KBK Workstation Crane for Switzerland, 500KG Light Bridge Crane

Efficient light workstation bridge crane offering space-saving, quiet operation & reliable lifting for Swiss workshops & industries.Get workstation crane!

Category: Workstation Crane

Your Trusted KBK Workstation Crane Manufacturer & Supplier

KBK Workstation Crane for Switzerland, 500KG Light Workstation Bridge Crane

Efficient light workstation bridge crane offering space-saving, quiet operation & reliable lifting for Swiss workshops & industries.Get workstation crane!

Introduction

This project focuses on supplying a KBK workstation crane system to a client in Switzerland. The client runs a light manufacturing workshop with limited ceiling height and tight space. They needed a solution that fits well in a compact area without compromising on performance.

Light workstation bridge cranes like the KBK system are perfect for such environments. Swiss workshops often have strict requirements on space and noise. That's why a lightweight, modular crane system is ideal. It helps maximize the workspace while keeping operations smooth and quiet.

Client Requirements for Workstation Crane in Switzerland

The client's main concern was saving space. The workshop has low ceilings and narrow aisles, so a traditional crane wouldn't fit well. They needed a system that uses ceiling space efficiently, leaving room for other equipment and workers.

Noise was another big issue. The workshop operates near offices and testing areas where quiet is important. So, the crane had to run smoothly with minimal vibration and sound.

Safety and reliability were also critical. The crane must handle smaller parts repeatedly without fail. Accurate load positioning was needed for precision work, plus built-in safety features to protect both operators and the equipment.

In short, the KBK workstation crane had to be:

- Compact and space-saving, perfect for low headroom

- Quiet and smooth to not disturb nearby work areas

- Reliable for daily use with safe and precise handling

- Easy to integrate into the existing workshop setup

This combination made the KBK light workstation bridge crane the best fit for the client's Swiss workshop needs.

KBK Workstation Crane

The KBK workstation crane system is designed for smooth, safe, and quiet handling of light to medium loads. It uses an electric chain hoist that provides precise control, making it ideal for lifting small parts carefully and accurately.

Modular Design for Easy Setup and Growth: One of the biggest advantages of the KBK crane is its modular design, which simplifies both installation and future upgrades.

- The crane system is made of modular parts, such as pre-engineered steel rails and components.

- This allows quick and easy installation with minimal downtime.

- If you need to expand or change your workshop layout later, the system can be adjusted or extended without hassle.

Adapts to Different Workshop Spaces: The KBK crane is built to work well in a variety of workshop layouts and ceiling conditions, making it very versatile.

- The KBK crane fits well in many types of workshops.

- It works with straight runways, corners, or uneven ceiling shapes.

- Because the rails hang close to the ceiling, it saves floor space.

- The lightweight but strong rails are perfect for workshops with limited support structures.

The KBK workstation crane offers quiet, precise operation combined with a flexible design to meet the needs of compact workshops.

- Quiet and smooth electric chain hoist for careful handling

- Modular parts for fast installation and easy future changes

- Flexible setup that fits low ceilings and tight spaces

This makes the KBK workstation crane a practical and efficient choice for Swiss workshops aiming to improve material handling safely and effectively.

Technical Specifications of the Workstation Crane Project for Switzerland

The KBK workstation crane is designed with precise technical details to fit the client's workshop needs perfectly. These specs focus on performance, safety, and ease of use.

Lifting Capacity and Height

- Capacity: 0.5 tons (500 kg), perfect for light-duty lifting tasks

- Maximum lifting height: 8 meters, providing ample vertical reach for workshop operations

This capacity and height suit the handling of smaller parts and components, common in detailed assembly or manufacturing work.

Runway Length and Layout

- Runway length: 42.5 meters of straight monorail track

- Installation: Suspended KBK rails for a low-profile setup

The long, straight runway covers the required workspace while keeping the floor area clear and maximizing ceiling space.

Power and Controls

- Power supply: 380V, 50Hz, three-phase, standard for industrial facilities

- Control options: Pendant control for manual operation and optional wireless remote for flexible, safer use

These controls allow operators to move loads smoothly and safely, either from close by or at a distance.

Together, these technical details ensure the KBK workstation crane is a reliable, efficient, and user-friendly solution tailored for the Swiss workshop environment.

workstation crane kbk rail - types of kbk cranes for sale

Workstation crane kbk

workstation crane parts and components

kbk workstation crane parts and components packaged for delivery to Switzerland

Key Advantages of the KBK Workstation Crane System

The KBK workstation crane system stands out for its practical benefits, perfectly suited for Swiss workshops that value space efficiency and precision.

- Compact Design: The system's compact build is ideal for low-headroom environments. By using suspended KBK rails, it saves valuable ceiling space and keeps the workshop floor open and safe.

- Quiet, Low-Vibration Operation: Smooth and quiet operation minimizes noise and vibration. This makes it great for sensitive tasks where a calm and focused atmosphere is needed.

- Modular Flexibility: Thanks to its modular design, the system can be easily installed and adapted. Whether extending the runway or changing layout, adjustments are straightforward and cost-effective.

- Reliable Handling: Built for light-duty, moderate-use scenarios, it ensures consistent and accurate load control. This reliability helps maintain smooth daily workflows without interruptions.

Overall, the KBK workstation crane offers a balanced combination of space-saving design, operational quietness, adaptability, and dependable performance for Swiss workshops.

125 kg up to 3,200 kg Workstation Bridge Crane with KBK Rail System for Sale in Switzerland

When looking for a workstation bridge crane system in Switzerland, the KBK rail system offers versatile options tailored to different workshop needs. Here are the common types available:

Single Girder KBK Workstation Bridge Crane

This is the most popular type for light to medium-duty applications. It features one KBK rail supporting the electric chain hoist. It's ideal for workshops with limited space and lower lifting requirements.

- Compact and lightweight design

- Easy to install and maintain

- Suitable for precise, repetitive tasks

Double Girder KBK Workstation Bridge Crane

For heavier loads or longer spans, a double girder KBK crane provides extra stability and higher lifting capacity. It uses two parallel KBK rails and is well-suited for workshops that require frequent lifting of heavier components.

- Increased load capacity (up to several tons)

- Greater rigidity and safety

- Flexible for larger or more complex layouts

Suspended Monorail KBK Crane

This type is designed for straight monorail applications with fixed pathways. It's efficient for linear material movement along a set route inside the workshop.

- Space-saving ceiling suspension

- Simple track layout

- Ideal for repetitive, linear workflows

Curved or Flexible KBK Crane System

The KBK system can also be customized with curved rails or flexible layouts, allowing cranes to follow non-linear paths around workshop obstacles or unique floor plans.

- Custom curved rail options

- Enables optimized material flow

- Adaptable to complex building structures

Each type of KBK workstation bridge crane system for sale in Switzerland can be tailored for lifting capacity, span length, and control options. This makes it easy to find the right crane that fits your exact workshop requirements and improves workflow efficiency.

Main Parameters of Workstation KBK Crane System

- Lifting Capacity: Typically ranges from 125 kg up to 3,200 kg (3.2 tons)

- Lifting Height: Usually customizable, common heights between 3 m to 10 m or more

- Span Length: Depends on workshop layout, commonly from 5 m up to 50 m or longer

- Runway Type: Suspended KBK modular rail system, straight or curved track options

- Operation Mode: Electric chain hoist with pendant control or wireless remote control

- Power Supply: Commonly 380V, 50Hz, 3-phase (customizable per region)

- Duty Classification: Light to moderate duty (e.g., H3 to H4 according to FEM standards)

- Installation Height: Adapted for low-headroom spaces, typically 2.5 m to 4 m clearance

- Control Options: Pendant control, wireless remote, or manual operation available

- Noise & Vibration: Designed for low noise and smooth, vibration-free operation

- Safety Features: Limit switches, overload protection, emergency stop, anti-drop devices

These parameters ensure the KBK workstation crane system fits well in compact, precise environments like Swiss workshops, offering safe and efficient material handling.

Optional Features for Customized Light Workstation Bridge Crane Solutions

To make sure the KBK workstation crane system perfectly fits your workshop needs, several optional features can be added. These options improve control, safety, and adaptability for different working environments.

Control Options

You can choose between different control methods depending on your preference and operational requirements:

- Pendant Control: This is a simple and reliable wired control that hangs from the crane. It allows precise control of lifting and movement, making it easy to operate the crane safely.

- Wireless Remote Control: For more flexibility, wireless remotes let operators control the crane from a distance. This increases safety by allowing the operator to stand in the best position for visibility and avoid hazardous areas.

Safety Devices

Safety is a priority, especially in light-duty but precise handling tasks. These devices help prevent accidents and equipment damage:

- Limit Switches: These automatically stop the hoist when it reaches its maximum lifting height or travel limits, avoiding over-travel and potential collisions.

- Emergency Stop: An easily accessible emergency stop button can immediately halt crane operation in case of unexpected issues, protecting both personnel and materials.

- Overload Protection: Prevents lifting loads beyond the crane's rated capacity, ensuring long-term equipment safety and reducing maintenance costs.

Structural Adaptations

Each workshop is unique. To fit perfectly into your space, the KBK crane system can be adapted structurally:

- Additional Support Brackets: For ceilings that require extra support, these brackets provide secure attachment points for the KBK rail system.

- Flexible Connection Joints: These allow the crane runway to navigate around obstacles or follow irregular ceiling layouts without compromising stability or safety.

- Custom Runway Lengths and Curves: The modular KBK rail system can be designed with straight or curved tracks to maximize the use of your available workspace.

These optional features let you tailor your workstation bridge crane system to match your exact needs, ensuring efficient, safe, and flexible operation in your Swiss workshop.

Client Input Checklist for Accurate KBK Workstation Crane Quotation

To provide a precise and cost-effective quotation for your KBK workstation crane, we need detailed information about your workshop and operational needs. The more accurate your input, the better we can tailor the system to fit your requirements.

Workshop Layout and Runway Beam Drawings

Please share any existing layout plans or structural drawings of your workshop. These should clearly show:

- The positions of runway beams or support structures where the KBK rail system will be installed

- Dimensions of the working area including length, width, and any obstacles

- Any special architectural features or restrictions that could affect crane installation

Having these details helps us design the crane runway to maximize space and avoid installation issues.

Installation Height and Ceiling Clearance

Provide precise measurements for the available vertical space:

- Height from floor to ceiling or overhead obstacles

- Minimum clearance needed above the workspace

- Any variations in ceiling height along the runway path

This information ensures the crane system fits perfectly within your workshop's limited headroom while maintaining safe lifting heights.

Load Type, Lifting Frequency, and Control Preferences

Understanding your lifting needs is crucial for selecting the right equipment:

- Describe the typical loads to be handled (weight, size, shape, fragility)

- Indicate how often the crane will be used (occasional, regular, or continuous operation)

- Specify your preferred control method (wired pendant or wireless remote)

- Mention any special handling requirements such as precise positioning or sensitive materials

This data helps us recommend the most suitable electric chain hoist and control system for reliable and safe operation.

Providing this information at the start of your inquiry ensures a smooth and efficient quotation process, saving time and avoiding misunderstandings. Feel free to send drawings, photos, or any extra details to help us support your project better.

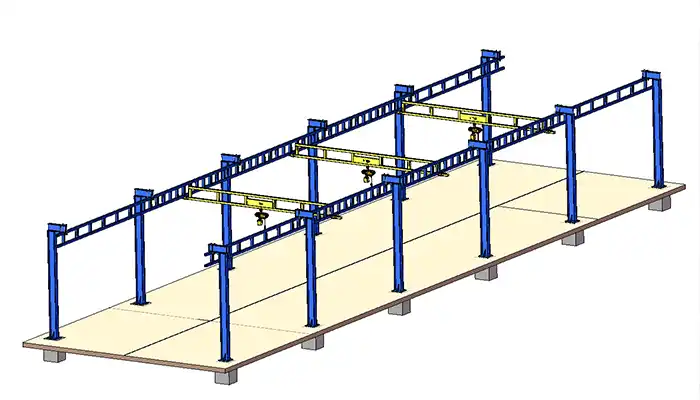

kbk worksation crane with long travelling length

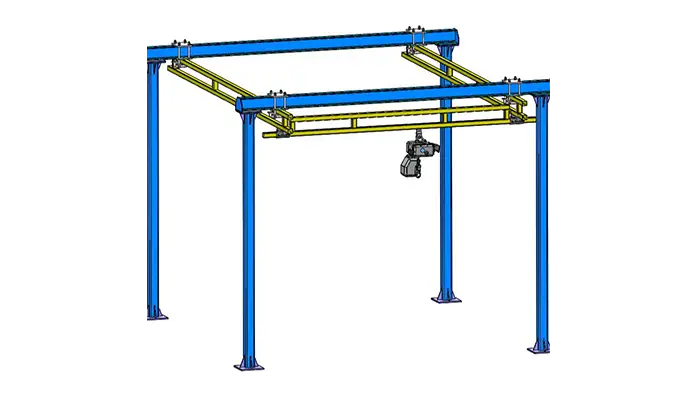

Workstation bridge crane with light kbk rail system

KBK Workstation Crane Inquiry Form

About Your Workstation

| Item | Please Provide Details | Notes / Examples |

|---|---|---|

| Workshop layout | [Attach drawing or sketch showing runway beam locations] | Floor plan or structural drawing preferred |

| Ceiling height & clearance | [Measure floor to ceiling height and note any obstacles] | Include pipes, lights, ducts, or other obstructions |

Crane Specifications

| Item | Please Provide Details | Notes / Examples |

|---|---|---|

| Load type and weight | [Describe the materials or items to lift + their max weight] | Example: Steel parts, max 500 kg |

| Lifting frequency | [How often will the crane be used?] | Example: 10 lifts per hour, continuous use, etc. |

| Control method | [Choose pendant control or wireless remote control] | Select based on ease of use and safety needs |

Additional Information

| Item | Please Provide Details | Notes / Examples |

|---|---|---|

| Special requirements | [Any extra features needed? e.g., safety devices, extra supports] | Limit switches, emergency stops, custom supports |

Feel free to fill in the details and send this back. This helps us provide you with the most accurate and tailored KBK workstation crane solution.

Get Your Workstation Crane Price – Tailored KBK Solutions for Swiss Workshops

The KBK workstation crane system is designed to meet the exact needs of light-duty workshops in Switzerland. Its compact and quiet design makes it ideal for tight spaces, ensuring safe and precise material handling without disrupting your work environment.

Thanks to its modular construction, the system can be easily customized and expanded to fit your workshop layout perfectly. Whether you need a simple or advanced setup, the KBK crane delivers reliable performance every day.

Ready to know how much a KBK workstation crane will cost for your facility? Send us your workshop details and lifting requirements. We'll prepare a clear, competitive price quote tailored specifically for you.

Contact us now to get your workstation crane price and discover how this flexible system can improve your workshop's efficiency and safety.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch