minerals

Engine rooms in mills and crusher units deal with heavy, abrasive loads. Cranes must be robust, dust-resistant, and capable of flexible positioning for maintenance.

- Engine Rooms: Mill engine rooms, crusher drive units

- Crane Types: Gantry, Double Girder

- Capacity: 10–40 tons

Special Features:

- Dust- and abrasion-resistant components

- High-strength hoists for heavy, abrasive equipment

- Flexible positioning for maintenance of crushers and mills

Buyer Reminder: Share environmental conditions such as dust or abrasive exposure. This ensures the crane is durable and long-lasting.

Ports & Docks

Floating platform and dock machinery rooms often have limited floor space and marine exposure. Cranes must be ceiling-mounted and corrosion-resistant.

- Engine Rooms: Floating platform engine rooms, dock machinery rooms

- Crane Types: Underhung, Monorail

- Capacity: 5–20 tons

Special Features:

- Ceiling-mounted to save floor space

- Corrosion-resistant for marine environments

- Smooth, precise hoist control for docking machinery alignment

Buyer Reminder: Provide ceiling height, access points, and floor strength to ensure safe and efficient installation.

Water & Wastewater

Pump engine rooms in water and wastewater facilities often require compact, moisture-resistant cranes capable of frequent maintenance lifts.

- Engine Rooms: Pump engine rooms

- Crane Types: Single Girder, Monorail

- Capacity: 2–10 tons

Special Features:

- Compact design for small rooms

- Moisture-resistant components

- Smooth hoist operation for frequent maintenance lifts

Buyer Reminder: Include room dimensions, lifting frequency, and pump types to allow suppliers to recommend the most efficient, space-saving solution.

Practical Buyer Insight

Key Functions and Features Buyers Need to Know

Engine room cranes are designed to lift, move, and position heavy machinery safely and efficiently, even in tight or challenging spaces. Understanding the primary functions and essential features will help buyers choose the right crane for their specific engine room.

Primary Functions

- Lifting, moving, and precisely positioning heavy engines, turbines, pumps, and other machinery.

- Supporting maintenance operations safely and efficiently without damaging equipment.

Essential Features

Before choosing a crane, consider these key features that ensure safe and reliable operation:

- Low Headroom Design

Allows installation in confined engine rooms without reducing lifting capacity. - High-Precision Movement

Enables accurate alignment of engines, turbines, and pumps, reducing installation errors. - Safety Systems

Includes overload sensors, limit switches, and emergency stops to protect personnel and equipment. - Smooth Trolley and Hoist Operation

Ensures controlled lifting and lowering, reducing the risk of swinging loads and collisions. - Durability in Harsh Environments

Resistant to heat, humidity, vibration, oil, and dust, making it suitable for marine, power, and petrochemical sectors. - Customizable Options

Span, lift height, hoist type, and trolley configuration can be tailored to specific engine room requirements.

Practical Buyer Note:

When sending an inquiry, specify engine weights, room dimensions, environmental conditions, and frequency of lifts. This ensures suppliers can recommend the most suitable crane with the right features for your operations.

Practical Buying Tips

Choosing the right engine room crane requires careful planning. Keep these tips in mind:

- Measure Engine Room: Span, ceiling height, rail position. Ensures proper fit and smooth operation.

- Check Maximum Load: Include heaviest load + future upgrades. Add 20–30% safety margin.

- Consider Environment: Marine, petrochemical, steel, mining, or power plant conditions affect crane design.

- Select Crane Type: Underhung saves floor space; gantry offers flexibility for maintenance and multiple lifts.

- Verify Compliance: Ensure CE, ISO, or other required safety certifications.

Tip: Providing dimensions, loads, environment, and preferred crane type upfront helps suppliers give accurate solutions and faster quotes.

Engine Room Overhead Crane FAQ – Buyer Guide

Engine room cranes can be complex. Here's a concise guide answering the most common buyer questions:

1. How do I choose the right crane capacity?

Before buying, determine the heaviest equipment you plan to lift and add a 20–30% safety margin.

- Typical range: 2–50 tons depending on industry and application.

- Buyer Tip: Include potential future upgrades when specifying load.

2. Which crane type fits my engine room?

- Single Girder: Light loads, tight spaces (1–20 tons)

- Double Girder: Heavy engines, precise positioning (10–50 tons)

- Gantry: Flexible installation where overhead support is limited (2–30 tons)

- Underhung / Monorail: Saves floor space, ideal for compact rooms (1–20 tons)

- Buyer Tip: Match the crane type to room layout and maintenance access.

3. What if my engine room has low ceilings?

Use low headroom cranes or underhung designs to maximize lifting capacity without reducing vertical clearance.

4. Which safety features are essential?

- Overload sensors and limit switches

- Emergency stop functions

- Anti-sway and precise speed control

- CE, ISO, or local safety compliance

- Buyer Tip: Safety features should match the load and environment for reliable operation.

5. Can cranes handle harsh environments?

Yes. Cranes can be customized for:

- Marine environments (corrosion-resistant)

- Petrochemical or oil/gas areas (oil- and chemical-resistant, explosion-proof)

- High-temperature, dusty, or vibrating areas

- Buyer Tip: Specify environmental conditions upfront for long-lasting durability.

6. How do I ensure smooth and precise lifting?

Look for cranes with smooth trolley and hoist movement, high-precision control, and anti-sway systems—especially for turbines, pumps, and generators.

7. What info should I include in a quote request?

- Maximum load and equipment type

- Engine room dimensions and ceiling height

- Rail positions and access points

- Environmental factors (temperature, chemicals, humidity)

- Lifting frequency and precision requirements

- Preferred crane type and any certifications

- Buyer Tip: Detailed info helps suppliers offer accurate solutions faster.

8. Are custom cranes available for unusual engine rooms?

Yes. Many suppliers can provide custom spans, lift heights, hoist types, and protective features for tight spaces or special layouts.

Related Products

Affordable 10 ton double girder overhead crane with CD/MD hoist trolley, built for U.S. standards, ideal for construction and industrial lifting

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch