Your Trusted Overhead Crane Manufacturer & Supplier

Overhead Cranes, EOT Cranes, and Explosion-Proof Cranes for Sale in Saudi Arabia

Overhead EOT Cranes for Sale Saudi Arabia

Growing Demand for Industrial Cranes in Saudi Arabia

Saudi Arabia's industrial sector has been expanding steadily, driven by projects in steel manufacturing, oil and gas, logistics, energy, and large-scale infrastructure under the Vision 2030 program. This growth has created a rising demand for reliable material handling solutions—especially industrial cranes that can improve productivity and safety in heavy-duty operations.

In sectors such as steel fabrication, warehousing, petrochemicals, and power generation, cranes are used daily to lift, move, and position heavy materials and equipment. As facilities grow in size and complexity, so do the requirements for more specialized crane systems.

Why Choosing the Right Crane Type Matters

Selecting the correct crane type is not just about lifting capacity. It's about matching the crane to the actual working environment, the materials being handled, the frequency of use, and the safety requirements.

A poorly matched crane can cause delays, safety hazards, and increased wear or failure. On the other hand, a well-chosen crane supports faster operations, fewer breakdowns, and easier compliance with local safety regulations.

When buying a crane in Saudi Arabia, consider:

- What materials you're lifting – steel coils, slabs, machinery, chemicals, etc.

- Where the crane will operate – indoor workshop, open yard, or hazardous area

- How often it will be used – occasional maintenance vs. 24/7 production

- Environmental conditions – high temperature, dust, corrosive atmosphere, etc.

Overview of the Three Main Crane Types

This guide focuses on three widely used crane types in Saudi Arabia. Each serves different purposes and fits specific industrial needs:

- Overhead Cranes These cranes operate on elevated runways fixed to the building structure. Common in workshops and factories, they are used for general material handling across bays or production lines.

- EOT Cranes (Electric Overhead Traveling Cranes): A type of overhead crane powered by electricity. EOT cranes are widely used in steel plants, warehouses, and heavy industry for regular, repetitive lifting operations. They come in single girder or double girder formats.

- Explosion-Proof Cranes: Designed for environments with flammable gases, vapors, or dust. These cranes are built with sealed motors, controls, and wiring to reduce the risk of ignition. Often used in oil refineries, chemical plants, or certain steel production zones.

Your Trusted Overhead Crane Manufacturer & Supplier

Overhead Crane for Sale in Saudi Arabia

Indoor Ovehread Crane for Sale Saudi Arabia – Workshop, Warehouse & Industrial Use

Overhead and EOT Cranes

What Are Overhead Cranes and EOT Cranes?

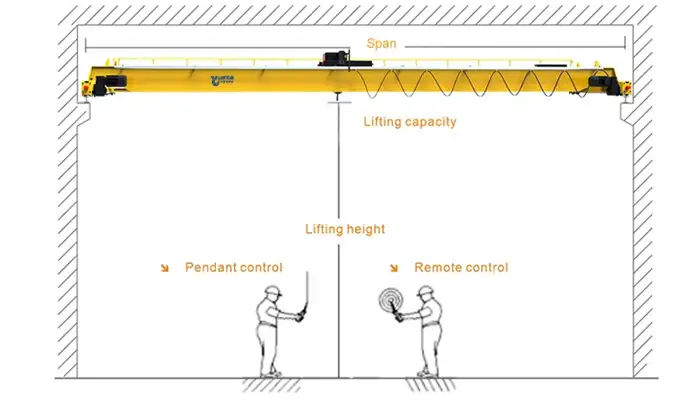

Overhead cranes are lifting equipment used to move heavy loads horizontally across a fixed overhead runway system. These cranes are commonly installed in factories, workshops, warehouses, and production facilities. Their main advantage is they do not take up floor space, which keeps the working area clear for other operations.

An EOT crane, or Electric Overhead Traveling crane, is a specific type of overhead crane that runs on electricity and is controlled via a pendant, radio remote control, or cabin. EOT cranes are the most common overhead cranes used in industrial settings due to their efficiency and wide range of lifting capacities.

Looking for reliable overhead cranes for sale in Saudi Arabia? Whether you're equipping a steel structure plant, warehouse, or factory, the right crane system improves safety, speeds up material flow, and saves labor. Below are the main types of overhead cranes available for general and heavy-duty use across Saudi industries.

Single Girder Overhead Cranes for sale Saudi Arabia 1 to 20 tons

An affordable and efficient solution for light to medium-duty lifting.

- Applications: Machine shops, fabrication workshops, general warehouses

- Advantages: Easy to install, low maintenance, ideal for simple lifting tasks

Double Girder Overhead Crane for Sale Saudi Arabia 5 to 100+ tons

A heavy-duty crane for demanding operations and higher lift requirements.

- Applications: Steel mills, casting plants, heavy assembly lines

- Advantages: Higher hook height, better stability, supports auxiliary hoists or walkways

Underslung (Underhung) Overhead Cranes for Sale Saudi Arabia 1 to 10 tons

Ceiling-mounted crane ideal for facilities with limited floor space or headroom.

- Applications: Light-duty handling in assembly shops, production cells

- Advantages: No floor columns required, flexible layout, smooth movement in narrow spaces

Freestanding Overhead Crane for Sale Saudi Arabia

Installed on independent steel columns without relying on the building structure.

- Capacity: Customizable based on span and coverage

- Applications: Warehouses, workshops, or temporary facilities

- Advantages: Ideal for buildings without suitable load-bearing supports

Low Headroom Overhead Crane1 to 10 tons

Designed for workshops with limited vertical space.

- Applications: Existing workshops with height constraints

- Advantages: Compact hoist design maximizes lifting height in low-clearance areas

Heavy-Duty Overhead Crane with Open Winch for Sale Saudi for Heavy Lifting 30 to 250 tons or more

Custom-built for continuous and intensive lifting operations.

- Applications: Steel handling, turbine workshops, industrial foundries

- Advantages: High-precision control, large lifting height, durable for harsh environments

Overhead Cranes and EOT Cranes All Your Need to Know

If you're looking for a crane for sale in Saudi Arabia, make sure to consider your lifting needs, span requirements, power supply, and installation site conditions. We offer custom crane systems with SASO compliance, local support, and tailored configurations for Saudi workshops, factories, and industrial plants.

Common Lifting Capacities and Span Ranges

Crane capacity and span are usually selected based on your building size and material handling needs.

Typical Capacity Options:

- 5–10 Ton: Suitable for light steel processing, machinery maintenance, and coil or tool handling

- 10–20 Ton: Used in fabrication shops, pipe handling, or production lines

- 20–50 Ton: Common in steel plants for billets, heavy components, and steel frames

- 50–100 Ton+: Required for slab handling, mold lifting, and heavy industrial applications in continuous-duty environments

Hot Sale Capacity of Overhead Cranes in Saudi Arabia

We offer a full range of overhead bridge cranes for sale in Saudi Arabia, from 1 ton light-duty cranes to 320 ton heavy-duty cranes. Our product line includes single girder, double girder, gantry, and specialized bridge cranes, providing the perfect solution for workshops, factories, warehouses, and industrial plants worldwide.

Span Ranges:

- Single Girder Overhead Cranes: Typically up to 25–30 meters

- Double Girder Overhead Cranes: Can exceed 30 meters, depending on building structure and design requirements

Note: Span is based on the width of your building's runway beams. Accurate measurements are critical for correct crane design.

Single Girder vs. Double Girder Options

Both types of cranes are available across most capacity ranges, but each has different strengths.

Single Girder EOT Cranes:

- More cost-effective for loads up to 20 tons

- Easier and faster to install

- Ideal for smaller buildings with limited headroom

- Limited in span and lifting height compared to double girder designs

Double Girder EOT Cranes:

- Recommended for loads above 20 tons or long spans

- Offers better hook height and stability

- Suitable for frequent, heavy-duty lifting

- Supports additional features like walkways, secondary hoists, or explosion-proof systems

Tip: Even in medium capacities (10–20 tons), some buyers prefer double girders for future flexibility.

Key Applications in Saudi Arabia

In Saudi Arabia, the use of overhead and EOT cranes is widespread across industries where material handling is a daily need.

Common applications include:

- Steel plants: Moving steel coils, slabs, billets, and parts across processing lines.

- Fabrication yards: Lifting structural components for welding, cutting, and assembly.

- Logistics centers: Loading and unloading materials from trucks or internal transfer.

- Warehouses: Storing and retrieving heavy goods in high-rack storage systems.

- Power and energy sectors: Handling turbines, transformers, and heavy equipment in substations and maintenance bays. Click to learn more about overhead cranes, gantry cranes, jib cranes and elecric hoists projects for sale in Saudi Arabia.

Indoor vs. Outdoor Use

- Indoor cranes are typically used in factories, workshops, and warehouses with fixed structural supports.

- Outdoor cranes may require weatherproofing and anti-corrosion protection, especially in coastal cities like Dammam or industrial zones like Jubail.

Advantages for Saudi Industry

Overhead and EOT cranes bring several benefits to businesses looking to improve handling efficiency and reduce operational risk:

- Efficient Material Handling

Move heavy items safely and quickly from one point to another with minimal manual labor. Useful in improving production flow and reducing bottlenecks. - Better Use of Vertical Space

Since the crane operates overhead, floor space remains free for workstations, forklifts, or inventory. This is especially helpful in tight facilities or when expanding vertically. - Increased Safety and Reduced Labor

Cranes reduce the risk of injury from manual lifting and limit the need for forklifts or temporary lifting setups. Electric controls also allow for precise load placement with fewer workers.

Your Trusted Overhead Crane Manufacturer & Supplier

Explosion-Proof Hoists and Cranes for Sale Saudi Arabia

Explosion Proof Cranes for Industrial Uses in Oil and Gas, Checmial Processing, Paiting and Steel Mill

Types of Explosion-Proof Hoists for Sale in Saudi Arabia

These hoists are lifting devices designed with explosion-proof features for safe use in hazardous areas.

Explosion-Proof Wire Rope Hoist for Sale Saudi Arabia

Heavy-duty hoists suitable for lifting large loads at significant heights in flammable environments.

- Suitable for heavy lifting in oil fields, petrochemical plants, and steel dust zones

- Features flameproof motors, sealed electrical systems, and high lifting heights

Explosion-Proof Chain Hoists for Sale Saudi Arabia

Compact hoists ideal for smaller loads and tight spaces in hazardous zones.

- Compact design for small workshops, chemical mixing, and paint areas

- Easy installation in tight or confined spaces

Explosion-Proof Low Headroom Hoists for Sale Saudi Arabia

Specialized hoists designed for facilities with limited vertical space while maintaining explosion-proof safety.

- Designed for indoor areas with limited ceiling height

- Used in gas treatment plants, calibration labs, and process halls

Explosion-Proof Open Winch Crab Trolley for Sale Saudi Arabia

Flexible trolley systems that accommodate explosion-proof wire rope hoists for specific lifting tasks.

- Specialized hoist trolley for specific lifting needs

- Offers flexibility for wire rope hoist mounting

Types of Explosion-Proof Cranes for Sale in Saudi Arabia

These cranes integrate explosion-proof hoists and components, engineered for lifting in hazardous industrial environments.

Single Girder Explosion-Proof Overhead Crane for Sale in Saudi Arabias

Cost-effective cranes designed for moderate loads and medium-risk indoor areas.

- Ideal for indoor workshops and process halls with medium hazard risk

- Simple design with lower cost and easier maintenance

Double Girder Explosion-Proof Overhead Cranes for Sale in Saudi Arabia

Heavy-duty cranes for demanding operations requiring high capacity and continuous use.

- Capacity:

- Heavy-duty cranes for continuous operation in petrochemical and steel plants

- Provides higher lifting heights and better stability

Explosion-Proof Gantry Cranes for Sale in Saudi Arabia

Outdoor cranes that do not require building support, suitable for open hazardous yards.

- Used outdoors in hazardous yards for gas cylinders and chemical drums

- No building support needed, suitable for open spaces in industrial zones like Jubail

Explosion-Proof Underhung Bridge Crane for Sale in Saudi Arabia

Cranes designed to fit low ceiling heights while maintaining explosion-proof features.

- Designed for low headroom applications with explosion-proof features

- Useful in confined spaces where overhead clearance is limited

Explosion-Proof Jib Crane for Sale in Saudi Arabia

Localized cranes mounted on walls or pillars, perfect for small, repetitive lifting tasks in hazardous zones.

- Localized lifting solution for hazardous areas

- Mounted on walls or pillars for small lifting tasks

Explosion-Proof Portable Crane for Sale in Saudi Arabia

Mobile lifting solutions that maintain safety standards in explosive environments.

- Mobile and flexible lifting options for various site locations

- Designed to meet explosion-proof safety requirements

Explosion-Proof Manual Overhead Crane for Sale in Saudi Arabia

Simple, manually operated cranes for light loads where power may not be available.

- Non-powered, manual operation for simple, light-load handling

- Used in hazardous zones without power supply

Explosion-Proof Options Across Various Capacities

Explosion-proof cranes are available in the same capacity ranges as standard cranes, but the components are designed for safe use in hazardous areas.

- 5–10 Ton Explosion-Proof Cranes: Often used in maintenance areas of refineries or chemical storage buildings

- 15–30 Ton Explosion-Proof Cranes: Suitable for process lines in gas treatment or steel dust zones

- 50 Ton and Above: Used in large-scale operations where heavy equipment must be lifted safely in explosive environments

Explosion-proof cranes can be designed as single or double girder, depending on the load and zone classification.

What Makes a Crane Explosion-Proof?

Explosion-proof cranes are designed for use in hazardous environments where flammable gases, vapors, or combustible dust may be present. These cranes are built with special components and construction methods that reduce the risk of sparks, high temperatures, or electrical faults that could ignite an explosion.

Key Protection Principles

- Zone Classifications:

Hazardous areas are divided into zones (e.g., Zone 1, Zone 2 for gases; Zone 21, Zone 22 for dust) depending on how often explosive atmospheres occur. - Ingress Protection (IP Ratings):

Explosion-proof cranes typically have IP55 or higher ratings, ensuring protection against dust and water ingress, which is critical in environments with fine powders or high humidity.

Main Explosion-Proof Components:

- Explosion-Proof Motors:

Specially enclosed motors prevent internal sparks from igniting the surrounding atmosphere. - Sealed Electrical Enclosures:

Control panels and junction boxes are tightly sealed and grounded to eliminate spark risk. - Explosion-Proof Brakes:

Heat-resistant and spark-free brakes designed for safe stopping under load. - Safe Control Systems:

Includes flame-proof push buttons, remote controls, and overload protection built to ATEX/IECEx standards.

Important: These cranes are not simply "dust-protected"—they are engineered and certified to perform safely in dangerous areas.

Industries in Saudi Arabia That Need Explosion-Proof Cranes

Several industries in Saudi Arabia require explosion-proof lifting systems due to the presence of flammable materials, gas, or dust in their operations.

Common Applications:

- Oil and Gas Plants:

Used for equipment handling in refineries, gas treatment plants, and offshore platforms where hydrocarbons are processed. - Chemical Processing Facilities:

Cranes are required in zones where solvents, acids, or volatile compounds are used or stored. - Paint and Coating Workshops:

Paint spray booths and coating lines produce fine aerosols and flammable fumes. - Steel and Aluminum Plants:

Especially in areas where coal dust, aluminum powder, or fine metal shavings are present.

Tip: If your process involves flammable materials, consult your safety officer to determine the hazardous area classification before selecting a crane.

Compliance and Safety Standards

Explosion-proof cranes must follow strict international and national standards to ensure they are safe and legal to operate in hazardous areas.

Key Standards to Know:

IECEx and ATEX Certifications: These are globally recognized systems for equipment intended for use in explosive atmospheres.

- ATEX: Used mainly in the EU

- IECEx: Internationally accepted and widely applied in Saudi projects

SASO Compliance (Saudi Arabia Standards Organization):

Equipment imported or installed in the Kingdom must comply with SASO guidelines, including safe operation, energy use, and installation practices.

Third-Party Inspections and Approvals:

Authorities such as TÜV, SGS, or BV (Bureau Veritas) often perform independent inspections to verify compliance before delivery or commissioning.

Reminder: Having proper certification helps with customs clearance, insurance coverage, and workplace safety audits.

Your Trusted Overhead Crane Manufacturer & Supplier