Eot & Gantry Crane Kits for Sale in Qatar: 5 Ton, 10 Ton & 3 Ton

5 &10 Ton Overhead Bridge Crane Kits & 3 Ton Semi Gantry Crane kits offering flexibility, cost savings & easy installation for Qatar’s industry.

Category: Qatar

Your Trusted Overhead Bridge Crane Manufacturer & Supplier

Crane Kits for Sale in Qatar: 5 Ton, 10 Ton & 3 Ton

5 Ton & 10 Ton Overhead Bridge Crane Kits & 3 Ton Semi Gantry Cranes

Crane kits offering flexibility, cost savings, and easy installation for Qatar's manufacturing industry, including 5, 10, and 3-ton systems.

Introduction: Flexible Crane Solutions for Qatari Manufacturers

In Qatar's growing manufacturing sector, more companies are investing in better ways to move heavy materials. As production scales up, having a reliable lifting system becomes more than just a need—it's a key part of staying efficient and competitive.

But not every factory has the same layout or the same needs.

Why Standard Cranes Don't Always Work

Many ready-made overhead cranes come as complete systems, including the main girder. While that may sound convenient, it also means:

- Higher shipping costs, especially for long girders

- Limited flexibility for custom spans

- A system that may not fully match your existing workshop dimensions

For manufacturers with access to steel fabrication and skilled labor, there's a smarter way to go.

Crane Kits Without Main Girders: A Practical Choice

Crane kits are delivered with all the key components—hoists, end carriages, electrics, and controls—but without the main girder. This offers several practical benefits:

- Lower transportation costs since you're not shipping large steel beams

- Freedom to fabricate the girder locally, to match your exact workshop layout

- Easier handling on site, especially in areas with space or access limits

And for companies in Qatar, where skilled welders and fabricators are often available, this setup makes a lot of sense.

Simple. Modular. Cost-Effective.

Using a crane kit doesn't mean giving up quality or performance. It just means more control and smarter logistics. You get:

- The same strength and safety

- The ability to customize your system

- A quicker path to installation, especially when working with local teams

If you're looking for a way to upgrade or expand your material handling setup—without the extra cost or bulk—a crane kit might be the answer.

Client Overview: Manufacturing Sector Needs

The client is a company operating in Qatar's manufacturing industry. Their daily work involves moving materials, feeding machines, and handling finished products across multiple zones in the facility.

To do this efficiently, they needed reliable overhead lifting equipment. But not just one crane—they needed several, and each for a different workshop area.

What the Client Needed

The project included:

- Multiple lifting systems, not just one or two

- Different capacities for different production areas

- A solution that could be assembled and installed quickly

This wasn't a one-size-fits-all job. Each crane had to be matched to a specific workflow.

Key Goals Behind Their Decision

To keep the project cost-effective and efficient, the client focused on three main goals:

- Reduce shipping costs

Shipping complete cranes with main girders would've meant paying a lot more in freight, especially due to the long spans. - Keep design flexible

They wanted the ability to adjust girder lengths and layout based on workshop dimensions. Local fabrication gave them that freedom. - Speed up installation

By fabricating the girders locally, the site team could prepare while crane components were still in transit. That saved time overall.

This made crane kits—without main girders—a very practical choice.

Crane Kits Supplied: Summary of Delivered Equipment

To meet the client's lifting needs across different workshop areas, a combination of crane kits was supplied. Each kit was designed for local assembly and did not include the main girder, giving the client more control over layout and installation.

5 Ton Overhead Bridge Crane Kits

These were the most needed across the facility, used in several areas for general material handling tasks.

- Quantity: 7 sets

- Crane span: 22 meters

- Lifting height: 9 meters

- Power supply: 415V, 50Hz, 3 Phase

These kits were used in zones with medium-duty lifting needs—ideal for moving raw materials and semi-finished goods.

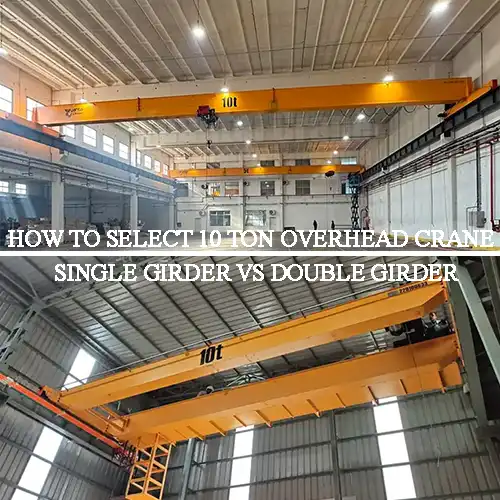

10 Ton Overhead Bridge Crane Kit

This was required for a heavier-duty section of the production line, likely where heavier equipment or stock was handled.

- Quantity: 1 set

- Crane span: 22 meters

- Lifting height: 9 meters

- Power supply: 415V, 50Hz, 3 Phase

Even though only one unit was needed, it played a critical role in the workflow where heavier loads were managed.

overhead crane kit -electric hoist assembly

electric overhead travelling crane hoist

overhead bridge crane assembled, European style single girder overhead bridge crane

3 Ton Semi Gantry Crane Kits

These were used in smaller bays or side workshops. Semi gantry cranes are great where part of the crane can run on the ground rail while the other end runs on a wall-mounted beam.

- Quantity: 16 sets

- Crane span: 9 meters

- Lifting height: 4 meters

- Power supply: 415V, 50Hz, 3 Phase

They were chosen for areas with lower ceilings or where a full overhead system wasn't necessary.

All kits were engineered to fit Qatar's standard power system and came with matching control and electrical units. By choosing kits over complete cranes, the client could manage costs, customize layouts, and coordinate installation smoothly.

3 ton semi gantry crane kits, 16 sets installed in Qatar

indoor gantry crane with single leg design

3 ton semi gantry crane kit with electric chain hoist

Wall travelling end of the semi gantry crane for sale Qatar

Why Crane Kits Made Sense for This Project

For this manufacturing project in Qatar, using crane kits instead of complete crane systems turned out to be the better choice. It offered savings, flexibility, and a faster setup.

Here's why the decision made sense:

Lower Transportation Costs

Shipping long steel girders across borders can be expensive and complicated. The client avoided these issues by ordering crane kits without the main girders.

- Only compact components like hoists, end carriages, and electrical parts were shipped.

- This reduced the overall shipping volume and saved money on freight.

- It also helped avoid delays that can happen with oversized cargo.

Local Fabrication of Main Girders

The client had access to local workshops with steel fabrication skills. This allowed them to build the girders on-site.

- They didn't have to wait for large steel structures to arrive.

- Girders were made exactly to fit their workshop space.

- If any adjustments were needed, they could be handled immediately on-site.

This gave the client more control and supported faster project progress.

Easy and Accurate Assembly

Each crane kit came with the main operating components already matched and ready to install.

- This included the hoist, end carriages, electrical panels, and control systems.

- All components were designed to work with the local 415V, 50Hz, 3-phase power supply.

- Once the girders were fabricated, the cranes could be assembled without issues.

The local team found the process straightforward, with no need for major changes or adjustments.

Overall, the crane kits allowed the client to reduce costs, stay flexible, and install the systems on schedule—all without compromising on quality or performance.

Production & Delivery Timeline

Throughout the project, the manufacturing and delivery process followed a clear, step-by-step timeline. Progress updates were shared regularly, helping the client stay informed and aligned with every phase.

Here's a snapshot of how the work moved forward:

August 2 – Order Confirmed, Production Began

As soon as the order was confirmed, production kicked off right away. The team started working on the crane kits, including component selection, initial machining, and preparing the production plan based on the client's specs.

August 9 – Design Adjustments: Shock Buffers Added

Just a week into production, the client requested a design modification.

A total of 32 shock buffers were added to the main beam design. These buffers help absorb impact during crane travel and improve safety. The design team quickly integrated the change without affecting the overall timeline.

August 24 – Chain Hoists Completed

By this point, the chain hoists were fully assembled and passed initial checks. At the same time, work continued on the European-style wire rope hoists and the end beams. These were at the stage of mechanical assembly and quality inspection.

September 11 – End Beams Near Completion

By mid-September, the end beams were completed structurally. The only step left was surface treatment and painting, which would prepare them for final delivery.

September 20 – Final Touches and Client Approval

The painting of end beams was completed, and photos were shared with the client for confirmation. This helped ensure that everything matched expectations before packing and shipment.

Thanks to regular updates and good coordination, production stayed on track without major delays. The client was kept in the loop from start to finish, making it easier to plan installation and fabrication work on their side.

Outcome: What the Client Achieved

By choosing crane kits, the client was able to meet their goals effectively and efficiently. The project resulted in several key outcomes that helped improve their manufacturing processes.

Seamless Integration of Crane Kits into Existing Infrastructure

The crane kits were designed to fit perfectly with the client's existing setup. Local fabrication of the girders ensured that each crane was tailored to their specific space, resulting in:

- Smooth integration into their production lines

- Minimal downtime during installation

- Immediate use of cranes once installation was complete

Fast Turnaround on Production and Delivery

The client needed a solution that would be delivered and installed quickly. Thanks to careful planning and a clear production timeline, the project was completed on schedule:

- From order confirmation to delivery, the production took just a few weeks.

- The client didn't experience any major delays, and crane systems were ready for installation right on time.

Full Control Over Girder Fabrication and Workshop Layout

With local fabrication of the main girders, the client had complete control over how the cranes were built to match their workshop layout:

- Girders could be customized on-site, ensuring they fit perfectly in the available space.

- The client was able to adjust design features to accommodate any unique needs in their manufacturing process.

Crane Systems Matched to Operational Needs and Local Electrical Standards

Each crane was engineered to meet the client's exact operational requirements:

- The cranes were tailored to handle the materials and weights in each specific zone of the workshop.

- Electrical components were compatible with Qatar's local power supply standards (415V, 50Hz, 3-phase), ensuring seamless operation without any electrical issues.

In the end, the client achieved a cost-effective, customized crane system that fit their facility's needs perfectly. The fast turnaround and flexibility in design made the whole process smoother and more efficient.

Lessons for Other Manufacturing Facilities in Qatar

This case highlights several valuable lessons for other manufacturers in Qatar who might be considering crane systems for their own facilities. Here's what can be learned:

Cost-Effective, Modular Crane Systems

For manufacturers who need a cost-efficient solution, crane kits offer a great option. This approach:

- Reduces shipping costs by eliminating the need for bulky, long steel girders to be shipped internationally.

- Provides flexibility in design, as local teams can customize the crane's girder to fit specific workshop layouts.

- Offers a modular approach that allows businesses to start small and scale up later if needed.

Minimizing Shipping Expenses & Maintaining On-Site Control

Manufacturers looking to cut down on logistics costs and maintain control over the assembly process will benefit from crane kits. By handling parts locally:

- Businesses can avoid high international freight costs and delays that come with large crane shipments.

- Local fabrication of main girders gives companies more control over how their crane system is built and assembled, ensuring it fits their space perfectly.

Tight Deadlines and Phased Delivery

For projects with tight timelines, crane kits offer a phased delivery model that works well. This is especially useful for businesses that need to:

- Start installations while waiting for some components, making sure there's no downtime.

- Have a faster overall turnaround by receiving parts in stages (e.g., hoists and end carriages first, then girders later).

In conclusion, crane kits offer flexibility, lower costs, and a quicker path to installation. They are an ideal solution for manufacturing facilities in Qatar that want to improve efficiency without unnecessary delays or expenses.

Thinking About Crane Kits for Your Plant?

Crane kits might be the right choice for your plant if you're looking for a cost-effective and flexible solution. Here's when crane kits are ideal:

Access to Local Steel Structure Fabrication

If you have local workshops capable of fabricating steel structures, crane kits are perfect. You can:

- Design and build girders tailored to your plant's exact measurements.

- Keep costs down by avoiding expensive long-distance shipping for large beams.

Need Flexibility in Span or Workshop Layout

If your plant layout is unique or you're working with different production zones:

- Customizable girder lengths give you the flexibility to fit the cranes perfectly into your existing space.

- You can adjust the crane's design as needed, whether it's for tight spaces or large open areas.

Prefer Phased Project Execution or Want to Upgrade Existing Systems

For projects that need to be completed in stages or businesses looking to upgrade their current lifting systems:

- Crane kits allow for phased delivery and installation, making the project more manageable.

- You can start with one crane and add more as your production grows.

If these points resonate with your needs, crane kits could offer you an efficient, flexible, and cost-effective way to improve your material handling. Ready to get started?

Contact us to Get Your Customized Crane Kit

If crane kits seem like the right fit for your plant, here's how to move forward:

Assess Your Facility's Lifting Needs, Available Space, and Local Fabrication Capabilities

Start by understanding your plant's requirements:

- Evaluate the weight and size of materials that need to be moved.

- Measure the available space to determine the crane span and lifting height.

- Check if you have local fabrication resources to build the main girder and support structures.

Choose Kit Capacities and Features That Suit Your Production Flow

Next, select the crane kit that fits your production lines:

- Decide on the lifting capacity (e.g., 5 ton, 10 ton) based on your material handling needs.

- Choose features like hoist types, control systems, and end carriages that match your workflow and the equipment used in your plant.

Coordinate Installation with Your Local Engineering Team

To ensure a smooth installation:

- Work closely with your local engineering team to schedule and prepare for assembly.

- Plan for any necessary space modifications or adjustments in the workshop layout.

- Ensure your team is ready to receive the kits and begin the installation process as soon as the components arrive.

By taking these steps, you'll set up a crane system that improves efficiency, reduces costs, and fits perfectly into your plant's operations. Let me know if you need assistance with any part of the process or have questions about the next steps!

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch