15 Ton Overhead Crane Price – When Standard Becomes Specialized

Discover why 15 ton overhead cranes offer ideal capacity and cost balance for mid-sized industrial lifting needs.Get your customized 15 ton overhead crane!

Category: Ton & Price

Your Trusted 15 Ton Overhead Crane Manufacturer & Supplier

15 Ton Overhead Crane Price – When Standard Becomes Specialized Crane Solution

Introduction: Why Buyers Shouldn't Overlook 15 Ton Overhead Cranes

Why More Buyers Are Choosing 15 Ton Overhead CranesIf you're stuck between a 10-ton crane that feels a bit underpowered, and a 20-ton crane that's too expensive for what you actually lift—you're not alone.

Many buyers find that a 15 ton overhead crane is the right match, even though it's not the most talked-about option. After checking real load weights and usage, people start searching for terms like "15 ton overhead crane for sale" or "15 ton bridge crane suppliers"—because it turns out, it's the size they actually need.

When 10 Tons Isn't Quite Enough, and 20 Tons Is Overkill

Plenty of industrial loads fall right between the usual crane sizes. Not everything fits neatly into a catalog spec. For example:

- Steel coils or metal rolls can easily weigh 12 to 14 tons. That's pushing the upper limit of a 10-ton crane, especially for repeated use.

- Molds and dies for automotive or injection molding? Some come in just under 15 tons once you factor in lifting tools.

- Precast concrete panels, machine components, and heavy assemblies often fall in the 13–15 ton range.

If your load hovers above 10 tons, a 15 ton bridge crane gives you room to work without stressing your equipment—or your budget.

Practical Benefits of a 15 Ton Overhead Crane

Choosing a 15 ton overhead crane is about being smart with your capacity. You're not overbuilding for the occasional heavy lift, and you're not risking safety or extra wear by maxing out a smaller crane.

Here's what makes it a practical option:

- Better fit for mid-heavy loads without jumping into 20-ton structural demands

- More affordable price range, especially if you don't need high duty cycles

- Easier installation and lighter runway support than 20-ton models

- Available in both single girder and double girder setups to match workshop layout and span requirements

A crane that's too big costs more upfront, and it often means a bigger motor, bigger structure, and higher long-term maintenance. On the flip side, going too small increases the chance of overload, faster wear, and downtime.

Why Buyers Search for "15 Ton Overhead Crane for Sale"

The truth is, 15 ton cranes don't always show up in basic catalogs. But more buyers are specifically asking for them because:

- Their lifting needs aren't extreme—but they're not light either

- They want a crane tailored to their actual workload, not a one-size-fits-all solution

- They're trying to stay within budget without sacrificing safety or flexibility

If your production line, warehouse, or shop floor regularly handles items between 12 and 14 tons, it's worth getting a quote on a 15 ton overhead crane price. You might find it saves you money and fits your operation better than the more common options.

What Does a 15 Ton Overhead Crane Really Handle?

If you're wondering what kind of work justifies investing in a 15 ton overhead crane, the answer is pretty straightforward—it's for lifting jobs that regularly go over 10 tons but don't quite demand a full 20-ton system. That's where 15 tons hits the mark.

It's not just about numbers on paper. These cranes are working every day in real-world applications that need consistent, reliable mid-range lifting power. Let's look at the kind of loads a 15 ton crane is built to handle.

Common Loads Handled by 15 Ton Overhead Cranes

Whether you're buying your first unit or replacing an older one, here are the materials and equipment that commonly fall into the 15-ton capacity range:

- Steel plates and billets – Ranging from 8 to 12 meters in length, depending on the grade and thickness, often weighing 10 to 14 tons

- Molds and dies – Frequently used in automotive, injection molding, and casting shops, many reach 12–14 tons with lifters and rigging included

- Steel coils or metal rolls – High-density coils, especially hot-rolled ones, can easily weigh 10–15 tons each

- Medium-sized machinery and equipment – Gearboxes, engines, and industrial machines for assembly, testing, or repair

- Finished components and structures – Tanks, beams, pipe assemblies, and frame structures often land in the 12 to 15-ton weight range

- Precast concrete parts – Panels, slabs, and blocks used in modular construction or bridge building

If you handle these kinds of items regularly, searching for a 15 ton bridge crane or 15 ton overhead crane for sale makes a lot of sense. It gives you lifting power with room to spare—without the added size and cost of a 20-ton system.

Best Use Cases for a 15 Ton Overhead Crane

So, where do 15 ton cranes make the most impact? You'll typically find them in places where lifting is heavy, but not extreme. Buyers in these industries often find this capacity fits like a glove:

- Mid-sized foundries and steel warehouses – Moving steel stock, billets, or ingots safely without overloading

- Mold and tooling shops – Frequent handling of heavy molds or dies that exceed 10 tons but fall under 15

- Metal fabrication plants – Lifting structural frames, parts, and subassemblies into place for welding or machining

- Machinery maintenance bays – For pulling and placing engines, compressors, or hydraulic systems during service work

- Precast concrete production yards – Handling concrete elements like stairs, slabs, or beams up to 14 tons each

Each of these environments deals with loads that are heavy—but not quite heavy enough to justify the size, cost, and support requirements of a 20 ton crane.

That's where the 15 ton overhead crane fills the gap perfectly.

- Check our tailored 15 ton overhead crane for sale projects for your reference.

- C Hook Overhead Crane 15 Ton for Steel Coil Handling Bangladesh

- 15 Ton Overhead Cranes Optimizing Space in Steel Mills Argentina

- 15 Ton Overhead Crane for Sale Poland, Double Girder Crane Design

- 15 Ton Eot Cranes for Sale Pakistan: Production & Commissioning

If you have any need of 15 ton overhead cranes, please feel free to contact us. WhatsApp: + 86 151 3871 1597.

15 Ton Overhead Crane Price Breakdown: What You're Really Paying For

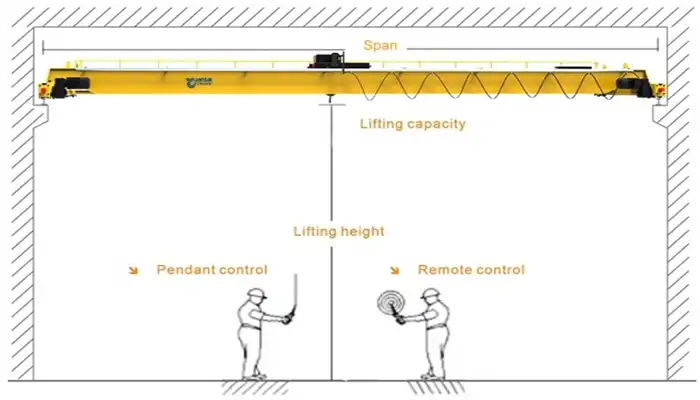

When you're comparing 15 ton overhead crane prices, it's important to look beyond the sticker. The numbers you see—whether online or in supplier catalogs—often reflect only the base equipment. The real cost depends on a mix of crane design, performance specs, and project-specific needs like span, lifting height, and custom controls.

That's why two cranes with the same rated capacity can be priced thousands of dollars apart.

Typical Price Ranges You Can Expect

These are ballpark factory prices for standard configurations. Customization, installation, and logistics will raise the total, but this gives you a realistic starting point when budgeting.

- Standard 15 ton single girder crane:

$18,000 – $26,000

(Good for short spans, light to moderate use, lower headroom needs) - 15 ton double girder crane with higher lifting height or longer span:

$28,000 – $45,000

(More stable for frequent or high-duty lifting, allows walkways and auxiliary hoists) - European-style 15 ton bridge crane (FEM/DIN standard):

$40,000 – $60,000

(Includes inverter drive, higher hoisting speeds, low noise, compact design)

This is just equipment pricing. If you need a complete solution—delivery, runway beams, installation—it's best to request a full quote.

What Affects the Final Price of a 15 Ton Crane?

Not all 15 ton cranes are built the same. Several key factors push the cost up or down, depending on your project specs and priorities.

Design type: Single girder vs. double girder

- Single girder designs are more affordable but limited in span and lifting height

- Double girder cranes offer better hook travel and support for heavier-duty usage

Span and lifting height

- Longer span = more steel, larger end trucks

- Higher lifting height = taller supports, reinforced hoisting structure

Duty cycle (A3, A4, A5 classifications)

- A light-use crane in a maintenance bay costs less than a crane that runs 24/7 in a fabrication plant

- Higher classifications mean reinforced motors, gearboxes, and structures

Lifting mechanism

- Standard wire rope hoist is common for most 15 ton bridge cranes

- Trolley hoists or custom dual-speed hoists can increase price and performance

Optional features

- Variable Frequency Drives (VFD) for smoother motion

- Wireless remote control or cabin control options

- Load limiters, limit switches, anti-sway systems for better safety and control

- Explosion-proof or outdoor-grade components (IP55+ enclosures, rain hoods)

Installation and shipping location

- Domestic vs. overseas delivery will affect shipping costs

- On-site conditions (tight spaces, no runway beams, no crane bay) may require extra customization or local erection support

Cost-Saving Tip: Consider 15 Ton Crane Kits

If you're in a region with the ability to fabricate the main girder or runway beams locally, ask about 15 ton overhead crane kits. These kits typically include:

- Hoisting mechanism (hoist + trolley)

- End trucks and wheel assemblies

- Electrical control panel and wiring

- Travel drives and mounting gear

Using your own steel structure or local fabricator can:

- Lower shipping weight and volume

- Save on import duties or oversized freight

- Allow quicker installation using in-house labor

Many buyers in steel fabrication, general manufacturing, and even construction companies prefer this route—it offers flexibility and keeps costs under control.

Comparing Crane Sizes: 10 Ton vs. 15 Ton vs. 20 Ton — Which One Fits Best?

When you're buying a crane, choosing the right lifting capacity is one of the first (and most important) decisions. Many buyers start out thinking a 10-ton crane will be enough, but later realize they need more capacity for safety or growth. Others think they need a 20-ton crane and end up overpaying for something they don't fully use.

That's where a 15 ton overhead crane often turns out to be the best fit—especially in applications where loads regularly hit 12 to 14 tons.

Side-by-Side Capacity Comparison

Here's a quick comparison of the three most commonly debated sizes:

| Feature | 10 Ton | 15 Ton | 20 Ton |

|---|---|---|---|

| Rated Load | 10,000 kg | 15,000 kg | 20,000 kg |

| Common Loads | Small molds, parts, light equipment | Steel coils, mid-size dies, heavy machine parts | Large castings, long beams, full assemblies |

| Safe Range for 12–14 Ton Loads | No – overloaded | Yes – ideal operating zone | Yes – but oversized |

| Typical Price Range | $12,000 – $20,000 | $18,000 – $45,000 | $28,000 – $60,000+ |

| Energy Usage | Low | Moderate | High |

| Structure Requirements | Minimal runway support | Moderate structure required | Strong structure, heavy runway beams |

Why a 15 Ton Overhead Crane is Often the Right Choice

A 15 ton bridge crane is the sweet spot for many industrial users—strong enough to safely handle heavier items, but not so oversized that it drives up costs and structural demands. It's especially useful when your actual working loads range from 10 to 13 tons.

Compared to a 10-ton model, the 15 ton EOT crane gives you:

- More headroom for unexpected load increases

- Longer service life by avoiding overload conditions

- Room for upgrades like longer span or faster hoist speeds

- Less risk of premature wear or breakdown

And compared to 20-ton units, a 15 ton overhead crane saves you:

- Unnecessary material and motor costs

- Lower power consumption

- Simpler building and runway requirements

- Easier shipping and faster installation

15 Ton Single Girder vs. 15 Ton Double Girder Crane

When it comes to design, both 15 ton single girder cranes and 15 ton double girder cranes are available—each with its own benefits.

15 ton single girder crane:

- More economical

- Ideal for low headroom applications

- Easier to install, especially for shorter spans

- Suited for lighter-duty lifting (A3–A4)

15 ton double girder crane:

- Handles longer spans and higher lifting heights

- Offers better load distribution and stability

- Can support heavy-duty hoists, walkways, and service platforms

- Preferred for continuous or frequent heavy lifting (A5+)

If you're not sure which to choose, think about your span, lifting height, and how often you'll use the crane. For regular production work, a 15 ton double girder crane may give you the durability and flexibility you need. For lighter use in a compact workshop, a 15 ton single girder crane can offer a lower-cost solution without giving up safety.

Buyer Insight: 15 Tons Covers the Gap That Others Miss

If your lifting needs often go above 10 tons, but you rarely push beyond 14 tons, a 15 ton overhead crane gives you that extra buffer—without the full commitment of a 20-ton system. It's a solid, long-term investment that balances lifting power with cost-efficiency.

Whether you're searching for a 15 ton EOT crane for sale, comparing quotes on a 15 ton bridge crane, or just trying to figure out the right size for your new plant, don't skip over this middle option. It may not be the most common, but it could be the smartest.

What to Look for in a 15 Ton Overhead Crane for Sale

Buying a 15 ton overhead crane is a big step. You want to make sure the crane you pick fits your real needs and your site's conditions perfectly. Here are some practical points to consider before you commit.

Understand Your Actual Lifting Needs

Start by getting clear on what you actually need to lift every day. Ask yourself:

- What are the daily loads and the heaviest single load?

- How often will you be lifting near the maximum 15-ton capacity?

- What's the duty cycle — light, medium, or heavy use?

Knowing this helps you avoid overspending on a crane that's overkill, or worse, buying one that can't handle your workload reliably.

Know Your Site Conditions

Before you order, check the physical space and power details at your facility:

- What's the runway beam size and condition? Can it handle a 15 ton crane's weight and load reactions?

- How tall is your workshop or building? Does it allow enough lifting height and hook travel?

- What power supply is available? Is it compatible with the crane's requirements?

These details affect not only the crane design but also installation costs and timeline.

Design Choices: Single Girder or Double Girder?

Your crane's design will influence price, installation, and usability.

- 15 ton single girder crane: Usually more budget-friendly and space-saving. Great if your span and lifting height are moderate and you want simpler maintenance.

- 15 ton double girder crane: Offers better stability, longer spans, and higher lifting heights. Ideal for demanding production lines or workshops needing smoother trolley travel and heavier-duty hoists.

Check the Supplier's Credentials

Choosing the right manufacturer or supplier matters just as much as the crane specs.

- Look for ISO and CE certifications—these prove quality and compliance with international safety standards.

- Ask for references or proven cases where they supplied 15 ton overhead cranes—past projects like yours are a good sign.

- Confirm they provide installation drawings, parts availability, and a clear warranty to protect your investment.

Explore Customization Options

A standard crane might not fit all needs. Good suppliers offer customization such as:

- Outdoor 15 ton overhead cranes with rain covers or weatherproofing for harsh environments

- Cranes with dual-speed hoists or inverter controls for precise lifting and energy savings

- Crane kits (including hoist, trolley, end trucks, and control panel) designed for customers who want to fabricate or install runway beams locally—saving on shipping and adapting to local conditions

When shopping for a 15 ton overhead crane for sale, these factors help ensure you get a crane that fits your work, your space, and your budget. Take your time, ask the right questions, and request detailed quotes with drawings and specs to compare apples to apples.

Practical Use Tips for Buyers of 15 Ton Overhead Cranes

Buying a 15 ton overhead crane is more than just picking a number. To get the most out of your investment, it pays to think through some key practical points before you finalize your order.

Leave a Safety Margin on Your Load

Never size your crane exactly to your heaviest expected load. Instead, plan for a 20 to 25% load margin above your maximum weight. This buffer accounts for:

- Unexpected load weight variations

- Dynamic forces during lifting and moving

- Equipment wear over time

For example, if your heaviest regular load is 12 tons, aim for a crane rated for at least 15 tons—just like a 15 ton bridge crane designed to handle those occasional heavier lifts safely.

Consider Lifting Height and Hook Travel Early

Don't wait until installation to finalize lifting height and hook travel requirements. These two factors heavily influence crane design and cost.

- Higher lifting height needs taller crane structures and longer hoist ropes

- Longer hook travel requires stronger end trucks and reliable trolley systems

Sharing your workshop dimensions and expected lift points with your supplier early will help them design a 15 ton overhead crane that fits your space perfectly without costly redesigns.

Ask for 3D Drawings or Layout Support

If possible, request 3D drawings or layout plans from your crane supplier. Visualizing the crane in your actual workshop space helps you:

- Spot potential clashes with lighting, cranes, or equipment

- Optimize runway beam placement and support structures

- Plan for safe operation zones and maintenance access

Many reputable suppliers include this as part of their service when you're buying a 15 ton EOT crane.

Check Structural Support and Floor Capacity

A common oversight is not verifying if your existing building structure and floor can handle the crane's loads.

- The crane runway beams transfer heavy loads to columns or walls—make sure they're rated for the expected reaction forces

- Check if the floor can support any wheels or support columns without cracking or settling

- Consult with a structural engineer if you're unsure

Proper preparation prevents costly modifications or safety issues after installation.

Final Thoughts and Buyer Action Plan for 15 Ton Overhead Cranes

If you're searching for a 15 ton overhead crane for sale, you're not alone. Interest in this capacity is growing because it fits a wide range of real-world lifting needs without the extra cost or complexity of a 20-ton crane.

Before you decide, think carefully about what your actual lifting tasks demand. Don't overspend on a heavier crane if you don't need it. A 15 ton overhead crane often hits the sweet spot—balancing lifting power, safety, and cost-effectiveness.

Here's a simple plan to help you move forward confidently:

- Request detailed quotes from reputable suppliers that include full specifications, drawings, and shipping details. This helps you compare offers fairly.

- Ask for photos or case studies of similar 15 ton bridge crane installations. Seeing proven projects can give you peace of mind about the supplier's experience and quality.

- Don't hesitate to clarify your site conditions and lifting needs so your supplier can tailor the solution precisely.

Choosing the right crane is about matching your needs—not just picking the biggest number. With the right info and trusted supplier, your 15 ton overhead crane will serve your operation safely and efficiently for years to come.

Ready to Get Your 15 Ton Overhead Crane Quote?

If you're serious about finding the right 15 ton overhead crane, working directly with a trusted manufacturer can save you time, money, and headaches. We're an ISO and CE certified Chinese crane manufacturer specializing in factory-direct design and supply. That means you get quality cranes without middleman markups.

Custom Solutions Tailored to Your Needs

No two lifting jobs are exactly the same. Whether you need a 15 ton single girder crane for a compact workshop or a 15 ton double girder bridge crane for heavy-duty production, we can customize your crane's specifications to match your exact lifting height, span, duty cycle, and site conditions.

Our engineers are ready to design cranes with features like:

- Dual-speed hoists or inverter drives for smooth operation

- Weatherproofing for outdoor use

- Advanced safety systems including overload protection and anti-sway control

- Remote control or cabin operation options

Flexible Shipping and Crane Kits for Easier Installation

We offer global shipping and can provide complete 15 ton crane kits—which include hoists, trolleys, end trucks, and electrical control panels. This is especially useful if you want to fabricate runway beams locally or reduce shipping costs.

Get Your Free Drawings, Pricing, and Expert Consultation

Don't wait to get started. Contact us today for:

- Free 3D layout drawings tailored to your facility

- Transparent, detailed pricing quotes with no hidden fees

- Expert consultation to help you choose the right crane design and options

Buying a 15 ton overhead crane doesn't have to be complicated. With the right partner, it's a smooth process from inquiry to installation.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch