KBK Rail Modular Crane, KBK Modular Crane System 250Kg, 500Kg, 1000Kg

KBK rail modular crane for sale. Custom kbk modular crane system for light loads handling with capacity of 250Kg, 500Kg, 1000Kg, 2000kg. Get your modular crane.

Category: Modular Cranes and Hoists

Your Trusted Overhead Modular Crane Manufacturer & Supplier

KBK Rail Modular Crane, KBK Modular Crane System 250Kg, 500Kg, 1000Kg

KBK rail modular crane for sale. Custom kbk modular crane system for light loads handling with capacity of 250Kg, 500Kg, 1000Kg, 2000kg. Get your modular crane.

Comprehensive Guide on KBK Modular Crane System

In the ever-evolving landscape of material handling technology, the KBK Modular Crane System stands out as a pinnacle of innovation and adaptability. This comprehensive guide aims to delve into the intricacies of KBK modular crane technology, exploring its definition, evolution, and the crucial role played by modular design in revolutionizing material handling systems.

The KBK Modular Crane System is a cutting-edge solution designed to meet the diverse and dynamic needs of modern industries. Originating from the German engineering prowess, KBK, which stands for "Kranbahnsysteme" (crane runway systems), has undergone a remarkable evolution over the years.

Initially conceived as a flexible and customizable crane system, KBK has evolved to incorporate state-of-the-art modular design principles. This evolution is marked by a continuous commitment to innovation, allowing the KBK system to remain at the forefront of material handling technology.

Importance of Modular Design in Material Handling Systems

Modular design plays a pivotal role in the success and widespread adoption of the KBK Crane System. Unlike traditional, fixed crane solutions, the modular approach allows for a high degree of flexibility and adaptability. Each component of the KBK system is designed to be modular, meaning it can be easily assembled, disassembled, or reconfigured.

This modularity empowers industries to tailor the crane system to their specific requirements, providing a level of customization that is unparalleled. Whether adapting to changes in workflow, load characteristics, or spatial constraints, the KBK Modular Crane System ensures that businesses can optimize their material handling processes efficiently.

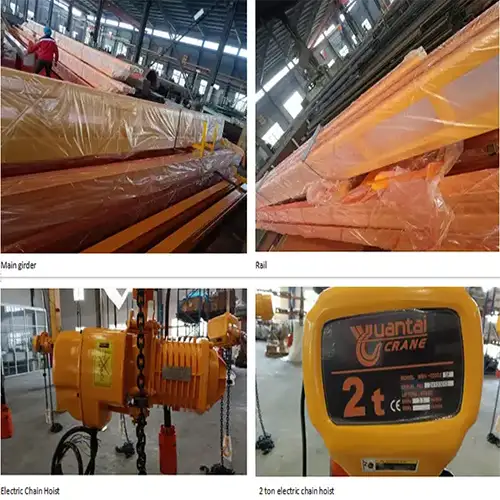

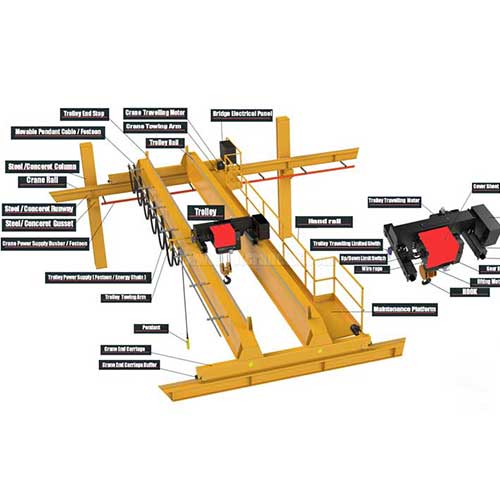

Key Components of KBK Modular Crane System

The KBK Modular Crane System comprises several key components that work in harmony to deliver precision, efficiency, and reliability in material handling. These components include:

- KBK Rails: The foundation of the system, KBK rails form the crane runway and provide the structural support for the entire setup.

- Trolleys: These movable units run along the KBK rails, carrying the load and enabling smooth horizontal movement.

- Hoists: Integral to the system, hoists lift and lower the loads with precision. The modular design allows for the integration of various hoist types based on the application's requirements.

- Control Systems: KBK systems are equipped with advanced control systems that ensure seamless and precise operation. These systems can be tailored to meet specific automation and control needs.

As we journey through this guide, we will explore each of these components in detail, understanding their functionalities and how the modular design enhances their performance. Join us in unraveling the complexities and advantages of the KBK Modular Crane System.

Types of KBK Modular Crane Systems

The KBK Modular Crane System boasts a diverse range of configurations to meet the specific demands of various industries. Understanding the nuances of each type is essential to leverage the system's full potential. Let's explore the distinctive features, load capacities, and applications of the main types of KBK Modular Crane Systems.

Single-Girder KBK Modular Cranes

- Design and Structure:Single-girder KBK cranes feature a simplistic yet robust design. A single horizontal beam, supported by the KBK rails, serves as the primary load-bearing element. The modular nature of this design facilitates easy customization and integration into diverse work environments.

- Load CapacitiesSuited for lighter loads, single-girder KBK cranes typically handle capacities ranging from a few hundred kilograms to a ton. The modular design allows for scalability, ensuring optimal performance within specified load ranges.

Key Features and Benefits

Adaptability: Easily adaptable to changing work processes and layouts.

Cost-Effective: Well-suited for applications with lighter loads, providing a cost-effective solution.

Quick Installation: The modular components enable swift installation and modifications.

Ceiling Mounted Double-Girder KBK Modular Cranes

- Enhanced Load Capacities : Double-girder KBK cranes are designed for heavier lifting requirements. The dual horizontal beams provide increased stability and load-bearing capacity, making them suitable for demanding applications.

- Stability and Precision : The dual-girder configuration enhances stability and precision during load movement. This makes double-girder KBK cranes ideal for scenarios where accuracy is paramount.

- Common Applications : - Heavy Machinery Manufacturing: Lifting and maneuvering large components during the manufacturing process. - Shipbuilding: Precision handling of heavy ship components and materials.

Articulated KBK Rail Modular Cranes

- Flexibility in Movement : Articulated KBK cranes, known for their flexibility, feature articulated arms that can reach into confined spaces and around obstacles. This design provides enhanced maneuverability in complex work environments.

- Applications in Complex Environments : - Confined Spaces: Ideal for navigating and lifting loads in tight and restricted areas. - Laboratories: Precision handling in research and testing laboratories.

Monorail KBK Modular Crane Systems

- Linear Movement Efficiency - Monorail KBK crane systems are characterized by a single rail, providing linear movement along a specified path. This design optimizes efficiency in material handling processes.

- Space-Saving Design - Suitable for facilities with limited space, monorail systems offer a compact and space-saving solution. This design is often preferred in congested work environments.

- Applications Across Industries - Warehousing and Logistics: Efficient movement of goods within warehouses. - Continuous Material Flow: Manufacturing processes requiring continuous and linear material flow.

As we unravel the intricacies of each KBK Modular Crane System type, it becomes evident that the modular design philosophy ensures adaptability, efficiency, and precision across diverse industrial applications. Join us in the next sections as we delve into the specific features, benefits, and real-world applications of each KBK Modular Crane System type.

Features and Benefits of KBK Modular Crane Design

The modular design philosophy inherent in KBK Modular Crane Systems brings forth a myriad of features and benefits that cater to the dynamic needs of modern material handling. Let's delve into the core attributes that make KBK Modular Crane Systems stand out:

Configurability and Adaptability

Tailored Solutions for Different Work Environments - The hallmark of KBK Modular Crane Systems is their ability to be tailored to the specific needs of diverse work environments. Whether it's a manufacturing facility, warehouse, or laboratory, the configurability ensures an optimal fit for different applications.

Accommodating Changes in Workflow - As workflows evolve, KBK Modular Crane Systems seamlessly adapt. The modular components can be reconfigured to accommodate changes in production processes or layout, ensuring continuous operational efficiency.

Ease of Installation and Expansion

- Quick Assembly and Disassembly - Modularity translates to simplicity in installation. KBK Modular Crane Systems can be quickly assembled and disassembled, reducing downtime during setup or modifications.

- Scalability for Growing Operations - The scalable nature of the modular design allows businesses to expand their operations without significant infrastructure changes. As production demands increase, KBK Modular Crane Systems can grow with the business.

Cost-Effective Solutions

- Minimizing Waste and Reducing Costs - Modular components mean that only the necessary elements are utilized, minimizing waste and reducing overall costs. Businesses can invest in the exact components needed for their specific application.

- Long-Term Value of Modular Design - The long-term value of KBK Modular Crane Systems lies in their adaptability over time. As industry requirements change, the crane system can be upgraded or reconfigured, ensuring sustained value and relevance.

Floor mounted kbk modular crane system

Floor mounted kbk modular crane systemCustomization Options

- Choosing Components Based on Specific Requirements - KBK Modular Crane Systems offer a diverse range of components, allowing users to select those that align precisely with their requirements. This customization ensures that the crane system meets the unique challenges of each application.

- Aligning Crane System with Application Needs - The ability to align the crane system with specific application needs ensures that businesses get a solution that optimally addresses their material handling challenges. Whether it's load capacities, movement precision, or specialized functions, customization options abound.

In the ever-evolving landscape of material handling, KBK Modular Crane Systems stand as versatile and adaptable solutions. The features and benefits derived from the modular design cater to the nuances of different industries and applications. Join us in the subsequent sections as we explore the specific applications across various industrial sectors, showcasing how KBK Modular Crane Systems provide practical solutions to unique challenges.

Industrial Applications of KBK Modular Crane System

The versatility of KBK Modular Crane Systems finds its true value in a diverse range of industrial applications. Let's explore how this crane system excels in different sectors, providing practical solutions to unique challenges.

Automotive Manufacturing

- Assembly Lines and Component Handling - In the fast-paced world of automotive manufacturing, KBK Modular Crane Systems play a pivotal role in handling components along assembly lines. The configurable design ensures that the crane system adapts to the dynamic needs of automotive workshops.

- Benefits of Configurable Design for Automotive Workshops - The configurable nature of KBK Modular Crane Systems brings unparalleled benefits to automotive workshops. As production requirements shift, the crane system can be quickly reconfigured to optimize material handling processes.

Electronics Industry

- Delicate Parts Handling and Precision Control - In the electronics industry, where precision is paramount, KBK Modular Crane Systems shine in delicately handling electronic components. The ability to control movements with precision ensures the safe and accurate handling of delicate parts.

- Applications in High-Tech Manufacturing Facilities High-tech manufacturing facilities leverage the adaptable nature of KBK Modular Crane Systems. These cranes contribute to the efficient flow of materials, supporting the intricate processes involved in electronics production.

Warehousing and Logistics

- Efficient Material Handling in Distribution Centers - The warehousing and logistics sector benefits from the efficiency of KBK Modular Crane Systems in material handling. These cranes streamline processes in distribution centers, ensuring swift and organized movement of goods.

- Role of Modular Design in Optimizing Warehousing Processes - The modular design allows for the optimization of warehousing processes. As storage configurations change or new product lines are introduced, KBK Modular Crane Systems can be easily adapted to meet evolving logistics requirements.

Construction and Building Sites

- Material Transport and Positioning - On construction sites, where materials need precise transport and positioning, KBK Modular Crane Systems showcase their adaptability. The crane system efficiently moves and places construction materials with accuracy.

- Adaptability to Dynamic Construction Environments - The dynamic nature of construction sites demands equipment that can adapt swiftly. KBK Modular Crane Systems provide the adaptability required to navigate the changing landscapes of construction environments.

Mining and Resources

- Material Handling in Mining Operations - In the mining industry, where heavy materials must be moved with precision, KBK Modular Crane Systems excel in material handling. Their robust design and configurable nature make them valuable assets in mining operations.

- Benefits of Modular Crane Systems in Resource Extraction - The benefits of modular design become apparent in resource extraction scenarios. KBK Modular Crane Systems offer flexibility and scalability, allowing mining operations to tailor their material handling solutions to the unique challenges of resource extraction.

As we journey through the applications in these diverse industrial sectors, the adaptability and versatility of KBK Modular Crane Systems become increasingly evident. Join us in the next section as we explore the main components of KBK Modular Crane Systems, shedding light on the integral parts that make these systems efficient and reliable.

Case Studies: Applications in Various Sectors

In this section, we delve into real-world case studies to showcase the successful implementations of KBK Modular Crane Systems across different industrial sectors. These case studies not only highlight the adaptability of KBK cranes but also emphasize the design benefits that contribute to their efficiency in specific industrial environments.

Showcasing Successful Implementations

Automotive Manufacturing Excellence

In an automotive manufacturing facility, the challenge was to streamline the handling of diverse components along the assembly line. KBK Modular Crane Systems were successfully implemented, offering a configurable design that adapted to the changing demands of the production process. This resulted in improved efficiency, reduced downtime, and enhanced overall productivity.

Precision in the Electronics Industry

A high-tech electronics manufacturing facility sought a crane system that could handle delicate components with precision. KBK Modular Crane Systems proved to be the ideal solution, providing precise control over movements. The modular design allowed for quick adjustments to accommodate varying component sizes, contributing to the precision required in electronic assembly.

Warehousing Optimization

In a large distribution center, the challenge was to optimize material handling processes amidst changing storage configurations. KBK Modular Crane Systems demonstrated their efficiency by easily adapting to new warehouse layouts. The ability to reconfigure the crane system resulted in a more organized and streamlined logistics operation.

Highlighting Design Benefits in Specific Industrial Environments

- Automotive Sector: Configurability for Changing Production Lines - The configurability of KBK Modular Crane Systems proves invaluable in the automotive sector, where production lines frequently change to accommodate different models and components. The ability to quickly reconfigure the crane system ensures minimal disruption and optimal workflow.

- Electronics Industry: Precision Control for Delicate Parts - In the electronics industry, precision control is crucial for handling delicate parts. KBK Modular Crane Systems offer precise movements, reducing the risk of damage to sensitive electronic components. The adaptable design allows for customization to specific electronic assembly requirements.

- Warehousing and Logistics: Optimizing Storage Configurations - KBK Modular Crane Systems contribute to optimizing warehousing processes by easily adapting to changing storage configurations. This design benefit ensures that the crane system remains aligned with evolving logistics needs, ultimately improving operational efficiency in distribution centers.

- Construction Sites: Adapting to Dynamic Environments - The dynamic nature of construction sites requires equipment that can adapt to changing landscapes. KBK Modular Crane Systems excel in adapting to dynamic construction environments, offering the flexibility needed for efficient material transport and positioning.

- Mining and Resources: Robust Design for Heavy Materials - In mining operations dealing with heavy materials, the robust design of KBK Modular Crane Systems is a key design benefit. The crane system can withstand the harsh conditions of mining environments while providing efficient and adaptable material handling solutions.

As we explore these case studies and highlight design benefits, the practical applications of KBK Modular Crane Systems become evident. Join us in the next section as we delve into the main components of KBK Modular Crane Systems, unraveling the intricacies of these systems that contribute to their efficiency and reliability.

Considerations for Implementing KBK Modular Crane Systems

Implementing KBK Modular Crane Systems requires a thoughtful and strategic approach to ensure that the crane system aligns seamlessly with the specific requirements of the application. In this section, we explore the key considerations for a successful implementation, covering the assessment of application-specific requirements, collaboration with design and engineering teams, and the integration of KBK Modular Crane Systems with existing operations.

Assessing Application-Specific Requirements

Before implementing KBK Modular Crane Systems, a thorough assessment of application-specific requirements is essential. This involves understanding the nature of the materials to be handled, the required load capacities, the layout of the workspace, and any unique challenges posed by the industrial environment.

- Material Characteristics: Consider the weight, size, and nature of the materials that the crane system will handle. Different applications may require specific features or attachments for optimal material handling.

- Load Capacities: Assess the load capacities needed for the application. KBK Modular Crane Systems come in various configurations, each with its own load capacity range. Ensure that the selected system can handle the required loads efficiently.

- Workspace Layout: Evaluate the layout of the workspace, including any obstacles, workstations, or specific areas where the crane system needs to operate. This assessment helps determine the most suitable crane configuration for optimal coverage and efficiency.

- Environmental Conditions: Consider the environmental conditions of the industrial facility. Factors such as temperature, humidity, and the presence of dust or corrosive materials can influence the choice of materials and coatings for the crane system.

Collaborating with Design and Engineering Teams

Successful implementation of KBK Modular Crane Systems involves collaboration with design and engineering teams. This collaborative effort ensures that the crane system is tailored to meet the specific needs of the application and adheres to industry standards and regulations.

- Design Consultation: Engage in consultations with design teams to discuss the unique requirements of the application. Provide insights into workflow processes, material handling challenges, and any specific preferences or constraints.

- Customization Options: Leverage the customization options offered by KBK Modular Crane Systems. Work closely with design teams to tailor the crane system to the application's exact specifications, including specialized attachments, controls, or safety features.

- Compliance and Safety: Collaborate with engineering teams to ensure that the designed crane system complies with safety standards and regulations. Prioritize safety features such as overload protection, emergency stop functionality, and collision avoidance systems.

- Simulation and Testing: Utilize simulation tools and testing processes during the design phase. This allows for a virtual assessment of how the crane system will perform in the actual workspace, identifying any potential issues and refining the design accordingly.

Integrating KBK Modular Crane Systems with Existing Operations

Integration of KBK Modular Crane Systems with existing operations is a critical aspect of implementation. Seamless integration ensures minimal disruption to ongoing processes and maximizes the efficiency of material handling operations.

- Workflow Analysis: Conduct a thorough analysis of existing workflows to identify opportunities for integration. Understand how the crane system can enhance current processes, improve material flow, and contribute to overall operational efficiency.

- Minimizing Downtime: Plan the installation and integration process to minimize downtime. KBK Modular Crane Systems are designed for quick assembly and disassembly, allowing for efficient installation without prolonged interruptions to operations.

- Training Programs: Implement training programs for personnel who will operate and maintain the crane system. Ensure that the workforce is familiar with the system's controls, safety features, and maintenance procedures to optimize performance and longevity.

- Monitoring and Optimization: Establish monitoring systems to track the performance of the integrated crane system. Regularly assess its efficiency, address any issues promptly, and explore optimization opportunities to continuously enhance material handling operations.

By carefully considering these implementation factors, organizations can maximize the benefits of KBK Modular Crane Systems in their specific industrial applications. The next section delves into the main components of KBK Modular Crane Systems, providing a detailed understanding of the key elements that contribute to their functionality and adaptability.

Future Trends and Innovations in KBK Modular Crane Technology

As industries continue to evolve, so does the technology behind material handling systems. In this section, we explore the future trends and innovations in KBK Modular Crane Technology, focusing on technological advancements and the evolving design concepts that are shaping the industry.

Technological Advancements in Modular Crane Systems

- Smart Automation: The integration of smart automation features is becoming more prevalent in modular crane systems. This includes advanced control systems, IoT connectivity, and data analytics to enhance operational efficiency, monitor performance, and facilitate predictive maintenance.

- Robotics and Collaborative Systems: The incorporation of robotics into modular crane systems is on the rise. Collaborative systems that allow for interaction between cranes and robotic devices are becoming integral in streamlining complex material handling processes.

- Advanced Safety Features: Future modular crane systems are expected to incorporate even more sophisticated safety features. This includes real-time monitoring, artificial intelligence for predictive safety measures, and enhanced collision avoidance systems to ensure a safer working environment.

- Energy-Efficient Solutions: There is a growing emphasis on developing energy-efficient modular crane systems. This involves the integration of regenerative braking systems, energy recovery technologies, and the use of lightweight materials to reduce energy consumption during operation.

Industry Adoption and Evolution of Design Concepts

- Increased Customization Capabilities: Future modular crane systems will likely offer even greater customization capabilities. This will allow industries to tailor crane configurations more precisely to their unique material handling needs, ensuring optimal performance and efficiency.

- Ergonomic Design Considerations: Design concepts will increasingly prioritize ergonomic considerations to enhance the user experience. This includes user-friendly controls, intuitive interfaces, and ergonomic features that make operating and maintaining the crane system more efficient.

- Adoption of Sustainable Practices: The industry is moving towards more sustainable practices, and modular crane systems are no exception. Expect to see the incorporation of eco-friendly materials, energy-efficient designs, and systems that contribute to a more sustainable and environmentally conscious approach.

- Global Integration of Standards: As modular crane systems become more prevalent globally, there will likely be an increased effort to standardize design concepts and safety features. This global integration of standards aims to facilitate smoother cross-border operations and ensure consistency in crane system performance.

By staying abreast of these future trends and innovations, industries can position themselves to adopt cutting-edge technology, enhance their material handling capabilities, and stay competitive in an ever-evolving landscape. The guide concludes with a comprehensive summary of the versatility and benefits of KBK Modular Crane Systems, emphasizing their adaptability across various industrial sectors.

Conclusion

In conclusion, the KBK Modular Crane System stands as a beacon of innovation in the realm of material handling. The guide has provided a thorough exploration of its definition, evolution, and the pivotal role played by modular design in shaping the landscape of modern material handling systems.

- Configurability and Adaptability: The modular design of KBK crane systems allows for tailoring solutions to different work environments. This adaptability accommodates changes in workflow, ensuring that the crane system remains versatile and effective.

- Ease of Installation and Expansion: The quick assembly and disassembly of KBK modular crane components contribute to ease of installation. Scalability ensures that the system can grow alongside operational needs, making it a cost-effective choice for evolving businesses.

- Cost-Effective Solutions: The minimization of waste and reduction in costs are intrinsic benefits of the modular design. Long-term value is inherent in KBK Modular Crane Systems, offering a sustainable and efficient solution for material handling challenges.

- Customization Options: The variety of components available allows for the selection of specific parts based on requirements. This customization aligns the crane system with the unique needs of different applications, ensuring optimal performance and efficiency.

As industries face evolving material handling challenges, embracing modular solutions becomes a strategic imperative. The KBK Modular Crane System, with its array of benefits and future-ready design, positions itself as a key player in enhancing efficiency, safety, and adaptability across diverse industrial sectors.

In light of the comprehensive information provided in this guide, industries are encouraged to explore the possibilities offered by KBK Modular Crane Systems. Whether in automotive manufacturing, the electronics industry, warehousing and logistics, construction sites, or mining operations, the modular design proves its worth in delivering tailored solutions for unique material handling demands.

In the dynamic landscape of material handling technology, KBK Modular Crane Systems emerge not just as equipment but as partners in progress. The flexibility, efficiency, and innovation embedded in their design make them an invaluable asset for industries looking to stay at the forefront of the ever-evolving world of material handling.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch