Top 5 Rubber Tyred Gantry Cranes, Get Your Fit Gantry Crane

Compare the top 5 rubber tyred gantry cranes, their capacities, mobility, and best applications for efficient material handling operations.

Category: Featured

Your Trusted Rubber Tyred Gantry Crane Manufacturer & Supplier

Top 5 Rubber Tyred Gantry Cranes for Sale

Which One Fits Your Operation?

Introduction

Rubber Tyred Gantry (RTG) cranes are a common sight in ports, container yards, shipyards, and large industrial sites. These cranes are mounted on rubber tires, which gives them mobility across paved surfaces, making them extremely versatile for moving heavy loads like containers, large machinery, or raw materials. Unlike fixed gantry cranes, RTG cranes can be repositioned as your operation changes, allowing you to adapt quickly to evolving handling needs.

Choosing the right RTG crane isn't just about picking the biggest or fastest model. Your decision directly affects how smoothly your operations run, how safe your team is, and how much it costs you over the long term. The wrong crane can lead to delays, excessive maintenance, or even accidents, while the right crane will match your workflow, lifting requirements, and yard layout.

The goal of this guide is to help you make an informed choice. We'll take a close look at five hot-selling types of RTG cranes and explain which types are best suited for different operations. By the end, you'll have practical insights on what to consider, so you can select a crane that truly fits your site and workload.

Key points to keep in mind before choosing an RTG crane:

- Operational requirements: What loads and sizes you need to move.

- Site conditions: Space, surface, and mobility considerations.

- Lifting height and span: Ensuring the crane fits your operation without compromising efficiency.

- Power source: Diesel, electric, or hybrid depending on your environment and costs.

- Maintenance and lifecycle: Long-term reliability and ease of servicing.

Basics of Rubber Tyred Gantry Cranes

Rubber Tyred Gantry (RTG) cranes are designed to handle heavy loads while moving freely across a yard or facility. Understanding their structure and features is essential for choosing the right model for your operation.

Key Components and Structural Features

RTG cranes are built with several core parts that make them practical and flexible:

- Main Girder: The horizontal beam that carries the trolley and hoisting mechanism. It determines the span and stability of the crane.

- Trolley and Hoist: Moves along the girder to lift and lower containers or materials. Hoist capacity must match your heaviest loads.

- Rubber-Tired Legs/Wheels: Allow the crane to move around the yard or site without relying on fixed rails. Tires are usually heavy-duty to handle industrial loads.

- Operator Cabin: Elevated for full visibility of the operation area; some modern models allow remote operation.

- Control Systems: Can be manual, semi-automatic, or fully automated, depending on your operational needs.

Advantages Over Other Crane Types

RTG cranes offer practical benefits that fixed or rail-mounted cranes cannot match:

- Mobility: Move quickly across paved surfaces; no need for a permanent track system.

- Minimal Infrastructure: Avoids costly rail installation or concrete work.

- Operational Flexibility: Can adjust to changing yard layouts or expand operations without major modifications.

- High Lifting Capacity: Capable of handling very heavy containers or industrial loads safely.

- Quick Deployment: Can start operating in new areas with minimal setup.

Typical Applications

RTG cranes are widely used in industries that require heavy lifting and flexible movement:

- Ports and Container Yards: Efficiently stack and transport shipping containers.

- Shipyards: Lift and move ship components or small boats.

- Factories: Handle large machinery, molds, or industrial materials.

- Storage Yards: Move heavy pallets, raw materials, or bundled steel products.

Key Considerations for Buyers

Choosing the right Rubber Tyred Gantry (RTG) crane requires more than looking at price or size. Each operation has unique requirements, and selecting a crane that fits your specific needs can save time, reduce costs, and improve safety. Here are the main factors to consider:

Load Capacity

The first thing to check is how much weight the crane needs to lift. Different RTG cranes handle different maximum loads.

- Always calculate the heaviest load your operation will require, including containers, bundled materials, or machinery.

- Consider a safety margin of 20–30% above your maximum expected load to prevent overloading and extend the crane's lifespan.

- Lifting heavy loads frequently may require a double girder design for better stability.

Span and Lifting Height

The crane's span and lifting height must match your site layout and operational requirements.

- Span: Distance between the legs of the crane; determines how wide a load you can handle.

- Lifting Height: Maximum vertical reach; make sure it accommodates stacked containers or tall industrial loads.

- Adjustable or modular designs can help optimize these parameters if your yard or factory layout changes.

Mobility and Ground Conditions

Since RTG cranes are rubber-tired, the condition of your ground or yard plays a major role.

- Ensure surfaces are smooth, stable, and strong enough to support heavy loads.

- Check turning radius requirements for maneuvering in tight spaces.

- Some cranes are designed with reinforced tires or wider wheelbases for uneven surfaces.

Power Supply Options

RTG cranes can run on diesel, electricity, or hybrid systems. Your choice depends on operational and environmental factors.

- Diesel: High mobility, no need for electrical infrastructure, suitable for outdoor yards.

- Electric: Lower running costs and reduced emissions; requires stable power supply.

- Hybrid: Combines diesel and electric for flexibility and fuel efficiency.

Operational Environment

Your site's conditions determine which RTG crane is most suitable.

- Outdoor Ports/Yards: Weather-resistant models with corrosion protection are essential.

- Indoor Factories: May require compact designs or electric power to reduce emissions.

- Shipyards: High lifting height and heavy-duty cranes are needed for components or small vessels.

Maintenance and Lifecycle Costs

A crane isn't just a purchase—it's a long-term investment.

- Consider ease of maintenance and availability of spare parts.

- Regular inspections and servicing reduce downtime and extend operational life.

- Factor in long-term costs, including tires, hoist mechanisms, and control systems.

By carefully evaluating these factors, buyers can select an RTG crane that meets operational needs, reduces safety risks, and ensures long-term efficiency.

Hot-Sale Rubber Tyred Gantry Cranes

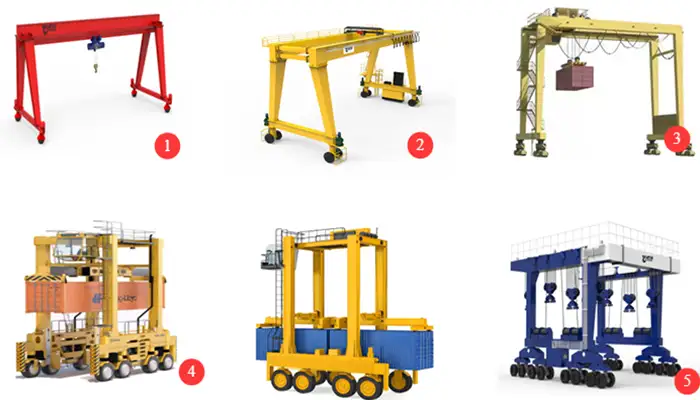

Detailed overview of top-performing models with specifications, advantages, and best-fit applications:

- Single Girder Rubber Tyred Gantry Crane – Compact design, ideal for light loads and small yards.

- Double Girder Rubber Tyred Gantry Crane (A Frame) – Medium to heavy loads, suitable for standard container handling with good stability.

- Double Girder Rubber Tyred Gantry Crane (U Frame) – High-capacity operations, optimal for large container yards and heavy-duty handling.

- Rubber Tyred Straddle Carrier – Efficient container transport, multi-directional mobility, and rapid yard operations.

- Boat Lift Rubber Tyred Crane – Specialized crane for shipyard operations, capable of handling boats with significant lifting height.

Comparative Overview

To make choosing the right Rubber Tyred Gantry (RTG) crane easier, it helps to see how the top models compare across critical factors. The table below summarizes their capacity, span, mobility, power options, and best applications.

| Crane Type | Load Capacity | Span & Lifting Height | Mobility Features | Ideal Applications |

|---|---|---|---|---|

| Single Girder RTG Crane | 5–20 tons | Span up to 15m Moderate height | Compact Easy to maneuver | Small storage yards Workshops Light material handling |

| Double Girder RTG Crane (A Frame) | 20–60 tons | Medium span Standard height | Stable movement Moderate footprint | Container terminals Medium industrial yards Regular stacking operations |

| Double Girder RTG Crane (U Frame) | 40–100+ tons | Wide span High height | Heavy-duty Suitable for large yards | Large container yards Ports Shipyards Heavy industrial sites |

| Rubber Tyred Straddle Carrier | 20–50 tons | Flexible span Moderate height | Multi-directional mobility Fast transport | Container transport within yards Logistics hubs Temporary storage areas |

| Boat Lift Rubber Tyred Crane | 10–80 tons | Moderate to high span High height | Adaptable to uneven surfaces Near docks | Shipyards Boat storage yards Vessel maintenance operations |

Key Takeaways for Buyers:

- Match capacity to your heaviest loads to avoid overloading and reduce maintenance costs.

- Span and lifting height must align with your yard layout, stacking requirements, and load dimensions.

- Mobility features determine how efficiently the crane can operate in tight spaces or across large yards.

- Power source affects operational cost, environmental compliance, and suitability for indoor or outdoor use.

- Operational environment guides your choice between specialized cranes like the Boat Lift or flexible models like the Straddle Carrier.

This comparison gives a practical overview to help buyers quickly identify which crane type fits their operational needs.

Practical Recommendations for Buyers

Selecting the right Rubber Tyred Gantry (RTG) crane goes beyond technical specifications. To get the most value and ensure smooth operations, buyers should consider practical aspects of their site, workflow, and long-term needs.

Match Crane Selection to Operational Requirements

Before making a decision, carefully evaluate your actual lifting needs:

- Identify the heaviest loads and maximum stacking requirements.

- Consider your yard or factory layout, including turning radius, aisle width, and surface conditions.

- Factor in frequency of use—cranes for daily heavy operations need more durability than those used occasionally.

- Determine if specialized models (e.g., Boat Lift or Straddle Carrier) are required for specific tasks.

Evaluate Upfront Investment vs. Long-Term ROI

Price is important, but total cost of ownership matters more:

- Compare initial purchase costs against long-term operational savings.

- Consider fuel or power consumption, maintenance intervals, and spare parts availability.

- Think about future expansion—a slightly larger or modular crane may be more cost-effective in the long run.

Work with Experienced Manufacturers

Choosing a crane isn't a solo task—partnering with reliable manufacturers ensures practical and safe solutions:

- Request tailored quotations based on your specific load, span, and yard conditions.

- Ask for technical support, including installation guidance and maintenance training.

- Look for factory certifications and references to ensure product quality and reliability.

Conclusion

Choosing the right Rubber Tyred Gantry (RTG) crane can make a big difference in how efficiently and safely your operations run. Each hot-sale model we've covered has its own strengths:

- Single Girder RTG Crane: Compact and ideal for light loads and small yards.

- Double Girder RTG Crane (A Frame): Stable, medium to heavy loads, standard container handling.

- Double Girder RTG Crane (U Frame): High-capacity, heavy-duty operations for large yards or ports.

- Rubber Tyred Straddle Carrier: Flexible and fast container transport within yards.

- Boat Lift RTG Crane: Specialized for shipyards and boat handling with high lifting heights.

The key takeaway for buyers is to match your crane choice with your workflow, yard layout, and budget. Don't just pick based on capacity alone—consider mobility, lifting height, span, and maintenance requirements to ensure the crane fits your actual operational needs.

Whenever possible, simulate or test operations with the selected crane. This step helps verify performance in your specific environment, prevents surprises, and ensures the investment truly meets your long-term requirements.

With the right planning and careful selection, your RTG crane will not only handle heavy loads efficiently but also support safer, smoother, and more productive operations for years to come.

Related Products

Latest project

150 Ton Overhead Crane Installation Feedback – Paraguay Case

QDX 150 ton overhead crane in action in Paraguay. Installation photos, video, and client feedback show performance, safety, and heavy-lifting efficiency.

Free consultation to Confirm Parameters & Specifications and Get

Latest Crane Price & Crane Rate.

- Types of overhead cranes : _______?

- Optional: Overhead travelling crane, goliath gantry crane,Slewing jib crane, Single girder or double girder crane,small portable crane or kbk crane, etc.

- Capacity of overhead crane: _______?

- Optional: 0.25ton, 0.5 ton, 1 ton, 2 ton, 3ton, 5 ton, 10 ton,15ton, 20ton, 25 ton, 30ton,35ton, up to 550ton, etc.

- Crane span & lifting height : _______?

- Crane travelling length : _____?

- Control of overhead crane:_______?

- Optional: pendant/ remote/cabin control

- Voltage supply of overhead crane:_____?

- Eg,: 380V50/60HZ,3Phase or others,etc.

- Application/usage of crane:_______?

- Eg,: Steel mill, ,injection mold, cement,stone, concrete,granite, general manufacturing, etc.

Just leave a message via the contact form and our hoist and crane engineer will contact you with in 24working hours.

Get In Touch