Common Overhead Crane Capacity Mistakes and Solutions

Avoid costly crane selection errors by understanding capacity, duty cycle, environment, and specifications for safer, more efficient operations.

Category: Featured

Your Trusted Overhead Crane Manufacturer & Supplier

Common Overhead Crane Capacity Mistakes and How to Avoid Them

Overhead Crane Capacity

When it comes to overhead cranes, selecting the right capacity is crucial for smooth operations. A crane that’s too weak or too powerful for the job can lead to all sorts of problems, from safety risks to unnecessary costs.

The wrong capacity can impact your entire operation. Here’s why getting it right matters:

- Safety: If the crane can’t handle the load, it can fail, leading to accidents.

- Efficiency: Using the wrong crane can slow down operations, causing delays and frustrations.

- Cost: An oversized crane costs more to buy and maintain. A crane that’s too small might break down more often, leading to repairs and replacements.

So, understanding how to choose the correct crane capacity is essential for keeping things running smoothly. Let's take a closer look at some common mistakes people make when selecting crane capacity and how you can avoid them.

Capacity Range:

- Light Duty: 1T – 20T

- Common Use: Smaller workshops, warehouses, and factories handling light to medium loads.

Features:

- Simple, cost-effective design.

- Lower lifting heights and smaller spans.

Capacity Range:

- Medium Duty: 5T – 50T

- Heavy Duty: 50T – 100T+

- Common Use: Industrial settings like steel production, manufacturing plants, and heavy machinery handling.

Features:

- More stable, with the capacity to handle heavier loads.

- Suitable for larger spans and higher lifting heights.

Capacity Range:

- Light Duty: 1T – 3T

- Medium Duty: 3T – 10T

- Common Use: Small workshops, assembly lines, or areas with limited headroom.

Features:

- Saves floor space by traveling along ceiling beams.

- More affordable and less complex compared to top-running cranes.

Explosion-Proof Overhead Crane

Capacity Range:

- Light Duty: 1T – 10T

- Medium Duty: 10T – 32T

- Heavy Duty: 32T – 50T+

- Common Use: Hazardous environments such as chemical plants, oil rigs, or mining operations.

Features:

- Designed to prevent sparks and ensure safety in explosive atmospheres.

- Customizable for different levels of protection.

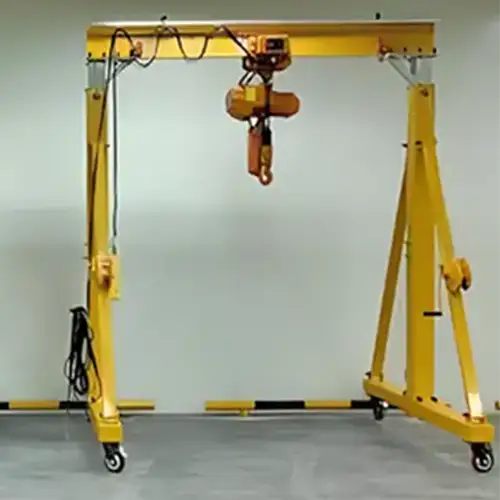

Capacity Range:

- Light Duty: 5T – 20T

- Heavy Duty: 50T – 200T+

- Common Use: Outdoor environments like ports, shipyards, and construction sites.

Features:

- Moves over a wider area, thanks to its own support legs.

- Perfect for handling large and heavy loads, such as shipping containers and construction components.

Each type of overhead crane is designed with a specific capacity range to meet different lifting needs. The crane capacity you choose should be based on your load requirements, facility space, and the environment in which the crane will operate. Selecting the right crane ensures operational safety, efficiency, and longevity.

Mistake 1: Underestimating Load Weight

One of the most common mistakes when selecting an overhead crane is underestimating the weight of the load. It's easy to assume that a crane with a slightly lower capacity will do the job, but that could lead to serious issues.

Problem: Selecting a Crane with Too Low a Capacity for the Intended Load

When a crane is chosen based on an incorrect or underestimated load weight, it’s like setting up a system to fail. The crane might not have enough lifting power to handle the load, which can lead to major problems. Whether it's lifting heavy materials or equipment, the capacity of the crane must always match or exceed the weight of the load.

Consequences: Increased Risk of Accidents, Damage to the Crane or Load, and Operational Delays

- Accidents: If the crane is not strong enough, it can result in load slippage or even collapse, posing a huge safety risk to workers and anyone nearby.

- Crane Damage: Operating a crane beyond its weight limit can cause strain on its components, leading to breakdowns, expensive repairs, or even permanent damage.

- Load Damage: Inadequate lifting capacity can lead to dropped loads or unstable lifting, which can damage the materials being moved.

- Delays: If the crane is constantly overworked, it might not perform as efficiently. This can slow down production, lead to downtime, and increase costs due to the need for repairs or replacements.

Solution: Conduct Thorough Load Assessments

Before choosing a crane, always perform a detailed load assessment. This includes not only weighing the load itself but also considering factors that can affect the total load weight, such as:

- Attachments: Cranes often use different types of hooks, grabs, or slings. These add extra weight to the load.

- Load Shape and Stability: Irregularly shaped loads can be harder to lift and might cause shifting, increasing the effective load weight.

- Environment: Environmental factors like wind or uneven ground can add stress to the crane and affect the total lifting capacity.

Account for Dynamic Load Factors, Including Lifting Speed and Load Swings

It’s important to keep in mind that the load isn’t always static when it’s lifted. Lifting speed and swinging loads can introduce additional forces. For example:

- Lifting Speed: The faster the crane lifts, the more force it applies to the load. Cranes that operate too quickly while carrying a heavy load can create additional strain.

- Load Swing: As the crane moves, the load may sway. This swinging motion can increase the effective weight of the load and put unnecessary pressure on the crane.

Always Allow for a Safety Margin Above the Actual Load

A good rule of thumb is to always choose a crane with a lifting capacity slightly above your maximum expected load. Adding a safety margin ensures that the crane will handle unforeseen circumstances without issue. For example, if the heaviest load you expect to lift is 10 tons, selecting a crane with a 12-ton capacity can help account for any additional forces.

In summary, underestimating the load weight and selecting an underpowered crane can lead to serious safety, efficiency, and cost problems. Conducting thorough assessments and allowing for a safety margin is the best way to avoid this mistake.

Mistake 2: Overestimating Load Capacity

While underestimating the load is a common mistake, overestimating crane capacity can also cause problems. It’s easy to think that a more powerful crane is always the better option, but this isn’t necessarily true.

Problem: Choosing a Crane with Excessive Lifting Capacity, Leading to Higher Costs

When you choose a crane that’s too powerful for the job, you’re not making the most of your investment. While a larger crane may give you the flexibility to lift heavier loads, if your regular lifting requirements are much lighter, you’ll be paying for unnecessary capacity.

Consequences: Unnecessary Higher Initial Investment and Operational Costs

- Higher Initial Investment: Cranes with higher capacities often come with a much higher price tag. If you don’t need that extra lifting power, you're spending more than you should upfront.

- Increased Energy Consumption: Bigger cranes typically consume more energy to operate, even when lifting lighter loads. This translates to higher electricity costs over time.

- Higher Maintenance Costs: More powerful cranes tend to have more complex systems, leading to more frequent maintenance needs. You’ll spend more on repairs, inspections, and parts that wouldn’t have been necessary with a smaller crane.

- Inefficiency: Larger cranes are often less efficient when lifting lighter loads. They may not run as smoothly, and their systems may be overworked, leading to wear and tear.

Solution: Choose a Crane Capacity That Matches Your Regular Load Requirements

To avoid overspending, assess the typical loads your crane will need to handle. Choose a crane that suits your everyday needs instead of opting for one with far more capacity than necessary. This will help you get the most value for your investment.

- Understand Your Load Range: Look at the typical weight of the materials you lift. If your loads are generally light, choose a crane that meets those requirements.

- Balance Cost and Performance: By selecting a crane that matches your needs, you’ll keep costs down without sacrificing the performance you require.

Consider the Specific Working Environment and Tasks to Avoid Overspending

Think about your unique environment and the tasks your crane will be used for. If you mostly handle lightweight materials, there’s no need for a heavy-duty crane. Similarly, if you need a crane for specific, high-precision tasks, features like lifting speed control or specialized hoists may be more important than lifting capacity alone.

- Material Type: Choose a crane based on the materials you’re handling. For example, handling bulk goods or containers might require a different approach than lifting small, delicate items.

- Operational Factors: Consider the work environment. If you work in tight spaces or high-clearance areas, the crane’s design features may matter more than its raw lifting power.

Opt for Adjustable or Modular Crane Systems That Can Be Scaled to Your Needs

One way to avoid overpaying for excessive capacity is to choose adjustable or modular crane systems. These cranes can be adapted to different tasks, allowing you to adjust the capacity depending on the workload.

- Scalability: Start with a crane that fits your current needs and upgrade when your requirements change.

- Flexibility: Modular cranes give you the option to adapt the system as your business grows, avoiding the need for a complete overhaul.

In conclusion, overestimating crane capacity leads to unnecessary costs in both the short and long term. By choosing a crane that aligns with your actual lifting needs and considering adjustable systems, you can save money while still ensuring efficiency and performance.

Mistake 3: Ignoring Future Growth Needs

Many buyers make the mistake of selecting a crane based only on their current needs, without thinking ahead to how their operations may evolve. While it’s natural to focus on immediate requirements, neglecting future growth can result in costly and inconvenient upgrades down the line.

Problem: Selecting a Crane Based Solely on Current Needs Without Accounting for Future Expansions

When you purchase a crane, it's easy to focus only on the loads and tasks you'll be handling today. But operations change. Your production might grow, or you may start handling heavier materials. If your crane isn’t built to grow with your needs, it will quickly become inadequate.

Consequences: The Crane May Quickly Become Obsolete or Inadequate for Future Operations

- Obsolescence: If your business grows and you need to handle heavier loads, a crane that worked perfectly fine at the start might no longer be suitable. You could end up needing to replace it prematurely.

- Increased Costs: Without a scalable crane, you may face higher costs in the future when you have to buy a new crane or upgrade your equipment.

- Disruptions to Operations: If your crane can't keep up with your growing needs, production can be delayed. This can affect delivery times, lead to missed deadlines, and impact overall operational efficiency.

Solution: Plan for Future Capacity Requirements by Considering Potential Business Growth or Load Increases

Instead of buying a crane based only on your current load, it’s smart to plan for the future. Look at how your business might evolve over the next few years. Consider factors like:

- Expected Increase in Load Weight: Will you need to lift heavier materials as your business expands?

- Growing Production Volume: As your output increases, will the crane need to handle more frequent or heavier lifts?

- Market Expansion: If you’re planning to enter new markets or expand your product line, consider how these changes might affect your crane needs.

Planning ahead ensures that the crane you invest in today can continue to support your operations tomorrow.

Choose Cranes with Scalability or Upgrade Options

To future-proof your crane investment, opt for cranes that offer scalability or easy upgrade options.

- Scalable Systems: Modular cranes allow you to add more components or increase lifting capacity as your needs grow. You don’t have to buy a whole new crane to accommodate more weight or higher volume.

- Upgrade Paths: Some crane models offer the ability to upgrade key components (like the hoist or control systems) to handle heavier loads or more frequent use, giving you flexibility in the long run.

By planning for growth and selecting cranes that can be scaled or upgraded, you can avoid costly replacements and minimize downtime when your business needs change.

In summary, selecting a crane based only on current needs can leave you in a difficult position as your business grows. By thinking ahead and investing in scalable or upgradeable systems, you can ensure your crane meets both your present and future needs.

Mistake 4: Failing to Account for Load Distribution

Another common mistake in crane selection is failing to consider how the load will be distributed across the crane. Even if the load weight is within the crane’s capacity, improper distribution can cause problems.

Problem: Misjudging How the Load Will Be Distributed Across the Crane

Not all loads are uniform in shape or weight, and how the load is spread out on the crane makes a big difference in how safely and efficiently it can be lifted. If the load is unevenly distributed, it can place extra stress on certain parts of the crane, even if the total weight is within capacity.

For example, lifting a large sheet of metal with an unbalanced load can put strain on the crane’s hoist or cause instability during the lift.

Consequences: Uneven Loading That Can Cause Strain on the Crane and Lead to Failure or Wear

- Crane Strain: Uneven weight distribution can create excessive force on the crane’s components, leading to premature wear and tear. This can cause parts to fail, requiring expensive repairs or replacements.

- Load Instability: An unbalanced load can cause the crane to struggle with stability during the lift. This increases the risk of load slippage or swinging, which could damage the load or cause safety hazards.

- Potential Crane Failure: If the load is consistently uneven, it can cause structural issues in the crane over time. This can lead to a complete breakdown, halting operations and resulting in costly downtime.

Solution: Consider Load Distribution Factors Such as Weight Spread, Lifting Points, and Load Stability

When selecting a crane, consider not just the weight but how the load will be distributed during the lift. Here are a few factors to keep in mind:

- Weight Spread: Assess how evenly the weight is distributed across the load. A crane that can only handle a certain weight at a single point may struggle with unevenly distributed loads.

- Lifting Points: Determine how many lifting points are needed. A load with multiple lifting points helps ensure better weight distribution and stability during the lift.

- Load Stability: Consider how stable the load will be during lifting. For example, will the load sway or shift easily, or will it remain steady?

Use Cranes with Load-Balancing Features or Multiple Lifting Points to Ensure Even Load Distribution

To avoid uneven loading, choose cranes that come equipped with load-balancing features. These can help spread the weight more evenly across the crane, preventing unnecessary strain on any single part.

- Multiple Lifting Points: Cranes that support multiple lifting points help balance the load and improve stability. This is especially useful for large or irregularly shaped loads that may not be evenly distributed.

- Load Balancers: Some cranes come with specialized load balancing systems that automatically adjust the lifting points to ensure the load remains stable throughout the process.

By accounting for load distribution when selecting a crane, you can prevent unnecessary damage to both the crane and the load, ensuring smoother, safer operations.

In summary, failing to consider how the load is distributed across the crane can lead to safety issues, increased wear and tear, and unnecessary downtime. Always factor in weight spread, lifting points, and stability to ensure the crane performs as expected without putting strain on its components.

Mistake 5: Overlooking Environmental Factors

When choosing a crane, many people focus primarily on the load capacity and operational needs without considering the environmental conditions the crane will be working in. But environmental factors can significantly affect a crane’s performance and lifespan.

Problem: Not Accounting for Environmental Factors (e.g., Temperature, Humidity, Dust) When Selecting Crane Capacity

Environmental conditions like extreme temperatures, humidity, dust, or corrosive materials can place additional stress on the crane and its components. If these factors are not taken into account when selecting a crane, it can lead to serious issues down the road.

For example, cranes used in high-temperature areas, such as steel mills or foundries, need to be designed to withstand heat without suffering damage. Similarly, cranes used in outdoor settings with heavy dust or moisture exposure may need additional protection against rust and wear.

Consequences: Crane Failure or Inefficiency in Harsh or Specialized Environments

- Crane Failure: If the crane is not built to handle specific environmental conditions, it may fail prematurely. For example, exposure to high temperatures or corrosive chemicals can cause parts to break down faster than expected.

- Inefficiency: In some environments, a crane that isn't suited for the conditions will operate less efficiently. This could be because it's struggling to handle external factors like humidity or dust, which could slow down the process and lead to energy waste.

- Increased Maintenance: Cranes exposed to harsh conditions tend to require more frequent maintenance. Without the right environmental protections, components like hoists, motors, and controls can wear out faster, increasing downtime and repair costs.

Solution: Assess the Work Environment Carefully Before Making a Capacity Choice

Before selecting a crane, assess the environment it will be working in. Consider factors such as:

- Temperature Extremes: Will the crane be exposed to high or low temperatures? Extreme temperatures can affect the crane’s components, so you’ll need to choose one that can withstand the heat or cold.

- Humidity: High moisture levels can cause rust and corrosion. Consider cranes with corrosion-resistant materials or coatings if you’re working in a humid environment.

- Dust or Chemical Exposure: If the crane will be working in a dusty environment (such as a quarry or steel mill) or one with chemical exposure, the crane may need special sealing and protection to prevent damage to sensitive components.

- Wind or Outdoor Use: Cranes used outdoors in areas with heavy winds or severe weather conditions should have reinforced components to ensure they remain stable and operational.

Consider Explosion-Proof, Corrosion-Resistant, or High-Temperature-Resistant Cranes When Necessary

In certain environments, you may need specialized cranes designed to withstand specific challenges:

- Explosion-Proof Cranes: In environments with flammable gases or dust (such as chemical plants or mines), explosion-proof cranes are necessary to prevent ignition and ensure safety.

- Corrosion-Resistant Cranes: In areas with high humidity or exposure to corrosive substances, corrosion-resistant cranes made with special materials like stainless steel or with protective coatings can ensure a longer lifespan.

- High-Temperature-Resistant Cranes: For environments with extreme heat, such as steel mills or foundries, you’ll need cranes that can operate effectively at higher temperatures, often with heat-resistant components or special lubricants.

Consult with Experts to Select a Crane That Can Handle Specific Environmental Conditions

When in doubt, consult with experts or manufacturers who specialize in cranes for specific environments. They can guide you in choosing a crane that meets your operational needs and environmental challenges. Whether it's selecting the right materials or deciding between different crane models, expert advice can help you make the best decision.

In summary, overlooking environmental factors can lead to crane failure, inefficiency, and higher maintenance costs. Always assess the environment where the crane will operate and select one that is designed to withstand those conditions. Whether it’s temperature extremes, humidity, or exposure to chemicals, a crane tailored to your environment will ensure safe, efficient, and long-lasting performance.

Mistake 6: Misunderstanding Duty Cycle Requirements

Another key mistake in crane selection is not properly assessing the crane’s duty cycle. The duty cycle refers to how often and how long a crane will be used over a given period, which directly impacts the crane's performance and longevity. Understanding your duty cycle is crucial for ensuring your crane can handle the demands of your operations.

Problem: Failing to Assess the Crane's Duty Cycle Based on the Frequency of Use

The duty cycle defines how frequently and for how long a crane will be in use. It’s important to assess how often your crane will be lifting, as well as the intensity of each lift. If you don't properly account for this, you may end up selecting a crane that isn't designed for the level of activity your operation requires.

- Heavy-Duty Operations: If your crane will be used frequently and for long hours, it needs to be rated for heavy-duty operations. A crane that isn’t built for continuous use could overheat, wear out prematurely, or fail.

- Light-Duty Operations: If your crane is only needed for occasional lifts, a lighter-duty crane might suffice. However, choosing a crane that’s too powerful for light tasks can lead to inefficiencies and unnecessary costs.

Consequences: Crane Capacity May Be Insufficient for Heavy or Continuous Operations, Leading to Overheating or Breakdowns

- Overheating: Cranes used continuously in heavy-duty applications are at risk of overheating if they aren’t rated for the appropriate duty cycle. Overheating can cause severe damage to the motor and other components, leading to downtime and costly repairs.

- Premature Breakdown: If the crane is constantly pushed beyond its intended duty cycle, parts will wear out faster. This could lead to a breakdown, stopping operations and causing delays.

- Inefficiency and Downtime: A crane that’s overworked can lead to inefficiencies in your operation. If the crane struggles to keep up with the workload, it can cause delays and affect overall productivity.

Solution: Choose a Crane That Matches Your Duty Cycle, Whether Heavy-Duty, Medium-Duty, or Light-Duty

To avoid these issues, you need to select a crane that matches the duty cycle required for your operations. Cranes are typically rated for:

- Heavy-Duty: For operations that require continuous use or frequent lifting, such as in manufacturing, steel mills, or distribution centers.

- Medium-Duty: For moderate use, where the crane is used intermittently throughout the day but isn’t required to operate at full capacity for extended periods.

- Light-Duty: For occasional use, such as in smaller workshops or for infrequent tasks, where the crane will only be used for short periods.

Make sure to review your crane’s expected usage and select a model rated for that duty cycle. This ensures the crane can handle the workload without failing prematurely.

Ensure the Crane Is Rated for the Expected Frequency and Intensity of Use

Before making a purchase, check the crane’s duty cycle rating to ensure it matches your needs. Some cranes have adjustable settings for different duty cycles, while others are fixed based on their design. If you expect high-frequency lifts or continuous operation, invest in a crane that’s designed to handle that intensity.

By carefully matching the crane’s duty cycle to the level of activity in your facility, you can prevent overheating, breakdowns, and inefficiencies. It ensures the crane will perform optimally over time, extending its lifespan and reducing the likelihood of costly downtime.

In summary, understanding the duty cycle is essential for choosing the right crane. Whether your operation requires heavy, medium, or light-duty performance, make sure the crane you choose is up for the job. This will ensure reliability, efficiency, and long-term value.

Mistake 7: Focusing Only on Lifting Capacity and Ignoring Other Specifications

It’s easy to focus solely on lifting capacity when choosing a crane, but that can lead to overlooking other important factors that affect crane performance. While lifting capacity is a critical consideration, it’s not the only specification that matters. Failing to take other factors into account can result in a crane that doesn't meet the specific requirements of your operation.

Problem: Neglecting to Consider Other Crucial Specifications, Such as Span, Height of Lift, and Speed

Lifting capacity is often the first thing that comes to mind when selecting a crane, but there are several other specifications that play a major role in ensuring the crane fits your operational needs. These include:

- Span: This is the distance the crane can cover, which is crucial for determining whether the crane can reach all the areas it needs to serve.

- Height of Lift: The maximum height to which the crane can lift a load is essential, particularly in facilities with tall structures or elevated platforms.

- Speed: The speed of the crane affects how quickly it can complete tasks, which is especially important in high-output environments.

If you fail to consider these specifications, you may end up with a crane that can handle the weight but not the specific tasks required.

Consequences: Choosing a Crane That Doesn’t Fit the Specific Operational Requirements of the Task

- Inadequate Reach: If the crane’s span isn’t wide enough, it may not be able to reach all the work areas, resulting in inefficiency and potential safety hazards.

- Insufficient Lifting Height: If the crane can’t lift to the required height, it can cause delays or force you to perform work outside the optimal height range, leading to unnecessary adjustments or risks.

- Slow Operation: A crane with inadequate speed may slow down operations, reducing productivity and leading to costly downtime. In fast-paced environments, this can be a significant issue.

- Inefficient Workflow: If the crane’s specifications don’t align with your workflow, it can lead to bottlenecks, unnecessary repositioning, or inefficient lifting cycles.

Solution: Ensure All Factors (Span, Lift Height, Speed) Align with Your Operational Needs, Not Just Lifting Capacity

When selecting a crane, it’s important to consider the full range of specifications that will affect its performance. Here’s how to do that:

- Span: Measure the area the crane will need to cover and choose a crane with a span that allows it to reach all required locations.

- Height of Lift: Consider the height at which the crane will be lifting loads, especially in tall workshops or areas with elevated platforms.

- Speed: Evaluate the speed at which the crane needs to operate. In some environments, you may need a crane with faster lifting and lowering speeds for more efficient operations.

- Other Features: Don’t forget to consider additional specifications like hoist type, hook approaches, or control systems, which can all impact your crane's efficiency and safety.

Consult with Crane Suppliers for Customized Solutions Based on Your Full Set of Requirements

To ensure you get the right crane for your needs, work closely with your crane supplier. They can help you identify all the important specifications required for your specific operations and recommend a crane that meets all of your needs, not just the lifting capacity.

- Customized Solutions: A good supplier will be able to offer customized crane solutions that are tailored to your operational requirements. They can guide you on selecting the right span, lift height, and speed that fit your workflow and production goals.

In summary, while lifting capacity is important, it’s just one part of the equation. To avoid selecting a crane that doesn’t meet your needs, ensure that all relevant specifications—such as span, lift height, and speed—align with the requirements of your operation. Consulting with an expert supplier will help ensure that all factors are considered, leading to better performance and more efficient operations.

Conclusion

In this guide, we’ve walked through the most common mistakes made when selecting overhead cranes, from underestimating load weight to ignoring environmental factors. Each of these errors can lead to serious consequences, from safety risks to costly breakdowns and inefficiencies.

Recap of Common Mistakes and How Careful Planning Can Prevent Costly Errors

Quick recap of the mistakes we discussed:

- Underestimating Load Weight: Choosing a crane with too low a capacity can lead to accidents and delays.

- Overestimating Load Capacity: Opting for a crane with unnecessary high capacity can drive up costs without any benefit.

- Ignoring Future Growth Needs: Failing to plan for future increases in load demands can make the crane inadequate as your business grows.

- Failing to Account for Load Distribution: Not considering how a load will be distributed can result in excessive strain on the crane and potential failure.

- Overlooking Environmental Factors: Not choosing the right crane for specific environmental conditions can lead to breakdowns or inefficiency.

- Misunderstanding Duty Cycle Requirements: Choosing a crane that doesn’t match the frequency of use can lead to overheating or early wear.

- Focusing Only on Lifting Capacity: Ignoring other important specifications like span, height of lift, and speed can make a crane unsuitable for your tasks.

Each of these mistakes can be avoided with careful planning and attention to detail when selecting your crane.

The best way to avoid these costly mistakes is to thoroughly assess your operational needs and consult with crane experts. These professionals can help guide you in selecting the right crane based on your specific requirements, ensuring all factors—like load capacity, span, lift height, and environmental conditions—are taken into account. They can also provide tailored solutions that consider both your current needs and potential future growth.

Selecting the right crane capacity isn’t just about meeting immediate needs; it’s about ensuring long-term operational success. A crane that’s properly matched to your business’s requirements will not only improve efficiency and productivity but also reduce the likelihood of expensive breakdowns and repairs. Investing in the right crane from the start can save you money, enhance safety, and contribute to smoother operations in the long run.

In conclusion, take the time to assess all the factors that influence crane selection and consult with experts to ensure you’re making the best choice. Proper planning and careful consideration of your operational needs will lead to smarter decisions, reducing risks and costs, and supporting your business’s growth and success.

Related Products

Affordable 10 ton double girder overhead crane with CD/MD hoist trolley, built for U.S. standards, ideal for construction and industrial lifting

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch