Explosion-Proof Circuit Breaker for ExProof Cranes and Hoists

Protects exproof overhead cranes and hoists in explosive areas by safely controlling electrical circuits, preventing sparks & ensuring flameproof .

Category: Crane Kit Parts

Your Trusted Explosion Proof Overhead Crane Manufacturer & Supplier

Explosion-Proof Circuit Breaker for Explosion Proof Overhead Cranes and Hoists

Explosion-Proof Circuit Breakers are designed to provide reliable protection for electrical circuits in hazardous environments where explosive gases or dust may be present. These circuit breakers are essential components for ensuring the safety of electrical systems in industries such as oil and gas, chemicals, mining, and manufacturing. They are built with special enclosures and mechanisms that can withstand the pressures and hazards of potentially explosive atmospheres, preventing any sparks or heat from igniting the surrounding environment.

The BDZ52 Explosion-Proof Circuit Breaker is engineered to meet stringent international standards for explosion protection, including Ex db eb IIC T4 Gb and Ex tb IIIC T80℃ Db markings, which indicate its ability to withstand various types of hazardous conditions. The breaker features an IP65-rated enclosure, ensuring it is resistant to dust and water ingress, which is crucial for operations in harsh industrial conditions.

With a rated voltage of AC380V/220V and a rated current of 100A, this explosion-proof circuit breaker provides superior performance, durability, and protection for critical electrical systems, significantly reducing the risk of explosions and electrical fires in dangerous environments. Its compliance with the latest GB/T 3836 standards ensures it meets the highest safety requirements for explosion-proof equipment.

Overview of Explosion-Proof Circuit Breakers

Explosion-proof circuit breakers are essential safety devices used to protect electrical systems in environments where there is a risk of explosions. These circuit breakers are designed to prevent sparks or excessive heat from igniting flammable gases or dust in the surrounding air. By isolating faults and safely interrupting electrical power, they help protect both equipment and workers in potentially dangerous settings.

The BDZ52 Explosion-Proof Circuit Breaker offers a high level of protection, making it suitable for industries that deal with hazardous materials. It's built to withstand harsh conditions while keeping electrical systems safe and running smoothly.

Importance in Hazardous Environments

In industries where hazardous gases or combustible dusts are present, any electrical fault can lead to catastrophic accidents. Traditional circuit breakers may not be able to handle these extreme conditions and could become sources of ignition themselves. Explosion-proof circuit breakers like the BDZ52 are specifically designed to handle this threat.

These breakers are built with special enclosures and internal components that prevent sparks, arcs, or heat from escaping. This ensures that, even in the event of a fault, the circuit breaker won't ignite the surrounding environment, reducing the risk of explosions and fires.

Primary Applications (Oil & Gas, Chemicals, Mining, etc.)

Explosion-proof circuit breakers are critical in industries where explosive or flammable substances are used or produced. Some of the key sectors that rely on these types of breakers include:

- Oil & Gas: In drilling rigs, refineries, and gas production plants, where there is constant exposure to flammable gases and vapors.

- Chemical Industry: In plants that process chemicals and solvents, where volatile compounds could easily catch fire.

- Mining: Especially in coal mines and other underground environments, where dust accumulation and gases pose significant risks.

- Pharmaceuticals: In factories where fine powders or chemical processes could create explosive atmospheres.

These industries require equipment that can safely operate in explosive atmospheres, which is why explosion-proof circuit breakers are a must-have for their electrical safety systems.

Product Specifications

The BDZ52 series explosion-proof circuit breaker is designed to safely control and protect electrical systems in environments where explosive gases or flammable dust may be present. It offers stable performance, reliable safety features, and a strong, corrosion-resistant body. It's well-suited for industries like oil and gas, chemical processing, and mining—anywhere electrical safety is critical.

Standards and Safety Compliance

This product is built in line with both Chinese and international explosion-proof standards. It ensures user safety and system reliability in high-risk environments.

- Complies with GB3836.1-2000: General requirements for equipment used in explosive gas atmospheres

- Complies with GB3836.2-2000: Flameproof enclosures "d"

- Complies with GB3836.3-2000: Increased safety protection "e"

- Meets IEC60079 standards for international use

These standards confirm that the circuit breaker can be safely used in hazardous areas classified as Zone 1 and Zone 2.

Electrical Ratings

The BDZ52 series supports a wide range of industrial power needs. The electrical ratings are suitable for both heavy-duty equipment and general circuit protection.

- Rated Voltage: AC380V or AC220V, 50Hz

- Current Ratings: Available in different sizes from 1A up to 630A

- Frequency: 50Hz, compatible with standard industrial systems

This flexibility allows the breaker to be used in many types of installations.

Protection Features

This breaker offers strong protection not just from electrical faults, but also from environmental damage.

- Ingress Protection: Rated IP54 or IP55, depending on the model. This means it is dust-resistant and protected from splashing water.

- Corrosion Resistance: Rated WF1, making it suitable for environments with medium levels of corrosive gas or moisture.

- Explosion-Proof Marking: Exde IIB T6 – designed for explosive gas atmospheres in groups IIA and IIB, with a maximum surface temperature of 85°C to 100°C.

These protection features make it suitable for use in hazardous gas or dust areas.

Model Options and Cable Entry Sizes

The BDZ52 series includes several models, each offering different current ratings and physical configurations. The table below summarizes the key options:

| Model | Rated Current (A) | Cable Diameter (mm) | Inlet Thread (G") | Explosion Marking |

|---|---|---|---|---|

| BDZ52-60 | 1, 2, 3, 5, 10, 15, 20, 25, 32, 40, 50, 60 | 14–22 | 1" | Exde IIB T6 |

| BDZ52-100 | 80, 100 | 22–28 | 1 1/2" | Exde IIB T6 |

| BDZ52-225 | 150, 200, 225 | 27–33 | 2" | Exde IIB T6 |

| BDZ52-400 | 250, 300, 400 | 34–42 | 2 1/2" | Exde IIB T6 |

| BDZ52-630 | 500, 630 | 42–50 | 3" | Exde IIB T6 |

When selecting a model, it's a good idea to choose a current rating that's slightly above your expected load. This gives you a bit of margin for safety and future expansion.

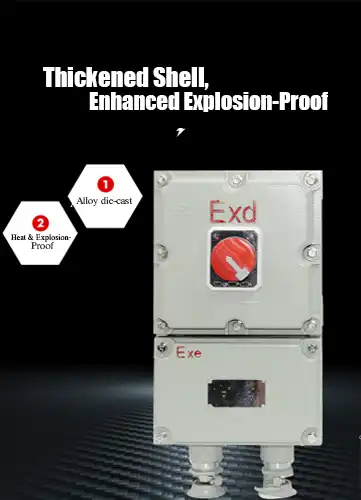

Enclosure and Material

The enclosure is designed to handle tough industrial conditions.

- Material: High-strength aluminum alloy, pressure-cast for durability

- Surface Treatment: Finished with a high-voltage electrostatic powder coating to improve corrosion resistance

- Mounting Options: Can be mounted using wall brackets or panels, depending on installation needs

This housing keeps the internal components safe from physical impact, moisture, and chemical exposure.

Internal Components and Protection Functions

Inside the BDZ52, you'll find quality electrical components. These are selected based on your specific model and application needs.

Circuit Type: Built with high-breaking miniature circuit breakers (MCB) or molded case circuit breakers (MCCB)

Protection Features:

- Overload protection

- Short-circuit protection

- Optional leakage protection can be added as needed

Wiring Method: Compatible with both armored cables and steel conduit systems

This flexibility means you can install it in new systems or retrofit it into existing ones.

Suitable Applications

This breaker isn't just for one type of industry. It's widely used across many sectors where explosive or flammable atmospheres are a concern.

- Suitable for use in Zone 1 and Zone 2 hazardous areas

- Works in environments with explosive gases classified under IIA, IIB

- Can handle temperature groups from T1 to T6

- Common in oil depots, chemical plants, grain processing facilities, paint shops, and other explosion-risk zones

Wherever safety comes first, the BDZ52 is a practical choice.

Key Features of the BDZ52 Series Explosion-Proof Circuit Breaker

Explosion-proof circuit breakers like the BDZ52 series are built for serious safety. They are not only electrical protection devices but also a crucial safety measure in hazardous environments. Here's a closer look at what makes this product stand out.

Thickended shell , exhandced explosion proof circulate breaker

Quanlity materials, precision built

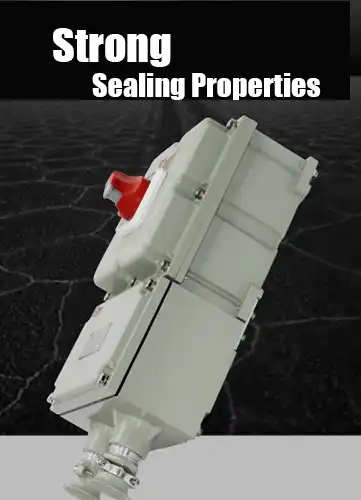

Stroong sealing properties

Elecgrostratic spray coating

The BDZ52 series is designed specifically to be used in areas where flammable gases or combustible dust are present. The construction and internal components are selected and tested to prevent ignition.

- It prevents internal sparks or arcs from escaping the enclosure.

- If an explosion occurs inside the unit, the casing holds it in, stopping it from reaching the outside environment.

- This design is essential for preventing chain reactions in gas or dust-heavy areas.

Simply put, even in case of internal failure, it won't trigger a disaster outside.

This circuit breaker provides dual protection—against explosive gases and flammable dusts. It's a dependable solution for facilities that handle both types of risks.

- Can be used in Zone 1 and Zone 2 for explosive gas environments.

- Also suitable for Zone 21 and Zone 22, where combustible dusts are present.

- Supports applications in IIA, IIB, and IIC gas groups, and T1 to T6 temperature classes.

So whether it's a chemical plant or a grain silo, it covers both risks in one device.

This is one of the key protection methods used in the BDZ52 design. The enclosure is tough and sealed.

- It contains any spark, flame, or arc produced during operation.

- Prevents the ignition of gases or vapors outside the enclosure.

- Designed to withstand the pressure of an internal explosion without damage.

This type of protection is required in many international standards for use in explosive environments.

Beyond containment, the breaker is also built to reduce the chance of ignition in the first place.

- All internal components are carefully spaced and designed to limit heat and electrical sparks.

- Wiring terminals are reinforced and isolated to prevent loosening or sparking.

- Used in combination with the "d" flameproof enclosure to enhance the overall safety level.

This makes the product even more secure during normal operations.

In places where dust is the main hazard, the BDZ52 offers a specific line of defense.

- The enclosure is sealed tightly to prevent dust from entering.

- It maintains a surface temperature low enough not to ignite any settled dust.

- Protects against both conductive and non-conductive dust environments.

This means it's a great fit for food processing, flour mills, woodworking, and other dusty operations.

This product isn't just designed for safety—it's tested and approved to meet strict national standards.

- GB/T 3836.1-2021: General requirements for electrical equipment in explosive atmospheres

- GB/T 3836.2-2021: Requirements for flameproof enclosures "d"

- GB/T 3836.3-2021: Requirements for increased safety "e"

- GB/T 3836.31-2021: Equipment with protection by enclosure for dust ignition "t"

By meeting all these standards, the BDZ52 series ensures reliable operation in the most demanding industrial environments.

Applications

The BDZ52 explosion-proof circuit breaker is designed for use in demanding and hazardous environments. It's built to handle both explosive gases and flammable dust.

Used in a Wide Range of Industries

- Oil and Gas Facilities: Drilling rigs, refineries, and fuel storage areas often have gas leaks or vapors. This breaker helps protect critical electrical systems in such environments.

- Chemical Plants: Where volatile substances are mixed or stored, even a small spark can be dangerous. These breakers add an extra layer of safety.

- Mining Operations: Underground and surface mines may have flammable gases or dust. The BDZ52 helps prevent electrical fires and explosions.

- Food Processing and Grain Storage: Combustible dust from flour, sugar, and grain is a real risk. A properly sealed circuit breaker makes a big difference.

- Paint and Coating Workshops: These places often contain explosive vapors. Using the right explosion-proof breaker is a must.

This breaker is suitable for Zone 1 & 2 gas areas and Zone 21 & 22 dust areas. It's flexible and reliable wherever risk is present.

Benefits

Explosion-proof circuit breakers like the BDZ52 do more than just turn circuits on and off. They add serious protection where it counts most.

Why It's a Smart Choice

- Enhanced Safety for Workers and Equipment

Keeps people safe by stopping electrical faults from triggering dangerous sparks or fires. Also protects machines from damage. - Reduces Risk of Explosions and Fires

The sealed enclosure and advanced safety features reduce ignition chances, even in places filled with gas or dust. - Long-Term Durability and Reliability

Built with corrosion-resistant materials and high-quality components. It's made to last—even in harsh or outdoor conditions. - Compliance with International Safety Standards

Fully certified to meet GB and IEC explosion protection standards. You can use it with confidence in regulated or inspected environments.

This breaker isn't just a box on the wall—it's a key part of your plant's safety system.

Conclusion

Choosing the right explosion-proof circuit breaker isn't just a technical decision—it's a safety investment. The BDZ52 series gives you protection, performance, and peace of mind.

- It meets strict national and international safety standards.

- It works in tough conditions with gases or dust.

- It helps prevent costly and dangerous accidents.

When safety matters—and it always does—go with a product that's tested, trusted, and designed for hazardous zones. The BDZ52 won't let you down. Contact us to get your free consulation to get your explosion proof hosit and crane design!

Related Products

Affordable 10 ton double girder overhead crane with CD/MD hoist trolley, built for U.S. standards, ideal for construction and industrial lifting

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch