Why Your Outdoor Sites Prefer Bridge Cranes Over Gantry Cranes

Check why production-oriented sites choose outdoor bridge cranes with elevated runways over gantry cranes for workflow, stability, & long-term efficiency.

Category: Featured

Your Trusted Outdoor Overhead Crane Manufacturer & Supplier

Outdoor Bridge Crane vs Gantry Crane

Why Production-Oriented Sites Prefer Elevated Runway Systems Even Without a Building

Most Important Takeaway:

Even in outdoor environments without a workshop building, elevated runway bridge cranes often outperform gantry cranes for production-oriented facilities, because they optimize workflow, maximize ground utilization, provide higher lifting height, improve operational stability, and enable process automation.

Key Takeaways

- Maximize Production Efficiency: Elevated bridge cranes integrate with the production process, not just move materials.

- Optimize Ground Space: No legs mean forklifts, trucks, and AGVs can move freely underneath.

- Higher Lifting Capacity and Clearance: Standalone runway systems deliver more usable hook height compared to gantry cranes.

- Wind Stability and Operational Reliability: Fixed runway structures handle wind loads better, reducing downtime.

- Transport and Installation Savings: Modular runway systems reduce logistics and installation complexity compared to heavy gantry crane legs.

- Long-Term Cost Benefits: Despite higher upfront CAPEX, total lifecycle cost is often lower for elevated runway bridge cranes.

- Automation Ready: Fixed travel paths and predictable behavior facilitate anti-sway systems, PLC control, and semi-automation.

Introduction: From Simple Lifting to Production Integration

Many crane buyers still think that if a site doesn't have a building, a gantry crane is the automatic choice. That's understandable. After all, gantry cranes are self-supporting, easy to move into open yards, and you don't need a roof or elevated runway. But this view comes from thinking about cranes purely as tools for moving loads—point A to point B.

In reality, modern industrial sites—like steel fabrication yards, precast concrete facilities, and heavy machinery workshops—use cranes differently. Here, cranes are not just lifting equipment; they are part of the production workflow. How a crane moves, how it positions loads, and how reliably it operates can directly affect the speed of production, the safety of workers, and even the quality of the output.

When lifting becomes part of the production line, the choice between a gantry crane and a bridge crane with an elevated runway matters much more than just cost or whether there's a building. You have to consider factors like workflow efficiency, ground clearance, operational stability, and the ability to integrate automation systems.

Key considerations at this stage:

- Workflow integration: Will the crane's path interfere with other production activities? Does it allow smooth material flow underneath?

- Positioning precision: How accurately does the crane place materials? Is repeatable positioning required for assembly or stacking?

- Production rhythm: Can the crane operate continuously without causing bottlenecks in the process?

- Ground utilization: Are forklifts, trucks, or AGVs restricted by crane legs or supports?

- Future-proofing: Will the crane system support upgrades, automation, or additional lifting tasks in the coming years?

Even outdoors, without a building, many production-focused facilities find that a bridge crane on a standalone elevated runway offers advantages over a gantry crane. It frees the ground area, allows more predictable lifting paths, and integrates better with workflow. In other words, the crane stops being just a piece of equipment and becomes part of the system that drives production.

Outdoor Bridge Cranes and Gantry Cranes

The differences, advantages, and limitations of outdoor bridge cranes versus gantry cranes for yard and industrial operations.

outdoor bridge crane with single girder overhead crane design

outdoor bridge crane with double girder overhead crane design

Outdoor Bridge Crane with Standalone Runway

An outdoor bridge crane with a standalone elevated runway operates on steel columns fixed to the ground. The crane moves along the elevated rails, just like an indoor overhead crane. Even outdoors, it provides precision and control suitable for production tasks.

Advantages:

- Fixed travel path ensures predictable and safe material movement

- Ground area remains completely unobstructed, improving workflow and logistics

- Precise load positioning suitable for production lines and assembly operations

- Easier integration with automation, anti-sway systems, and remote controls

- Can be built modularly for transport and phased installation

Practical Tip: Ideal for heavy or repetitive lifts in open yards where workflow efficiency and vehicle movement are critical.

Outdoor Gantry Crane

An outdoor gantry crane is self-supporting and travels on rails installed on the ground. Its portal frame structure provides stability and resists wind without a separate elevated runway. These cranes are commonly used in yards, storage areas, and temporary sites where flexibility is important.

Advantages:

- Flexible movement across yards and open areas

- Suitable for stacking and material transfer operations

- Does not require an elevated runway or additional columns

Limitations:

- Legs occupy valuable ground space, restricting vehicle and logistics flow

- More sensitive to wind conditions, which can limit outdoor operation

- Limited potential for automation and precise repeatable lifting

Practical Tip: Best suited for temporary operations, moderate loads, or sites where flexibility is more important than workflow efficiency.

Equipment vs Production System: The Core Difference

When choosing between a gantry crane and a bridge crane with an elevated runway, the decision goes beyond just structure or site layout. The real difference is how each crane interacts with your production workflow and the site as a whole.

A gantry crane is primarily an independent lifting tool. It's mobile, self-supporting, and designed to move materials from one point to another. It works well in yards or storage areas where flexibility is more important than integration. You can reposition it if the layout changes, which is convenient for temporary operations—but it doesn't actively enhance workflow or production efficiency.

A bridge crane with a fixed runway, on the other hand, functions as part of the production infrastructure. The runway supports precise movement, predictable positioning, and uninterrupted travel paths. Because it is integrated into the facility—even outdoors—it helps organize the workflow, reduces collisions or delays, and provides a stable platform for semi-automation or anti-sway control. In short, it is not just lifting loads; it supports the way work gets done.

Why this matters for crane buyers:

- Precision: Fixed elevated runways allow consistent, repeatable placement of loads, reducing errors in assembly or stacking.

- Workflow integration: Bridge cranes fit into the overall production layout, keeping material movement smooth and predictable.

- Operational reliability: Fixed structures resist sway and vibration better, which is critical for long-term performance and heavy-duty lifting.

- Automation-ready: Integration with PLCs, anti-sway systems, and repeatable lifting operations is much easier than with gantry cranes.

- Ground space efficiency: Unlike gantry legs, elevated runways leave the floor clear for forklifts, trucks, or other equipment.

Why Production-Oriented Sites Prefer Elevated Runway Bridge Cranes

Elevated bridge cranes improve workflow, operational efficiency, and reliability in outdoor production-focused environments, offering advantages beyond simple lifting.

Ground Space Optimization

Gantry crane legs take up valuable ground space, forcing forklifts, trucks, or AGVs to navigate around them. Elevated bridge cranes solve this by leaving the ground completely open, allowing vehicles and equipment to move freely underneath, improving logistics and workflow continuity.

- Eliminates obstacles for forklifts, trucks, and automated vehicles

- Frees up space for simultaneous operations under the crane

- Reduces safety risks caused by ground-level interference

Practical Insight: Ideal for production sites where continuous material flow and operational efficiency are critical.

Greater Effective Lifting Height

Running on an elevated runway, the crane provides a higher usable hook height than a gantry crane at the same structural elevation. This is crucial for handling tall or stacked materials and vertical assembly tasks.

- Maximizes vertical lifting envelope without increasing structure height

- Supports stacking, vertical assembly, and rotational handling

- Improves operational flexibility for various load types

Practical Insight: Useful for steel yards, precast concrete operations, or any site requiring high-clearance lifting.

Wind Load Management and Operational Stability

Elevated bridge cranes transfer wind and lateral forces to fixed steel columns and foundations, providing better stability than free-standing gantry cranes, which are more sensitive to wind.

- Fixed runway reduces sway and vibration

- Less downtime due to wind restrictions

- Safer handling of heavy or long loads in open yards

Practical Insight: Ideal for open-air sites prone to strong winds where operational reliability is essential.

Process Continuity and Automation Readiness

Fixed travel paths of elevated bridge cranes make them ideal for semi-automated operations and anti-sway systems. Gantry cranes are less precise due to their ground-supported legs, making repeatable operations harder.

- Supports precise and repeatable positioning along fixed paths

- Compatible with anti-sway systems and PLC-controlled automation

- Reduces human error in production-heavy lifting operations

Practical Insight: Recommended for production yards integrating automation or requiring consistent, reliable lifting routines.

Transport, Installation, and Hidden Costs

Beyond purchase price and load capacity, transport, installation, and hidden costs can significantly impact outdoor crane projects, especially for large-scale or export operations.

Gantry Crane Transport Challenges

Gantry cranes have tall, heavy, and reinforced legs that often exceed standard shipping dimensions. Transporting these components may require special permits, oversized vehicles, or route modifications.

- Oversized legs and portal frames may exceed shipping limits

- Long-distance transport increases risk of damage and delays

- Special transport arrangements add cost and require careful planning

- Installation time may increase if on-site assembly is complicated

Practical Insight: For international or long-distance projects, transport logistics can become a major cost factor and affect project timelines.

Modular Bridge Crane and Runway Advantages

Bridge cranes with elevated runways can use modular, standardized components for easier transport. Columns, rails, and bridge sections fit standard freight limits, reducing shipping complexity and risk.

- Smaller, modular components simplify transport and reduce costs

- Staged installation allows partial operation while remaining sections are completed

- Easier to upgrade or extend the system in the future

- Reduces risk of transport damage compared to oversized gantry legs

Practical Insight: Modular design and phased installation help align crane setup with production schedules while lowering overall cost and risk.

Total Cost of Ownership (TCO) Perspective

When selecting a crane, it's easy to focus only on initial purchase cost. Gantry cranes can seem cheaper upfront because you don't need to build an elevated runway or enclosure. But for production-oriented sites, lifecycle cost—or Total Cost of Ownership (TCO)—often tells a very different story.

Elevated bridge cranes, even without a building, can save money over the long term. Their design reduces downtime, minimizes maintenance, and makes future upgrades easier. When you factor in installation, operation, and maintenance over the life of the crane, bridge cranes can provide better value and reliability than a gantry crane that initially appeared cheaper.

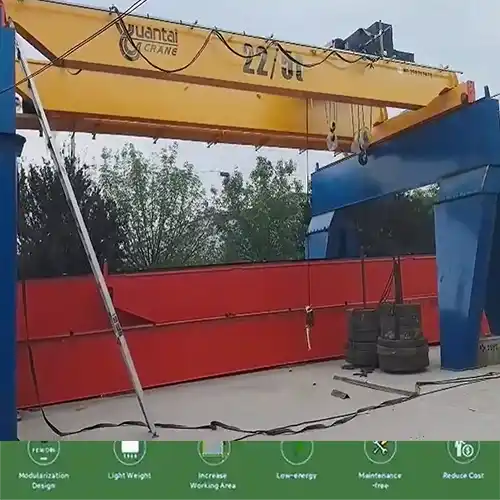

22/5 Ton Overhead Crane Load Testing, 22 Ton Main Hook 5 Ton Axuiliary Hook for Mixed Load Handling

Factors contributing to lower TCO with elevated bridge cranes:

- Reduced wind downtime: Fixed runway systems are more stable in outdoor environments, so production is less affected by strong winds compared to self-standing gantry cranes.

- Lower maintenance of moving components: No ground rails or heavy portal legs means fewer alignment issues, less wear, and fewer repairs.

- Better upgrade potential: Modular design allows adding capacity, automation, or new production lines without major structural changes.

- Transport and installation efficiency: Smaller, modular components reduce shipping and assembly costs compared to large gantry crane legs, especially for long-distance or export projects.

Practical takeaway for buyers: While gantry cranes might appear cheaper at first glance, considering wind exposure, maintenance, productivity, and future expansion, an elevated runway bridge crane often provides better return on investment over the crane's lifetime.

When Gantry Cranes Are Still Appropriate

While elevated runway bridge cranes offer many advantages for production-focused sites, gantry cranes still have clear applications where their flexibility and mobility make them the better choice. Not every site needs fixed runways or integration into a production line. Understanding these scenarios helps buyers make the right investment.

Situations where gantry cranes make sense:

- Temporary yards or uncertain layouts: If your site layout may change frequently or you are operating on a short-term project, a gantry crane can be moved and repositioned easily. You don't need to invest in foundations or elevated runways that might become redundant.

- Low-duty or storage-focused operations: For sites where lifting is occasional, light, or mostly for storage and stacking, the precision and integration of a bridge crane may not be necessary. Gantry cranes are sufficient and cost-effective.

- Flexibility over production integration: When moving materials between multiple areas or working in open yards, the ability to relocate a gantry crane quickly can outweigh the benefits of a fixed, elevated system.

Practical considerations for buyers:

- Evaluate load frequency and duty cycles: Gantry cranes are ideal for low-to-medium lifting frequency.

- Consider future site expansion or changes: If layouts are uncertain, gantry cranes provide mobility without requiring major infrastructure changes.

- Analyze workflow vs. flexibility needs: For operations prioritizing flexibility rather than production-line efficiency, gantry cranes remain competitive.

Practical Buyer Decision Framework

Selecting the right crane is about matching your lifting equipment to production needs, site layout, and long-term goals. Consider workflow, logistics, and future upgrades—not just price or capacity.

Production Line Integration

Question: Is lifting part of the production workflow or mainly for moving materials from point A to point B?

Guidance:

- If the crane is used repeatedly in assembly, stacking, or positioning, a bridge crane with an elevated runway is better suited.

- For occasional transfers or storage-focused tasks, a gantry crane may be sufficient.

Ground Access Needs

Question: How important is unobstructed ground access for forklifts, trucks, or automated vehicles?

Guidance:

- Elevated bridge cranes keep the floor clear, allowing smooth logistics and faster material flow.

- Gantry crane legs occupy ground space, which can slow down traffic and reduce flexibility.

Automation and Future Upgrades

Question: Will your site require automation, anti-sway systems, or PLC-controlled lifting in the future?

Guidance:

- Fixed runway cranes are easier to integrate with automation and precision systems.

- Gantry cranes are less predictable due to sway and structural movement, limiting automation potential.

Scenario 4: Site Stability

Question: Is the site layout expected to remain stable long term, or will it change frequently?

Guidance:

- For long-term, stable layouts, investing in a standalone elevated runway bridge crane pays off over the crane's lifetime.

- For temporary or frequently changing layouts, a gantry crane provides flexibility and lower upfront installation effort.

Summary

- Choose elevated runway bridge cranes when production workflow, precision, automation, and ground utilization are priorities.

- Choose gantry cranes when flexibility, temporary operation, or low-duty lifting is more important.

- Thinking through these questions helps avoid costly mistakes and ensures your crane system matches your operational needs.

Conclusion: Making Cranes Part of the Production System

Choosing an outdoor bridge crane with a standalone elevated runway is not just an alternative to a gantry crane—it's a deliberate, strategic decision for production-oriented sites. Even without a building, a bridge crane can become an integral part of your workflow, rather than just a tool for moving materials.

When evaluating outdoor lifting options, the key is to think beyond initial cost or mobility. Consider how the crane affects workflow efficiency, lifting precision, safety, and long-term operational costs.

Key Takeaways for Buyers:

- Workflow integration: Elevated bridge cranes allow continuous material movement without obstructing the ground, supporting smooth production.

- Higher lifting performance: Fixed runways provide greater usable hook height and precise load placement, ideal for stacking and assembly.

- Operational reliability: Stability in wind and predictable motion reduces downtime and improves safety.

- Automation readiness: Fixed paths and structural consistency support anti-sway systems, PLC-controlled lifts, and semi-automated operations.

- Lower hidden costs: Modular design reduces transport, installation, and maintenance challenges compared to large gantry crane legs.

- Production-focused investment: Rather than a one-off lifting tool, the crane becomes a long-term asset that supports operational efficiency and future expansion.

In short, elevated runway bridge cranes transform outdoor lifting from a simple material handling task into a structured, reliable part of your production system. For industrial sites aiming for efficiency, predictability, and scalability, this approach often provides the best balance of performance, cost, and flexibility.

Outdoor Bridge Cranes vs Gantry Cranes: FAQ for Production-Oriented Sites

Answers to key buyer questions on selecting electric cranes ( Outdoor Bridge Ccranes vs Outdoor Gantry Cranes )for outdoor, production-focused environments, focusing on workflow, cost, and operational efficiency.

1. When should I choose an outdoor bridge crane over a gantry crane?

Choosing between a bridge crane and a gantry crane depends on whether lifting is part of the production workflow or just material transfer.

Bridge cranes are ideal when:

- Lifting is integrated into a production line, requiring repeatable and precise placement.

- Ground access must remain clear for trucks, forklifts, or AGVs.

- Automation or semi-automation is planned, such as anti-sway systems or PLC-controlled operations.

- Long-term stability and site layout predictability are priorities.

Gantry cranes are better when:

- The site layout is temporary or may change frequently.

- Lifting is light-duty, occasional, or primarily for storage/yard operations.

- Flexibility and mobility outweigh workflow integration needs.

2. Can I use a bridge crane without building support?

Yes. An outdoor bridge crane can operate on a standalone elevated runway, supported by steel columns.

Key points:

- The crane moves along fixed rails just like an indoor overhead crane.

- Ground below remains open, allowing vehicles and personnel to move freely.

- Modular construction allows phased installation and flexible transport planning.

- Even outdoors, these cranes provide high precision, stability, and integration with production processes.

3. What are the productivity, stability, and workflow benefits of high-elevation overhead cranes?

Elevated bridge cranes offer advantages that go beyond simple lifting:

- Ground space optimization: Legs do not occupy floor space, keeping workflow and logistics uninterrupted.

- Higher usable lifting height: More hook clearance supports stacking, vertical assembly, and rotation.

- Wind resistance and operational stability: Loads are transferred to fixed columns, reducing downtime in outdoor conditions.

- Automation readiness: Predictable motion allows anti-sway systems, PLC control, and semi-automated lifting.

- Repeatable positioning: Critical for production processes where accuracy affects quality and efficiency.

4. How do transport, installation, and long-term costs differ between gantry cranes and bridge cranes?

Gantry cranes:

- Large legs require oversized transport, permits, and special handling.

- Long-distance or international shipping can increase cost and risk.

- Ground rails may need regular maintenance, adding hidden lifecycle costs.

Bridge cranes with elevated runways:

- Modular, standardized components fit standard shipping limits.

- Phased installation reduces disruption and aligns with production start-up.

- Lower lifecycle cost due to reduced wind downtime, fewer maintenance requirements, and easier upgrades.

5. Which crane type best suits a steel mill or fabrication plant outdoor lifting system?

For industrial production outdoors—like steel mills, fabrication yards, or precast concrete facilities—a bridge crane on an elevated runway often provides the best long-term solution:

- Maximizes workflow efficiency and ground utilization.

- Provides precision, reliability, and operational stability.

- Supports automation and future production upgrades.

- Reduces hidden costs related to transport, installation, maintenance, and wind downtime.

Gantry cranes are suitable in cases where:

- Lifting is temporary or low-duty.

- The site layout changes frequently.

- Flexibility and mobility are more important than workflow integration.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch