Modular Overhead Crane Packages & Modular Crane Systems

Modular overhead cranes for sale. Types of modular overhead cranes with single girder , double girder , top running & underhung crane design for sale. Click!

Category: Modular Cranes and Hoists

Your Trusted Overhead Travelling Crane Manufacturer & Supplier

Modular Overhead Crane Packages and Modular Crane Systems

Economical Single Girder & Double Girder Modular Overhead Crane 1 Ton to 80 Ton, Easy Assembly & Mainteance

Modular overhead cranes for sale. Types of modular overhead cranes with single girder, double girder , top running & underhung crane design for sale. Click!

Overhead crane packages and modular crane systems have emerged as game-changers, revolutionizing the way heavy lifting tasks are approached across industries.

Modular crane systems epitomize versatility and adaptability in meeting various lifting requirements. These systems are composed of distinct components that can be easily assembled, disassembled, or modified, offering a tailored solution for diverse lifting needs. By utilizing modular designs, industries gain the flexibility to customize crane systems according to specific spatial constraints, load capacities, and operational demands. This adaptability extends beyond initial installation, allowing seamless adjustments or expansions as business needs evolve.

At the core of crane technology lies the modular hoist, a critical component enabling efficient lifting operations. The modular hoist is designed to handle loads with precision while ensuring safety and reliability. Its adaptability to various load capacities and configurations makes it an indispensable element in the functionality of modular crane systems. The hoist not only supports lifting but also facilitates the smooth movement and positioning of heavy objects, contributing significantly to operational efficiency.

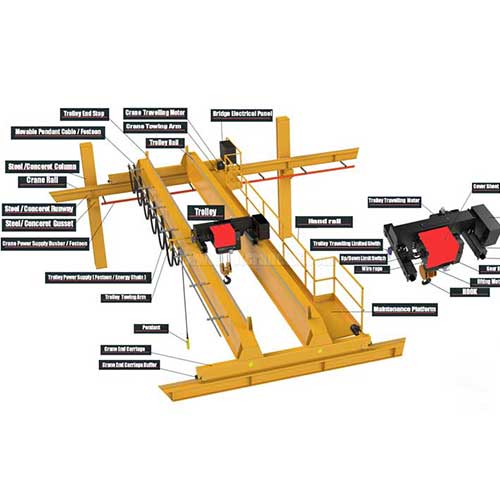

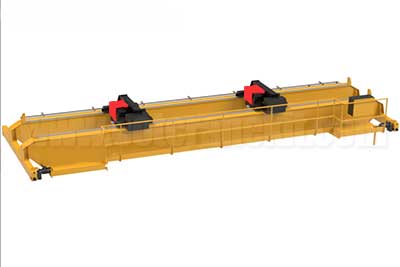

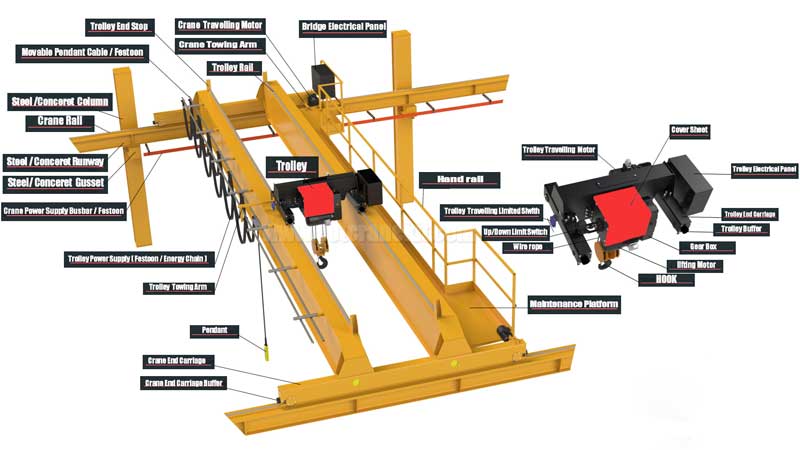

Modular Overhead Crane and Components of Modular Crane Systems

Modular crane systems are ingeniously engineered structures comprising crucial components that collectively enable efficient material handling. These components include bridge beams, end trucks, hoists, and sophisticated control systems. Bridge beams form the skeletal framework of the crane, spanning the length of the operational area. End trucks, mounted on either side of the bridge beams, facilitate horizontal movement along the runway. Hoists, the workhorses of the system, are responsible for lifting and lowering heavy loads with precision. The control systems, incorporating advanced technology, oversee and manage the crane's movements, ensuring safety and operational efficiency.

Advantages of Modular Crane Systems over Traditional Systems

The paradigm shift towards modular crane systems stems from their inherent advantages over traditional counterparts. Unlike rigid and fixed designs of conventional systems, modular cranes offer increased flexibility, adaptability, and scalability. They transcend the limitations of one-size-fits-all solutions, allowing for customization and modifications tailored to specific lifting needs. The modular approach facilitates swift alterations, expansions, or reconfigurations without necessitating substantial overhauls, thereby reducing downtime and operational disruptions.

The hallmark of modular crane systems lies in their inherent flexibility and customizable design features. These systems are adaptable to varying spatial constraints, load capacities, and operational requirements. The modular design enables the integration of specialized features such as motorized trolleys, adjustable spans, and diverse hoist configurations. This flexibility empowers industries to fine-tune crane systems according to specific applications, ensuring optimal performance in diverse operational settings.

Modular cranes have found widespread utility across a multitude of industries owing to their adaptive nature. From manufacturing plants requiring precision handling to logistics centers necessitating efficient material movement, modular crane systems offer versatile solutions. Industries such as automotive, aerospace, construction, warehousing, and heavy manufacturing benefit from the adaptability and efficiency of modular crane systems. Their ability to cater to varying load capacities, spatial limitations, and operational demands makes them indispensable tools in enhancing productivity and streamlining operations across sectors.

Types of Modular Bridge Cranes

Modular bridge cranes, designed for various lifting requirements, encompass a spectrum of types tailored to distinct operational needs and industries. Understanding the features, benefits, and applications of each type is crucial in selecting the most suitable crane system.

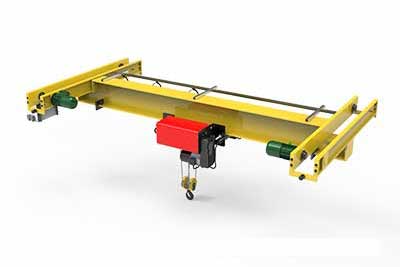

Single Girder Bridge Crane 1 Ton to 20 Ton

Features: Single girder bridge cranes are characterized by a single beam supporting the hoist and trolley. Their design is ideal for handling lighter loads and operating within smaller spaces.

- Benefits: These cranes offer cost-effectiveness in terms of both installation and maintenance. Their compact design enables easier maneuverability and efficient material handling in constrained environments.

- Applications: Commonly found in small workshops, assembly lines, and maintenance shops, single girder bridge cranes excel in operations requiring precision handling of relatively lighter loads.

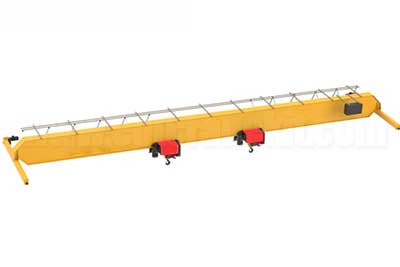

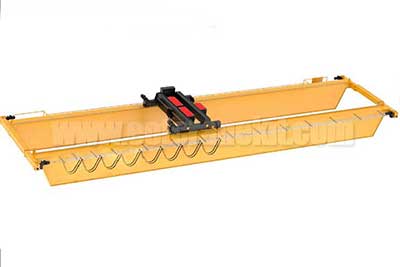

Double Girder Bridge Crane 3 Ton to 80 Ton

- Features: Double girder bridge cranes boast two parallel bridge beams, providing increased stability, higher lifting capacity, and enhanced precision in heavy-duty applications.

- Benefits: The design of double girder cranes allows for handling heavier loads with superior control and stability. They are suitable for industries requiring precision movements and robust lifting capabilities.

Applications: Predominantly used in steel mills, heavy manufacturing plants, and aerospace industries, double girder bridge cranes efficiently manage the demands of large-scale lifting operations.

Under Running (Underhung) Bridge Crane 1Ton to 10 Tons

- Features: Under running bridge cranes run on bottom-mounted rails, making them space-saving solutions. These cranes are well-suited for facilities with limited headroom.

- Benefits: Due to their design, under running bridge cranes optimize space, making them suitable for cleanrooms, smaller manufacturing units, and buildings with low ceilings.

Various Modular Crane Designs and Configurations

Your Trusted Modular Overhead Crane Manufacturer & Supplier

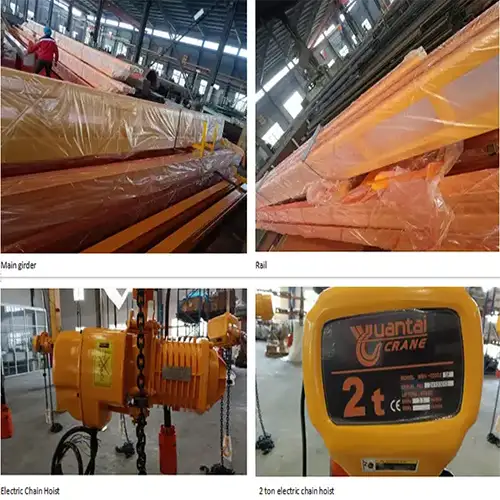

Modular Overhead Crane Kits: Main Parts and Components

Components of Modular Crane Systems

A well-functioning modular crane system is a culmination of various integral components working in synchrony to facilitate seamless lifting operations. Understanding the functionalities and significance of these components is essential for maximizing crane efficiency and safety.

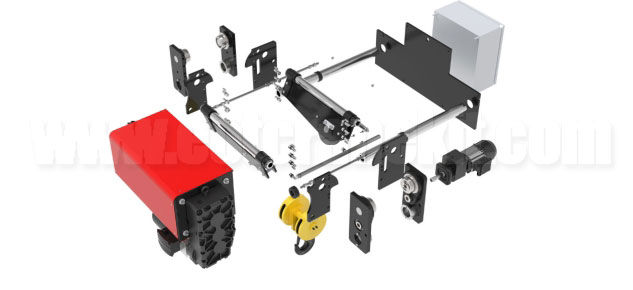

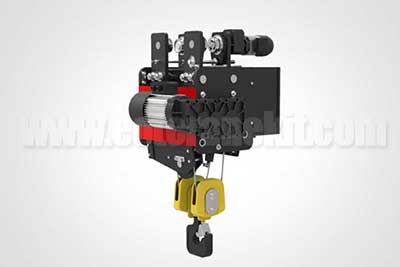

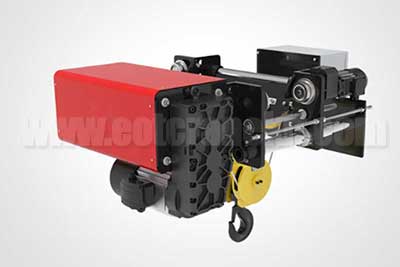

Modular Hoist: Key Functionalities and Variations

The modular hoist serves as the powerhouse of the crane system, responsible for lifting, lowering, and positioning heavy loads. Diverse types of hoists, such as electric chain hoists, wire rope hoists, and manual hoists, cater to varying load capacities, operational requirements, and environmental conditions.

Hot Sale Modular Hoists, Electric Hoists for Modular Cranes

NR mode standard headroom electric hoist

Lifting capacity: 3t~20t

Lifting height: 6m~30m

Work level: M3~M5

Application: For Single Girder Cranes

NR mode low headroom electric hoist

Lifting capacity: 3t~20t

Lifting height: 6m~30m

Work level: M3~M5

Application: For Single Girder Cranes

NRT crab electric hoist

Lifting capacity: 3t~80t

Lifting height: 6m~30m

Work level: M3~M5

Application: For Double Girder Cranes

Explosion Proof Electric Wire Rope Hoists

Lifting capacity: 3t~20t

Lifting height: 6m~30m

Work level: M3~M5

Application: For Single Girder Cranes

BNR low headroom explosion-proof electric hoist

Lifting capacity: 3t~20t

Lifting height: 6m~30m

Work level: M3~M5

Application: For Single Girder Cranes

BNRT crab model explosion-proof electric hoist

Lifting capacity: 3t~30t

Lifting height: 6m~30m

Work level: M3~M5

Application: For Double Girder Cranes

Electirc Hoist Options for Modular Overhead Cranes

Electric Chain Hoists: These hoists are versatile, compact, and suitable for lighter to moderate loads. They offer precise load control and are commonly used in workshops and assembly lines.

Wire Rope Hoists: Designed for heavier loads, wire rope hoists provide robust lifting capabilities and are commonly found in heavy manufacturing industries and construction sites.

European Style Electric Hoists: Ideal for low headroom workshop material handling operations or in situations where overhead cleanroom is limited or for limited space workshops or facilities.

Benefits and Versatile Lifting Capabilities:

Modular hoists provide benefits such as increased lifting efficiency, improved safety features like overload protection, and adaptability to diverse lifting needs. Their capabilities extend to precision handling, ensuring smooth and controlled load movements critical for operational safety.

Structural Elements of a Modular Crane

The structural components of a modular crane system encompass various elements that contribute to its stability, mobility, and adaptability.

Exploration of Trolley Systems and Various Girder Types:

Trolley Systems: These systems facilitate horizontal movement along the bridge beam, enabling precise positioning of the load. Motorized trolleys enhance operational efficiency by providing controlled and efficient load movement.

Various Girder Types: Different types of girders, such as single girders or double girders, play a crucial role in determining the crane's lifting capacity, stability, and adaptability. They serve as the primary load-bearing structure of the crane.

These structural elements contribute significantly to the modularity of the crane system, allowing for customization and adaptability based on specific lifting requirements, spatial constraints, and load capacities.

Control Systems and Automation in Modular Cranes

Control systems form the brains of modular cranes, integrating advanced technology for efficient operation, safety, and monitoring.

Details on Advanced Technology Integration:

- Safety Features: Incorporation of sensors, limit switches, and emergency stop mechanisms ensures safe crane operation, preventing accidents and damage.

- Monitoring Systems: Advanced control systems offer real-time monitoring of load capacity, position, and crane health, enhancing operational efficiency and safety.

Efficiency through Automation:

Automation in modular crane systems streamlines operations, allowing for precision movements, automated load positioning, and reduced manual intervention, thereby optimizing overall efficiency.

These core components of modular crane systems is crucial for assessing their capabilities, functionalities, and suitability for specific industrial applications.

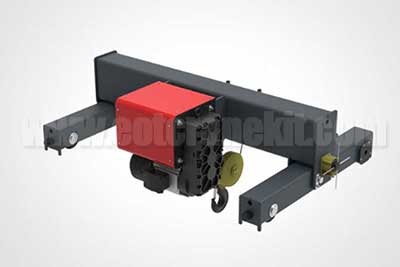

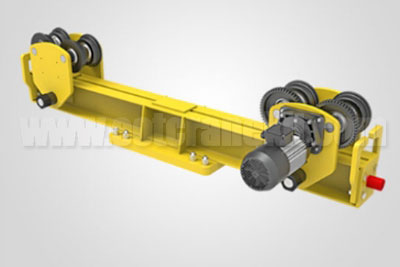

Modular End Carriage

Flexible Design , Easy Assembly, Wide Applications

The various combinations of 2 wheels,4 wheels,8 wheels, and 16 wheels will be satisfied withdifferent wheel pressure.

The various combinations of end carriage and main girder are easily adapted to different workshop space.

Top running single girder crane end carriage

Underhung single girder crane end carriage

Top running double girder crane end carriage

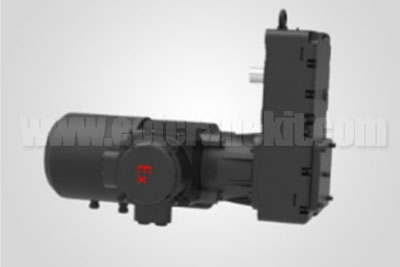

Gear Motor

Silent technology ,enjoy handling.We lead the way of drive for cranes.

You will enjoy silent handling with our new technology of drive.We advocate energy saving with our new technology of drive.

Electric motor

3-in-1 electric motor

Driven electric hoist

Explosion proof motor

Modular Overhead Crane Wheels, Rope Guide and Pulley

crane wheel group

driven wheel

wire rope guide

Pulley

Modular Overhead Crane Electrical Panel

electrical panel

electrical panel

electrical panel

electrical panel

Advantages and Benefits of Modular Cranes

Modular cranes have transformed the landscape of material handling, offering a plethora of advantages that significantly enhance operational efficiency and flexibility. Let's delve into the myriad benefits these systems provide across various industries.

Increased Scalability and Ease of Installation

The scalability inherent in modular crane systems allows for seamless adjustments to meet evolving operational demands. These systems offer adaptable configurations, making it easier to expand or modify crane setups without extensive overhauls. Such scalability ensures that businesses can swiftly respond to changing production requirements or facility expansions, minimizing downtime and maximizing productivity.

Real-world example: Consider a manufacturing facility that experiences sudden growth in production demand. With a modular crane system, they effortlessly expand their lifting capacities by adding supplementary components or altering configurations, ensuring uninterrupted operations.

Cost-effectiveness and Reduced Downtime for Modifications

The inherent cost-effectiveness of modular cranes stems from their adaptable nature. Their design enables modifications or upgrades to be executed with minimal disruption to ongoing operations. Reduced downtime during modifications translates into enhanced productivity and cost savings for businesses, avoiding extended periods of halted production often associated with traditional crane systems' modifications.

Case study: A logistics warehouse integrates a modular crane system, allowing for swift alterations in load capacities during peak seasons. This flexibility mitigates the need for investing in additional standalone equipment, optimizing both space and expenses.

Customization Options to Meet Specific Requirements

Modular crane systems offer a myriad of customizable features tailored to specific lifting needs and operational environments. Businesses can select from various hoist types, trolley configurations, and control systems to precisely match their unique requirements. This level of customization ensures optimal performance and efficiency in diverse industrial settings.

Illustrative example: In an automotive manufacturing plant, a modular crane system is customized with specialized attachments and controls, streamlining the precise handling of vehicle components during assembly, thereby enhancing production speed and accuracy.

Enhanced speed flexibility

Consistent peak performance

Increased productivity

Efficient time utilization

Quicker hoisting for lighter loads

Precision in movement

Accurate load control

Prevention of inadvertent acceleration

Applicable to hoist, trolley, and crane functions

Adjustable speed range: 1% to 99% of maximum

Ensures precise load positioning through reduced and predefined maximum speeds for all operations.

Slack rope prevention

Minimizes the risk of damage to crossbeams, ropes, slings, and sheaves

Optimizes load handling and loading cycles

Enhances productivity and safety

Automatically halts the lowering movement upon ground contact.

Inching

Ensures precise load positioning

Prevents collisions

Applicable to hoist, trolley, and crane movements

Enhances overall safety

Achieves accurate load positioning in predefined increments between 2 and 100 mm for hoist, trolley, and crane operations.

Restricted load

Safeguards the building structure from overloading

Establishes sturdy, secure boundaries for load areas

Ensures strict adherence to load restrictions during cross and long travel.

Sway control

Achieves maximum speed

Minimizes load sway

Enhances accuracy in load positioning

Reduces the risk of damage and injury

Controls load sway during cross and long travel.

Load floating

Extends the service life of brakes, steel construction, crane runway, mechanical components, etc.

Ensures safer and gentler load handling

Provides protection for fragile loads

Enables a faster and smoother restart of the hoisting or lowering process when the brake is open.

Shock load prevention

Extends the service life of steel construction, crane runway, ropes, crossbeams, and slings

Ensures safer and stabilized load handling

Provides protection for fragile loads

Enables smooth load lifting through reduced hoisting speed.

Tandem

Achieves synchronized start/stop of hoisting and cross travel

Enables simultaneous control of up to four hoists on a bridge

Facilitates load summation and high-safety operation

Allows simultaneous start and stop of hoist movements and cross travel for up to four hoists in tandem.

Synchronization

Continuously monitored synchronization, even with asymmetrical loads

Reduces the risk of accidents

Enhances productivity and safety

Allows simultaneous lifting of several hoists on a bridge, even with asymmetrical loads.

Ensures high operational safety

Facilitates simultaneous long travel and hoisting movements

Achieves synchronized lifting and lowering

Provides anti collision safety

Incorporates frequency inverter features and overload protection

Allows simultaneous long and cross travel, including lifting and lowering.

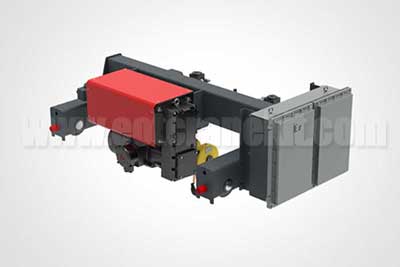

Modular Crane Design

Modular crane for light and medium material handling

Easy and quick manufacutring and assembly

Standard parts for easy maintenace

Processed Crane Design for Heavy & Special Application

Ensured safety, efficiency and durability

Modular design + processed design for efficient and economical solution

Maintenance Advantages and Ease of Servicing

Maintenance and servicing are streamlined with modular crane systems, thanks to their component-based structure. These systems allow for easier access to individual components, simplifying maintenance tasks and reducing downtime for repairs. Additionally, modular cranes often incorporate advanced monitoring systems, enabling predictive maintenance, which minimizes unexpected breakdowns and prolongs equipment lifespan.

Real-world instance: A steel fabrication facility employs a modular crane system with integrated monitoring features. This setup allows for proactive maintenance scheduling based on data insights, ensuring continuous operations without unplanned interruptions.

Understanding these advantages not only highlights the efficiency gains but also underscores the practicality and adaptability of modular crane systems. These benefits transcend industries, catering to diverse operational needs and positioning modular cranes as indispensable tools for enhancing productivity and operational efficiency.

Choosing the Right Modular Crane Manufacturing Company

Selecting the right modular crane manufacturer is a pivotal decision, laying the foundation for reliable, efficient, and safe material handling solutions. Here are key considerations and factors to assess when choosing a reputable manufacturer:

Criteria for Selecting a Reputable Manufacturer

When evaluating potential manufacturers, certain criteria can guide decision-making:

- Experience: Assess the manufacturer's industry tenure and track record. An experienced manufacturer often signifies expertise and reliability in producing quality crane systems.

- Certifications and Compliance: Verify if the manufacturer complies with industry standards and possesses relevant certifications (ISO, OSHA, CMAA, etc.). Compliance underscores their commitment to quality and safety.

- Customer Reviews and Reputation: Explore customer testimonials and reviews to gauge customer satisfaction levels. Positive reviews and a good reputation are indicators of consistent quality and service.

Importance of Quality Standards and Certifications

Adherence to quality standards and certifications is non-negotiable when selecting a modular crane manufacturer. Certifications signify a commitment to producing safe, reliable, and high-performance crane systems that meet industry benchmarks. Manufacturers adhering to stringent quality standards assure reliability, durability, and safety in their products.

Showcasing Successful Implementations

A reputable manufacturer should be willing to showcase their successful implementations. This can be in the form of case studies, testimonials, or industry success stories. These real-world examples provide insights into the manufacturer's capabilities, their ability to deliver on promises, and the practical application of their crane systems.

Highlighting Customer Support and After-sales Services

The significance of robust customer support and after-sales services cannot be overstated. A reliable manufacturer offers comprehensive support throughout the lifecycle of the crane system. This includes installation assistance, operator training, regular maintenance services, spare parts availability, and prompt response to queries or issues. Proactive after-sales support ensures optimal crane performance and longevity.

By considering these factors, businesses can make informed decisions when selecting a modular crane manufacturer. Investing time in researching and assessing manufacturers based on these criteria helps ensure the acquisition of a reliable and efficient crane system that meets specific operational needs and complies with safety standards.

Application Scenarios and Industries

Modular cranes, with their versatility and adaptability, find widespread application across various industries, revolutionizing material handling and lifting operations. Let's explore detailed examples of how modular cranes benefit and are utilized in specific sectors:

Manufacturing and Production Facilities

In manufacturing settings, efficiency and precision are paramount. Modular cranes play a pivotal role in streamlining processes, facilitating the movement of raw materials, components, and finished products. These cranes offer customizable solutions, aiding in tasks such as:

- Assembly Lines: Single or double girder cranes assist in the seamless movement and positioning of components during assembly processes, optimizing workflow and reducing manual labor.

- Material Handling: Electric chain hoists and trolley systems ensure swift and controlled material transfer, enhancing efficiency and minimizing production downtime.

Warehousing and Logistics

Efficient warehousing and logistics operations rely on optimized material flow and storage. Modular cranes provide tailored solutions for these requirements, enabling:

- Inventory Management: Top running bridge cranes efficiently handle pallets and goods, aiding in stock management by facilitating organized stacking and retrieval.

- Order Fulfillment: Under running bridge cranes offer space-saving solutions for precise picking and packing of goods, enhancing order fulfillment speed.

Construction and Infrastructure Projects

In the construction industry, where heavy lifting is routine, modular cranes offer the required strength and adaptability:

- Heavy Lifting: Double girder bridge cranes are instrumental in lifting and placing heavy construction materials and structural components with precision and safety.

- Flexibility in Sites: Modular cranes, especially under running systems, cater to diverse construction sites with varying spatial constraints, ensuring efficient material handling in constrained spaces.

Automotive and Aerospace Industries

Precision, safety, and reliability are crucial in industries like automotive and aerospace. Modular cranes prove indispensable in:

- Component Handling: Customizable hoists and trolley configurations aid in handling delicate or heavy components in automotive assembly lines or aerospace manufacturing units.

- Maintenance and Overhaul: Top running bridge cranes assist in lifting and moving aircraft parts during maintenance, ensuring efficient servicing and repairs.

The adaptability and versatility of modular cranes make them indispensable tools across a spectrum of industries. Their ability to cater to specific lifting needs, enhance operational efficiency, and ensure safety positions them as invaluable assets in various industrial applications.

The dynamic nature of industries necessitates solutions that can adapt and evolve. Modular crane systems epitomize this adaptability, catering to diverse operational demands. It's imperative to consider these systems when contemplating lifting solutions, given their flexibility, efficiency, and ability to align with evolving business needs.

To businesses contemplating material handling solutions, exploring modular crane systems is a strategic choice. By embracing these systems, businesses open avenues for efficient, tailored lifting solutions that can significantly enhance productivity and streamline operations. Informed decision-making and an understanding of the value these systems bring are crucial in leveraging the adaptability and efficiency of modular crane solutions.

In conclusion, modular crane systems stand as a testament to innovation and practicality in the realm of material handling. Their versatility, coupled with the numerous benefits they offer, makes them indispensable assets across industries. Embracing modular crane solutions represents not just a step forward in operational efficiency but a strategic investment in the future of efficient material handling practices.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch